Mobile Concrete Batch Plant Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430565 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Mobile Concrete Batch Plant Market Size

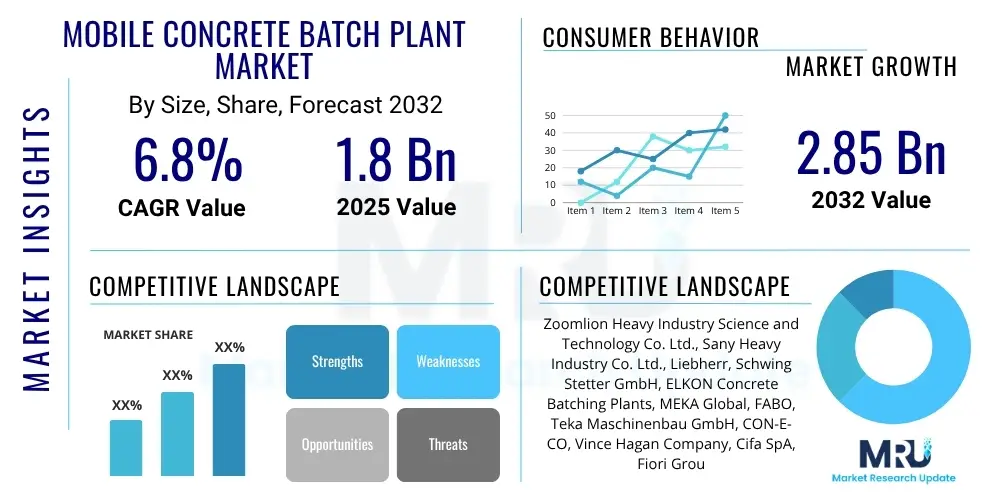

The Mobile Concrete Batch Plant Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $1.8 Billion in 2025 and is projected to reach $2.85 Billion by the end of the forecast period in 2032.

Mobile Concrete Batch Plant Market introduction

The Mobile Concrete Batch Plant Market is experiencing robust expansion driven by global infrastructure development and the increasing demand for flexible, on-site concrete production solutions. These plants are essentially portable factories designed to produce various types of concrete mixtures at construction sites, offering unparalleled mobility and efficiency compared to traditional stationary plants. Their ability to be easily transported, set up, and operated anywhere with minimal infrastructure makes them indispensable for remote projects, road construction, bridge building, and rapid urban development.

The product, a mobile concrete batch plant, typically comprises components such as aggregate bins, cement silos, water tanks, admixture systems, a mixing unit (pan, planetary, or twin-shaft mixer), and a control cabin, all mounted on a towable chassis or skid for ease of relocation. This integrated design allows for swift deployment, significantly reducing transportation costs for ready-mix concrete and ensuring a consistent supply directly at the point of use. Major applications span across large-scale infrastructure projects like highways, dams, and airports, as well as commercial and residential building construction, particularly in areas where access to conventional concrete supply is limited or economically unfeasible.

Key benefits associated with mobile concrete batch plants include enhanced operational flexibility, reduced logistical complexities, and significant cost savings over the project lifecycle due to on-site production. They offer precise control over concrete mix designs, leading to superior quality and reduced material waste. The primary driving factors for market growth encompass accelerated urbanization, substantial government investments in infrastructure development, a growing emphasis on project timelines and efficiency, and the increasing adoption of advanced construction technologies globally. These factors collectively contribute to the escalating demand for mobile concrete batching solutions.

Mobile Concrete Batch Plant Market Executive Summary

The global Mobile Concrete Batch Plant Market is characterized by dynamic business trends centered on technological innovation, sustainability, and operational efficiency. Manufacturers are increasingly integrating automation, telematics, and advanced control systems to enhance productivity, reduce labor requirements, and improve concrete quality. There is a noticeable trend towards modular designs that facilitate quicker assembly and disassembly, catering to the rapid pace of modern construction. Furthermore, market participants are focusing on developing eco-friendly solutions, including energy-efficient designs and systems compatible with sustainable concrete formulations, responding to stringent environmental regulations and corporate social responsibility initiatives. Strategic collaborations, mergers, and acquisitions are also prevalent, as companies seek to expand their product portfolios, geographic reach, and technological capabilities.

Regional trends indicate significant growth opportunities across various geographies. Asia Pacific continues to dominate the market, primarily fueled by massive infrastructure investments in countries like China and India, coupled with rapid urbanization. Developing economies in Latin America and the Middle East and Africa are also emerging as high-growth markets due to ongoing construction booms and government initiatives aimed at modernizing infrastructure. North America and Europe, while mature markets, demonstrate steady demand driven by the replacement of aging infrastructure, commercial development, and a strong focus on advanced, high-capacity mobile plants. These regions are also early adopters of innovative technologies and automation in concrete production.

Segmentation trends highlight a diverse market catering to varied project needs. The segment for plants with capacities ranging from 30-60 m3/h is experiencing robust demand, serving a wide array of medium to large-scale projects. Trailer-mounted plants remain popular due to their superior mobility and ease of transportation. Application-wise, road and bridge construction continues to be a major revenue generator, reflecting sustained global investment in transportation networks. However, the building construction segment is also witnessing substantial growth, driven by residential and commercial development, especially in urbanizing regions. End-users such as construction companies and rental firms are key customers, with rental companies showing increased interest due to the financial flexibility offered by renting specialized equipment.

AI Impact Analysis on Mobile Concrete Batch Plant Market

Common user questions regarding AI's impact on the Mobile Concrete Batch Plant Market revolve around its potential to enhance operational efficiency, improve concrete quality, facilitate predictive maintenance, and optimize logistics. Users are keen to understand how AI algorithms can contribute to more precise mix designs, reduce material waste, and automate plant operations, thereby minimizing human error and labor costs. There are also inquiries about the role of AI in real-time monitoring of plant performance, identifying potential failures before they occur, and optimizing transportation schedules for raw materials and finished concrete. Concerns often include the initial investment required for AI integration, the need for skilled personnel to manage AI systems, and potential cybersecurity risks associated with connected machinery. However, the overarching expectation is that AI will revolutionize productivity and decision-making in the concrete industry.

- AI-driven Predictive Maintenance: Utilizing sensor data and machine learning to forecast equipment failures, minimizing downtime and maintenance costs.

- Optimized Concrete Mix Designs: AI algorithms analyze various parameters (aggregates, cement, water, admixtures) to create optimal, cost-effective, and high-quality concrete mixtures in real-time.

- Automated Plant Operations: AI-powered control systems can automate batching, mixing, and dispensing processes, enhancing precision and reducing human intervention.

- Enhanced Quality Control: AI vision systems and sensors monitor concrete consistency, slump, and temperature, ensuring adherence to quality standards throughout production.

- Improved Logistics and Supply Chain: AI optimizes raw material procurement, inventory management, and delivery schedules, ensuring timely supply and reducing transportation inefficiencies.

- Real-time Performance Monitoring and Analytics: AI platforms collect and analyze operational data to provide insights into plant performance, energy consumption, and productivity.

DRO & Impact Forces Of Mobile Concrete Batch Plant Market

The Mobile Concrete Batch Plant Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the key Impact Forces. Robust drivers include significant global investments in infrastructure development, particularly in emerging economies, coupled with rapid urbanization that necessitates efficient and flexible construction solutions. The inherent benefits of mobile plants, such as on-site production, reduced logistics costs, and superior quality control, further fuel their adoption. Governments worldwide are prioritizing smart city initiatives and expanding transportation networks, directly contributing to the heightened demand for mobile batching technology. The imperative for timely project completion and increased operational efficiency also acts as a strong motivator for market growth.

However, several restraints pose challenges to market expansion. The high initial capital investment required for acquiring advanced mobile concrete batch plants can be a barrier for smaller construction firms or those in developing regions with limited financial resources. The operational complexity associated with managing sophisticated machinery, coupled with a shortage of skilled labor for maintenance and operation, can hinder widespread adoption. Stringent environmental regulations concerning dust emissions, noise pollution, and waste management also add to operational costs and compliance challenges for manufacturers and operators. Furthermore, fluctuations in raw material prices (cement, aggregates) and currency exchange rates can impact profitability and investment decisions within the market.

Opportunities for growth are abundant and strategically vital for market participants. The emergence of smart cities and integrated infrastructure projects presents a substantial avenue for mobile plants, which can adapt to diverse and evolving site requirements. The increasing focus on sustainable construction practices and green building initiatives opens doors for manufacturers to develop and market eco-friendly mobile batching solutions, leveraging innovative materials and energy-efficient designs. Digitalization and the integration of IoT, AI, and telematics offer significant opportunities for enhanced operational efficiency, predictive maintenance, and remote monitoring, creating a competitive edge. Expansion into remote and underserved areas, where conventional concrete supply is impractical, also represents a lucrative growth path. These impact forces collectively shape the competitive landscape and strategic direction of the Mobile Concrete Batch Plant Market.

Segmentation Analysis

The Mobile Concrete Batch Plant Market is comprehensively segmented across several crucial dimensions including type, capacity, application, and end-user. This granular segmentation provides a detailed understanding of the market's structure and helps in identifying specific growth pockets and evolving demand patterns. Each segment caters to distinct operational requirements and project scales, reflecting the diverse needs of the global construction industry. The continuous innovation in design and technology further refines these segments, allowing manufacturers to offer specialized solutions for various construction challenges.

- By Type

- Trailer Mounted

- Wheel Type

- By Capacity

- Less than 30 m3/h

- 30-60 m3/h

- More than 60 m3/h

- By Application

- Road and Bridge Construction

- Building Construction

- Others (Dams, Power Plants, Airports, Port Construction)

- By End-User

- Construction Companies

- Rental Companies

- Government Agencies

- Residential Developers

Value Chain Analysis For Mobile Concrete Batch Plant Market

The value chain for the Mobile Concrete Batch Plant Market begins with the upstream activities involving the sourcing and processing of various raw materials and components critical for manufacturing these complex machines. This includes suppliers of high-grade steel, electrical components, hydraulic systems, engines, control panels, and specialized mixing drums. Manufacturers engage with a diverse network of component producers, often leveraging global supply chains to ensure cost-effectiveness and quality. The design and engineering phase is also a crucial upstream activity, where research and development teams focus on innovation, efficiency, and adherence to international safety and environmental standards. Strategic partnerships with technology providers for automation and IoT integration are increasingly common in this segment.

Midstream activities primarily encompass the manufacturing and assembly of the mobile concrete batch plants. This involves fabricating the chassis, integrating the various mechanical and electrical systems, and rigorous quality control testing to ensure optimal performance and reliability. Manufacturers may specialize in certain types or capacities of plants, catering to specific market niches. Efficient production processes and lean manufacturing principles are essential here to manage costs and meet demand. After manufacturing, the plants move through various distribution channels to reach the end-users. These channels can be direct or indirect, depending on the manufacturer's strategy and the geographical reach.

Downstream activities involve the distribution, sales, after-sales service, and end-use of the mobile concrete batch plants. Direct sales typically involve manufacturers selling directly to large construction companies, government agencies, or major infrastructure developers, often including customized solutions and extensive technical support. Indirect channels involve a network of authorized dealers, distributors, and rental companies who market, sell, and lease the equipment to a broader range of customers, including smaller contractors and residential developers. After-sales services such as maintenance, spare parts supply, and technical training are critical for customer satisfaction and long-term relationships. The end-users then deploy these plants on various construction sites, completing the value chain by transforming raw materials into finished concrete for infrastructure, commercial, and residential projects.

Mobile Concrete Batch Plant Market Potential Customers

The primary potential customers and end-users of mobile concrete batch plants are diverse, reflecting the broad applicability of on-site concrete production across numerous construction and infrastructure sectors. Large-scale construction companies involved in major projects such as highways, bridges, dams, airports, and industrial complexes constitute a significant customer segment. These firms require high-capacity, reliable, and mobile solutions to maintain project timelines and quality standards across extensive or geographically dispersed construction sites. Their demand is often driven by the need for continuous concrete supply and the ability to adapt to varying site conditions and project phases.

Another crucial customer segment includes government agencies and public works departments responsible for developing and maintaining public infrastructure. These entities frequently engage in projects that span vast distances or are located in remote areas, where mobile batch plants offer an ideal solution for efficient and localized concrete production. Rental companies also represent a growing customer base, as they acquire and lease mobile concrete batch plants to smaller contractors, specialized construction firms, and developers who may not have the capital for direct purchase but require flexible access to high-quality concrete production equipment for specific projects. This allows smaller players to undertake larger or more remote projects without significant upfront investment.

Furthermore, residential and commercial developers, particularly those undertaking projects in rapidly urbanizing areas or locations with challenging logistics, are increasingly turning to mobile batch plants. These developers benefit from the ability to produce concrete exactly when and where it is needed, minimizing transportation costs and ensuring fresh concrete supply. Specialized construction contractors focused on niche applications, such as wind farm installations, mining infrastructure, or emergency repair work, also find mobile batch plants indispensable due to their rapid deployment capabilities and adaptability to unique project requirements. This broad spectrum of end-users underscores the essential role mobile concrete batch plants play in modern construction.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.8 Billion |

| Market Forecast in 2032 | $2.85 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Zoomlion Heavy Industry Science and Technology Co. Ltd., Sany Heavy Industry Co. Ltd., Liebherr, Schwing Stetter GmbH, ELKON Concrete Batching Plants, MEKA Global, FABO, Teka Maschinenbau GmbH, CON-E-CO, Vince Hagan Company, Cifa SpA, Fiori Group SpA, Aimix Group, Apollo Inffratech Pvt. Ltd., Aquarius Engineers, XCMG Construction Machinery Co. Ltd., Terex Corporation, Merlo S.p.A., Putzmeister Holding GmbH, KVM International A/S |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mobile Concrete Batch Plant Market Key Technology Landscape

The Mobile Concrete Batch Plant Market is experiencing a rapid evolution in its technological landscape, driven by the need for increased efficiency, precision, and sustainability in concrete production. Central to this advancement are sophisticated automated control systems, often based on Programmable Logic Controllers (PLCs) and HMI (Human Machine Interface) interfaces. These systems allow for precise control over batching sequences, aggregate weighing, cement and water dispensing, and admixture dosing, ensuring consistent concrete quality and reducing human error. Integration with digital platforms enables real-time monitoring and data logging, providing operators with critical insights into plant performance and material consumption.

Further technological advancements include the incorporation of telematics and Global Positioning System (GPS) capabilities. Telematics systems enable remote diagnostics, performance tracking, and geographical monitoring of mobile units, which is particularly beneficial for large fleets or plants deployed in remote locations. GPS integration assists in route optimization for transportation and precise positioning on construction sites. Internet of Things (IoT) sensors are increasingly being deployed throughout the plants to monitor various parameters such as temperature, pressure, mixer motor performance, and material levels, feeding data back into the control system for predictive maintenance and operational optimization. This proactive approach helps to minimize unscheduled downtime and extend equipment lifespan.

Moreover, there is a significant focus on advanced mixing technologies, with twin-shaft and planetary mixers gaining prominence due to their efficiency and ability to produce homogeneous concrete mixtures for various applications, including high-performance concrete. Energy-efficient designs, including optimized motor drives and hydraulic systems, are being adopted to reduce operational costs and environmental impact. The development of modular and compact designs facilitates quicker setup and dismantling, enhancing the mobility of these plants. Furthermore, advancements in material science and engineering are leading to the use of more durable and lightweight components, improving the overall reliability and transportability of mobile concrete batch plants, aligning with the industry's shift towards smarter and more sustainable construction practices.

Regional Highlights

- North America: Characterized by strong demand for high-capacity, automated mobile plants, driven by extensive infrastructure modernization projects and residential development in urban centers. The US and Canada are key markets, focusing on efficiency and technological integration.

- Europe: A mature market with steady demand for advanced, environmentally compliant mobile batch plants. Countries like Germany, the UK, and France are investing in sustainable construction practices and upgrading existing infrastructure, propelling the market.

- Asia Pacific (APAC): The largest and fastest-growing market, fueled by massive government investments in infrastructure, rapid urbanization, and a booming construction sector in countries such as China, India, and Southeast Asian nations. Cost-effectiveness and operational speed are significant drivers.

- Latin America: Experiencing substantial growth due to increasing infrastructure development, especially in Brazil, Mexico, and Argentina. Expanding mining operations and housing projects also contribute to the demand for mobile concrete solutions.

- Middle East and Africa (MEA): A high-potential market driven by large-scale commercial and residential construction projects, smart city initiatives, and diversification efforts away from oil economies. Countries like UAE, Saudi Arabia, and Qatar are significant contributors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mobile Concrete Batch Plant Market.- Zoomlion Heavy Industry Science and Technology Co. Ltd.

- Sany Heavy Industry Co. Ltd.

- Liebherr

- Schwing Stetter GmbH

- ELKON Concrete Batching Plants

- MEKA Global

- FABO

- Teka Maschinenbau GmbH

- CON-E-CO

- Vince Hagan Company

- Cifa SpA

- Fiori Group SpA

- Aimix Group

- Apollo Inffratech Pvt. Ltd.

- Aquarius Engineers

- XCMG Construction Machinery Co. Ltd.

- Terex Corporation

- Merlo S.p.A.

- Putzmeister Holding GmbH

- KVM International A/S

Frequently Asked Questions

What are the primary benefits of mobile concrete batch plants?

Mobile concrete batch plants offer significant benefits including enhanced operational flexibility, reduced logistics costs due to on-site production, superior quality control of concrete mixtures, and quicker project completion times. Their portability allows for efficient deployment in remote or rapidly changing construction environments.

How does a mobile concrete batch plant differ from a stationary one?

The key difference lies in mobility. Mobile plants are designed for easy relocation and quick setup, making them ideal for projects requiring frequent site changes or located in remote areas. Stationary plants, conversely, are fixed installations suited for long-term, high-volume production at a single location.

What factors influence the cost of a mobile concrete batch plant?

The cost is influenced by factors such as capacity (m3/h), level of automation, brand reputation, component quality, additional features like integrated cement silos, and after-sales service packages. Advanced technologies and higher capacities generally lead to increased costs.

What are the key technological advancements in this market?

Recent advancements include sophisticated automated control systems (PLCs), integration of telematics and GPS for remote monitoring, IoT sensors for predictive maintenance, advanced mixing technologies for higher quality concrete, and energy-efficient designs to reduce operational costs and environmental impact.

Which regions are showing significant growth in the mobile concrete batch plant market?

The Asia Pacific region, particularly countries like China and India, is experiencing the most significant growth due to extensive infrastructure development and rapid urbanization. Latin America and the Middle East & Africa are also emerging as high-growth markets driven by new construction projects and government investments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager