Mining Automation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431042 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Mining Automation Market Size

The Mining Automation Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2025 and 2032. The market is estimated at USD 7.8 Billion in 2025 and is projected to reach USD 18.0 Billion by the end of the forecast period in 2032. This substantial growth trajectory is underpinned by a global paradigm shift within the mining industry towards operational excellence, enhanced safety protocols, and sustainable resource extraction. Automation technologies, encompassing a diverse range of hardware components, sophisticated software platforms, and specialized services, are becoming indispensable tools for mining enterprises worldwide. These tools address critical industry challenges such as the increasing scarcity of skilled labor, the imperative to reduce escalating operational costs, and the need to comply with increasingly stringent environmental regulations. The integration of advanced analytics and real-time data processing capabilities further empowers mines to optimize their performance, leading to more efficient and profitable operations, fundamentally reshaping the competitive landscape.

The expansion of the Mining Automation Market is robustly driven by continuous and rapid advancements in foundational technologies such as artificial intelligence (AI), machine learning (ML), the Internet of Things (IoT), and advanced robotics. These innovations are collectively transforming traditional, labor-intensive mining operations into highly intelligent, interconnected, and largely autonomous systems. The deployment of these cutting-edge technologies facilitates unparalleled precision in drilling and excavation, enables proactive and predictive maintenance strategies, and supports data-driven decision-making across the entire mining value chain. This leads to a significant uplift in overall productivity, vastly improved asset utilization, and a reduction in unscheduled downtime. As the global demand for essential minerals and raw materials continues its upward trend, propelled by industrialization and urbanization, the widespread adoption of automation across both surface and underground mining environments is expected to accelerate significantly. This positions the Mining Automation Market as a pivotal sector driving industrial growth, fostering technological innovation, and redefining industry benchmarks for efficiency, safety, and environmental stewardship.

Mining Automation Market introduction

The Mining Automation Market represents a dynamic and transformative sector focused on the integration of advanced technologies and intelligent systems to automate, optimize, and streamline various operational processes within the global mining industry. This encompasses a broad spectrum of solutions, ranging from the deployment of autonomous haulage vehicles and drilling rigs to the implementation of sophisticated remote operation centers, advanced sensing equipment, and intelligent software platforms designed for comprehensive mine management. The fundamental objectives underpinning this technological shift are manifold: primarily, to significantly enhance safety standards for on-site personnel by removing them from inherently hazardous environments; secondly, to drastically improve operational efficiency and productivity through optimized extraction, processing, and logistics; thirdly, to achieve substantial reductions in overall operating costs; and finally, to minimize the environmental footprint of mining activities. These automated solutions are strategically applied across the entire mining value chain, from initial geological exploration and precision drilling to efficient material handling, mineral processing, and even post-mining rehabilitation efforts, thereby converting conventional labor-intensive operations into highly efficient, data-driven, and increasingly sustainable endeavors.

Key product offerings within this sophisticated market include state-of-the-art autonomous haulage systems, which effectively eliminate the necessity for human drivers in often dangerous and remote mining terrains, thereby mitigating risk and increasing operational uptime. Automated drilling rigs are deployed for their unparalleled precision and speed, ensuring optimal blast patterns and resource recovery. Remote-controlled excavators and loaders facilitate operations in challenging or unstable ground conditions, while intelligent mine management software provides real-time data analytics, predictive capabilities, and holistic operational oversight. Major applications for mining automation are extensively found in large-scale surface mines extracting critical commodities such as iron ore, copper, and coal, where economies of scale and efficiency gains are paramount. Furthermore, these technologies are crucial for complex underground operations, particularly in the extraction of precious metals and other valuable, high-grade minerals, where safety and precision are even more critical. The aggregate benefits derived from such widespread adoption are substantial and far-reaching, encompassing a dramatic reduction in workplace accidents, optimized resource recovery rates, lower operating expenses attributable to reduced fuel consumption, minimized equipment wear and tear, and vastly improved compliance with increasingly stringent global environmental and safety regulations.

The overarching driving factors propelling the expansion of the Mining Automation Market are multifaceted and deeply rooted in both economic and societal imperatives. Paramount among these is the escalating global demand for essential minerals and raw materials, necessitating higher and more consistent production efficiencies from mining companies worldwide. This demand is intrinsically linked with growing concerns over worker safety in what is inherently one of the world's most dangerous industries, making automation a compelling solution for risk mitigation. Concurrently, the rising cost of manual labor, coupled with a persistent and growing scarcity of skilled mining personnel in many developed and emerging economies, compels companies to invest in automated solutions that can maintain or even surpass current production levels with a smaller, more technologically adept workforce. Moreover, the increasing pressure for greater sustainability, manifested through reduced energy consumption, lower greenhouse gas emissions, and a minimized environmental footprint, further encourages the adoption of precise, automated extraction methods. Finally, the relentless pace of technological advancements, particularly in areas like AI, IoT, advanced sensing, and robust robotics, provides the foundational support and continuously enhanced capabilities for these innovative solutions, rendering them more reliable, effective, and economically viable than ever before.

Mining Automation Market Executive Summary

The Mining Automation Market is currently experiencing robust growth, driven by a confluence of business, regional, and segment-specific trends that underscore a profound shift in the mining industry towards technologically advanced and sustainable operations. Business trends are characterized by increased capital expenditure in digital transformation initiatives, a strategic focus on integrating artificial intelligence and machine learning into existing workflows, and a growing emphasis on strategic partnerships between technology providers and mining companies. This collaboration aims to develop tailored solutions that address specific operational challenges and accelerate the adoption of advanced automation. Companies are also investing heavily in data analytics platforms to derive actionable insights from the vast amounts of data generated by automated systems, facilitating predictive maintenance, optimized resource management, and improved overall decision-making across the enterprise.

Regional trends indicate that mature mining regions such as North America and Australia are leading the charge in adopting sophisticated automation solutions, primarily due to higher labor costs, stringent safety regulations, and the presence of advanced technological infrastructure. These regions often serve as innovation hubs, piloting new technologies before wider deployment. However, the Asia Pacific region, particularly countries like China and India with significant mining activities, is emerging as a critical growth hub, driven by new mining projects, government initiatives promoting modernization, and a burgeoning demand for resources. Latin American and African markets are also witnessing increasing interest and investment in automation, especially in large-scale projects, as they strive to enhance productivity, reduce risks, and improve competitiveness on a global scale. This regional diversification reflects a widespread recognition of automation's intrinsic value in achieving sustainable and efficient mining operations.

Segment trends highlight the dominance of autonomous haulage systems and automated drilling solutions due to their immediate and measurable impact on safety, operational efficiency, and cost reduction in both surface and underground mines. These equipment-based segments continue to attract significant investment. Concurrently, the software and services segment is projected to exhibit the fastest growth, primarily attributed to the ongoing need for advanced analytics, sophisticated predictive maintenance software, robust cybersecurity solutions, and specialized consulting and integration services required to implement, manage, and optimize complex automated systems. Furthermore, the ubiquitous integration of IoT devices and advanced sensor technologies for real-time monitoring and comprehensive data collection is becoming a standard practice across all segments, ensuring that automation is not merely about replacing human tasks but about creating intelligent, interconnected, and self-optimizing mining ecosystems.

AI Impact Analysis on Mining Automation Market

User inquiries regarding Artificial Intelligence's impact on mining automation frequently revolve around core themes such as enhancing operational efficiency, improving safety protocols, delivering predictive capabilities, addressing potential job displacement, and assessing the overall economic viability and return on investment of AI integration. Users are keen to understand how AI translates into tangible benefits like significantly reduced equipment downtime, improved resource recovery rates, and the creation of a fundamentally safer work environment, while also expressing legitimate concerns about the necessity for new skill sets, ethical considerations, and the substantial initial investment required for AI infrastructure. The prevailing expectation is that AI will not merely automate routine, repetitive tasks but will profoundly provide intelligent decision-making support and complex pattern recognition, leading to a transformative paradigm shift in how mining operations are strategically planned, dynamically executed, and continuously optimized across the entire value chain.

AI's influence within the Mining Automation Market is truly profound and revolutionary, fundamentally transforming traditional mining practices by enabling unprecedented levels of operational intelligence and functional autonomy. It empowers the mining industry to process and synthesize vast, heterogeneous datasets generated by a myriad of sensors, autonomous equipment, and operational systems. This advanced analytical capability leads to highly accurate and dynamic geological modeling, optimized mine planning that adapts to real-time conditions, and sophisticated dynamic process control within mineral processing plants. This capability significantly reduces operational inefficiencies, minimizes waste, and vastly enhances the precision of mineral extraction, thereby ensuring maximum resource utilization and profitability. Furthermore, AI-powered systems play an increasingly crucial role in enabling highly accurate predictive maintenance of heavy machinery, optimizing energy consumption across the mine site, and implementing proactive safety measures through continuous real-time monitoring, thereby creating a safer and more environmentally sustainable mining environment. The seamless integration of AI is driving forward the rapid evolution of fully autonomous fleets, smart processing plants, and cognitive operational centers, marking the undeniable dawn of a new era of intelligent mining.

- Predictive Maintenance: AI algorithms analyze equipment sensor data to forecast potential failures, proactively scheduling maintenance to minimize unscheduled downtime and optimize asset lifespan.

- Autonomous Operations: Enables self-driving vehicles, automated drills, and robotic equipment to operate independently or remotely, significantly improving safety by removing personnel from hazardous areas and increasing operational consistency.

- Geological Modeling and Resource Estimation: Enhances accuracy in identifying ore bodies, optimizing blast patterns, and precisely quantifying resource reserves through advanced data interpretation and simulation.

- Process Optimization: AI fine-tunes mineral processing plants in real-time by adjusting parameters for crushing, grinding, and separation, maximizing yield, reducing energy consumption, and improving overall recovery rates.

- Safety Monitoring and Risk Management: Utilizes real-time video analytics, sensor data, and behavioral patterns to detect potential safety hazards, monitor worker well-being, and prevent accidents through early warnings and automated responses.

- Dynamic Mine Planning: AI continuously updates and adapts mine plans based on evolving geological conditions, equipment performance, and market demands, ensuring optimal resource extraction and operational agility.

- Environmental Impact Assessment and Mitigation: AI assists in monitoring environmental parameters, optimizing water and energy usage, predicting and mitigating environmental risks, and ensuring compliance with regulatory standards.

DRO & Impact Forces Of Mining Automation Market

The Mining Automation Market is robustly propelled by a comprehensive set of drivers while simultaneously navigating significant restraints, presenting numerous opportunities, all of which are shaped by various impactful forces that continually influence its trajectory. Primary drivers include the global imperative for enhanced safety standards in mining operations, which historically have been among the most hazardous industries. Automation significantly reduces human exposure to inherent risks, thereby profoundly improving worker well-being and reducing accident rates. Coupled with this is the relentless pursuit of unparalleled operational efficiency and substantial productivity gains, as automation streamlines complex processes, drastically reduces cycle times, and precisely optimizes resource utilization. Rising labor costs across developed economies and the increasing scarcity of skilled mining personnel further accelerate the adoption of automated solutions, allowing companies to maintain or even increase production levels with a smaller, highly trained, and technologically adept workforce. Moreover, increasingly stringent environmental regulations are compelling mining companies towards more precise, less wasteful, and environmentally conscious extraction methods, which automation inherently supports through optimized planning, execution, and monitoring capabilities.

However, the market faces considerable and multifaceted restraints that temper its growth. The most significant is undoubtedly the high initial capital investment required for implementing sophisticated automation systems, which can be prohibitively expensive for smaller mining operations or those with limited access to capital, creating a significant barrier to entry for widespread adoption. Concerns regarding data security and the persistent potential for debilitating cyber-attacks on highly interconnected mining systems represent another critical challenge, as vulnerabilities could lead to severe operational disruptions, intellectual property theft, or even safety compromises. The inherent complexity of integrating cutting-edge new automation technologies with often aging and disparate legacy infrastructure poses substantial technical and logistical hurdles, demanding extensive planning, specialized expertise, and considerable downtime. Furthermore, the understandable potential for job displacement as human tasks become automated raises significant social and political concerns, necessitating careful workforce planning, extensive retraining initiatives, and strategic community engagement to mitigate adverse socio-economic impacts.

Despite these formidable challenges, numerous significant opportunities exist for market expansion and innovation. Emerging markets with vast untapped mineral resources and a pronounced drive for modern industrialization and economic growth present substantial growth prospects for automation vendors, especially as they leapfrog older technologies. The continuous development of more flexible, modular, and scalable automation solutions that cater specifically to the needs and budget constraints of small and medium-sized mines could unlock a large and currently underserved customer base. Ongoing and rapid advancements in foundational technologies such as AI, IoT, advanced sensing, high-bandwidth connectivity (e.g., 5G), and cloud computing promise to continuously enhance the capabilities, reliability, and cost-effectiveness of automation, making it more accessible and impactful. The accelerating global shift towards remote and fully autonomous operations, further catalyzed by global events requiring reduced onsite personnel, also creates vast new avenues for groundbreaking innovation, widespread deployment, and entirely new service models within the mining automation landscape. These opportunities unequivocally underscore the transformative potential of mining automation in shaping a more efficient, safer, and sustainable future for the entire industry.

Segmentation Analysis

The Mining Automation Market is extensively segmented to reflect the diverse technological components, specialized equipment types, distinct operational methodologies, and varied application areas inherent within the global mining industry. This comprehensive segmentation provides a granular and highly detailed view of the market dynamics, enabling all stakeholders to thoroughly understand specific growth drivers, navigate complex competitive landscapes, and precisely identify promising investment opportunities across various sub-sectors. The inherent structure of the market meticulously reflects the highly specialized and capital-intensive nature of mining operations, where different automation technologies are specifically tailored for distinct geological environments, unique mineral characteristics, and varied operational scales. A comprehensive and nuanced analysis of these intricate segments is absolutely crucial for effective strategic planning, targeted product development, and optimized market entry strategies, ultimately enabling companies to address highly specific industry needs and effectively leverage emergent trends within this rapidly evolving industrial sector.

Segmentation primarily categorizes the market based on the fundamental components that constitute advanced automation systems, the various types of automated equipment strategically deployed, the specific mining types (distinguishing between surface and underground operations), and the varied applications pertaining to the extraction of different mineral resources. Each distinct segment demonstrates unique characteristics in terms of current adoption rates, relative technological maturity, and market penetration levels, all of which are significantly influenced by a complex interplay of factors such as prevailing regional regulations, global commodity prices, the availability and cost of skilled labor, and the specific operational challenges encountered at individual mining sites. Understanding these distinct and dynamic segments is critically vital for both innovative market entrants and well-established industry players to meticulously tailor their product and service offerings, refine their value propositions, and achieve sustainable and profitable growth in this technologically accelerating and fiercely competitive industry landscape.

- By Component

- Hardware: This sub-segment includes the physical infrastructure of automation systems, such as advanced sensors (e.g., LiDAR, radar, vision systems), Global Positioning System (GPS) and Global Navigation Satellite System (GNSS) modules for precise navigation, sophisticated control systems (PLCs, DCS), robust communication systems (Wi-Fi, LTE, 5G), and specialized robotic arms for various tasks.

- Software: Comprises the intelligent applications and platforms that power automation, including comprehensive Mine Management Systems (MMS), advanced Data Analytics Platforms for extracting insights, AI/Machine Learning Software for predictive capabilities, Predictive Maintenance Software, and Simulation and Modeling Software for planning and optimization.

- Services: Encompasses the crucial support functions for automation adoption, such as expert Consulting services for strategic planning, System Integration services for seamless deployment, ongoing Maintenance and Support for operational continuity, specialized Training programs for personnel, and Data Management Services to handle vast datasets.

- By Equipment

- Autonomous Haulage Systems (AHS): Self-driving trucks for transporting ore and waste, operating without human intervention.

- Automated Drilling Systems: Robotic drill rigs offering enhanced precision, speed, and consistency for blast hole drilling and exploration.

- Automated Loading and Excavation Systems: Remotely operated or autonomous loaders and excavators improving safety and efficiency.

- Robotic Excavators and Dozers: Specialized robots for hazardous or repetitive digging and earthmoving tasks.

- Remote Operated Vehicles (ROVs): Drones and ground-based robots for inspection, mapping, and hazardous area assessment.

- Automated Underground Mining Equipment: Solutions tailored for the unique challenges of underground operations, including autonomous LHDs (Load-Haul-Dump), jumbos, and bolters.

- By Type

- Surface Mining Automation: Solutions for open-pit mines, focusing on large-scale autonomous fleets and processing efficiency.

- Underground Mining Automation: Technologies designed for confined, hazardous underground environments, emphasizing remote operation and safety.

- By Application

- Metal Mining: Automation applied to the extraction of metals like Iron Ore, Copper, Gold, Silver, Platinum, Zinc, and Nickel.

- Mineral Mining: Focuses on industrial minerals such as Phosphate, Potash, Bauxite, Diamonds, and other non-metallic minerals.

- Coal Mining: Automation solutions tailored for both surface and underground coal extraction, addressing safety and productivity.

Value Chain Analysis For Mining Automation Market

The intricate value chain for the Mining Automation Market commences with robust upstream activities that primarily involve intensive research and development (R&D), alongside the precision manufacturing of foundational and highly specialized components. This critical segment includes a diverse ecosystem of suppliers providing advanced sensors (e.g., LiDAR, radar, ultrasonic), high-precision GPS/GNSS modules for accurate positioning, powerful high-performance computing units essential for real-time processing, robust and high-bandwidth communication systems, and highly specialized robotic components such as actuators, manipulators, and complex gearing systems. These upstream manufacturers are instrumental in providing the essential building blocks for state-of-the-art automation solutions, often requiring deep expertise in sophisticated electronics, advanced materials science, complex software platforms, and precision engineering. The intrinsic quality, innovative capabilities, and reliability within this initial upstream segment directly and profoundly impact the overall performance, longevity, and ultimate capabilities of the final integrated automation systems, thereby establishing a critical foundation for sustained market growth and continuous technological advancement.

Midstream activities within the value chain are characterized by the complex integration, meticulous assembly, and sophisticated testing of these diverse components into complete, functional automation systems. This crucial phase is typically performed by specialized technology providers, leading equipment manufacturers, and system integrators who possess deep domain expertise. Key processes at this stage include the development of proprietary control software, sophisticated AI and machine learning algorithms, advanced human-machine interfaces (HMIs), and robust communication protocols that enable seamless autonomous operation, precise remote control, and powerful data analytics. These entities transform discrete components into cohesive solutions, often involving extensive customization to meet specific client requirements. Downstream in the value chain, the primary focus shifts to the critical deployment, meticulous implementation, and comprehensive ongoing support of these advanced automation solutions within actual, operational mining environments. This involves close and collaborative engagement with mining companies for site-specific customization, seamless system integration with existing legacy infrastructure, and providing comprehensive training programs, continuous monitoring, and proactive maintenance services to ensure optimal performance, maximum uptime, and long-term operational sustainability.

Distribution channels in the Mining Automation Market are characteristically multifaceted and highly specialized, reflecting the significant capital investment and complex technical requirements involved. Direct sales are predominantly common for large-scale, enterprise-level projects where major equipment manufacturers and specialized technology providers engage directly with large multinational mining corporations. These direct engagements often involve offering highly customized solutions, extensive project management, and comprehensive, long-term support packages tailored to the client's unique operational needs. Conversely, indirect channels involve strategic partnerships with a network of third-party distributors, expert system integrators, and value-added resellers (VARs) who possess an established regional presence and deep technical expertise in deploying specific automation technologies. These partners are instrumental in facilitating market penetration in geographically diverse and often remote areas, effectively catering to the specific needs of smaller to medium-sized mining operations. The overarching emphasis across all distribution channels is placed firmly on demonstrating profound technical expertise, providing robust and reliable service capabilities, and cultivating strong, enduring customer relationships, given the substantial investment and profound operational impact of adopting sophisticated mining automation technologies.

Mining Automation Market Potential Customers

Potential customers in the Mining Automation Market primarily comprise various diverse entities within the global mining and mineral extraction industry, all critically seeking to leverage advanced technological solutions for achieving unparalleled operational excellence, stringent safety compliance, and enhanced environmental stewardship. These discerning end-users are intrinsically characterized by their pressing need to significantly enhance safety standards for their workforce, drastically improve operational efficiency, achieve substantial reductions in long-term operational costs, and diligently meet increasingly stringent environmental protection and regulatory demands. The inherent scale of their operations, the specific type of minerals being extracted, and their geographical location significantly influence their unique automation requirements, their technological readiness, and ultimately their adoption rates. Identifying, thoroughly understanding, and meticulously categorizing these diverse customer segments is absolutely crucial for technology providers to precisely tailor their solutions, optimize their value propositions, and effectively formulate robust go-to-market strategies that resonate with specific industry needs.

The largest and most prominent segment of potential customers includes multinational mining corporations that operate extensive, often global, mining portfolios across multiple continents. These industry behemoths typically possess the substantial capital resources and the clear strategic imperative to invest in cutting-edge, comprehensive automation systems across their myriad sites. They are often the pioneering early adopters of highly advanced technologies such as fully autonomous haulage and drilling fleets, sophisticated remote operation centers, and advanced AI-driven analytics platforms that provide predictive insights and operational intelligence. Beyond these formidable industry giants, small and medium-sized mining enterprises (SMEs) also represent a rapidly growing and significant customer base. While their initial capital expenditure budgets might be comparatively lower, their fundamental need for improved efficiency, enhanced safety, and cost reduction is equally pressing, driving a strong demand for scalable, modular, and cost-effective automation solutions, often focused on automating specific tasks or implementing integrated retrofits to existing machinery. Government-owned mining entities, particularly prevalent in resource-rich nations, constitute another key customer group, frequently driven by national economic development goals, mandates for responsible resource management, and social responsibility initiatives.

Furthermore, an increasingly important customer segment includes contract mining service providers, who specialize in executing mining operations on behalf of asset owners. These specialized providers are increasingly investing in automation to significantly enhance their service offerings, improve their competitive edge in bidding processes, and ensure superior client satisfaction through highly efficient and reliably delivered project outcomes. Mineral processing plants, whether seamlessly integrated with mine sites or operating as standalone beneficiation facilities, are also highly significant buyers, as automation critically helps optimize material flow, improve energy consumption efficiency, and maximize recovery rates during the complex mineral beneficiation process. The spectrum of potential customers is exceptionally broad and diverse, ranging from those intently focused on high-volume bulk commodities like iron ore, copper, and coal to those extracting high-value precious metals such as gold and platinum, industrial minerals, and rare earth elements. Each of these segments presents unique operational challenges and distinct economic drivers that advanced mining automation technologies are uniquely positioned to address, providing tailored benefits and driving industry-wide transformation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 7.8 Billion |

| Market Forecast in 2032 | USD 18.0 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Caterpillar Inc., Komatsu Ltd., Epiroc AB, Sandvik AB, Liebherr Group, Hitachi Construction Machinery Co. Ltd., Rockwell Automation Inc., Hexagon AB, ABB Ltd., Siemens AG, Trimble Inc., Wenco International Mining Systems Ltd., Autonomous Solutions Inc. (ASI), FLSmidth & Co. A/S, Metso Outotec, MST Global, Micromine Pty Ltd., Dassault Systèmes SE, SAP SE, IBM Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mining Automation Market Key Technology Landscape

The Mining Automation Market is underpinned by a rapidly evolving and highly dynamic technological landscape, characterized by the synergistic convergence of several advanced digital and sophisticated engineering innovations. Central to this profound transformation is the widespread and accelerating adoption of the Internet of Things (IoT), which fundamentally involves deploying an extensive network of interconnected sensors, intelligent devices, and telemetry units across expansive mine sites. This network collects vast amounts of granular, real-time data on critical parameters such as equipment performance, dynamic environmental conditions, precise material flow, and geological anomalies. This rich, continuous stream of data forms the indispensable foundation for intelligent decision-making, predictive analytics, and proactive operational adjustments. Artificial Intelligence (AI) and Machine Learning (ML) algorithms are then leveraged to process and synthesize these complex, multi-modal datasets, enabling the identification of intricate patterns, optimization of operational parameters, accurate forecasting of equipment failures, and ultimately, the autonomous control of machinery, thereby moving mining operations far beyond mere automation towards truly cognitive, self-optimizing systems.

Robotics and advanced automation systems constitute another fundamental pillar of this technological revolution, encompassing a diverse array of autonomous haulage trucks, precision drilling rigs, and robust excavators that are capable of operating with minimal or no direct human intervention. These systems significantly enhance both safety and efficiency, particularly in inherently hazardous and remote environments. Global Positioning System (GPS) and Global Navigation Satellite System (GNSS) technologies provide unparalleled levels of precise positioning and real-time navigation capabilities for these autonomous vehicles, which is absolutely crucial for accurate and coordinated operations within dynamic and challenging mining landscapes. Big Data Analytics and scalable cloud computing infrastructures are essential for efficiently storing, rapidly processing, and comprehensively analyzing the massive volumes of heterogeneous data generated across the entire mining ecosystem. This allows for the extraction of profound, actionable insights into overall mine performance, facilitates optimized resource management strategies, and supports continuous operational improvement initiatives across the enterprise.

Further enhancing this sophisticated technological landscape are high-bandwidth communication networks, including the rapidly emerging 5G technology and robust private LTE networks, which provide the essential reliable, low-latency, and secure connectivity required for effective remote operation centers and seamless real-time data transmission from distributed autonomous fleets and remote sensors. Digital Twin technology, which involves creating virtual, dynamic replicas of physical mine sites, individual equipment units, and entire operational processes, allows for highly accurate simulation, rigorous testing, and continuous optimization of processes in a virtual environment before physical implementation. This significantly reduces operational risks, mitigates costly errors, and accelerates deployment timelines. Advanced sensor technologies, including sophisticated LiDAR systems, high-resolution radar, hyperspectral imaging, and thermal cameras, vastly improve situational awareness, enhance data accuracy, and enable proactive safety measures, making overall operations safer, more efficient, and environmentally compliant. The synergistic and integrated application of these cutting-edge technologies is consistently pushing the boundaries of what is possible in modern mining, thereby rendering operations demonstrably smarter, inherently safer, significantly more productive, and fundamentally more sustainable.

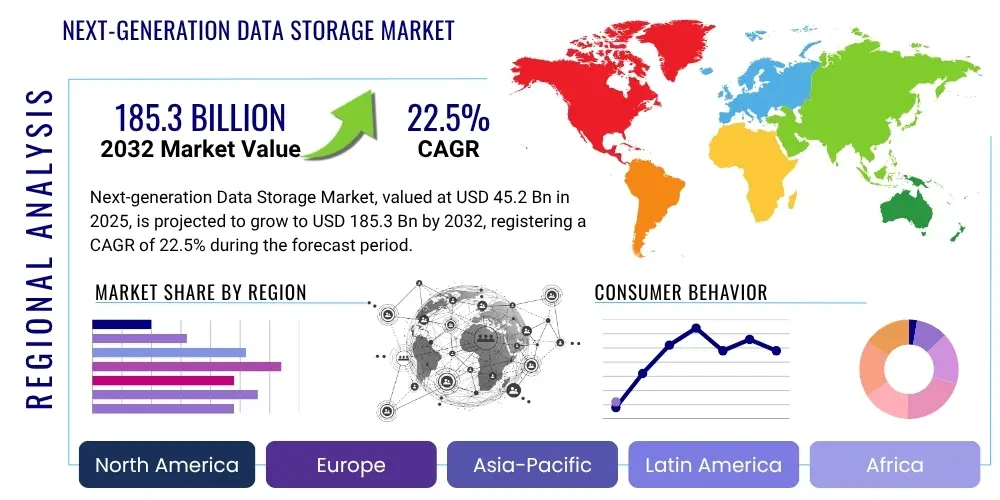

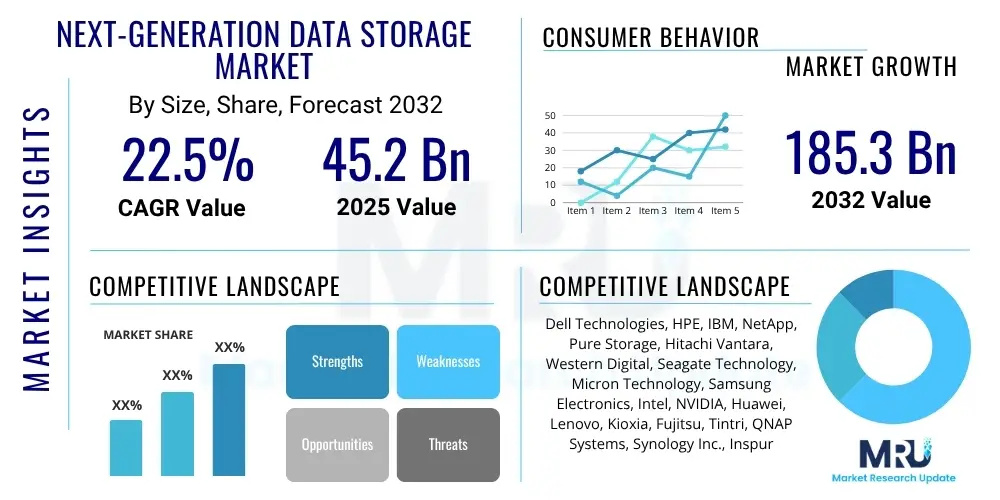

Regional Highlights

The global Mining Automation Market exhibits distinct and highly influential regional dynamics, primarily shaped by a confluence of factors including varying geological endowments, diverse regulatory environments, prevalent labor costs, and the overall technological readiness and investment capacity within each region. Each major geographical segment contributes uniquely to the overall market growth, presenting specific opportunities, distinct challenges, and varied adoption rates for automation solution providers. Understanding these complex regional nuances is critically imperative for businesses looking to strategically expand their global footprint, meticulously tailor their offerings to precise local market demands, and effectively navigate unique cultural and operational contexts. The adoption curve for mining automation technologies differs significantly across these regions, unequivocally reflecting their diverse stages of industrial development, prevailing economic conditions, and investment appetites.

North America, particularly encompassing the United States and Canada, stands out as a highly mature and leading market with remarkably high adoption rates of advanced mining automation solutions. This leadership is fundamentally driven by high labor costs, stringent safety regulations that mandate technological solutions, and a strong, inherent emphasis on continuous technological innovation to maintain global competitiveness within the mining sector. The region's extensive experience with large-scale surface and underground operations across various commodities like coal, copper, and precious metals has fostered an environment exceptionally conducive to early and widespread automation adoption. Europe, especially the Nordic countries like Sweden and Finland, is also a prominent frontrunner in mining automation, largely attributable to a proactive and pioneering approach to sustainable mining practices, significant and sustained R&D investments in advanced mining technologies, and a strategic focus on developing highly efficient, safe, and environmentally friendly underground operations. Countries like Germany also contribute through advanced engineering and industrial automation expertise.

The Asia Pacific (APAC) region represents arguably the largest and fastest-growing market for mining automation globally, fueled by extensive and rapidly expanding mining activities in key countries such as Australia, China, and India. Australia, with its vast mineral resources, advanced technological infrastructure, and established mining industry, is a recognized global leader in implementing large-scale autonomous haulage systems and sophisticated remote operation centers. China and India are witnessing increasingly accelerated adoption due to robust government initiatives promoting comprehensive mine modernization, imperative safety improvements, and a pressing need for increased productivity to meet surging domestic and international demand for raw materials. Latin America, particularly Chile and Brazil, plays an unequivocally crucial role due to its significant global production of copper and iron ore, respectively. The region is increasingly investing in automation to substantially improve operational efficiency, enhance worker safety, and boost competitiveness in its large-scale mining operations. Finally, the Middle East and Africa (MEA) region, with countries like South Africa holding substantial and diverse mineral reserves, is experiencing growing interest and nascent adoption in automation to effectively overcome challenges such as ultra-deep mining, high operational costs, and critical safety concerns, positioning it for significant future growth as infrastructure and investment capabilities develop.

- North America (USA, Canada): A mature market characterized by high labor costs, stringent safety regulations, a strong culture of technological innovation, and leading adoption rates for fully autonomous fleets and remote operations.

- Europe (Sweden, Finland, Germany): A leader in sustainable mining practices, significant investment in advanced underground automation, strong R&D capabilities, and driven by strict environmental compliance and safety standards.

- Asia Pacific (Australia, China, India, Indonesia): The largest and fastest-growing market globally, propelled by extensive new mining projects, aggressive modernization efforts, high commodity demand, and the presence of numerous large-scale operations. Australia is a benchmark for autonomous deployment.

- Latin America (Chile, Brazil, Peru): A critical region due to significant global production of copper and iron ore, witnessing increasing investments in automation to enhance efficiency, reduce costs, and improve safety in large-scale mining.

- Middle East and Africa (South Africa, Saudi Arabia): An emerging market with growing interest and investment in automation to address challenges associated with deep mining, high operational costs, and paramount safety needs, demonstrating substantial potential for future growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mining Automation Market.- Caterpillar Inc.

- Komatsu Ltd.

- Epiroc AB

- Sandvik AB

- Liebherr Group

- Hitachi Construction Machinery Co. Ltd.

- Rockwell Automation Inc.

- Hexagon AB

- ABB Ltd.

- Siemens AG

- Trimble Inc.

- Wenco International Mining Systems Ltd.

- Autonomous Solutions Inc. (ASI)

- FLSmidth & Co. A/S

- Metso Outotec

- MST Global

- Micromine Pty Ltd.

- Dassault Systèmes SE

- SAP SE

- IBM Corporation

Frequently Asked Questions

What are the primary benefits of mining automation?

Mining automation significantly enhances worker safety by removing personnel from hazardous environments, drastically improves operational efficiency through optimized processes and increased production rates, and reduces operational costs by minimizing fuel consumption, labor expenses, and equipment maintenance needs. It also supports environmental sustainability by enabling more precise extraction and resource management.

How does AI enhance safety in mining operations?

AI enhances safety by enabling predictive maintenance for equipment, preventing unexpected failures, and by continuously monitoring site conditions and worker behavior to detect and mitigate potential hazards in real-time. Autonomous vehicles, guided by AI, operate with higher precision and consistency, reducing the risk of human error-related accidents.

What are the main challenges in adopting mining automation?

Key challenges include the high initial capital investment required for implementing sophisticated systems, the complexity of integrating new technologies with existing legacy infrastructure, concerns regarding data security and potential cyber threats, and the need for a highly skilled workforce to manage and maintain automated systems. Resistance to change and job displacement concerns also pose social challenges.

Which regions are leading in mining automation adoption?

North America and Europe are mature markets with high adoption due to advanced infrastructure and stringent regulations. The Asia Pacific region, particularly Australia, China, and India, is the fastest-growing market, driven by large-scale projects and modernization initiatives. Latin America is also increasing investments, especially for copper and iron ore operations.

What future trends are expected in the mining automation market?

Future trends include greater integration of AI and Machine Learning for cognitive mining, widespread adoption of 5G for enhanced connectivity, further development of remote operation centers, increased focus on sustainability-driven automation, and the proliferation of digital twin technology for mine planning and optimization. The market will also see more modular and scalable solutions for SMEs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Mining Automation Market Size Report By Type (Underground Mining Automation, Surface Mining Automation), By Application (Metal Mining, Mineral Mining, Coal Mining, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Underground Mining Automation Market Statistics 2025 Analysis By Application (Metal Mining, Mineral Mining, Coal Mining, Other), By Type (Equipment, Software, Communication System), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager