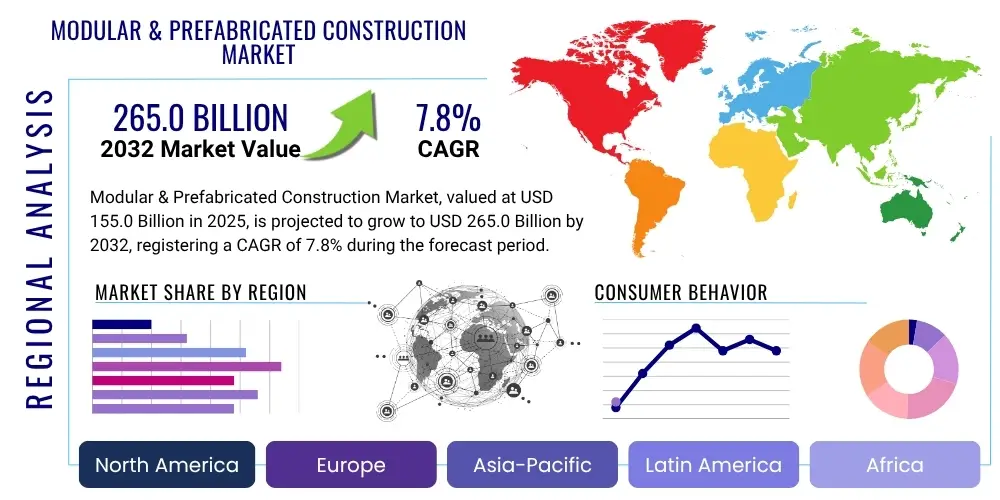

Modular & Prefabricated Construction Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429189 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Modular & Prefabricated Construction Market Size

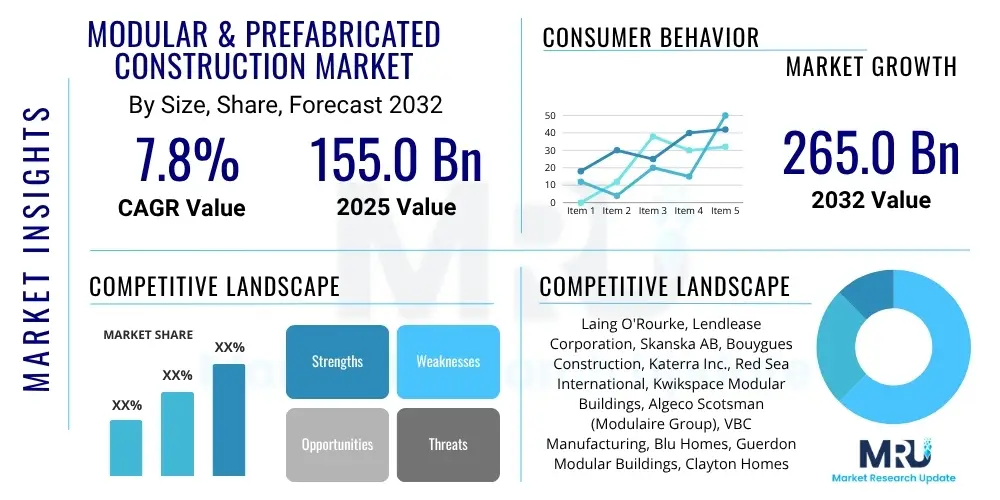

The Modular & Prefabricated Construction Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at $155.0 Billion in 2025 and is projected to reach $265.0 Billion by the end of the forecast period in 2032.

Modular & Prefabricated Construction Market introduction

The Modular & Prefabricated Construction Market encompasses the design, manufacturing, and assembly of building components or entire structures in an off-site, controlled factory environment before their final installation on a construction site. This innovative approach to building leverages advanced manufacturing techniques to produce standardized or customized modules, panels, and pre-cut components that adhere to stringent quality standards. Products range from volumetric modules that are complete three-dimensional units to two-dimensional panelized systems and hybrid solutions, offering a versatile spectrum of construction capabilities.

Major applications for modular and prefabricated construction span across diverse sectors, including residential buildings such as affordable housing, single-family homes, and multi-story apartments, as well as commercial developments like office complexes, retail spaces, hotels, and healthcare facilities. Furthermore, this method is increasingly adopted in industrial constructions for manufacturing plants and warehouses, educational institutions, and even specific infrastructure projects. The inherent benefits of this construction paradigm are substantial, primarily faster project completion times, significant cost efficiencies due to reduced on-site labor and waste, enhanced quality control through factory conditions, and improved worker safety.

Driving factors for the accelerated growth of this market include the escalating global demand for rapid and cost-effective housing solutions, particularly in urbanizing regions facing population growth and housing shortages. Furthermore, the increasing emphasis on sustainable building practices, coupled with the ability of off-site construction to minimize environmental impact through waste reduction and energy-efficient processes, positions it as a favored alternative. Technological advancements, such as Building Information Modeling (BIM), robotics, and automation, are also pivotal in enhancing efficiency, precision, and design flexibility, further propelling market expansion.

Modular & Prefabricated Construction Market Executive Summary

The Modular & Prefabricated Construction Market is experiencing robust growth, primarily fueled by the increasing imperative for efficient, sustainable, and rapid construction solutions across the globe. Key business trends indicate a strong move towards greater industrialization of construction, with an emphasis on advanced manufacturing processes and digital integration. Companies are investing heavily in automation, robotics, and integrated project delivery systems to optimize workflows, reduce material waste, and enhance productivity. The market is also witnessing a trend towards increased customization options, dispelling the historical perception of modular buildings as inflexible or aesthetically limited, thereby broadening their appeal to a wider client base and higher-value projects.

Regional trends highlight Asia Pacific as a dominant and rapidly expanding market, driven by extensive urbanization, government initiatives for affordable housing, and significant infrastructure development in countries like China, India, and Japan. North America and Europe also demonstrate substantial growth, characterized by strong adoption rates due to labor shortages, stringent environmental regulations, and a mature industrial base that facilitates technological integration. Latin America and the Middle East and Africa are emerging as promising markets, spurred by ambitious development plans and a growing need for resilient and cost-effective building solutions. These regions are increasingly exploring modular construction to address their unique challenges in infrastructure and housing.

Segment trends underscore the versatility of modular construction, with the residential sector, particularly affordable and multi-family housing, remaining a significant consumer, driven by population growth and government support. The commercial segment is also expanding rapidly, with modular solutions gaining traction in offices, hotels, and healthcare facilities seeking quick turnaround times and consistent quality. By material, steel and concrete modules continue to be prevalent for their durability and structural integrity, while wood and hybrid materials are gaining popularity due to their sustainable attributes and lighter footprint. The evolution of building systems, from volumetric modules to highly sophisticated panelized and hybrid constructions, demonstrates the market's adaptability and technological progression, catering to diverse project requirements and architectural visions.

AI Impact Analysis on Modular & Prefabricated Construction Market

User inquiries concerning AI's influence on the Modular & Prefabricated Construction Market primarily revolve around its potential to revolutionize design, optimize production, and enhance project management. Common questions explore how AI can automate design processes, improve material procurement, streamline factory operations, and predict potential project delays or cost overruns. There is keen interest in AI's role in enabling greater customization while maintaining efficiency, facilitating predictive maintenance for factory equipment, and ensuring higher quality control through automated inspection systems. Users also express curiosity about the challenges of integrating AI, such as data privacy, the need for skilled labor to manage AI systems, and the initial investment costs, alongside the expected benefits in terms of accelerated project delivery and enhanced resource utilization.

- AI-driven generative design accelerates architectural planning and optimizes structural layouts for efficiency and material usage.

- Predictive analytics enhance supply chain management, forecasting material demands and minimizing waste.

- Robotics and automation, powered by AI, increase precision and speed in off-site manufacturing processes.

- Quality control is improved through AI-powered visual inspection systems, detecting defects with high accuracy.

- AI algorithms optimize logistics and transportation routes for prefabricated modules, reducing costs and carbon footprint.

- Smart factory concepts leverage AI for real-time monitoring and operational efficiency, reducing downtime.

- Digital twins, integrated with AI, enable real-time performance tracking and predictive maintenance of modular buildings.

- Project management is optimized by AI-driven scheduling and risk assessment tools, anticipating and mitigating delays.

- Enhanced customization capabilities through AI allow for rapid prototyping and mass personalization of modular units.

- Improved worker safety is achieved through AI monitoring of hazardous environments and automated task execution.

DRO & Impact Forces Of Modular & Prefabricated Construction Market

The Modular & Prefabricated Construction Market is primarily driven by an escalating global demand for rapid, cost-effective, and sustainable building solutions. Key drivers include the pressing need for affordable housing in rapidly urbanizing areas, significant labor shortages in traditional construction sectors, and the inherent ability of off-site methods to offer faster project completion times. Furthermore, the enhanced quality control achievable in factory environments, coupled with reduced material waste and improved energy efficiency, strongly aligns with growing environmental sustainability mandates and client expectations. The drive for increased productivity and predictability in project timelines further strengthens the market's growth trajectory.

However, the market faces several notable restraints. Varying building codes and regulatory complexities across different regions and countries pose significant challenges to standardization and widespread adoption, making cross-border projects particularly arduous. Initial capital investment requirements for establishing advanced manufacturing facilities can be substantial, creating barriers to entry for smaller players. Additionally, the logistical challenges associated with transporting large modular units to remote or urban congested sites, alongside a lingering perception of limited design flexibility and aesthetic uniformity among some clients and architects, occasionally impede market penetration.

Despite these restraints, significant opportunities abound for market expansion and innovation. The rising adoption of modular construction in emerging economies, driven by rapid urbanization and infrastructure deficits, presents lucrative avenues for growth. Continuous technological advancements, particularly in Building Information Modeling (BIM), Artificial Intelligence (AI), robotics, and 3D printing, are enhancing design capabilities, optimizing production processes, and allowing for greater customization. Furthermore, the increasing focus on sustainable and net-zero building solutions provides a strong impetus for modular construction, as its controlled environment facilitates the integration of eco-friendly materials and energy-efficient designs, addressing the global climate crisis and attracting environmentally conscious clients.

Segmentation Analysis

The Modular & Prefabricated Construction Market is comprehensively segmented to reflect the diverse applications, materials, and technological approaches prevalent in the industry. This segmentation allows for a detailed understanding of market dynamics, growth drivers, and competitive landscapes across various dimensions. The primary segmentation categories include the type of modular building system, the materials utilized in construction, the end-use application sectors, and distinct geographical regions. This multi-faceted analysis helps stakeholders identify key trends and opportunities within specific niches of this rapidly evolving market, enabling targeted strategic planning and resource allocation.

- By Type

- Permanent Modular: Factory-built units that are transported and assembled on-site to form a complete, permanent structure, known for durability and long-term investment.

- Relocatable Buildings: Temporary or semi-permanent structures designed for easy disassembly and relocation, often used for construction site offices, classrooms, or emergency housing.

- Hybrid Modular: Combines modular components with traditional on-site construction methods, offering flexibility in design and construction.

- By Material

- Steel: Utilized for its high strength-to-weight ratio, durability, and fire resistance, commonly used in commercial and industrial modular buildings.

- Concrete: Valued for its robustness, thermal mass, sound insulation properties, and widespread availability, particularly for foundations and multi-story structures.

- Wood: A sustainable and lightweight option, increasingly popular for residential and low-rise commercial modular projects due to its aesthetic appeal and ease of fabrication.

- Plastic: Employed in specialized applications where lightweight, corrosion resistance, and specific thermal properties are required, such as sanitation units or temporary shelters.

- Composites: Advanced materials offering a combination of properties like high strength, lightweight, and customizability, used for specialized and high-performance modular components.

- By End-Use

- Residential: Encompasses affordable housing projects, single-family homes, multi-family apartments, and custom modular residences.

- Commercial: Includes office buildings, retail outlets, hotels, restaurants, and other commercial establishments.

- Industrial: Covers manufacturing facilities, warehouses, power plants, and specialized industrial structures.

- Institutional: Pertains to educational facilities, healthcare clinics, hospitals, government administrative buildings, and military structures.

- Infrastructure: Involves modular components for bridges, utility structures, temporary bridges, and other public works projects.

- By Building System

- Volumetric: Three-dimensional modules complete with internal finishes, transported as complete boxes.

- Panelized: Two-dimensional panels (walls, floors, roofs) manufactured off-site and assembled on-site.

- Skidded: Modules built on a permanent steel frame, often used for industrial and equipment housing.

- Pre-cut: Components cut to precise dimensions off-site and delivered for assembly.

- Hybrid: Combination of various modular systems and conventional construction.

Value Chain Analysis For Modular & Prefabricated Construction Market

The value chain for the Modular & Prefabricated Construction Market is characterized by a high degree of integration and specialization, differentiating it significantly from traditional construction. It begins with the upstream analysis, involving the sourcing and processing of raw materials such as steel, concrete, wood, and advanced composites. This stage also includes the manufacturing of specialized components like plumbing, electrical systems, HVAC units, windows, and doors, often by dedicated suppliers who operate under strict quality control. The efficiency of this upstream segment is critical, as any delays or quality issues directly impact the subsequent off-site fabrication process. Strong supplier relationships and robust material management systems are essential to maintain continuous production flow and cost-effectiveness.

The core of the value chain is the off-site manufacturing and assembly stage, where modular units or panels are fabricated in a controlled factory environment. This midstream process leverages advanced technologies like Building Information Modeling (BIM) for design and planning, robotics for automated assembly, and digital quality assurance systems. Manufacturers focus on optimizing production lines, minimizing waste, and ensuring precise adherence to design specifications before the modules are transported to the construction site. This phase also includes the finishing of interiors and exteriors to a high degree, reducing the need for extensive on-site work and contributing to faster project completion.

Downstream analysis involves the transportation of finished modules to the construction site, site preparation, and the final on-site assembly and installation. This stage requires meticulous logistics planning, often utilizing specialized heavy-haul carriers, and precise coordination with site teams for crane operations and utility hook-ups. The distribution channel is predominantly direct, with modular builders or specialized contractors engaging directly with end-users or developers to deliver integrated solutions. Indirect channels may involve partnerships with general contractors who subcontract the modular fabrication or work with third-party installers. The efficiency of the entire value chain, from raw material sourcing to final installation, is paramount in realizing the promised benefits of modular construction, including reduced timelines, cost savings, and enhanced quality.

Modular & Prefabricated Construction Market Potential Customers

The Modular & Prefabricated Construction Market serves a diverse range of end-users and buyers, each with specific needs that align well with the advantages offered by off-site construction methods. A significant segment of potential customers includes real estate developers and property owners who seek rapid project completion, cost predictability, and consistent quality for their residential, commercial, or institutional ventures. These clients are often focused on accelerating their return on investment and minimizing disruptions, making the faster construction timelines of modular systems highly attractive. Developers engaged in large-scale multi-family housing projects, affordable housing initiatives, and student accommodation schemes frequently turn to modular solutions to efficiently address high demand and tight schedules.

Government agencies and public sector organizations represent another substantial customer base, particularly for infrastructure projects, public housing programs, educational facilities, and healthcare units. These entities often operate under strict budget constraints and public accountability, finding modular construction appealing due to its cost-effectiveness, transparency in project delivery, and ability to meet community needs rapidly, especially in disaster relief or remote area development. Furthermore, the military and defense sectors utilize modular buildings for barracks, administrative offices, and temporary operational bases, valuing their quick deployment capabilities and robust, relocatable nature. The emphasis on sustainability and reducing environmental impact also resonates strongly with public sector procurement objectives.

Individual homeowners and small to medium-sized businesses are also increasingly becoming potential customers, particularly for custom modular homes, accessory dwelling units (ADUs), or small commercial premises like retail storefronts or pop-up shops. These buyers appreciate the streamlined process, reduced on-site disturbance, and often superior energy efficiency of factory-built homes. Companies in the industrial sector, such as manufacturing firms and logistics providers, are customers for modular offices, control rooms, and specialized facility expansions, prioritizing minimal operational disruption during construction and the ability to scale facilities quickly. The overall customer landscape is expanding as awareness grows about the benefits of modular and prefabricated methods beyond traditional temporary structures, demonstrating a shift towards more permanent and architecturally sophisticated applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $155.0 Billion |

| Market Forecast in 2032 | $265.0 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Laing O'Rourke, Lendlease Corporation, Skanska AB, Bouygues Construction, Katerra Inc., Red Sea International, Kwikspace Modular Buildings, Algeco Scotsman (Modulaire Group), VBC Manufacturing, Blu Homes, Guerdon Modular Buildings, Clayton Homes, Karmod Prefabricated Technologies, Pleko Prefabricated Systems, Etex Group, Sekisui House, Bechtel Corporation, Modular Building Institute, ATCO Structures & Logistics, Daiwa House Industry Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Modular & Prefabricated Construction Market Key Technology Landscape

The Modular & Prefabricated Construction Market is underpinned by a rapidly evolving technology landscape that is crucial for its efficiency, precision, and scalability. Building Information Modeling (BIM) stands as a foundational technology, enabling comprehensive digital representation of the building project, facilitating collaborative design, clash detection, and accurate material take-offs. BIM integrates various disciplines, from architectural design to structural engineering and MEP (mechanical, electrical, plumbing) systems, ensuring that all modular components fit together seamlessly, thereby reducing errors and rework during fabrication and assembly. This digital backbone is essential for the industrialized nature of off-site construction, allowing for virtual prototyping and performance simulation before physical production begins.

Robotics and advanced automation are transforming the factory floor, enhancing the speed and accuracy of manufacturing processes. Robotic arms are employed for tasks such as welding, precise cutting of materials, assembly of components, and even painting, significantly improving productivity and reducing manual labor requirements. Complementing this, 3D printing technology is emerging for producing complex, customized components, molds, or even entire small-scale structures, offering unprecedented design freedom and material efficiency. These automated systems contribute to higher quality outputs, consistent module production, and a safer working environment, pushing the boundaries of what is achievable in prefabricated construction.

Furthermore, the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is leading to the development of smart factories and digital twins. IoT sensors monitor production line performance, equipment health, and material flow in real-time, providing data that AI algorithms analyze to optimize operational efficiency, predict maintenance needs, and manage inventory. Digital twins create virtual replicas of both the manufacturing facility and the final modular building, allowing for continuous monitoring, performance analysis, and predictive maintenance throughout the lifecycle of the structure. These sophisticated technologies not only streamline the production process but also enhance the overall lifecycle management and sustainability of modular buildings, making them more resilient, energy-efficient, and responsive to user needs.

Regional Highlights

- North America: This region is a significant market, driven by labor shortages in traditional construction, strong technological adoption, and a growing demand for sustainable and disaster-resilient housing. Countries like the United States and Canada are witnessing increased investment in modular factories and advanced manufacturing techniques, particularly for commercial, multi-family residential, and healthcare projects.

- Europe: Characterized by stringent environmental regulations and a focus on energy efficiency, the European market is a leader in sustainable modular construction. Countries such as the UK, Germany, and the Nordics are actively promoting off-site construction to address housing crises, reduce carbon footprints, and improve construction safety and quality standards, with a strong emphasis on timber-based modular solutions.

- Asia Pacific (APAC): The largest and fastest-growing market globally, APAC is fueled by rapid urbanization, massive infrastructure development, and an urgent need for affordable housing in populous countries like China, India, and Japan. Government initiatives and large-scale public and private investments are accelerating the adoption of modular techniques to build quickly and efficiently.

- Latin America: This region presents emerging opportunities, driven by increasing foreign investment, a rising middle class, and the need for durable and rapid construction in urban and remote areas. Countries like Brazil and Mexico are exploring modular solutions for residential, educational, and disaster recovery projects, although regulatory harmonization remains a challenge.

- Middle East and Africa (MEA): The MEA market is experiencing growth due to ambitious development visions, such as Saudi Arabia's Vision 2030 and significant construction projects in the UAE. Modular construction offers speed and cost-efficiency in regions with harsh climates and remote project sites, particularly for commercial, hospitality, and industrial applications, as well as temporary worker accommodations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Modular & Prefabricated Construction Market.- Laing O'Rourke

- Lendlease Corporation

- Skanska AB

- Bouygues Construction

- Katerra Inc.

- Red Sea International

- Kwikspace Modular Buildings

- Algeco Scotsman (Modulaire Group)

- VBC Manufacturing

- Blu Homes

- Guerdon Modular Buildings

- Clayton Homes

- Karmod Prefabricated Technologies

- Pleko Prefabricated Systems

- Etex Group

- Sekisui House

- Bechtel Corporation

- Modular Building Institute

- ATCO Structures & Logistics

- Daiwa House Industry Co., Ltd.

Frequently Asked Questions

What is modular and prefabricated construction?

Modular and prefabricated construction refers to a building method where components or entire modules of a structure are manufactured off-site in a controlled factory environment. These pre-finished units are then transported to the final construction site for assembly, significantly reducing on-site labor and project timelines compared to traditional building methods.

What are the primary benefits of modular construction?

The main benefits include faster project completion times due to parallel on-site and off-site work, substantial cost savings from reduced labor and waste, enhanced quality control due to factory conditions, improved worker safety, and greater sustainability through waste reduction and energy-efficient designs. It also offers predictability in schedules and budgets.

Which industries primarily use modular and prefabricated construction?

Modular and prefabricated construction is widely used across various industries. Key sectors include residential (affordable housing, multi-family, single-family), commercial (offices, hotels, retail), institutional (schools, healthcare facilities), and industrial (manufacturing plants, warehouses). It is also increasingly applied in specific infrastructure projects.

What are the main challenges faced by the modular construction market?

Key challenges include navigating diverse and often inconsistent building codes and regulations across different regions, addressing complex logistics for transporting large modules, managing the significant initial capital investment required for factory setup, and overcoming a lingering perception of limited design flexibility compared to conventional construction.

How is technology impacting the modular and prefabricated construction market?

Technology is profoundly impacting the market by integrating Building Information Modeling (BIM) for design efficiency, employing robotics and automation for precise and rapid factory production, utilizing AI for supply chain optimization and quality control, and leveraging digital twins for real-time monitoring and predictive maintenance, all co

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager