Molded Pulp Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429565 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Molded Pulp Packaging Market Size

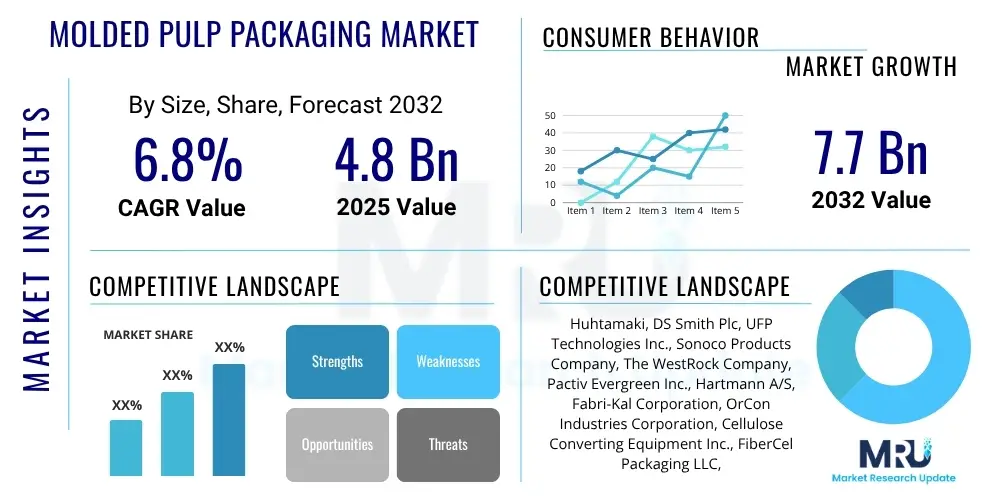

The Molded Pulp Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 4.8 Billion in 2025 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2032.

Molded Pulp Packaging Market introduction

The Molded Pulp Packaging Market encompasses the production and distribution of packaging solutions crafted from recycled paperboard, newsprint, or other virgin fibers. This eco-friendly packaging material is formed into various shapes using a molding process, offering a sustainable alternative to traditional plastic or foam packaging. Its inherent properties make it ideal for protecting delicate goods during transit and storage, appealing to industries prioritizing both product integrity and environmental responsibility.

Major applications span across the food and beverage, electronics, healthcare, and automotive sectors, where its cushioning and protective attributes are highly valued. Benefits include biodegradability, recyclability, lightweight design, and cost-effectiveness compared to some virgin materials. The market is primarily driven by a global surge in environmental awareness, stricter regulations against single-use plastics, and growing consumer demand for sustainable packaging solutions, pushing manufacturers to innovate and expand their molded pulp offerings across diverse product categories.

The product, often described as fiber packaging, uses a wet pulp slurry that is suctioned onto a forming screen, then pressed and dried. This versatile material can be engineered for various densities and surface finishes, from thick-walled industrial packaging to smooth, thin-walled consumer-facing items. Its ability to be molded into intricate shapes provides custom fit and superior shock absorption, making it a critical component in protecting items like fragile electronics, fresh produce, and pharmaceutical products, thereby reducing damage and waste throughout the supply chain.

Molded Pulp Packaging Market Executive Summary

The Molded Pulp Packaging Market is experiencing robust expansion, driven by a global pivot towards sustainable practices and stringent environmental regulations. Key business trends indicate a strong focus on automation and technological advancements to enhance production efficiency, improve product aesthetics, and broaden application versatility. Companies are increasingly investing in research and development to introduce innovative barrier properties for moisture and grease resistance, extending the shelf life and usability of molded pulp for a wider range of products, particularly within the food and beverage sector.

Regional trends highlight the Asia Pacific as a significant growth engine, fueled by rapid industrialization, increasing disposable incomes, and rising awareness regarding ecological footprint in countries like China and India. Europe continues to lead in sustainability initiatives, with strong regulatory frameworks promoting circular economy principles, thereby accelerating the adoption of molded pulp solutions. North America demonstrates consistent growth, driven by consumer demand for eco-friendly products and corporate sustainability pledges across various industries. These regional dynamics are fostering competitive landscapes and encouraging localized production and distribution networks.

Segmentation trends reveal that the food and beverage industry remains a dominant end-use sector, with increasing demand for egg cartons, fruit trays, and meal packaging. The electronics sector also presents substantial opportunities, utilizing molded pulp for protective inserts for consumer electronics. Furthermore, there is a notable shift towards thermoformed (thin-wall) molded pulp due to its smooth surface finish and superior aesthetic appeal, making it suitable for premium packaging. The market is also seeing greater integration of recycled content, aligning with circular economy objectives and reducing reliance on virgin materials, enhancing the overall sustainability profile of the industry.

AI Impact Analysis on Molded Pulp Packaging Market

User inquiries regarding AI's influence on the Molded Pulp Packaging Market frequently revolve around optimizing manufacturing processes, improving quality control, and reducing operational costs. Common concerns include the initial investment required for AI integration, the complexity of data management, and the need for skilled personnel to operate AI-powered systems. Users are keen to understand how AI can lead to more efficient pulp preparation, faster molding cycles, and precise drying processes, ultimately enhancing product consistency and throughput. Expectations include leveraging AI for predictive maintenance of machinery, optimizing raw material usage, and streamlining supply chain logistics for greater sustainability and cost-effectiveness across the entire value chain.

- AI-driven optimization of pulp slurry consistency and mixing ratios for improved material properties.

- Enhanced quality control through AI-powered visual inspection systems, detecting defects with high accuracy during production.

- Predictive maintenance of molding machinery, reducing downtime and extending equipment lifespan.

- Optimization of drying processes using AI algorithms to minimize energy consumption and improve efficiency.

- AI-assisted design for new molded pulp products, allowing for rapid prototyping and performance simulation.

- Supply chain optimization, including demand forecasting and logistics management for raw materials and finished goods.

- Automated sorting and identification of recycled fibers to ensure optimal feedstock quality.

- Personalized packaging design and customization based on consumer preferences and product requirements.

DRO & Impact Forces Of Molded Pulp Packaging Market

The Molded Pulp Packaging Market is primarily driven by increasing global environmental awareness and consumer preference for sustainable products, pushing industries to adopt eco-friendly packaging alternatives. Stricter government regulations worldwide, particularly banning single-use plastics, act as significant accelerators for market growth. The inherent benefits of molded pulp, such as its biodegradability, recyclability, and excellent cushioning properties for product protection, further bolster its demand across diverse sectors. Its cost-effectiveness, especially when utilizing recycled content, makes it an attractive option for manufacturers seeking to reduce operational expenses while adhering to sustainability goals.

However, the market faces restraints including the relatively higher initial capital investment required for specialized molding machinery compared to some conventional packaging methods, which can be a barrier for smaller enterprises. Limited design flexibility, particularly for intricate shapes or transparency requirements often met by plastics, poses a challenge in certain applications. Furthermore, molded pulp's susceptibility to moisture and grease without additional coatings or treatments restricts its use for specific food items or humid environments, although ongoing research aims to mitigate these limitations through innovative barrier technologies and material science.

Opportunities for growth are abundant, fueled by the rising global demand for sustainable packaging across e-commerce, food service, and personal care industries. Innovation in developing advanced barrier coatings and additive technologies will unlock new applications for molded pulp in moisture-sensitive and grease-prone products, expanding its market penetration. The continuous evolution of manufacturing technologies, including automation and advanced molding techniques, promises to enhance production efficiency, reduce costs, and improve the aesthetic appeal of molded pulp products, making them competitive with premium packaging solutions. The market also benefits from the increasing adoption of circular economy principles, emphasizing the use of recycled materials and product lifecycle sustainability.

Segmentation Analysis

The Molded Pulp Packaging Market is comprehensively segmented across various attributes, providing a detailed understanding of its diverse applications and material compositions. These segments allow for a granular analysis of market dynamics, highlighting growth pockets and areas of innovation based on how the packaging is produced, the raw materials utilized, the final product form, and the end-use industry. This multifaceted approach helps stakeholders identify specific opportunities and tailor strategies to meet the evolving demands of different market niches, from industrial protective packaging to consumer-facing retail solutions.

The market can be broadly categorized by the type of molded pulp, which dictates its strength, finish, and application suitability, ranging from robust thick-walled options to aesthetically refined thin-walled packaging. Further segmentation by source material differentiates between virgin and recycled fibers, reflecting sustainability commitments and resource utilization. Product forms, such as trays, clamshells, and end caps, address specific functional requirements across various industries, while the diverse end-use sectors underscore the material's versatility. Understanding these segments is crucial for market participants to develop targeted product offerings and distribution strategies.

- By Type

- Thick Wall (Industrial)

- Transfer Molded (Egg Cartons, Fruit Trays)

- Thermoformed (Thin-wall, Smooth Surface)

- Processed (Value-added with coatings, colors)

- By Source

- Virgin Fiber

- Recycled Fiber (Post-consumer, Post-industrial)

- By Product

- Trays

- Clamshells

- End Caps

- Bowls

- Cups

- Plates

- Other Products (e.g., inserts, wine shippers)

- By End-Use Industry

- Food & Beverage (Eggs, Fruits, Vegetables, Meat, Meal Packaging)

- Electronics (Consumer Electronics, Industrial Electronics)

- Healthcare & Pharmaceutical

- Automotive

- Industrial Packaging

- Consumer Goods (Cosmetics, Personal Care, Home Appliances)

- E-commerce

Value Chain Analysis For Molded Pulp Packaging Market

The value chain for the Molded Pulp Packaging Market begins with upstream activities focused on raw material sourcing. This primarily involves the collection and processing of waste paper, cardboard, and other cellulosic fibers from various industrial and post-consumer sources. Virgin pulp, derived from sustainably managed forests, also contributes to the raw material supply, especially for specialized applications requiring higher strength or specific aesthetic qualities. Key players in this stage include recycling companies, pulp and paper manufacturers, and sometimes forestry operations, all of whom play a critical role in ensuring a consistent and quality supply of fiber. Efficient sourcing and pre-processing of these materials are paramount to managing production costs and maintaining environmental credentials.

Midstream activities encompass the manufacturing process, where raw fibers are converted into molded pulp products. This stage involves several key steps: pulp preparation (slurrying and refining), molding (using various techniques like wet pressing, dry pressing, or thermoforming), drying, and often secondary processing such as trimming, coating, or printing. Manufacturers of molded pulp packaging are central to this stage, investing in machinery, technology, and skilled labor. Automation and process optimization are crucial for enhancing efficiency, reducing energy consumption, and improving product quality and consistency. Innovation in molding techniques and material science, including the development of natural barrier coatings, continues to drive advancements within this segment.

Downstream activities involve the distribution of finished molded pulp products to various end-use industries and ultimately to consumers. The distribution channel can be direct, where manufacturers supply directly to large industrial clients like food processors, electronics companies, or automotive manufacturers. Alternatively, indirect channels involve working with packaging distributors, wholesalers, or retailers who then supply to smaller businesses or directly to the consumer market, particularly for items like egg cartons or fruit trays. Effective logistics and supply chain management are essential to ensure timely delivery, reduce transportation costs, and maintain the integrity of the packaging. The growing e-commerce sector also represents a significant downstream channel, with molded pulp being increasingly utilized for protective packaging for online shipments, emphasizing the need for robust and efficient delivery networks.

Molded Pulp Packaging Market Potential Customers

The Molded Pulp Packaging Market serves a wide array of potential customers across diverse industrial and commercial sectors, driven by the universal need for protective, sustainable, and often customizable packaging solutions. End-users and buyers range from large multinational corporations to small and medium-sized enterprises (SMEs), all seeking to enhance their product's protection during transit and storage while simultaneously addressing environmental concerns and adhering to sustainability mandates. The versatility of molded pulp allows it to cater to specific requirements for cushioning, nesting, and containment, making it a preferred choice for companies committed to reducing their ecological footprint and improving brand perception through eco-conscious packaging. These customers are increasingly evaluating packaging not just for functional utility but also for its broader environmental impact and alignment with corporate social responsibility goals.

Key segments of potential customers include food and beverage producers, who utilize molded pulp for egg cartons, fruit trays, wine dividers, and increasingly for ready-to-eat meal containers due to its breathability and protective qualities. The electronics industry represents another significant customer base, requiring custom-fit inserts and end caps for consumer electronics, industrial equipment, and white goods to prevent damage from shock and vibration. Pharmaceutical and healthcare companies also rely on molded pulp for packaging sensitive medical devices and over-the-counter products, valuing its sterile and protective characteristics. Beyond these, the automotive sector uses molded pulp for protecting fragile components, while general consumer goods brands, including cosmetics, personal care, and home appliances, are adopting it for sustainable and aesthetically pleasing primary and secondary packaging solutions, responding to consumer demand for greener products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.8 Billion |

| Market Forecast in 2032 | USD 7.7 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Huhtamaki, DS Smith Plc, UFP Technologies Inc., Sonoco Products Company, The WestRock Company, Pactiv Evergreen Inc., Hartmann A/S, Fabri-Kal Corporation, OrCon Industries Corporation, Cellulose Converting Equipment Inc., FiberCel Packaging LLC, Henry Molded Products Inc., EnviroPAK Corporation, Keiding Inc., Pacific Pulp Molding Inc., BillerudKorsnas AB, Smurfit Kappa Group Plc, Mayr-Melnhof Karton AG, Mondi Group, Sappi Limited |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Molded Pulp Packaging Market Key Technology Landscape

The technology landscape for the Molded Pulp Packaging Market is continuously evolving, driven by the demand for enhanced efficiency, improved product performance, and expanded application versatility. The core manufacturing processes revolve around preparing a fibrous slurry and then molding it into desired shapes. Key technologies include various molding techniques such as dry pressing, wet pressing, and thermoforming. Dry pressing involves forming pulp into a shape and then drying it under pressure, resulting in a denser, smoother finish. Wet pressing is typically used for thicker, more robust industrial packaging. Thermoforming, a more advanced method, produces thin-walled, smooth-surfaced products akin to plastic, suitable for consumer-facing applications, requiring specialized tooling and precise temperature control. These processes are constantly being refined to optimize material usage, reduce cycle times, and minimize energy consumption, crucial for cost-effective and sustainable production.

Beyond the fundamental molding techniques, technological advancements are observed in several critical areas. Automation plays a significant role, with robotic handling systems, automated inspection, and integrated drying tunnels improving consistency and throughput while reducing labor costs. Pulp preparation technologies are also advancing, focusing on more efficient fiber deflaking, refining, and blending to achieve optimal pulp consistency and strength. Furthermore, the development of sophisticated tooling and die-making technologies allows for the creation of more intricate and precise packaging designs, catering to custom-fit requirements for delicate products. These innovations collectively contribute to higher quality outputs, lower production costs, and greater design flexibility, expanding the market's competitive edge against traditional packaging materials.

The integration of advanced material science is another crucial aspect of the technology landscape. This includes the development of natural and biodegradable barrier coatings to enhance molded pulp's resistance to moisture, grease, and oxygen, thereby broadening its application in food packaging and other sensitive product categories. Research into incorporating various additives, such as natural waxes, starches, or bioplastics, aims to improve strength, water repellency, and surface finish without compromising biodegradability. Furthermore, digital printing technologies are being adopted for direct-to-product customization and branding, offering aesthetic appeal and marketing advantages. These technological strides are not only improving the functional properties of molded pulp but also elevating its perception as a premium, sustainable packaging solution capable of meeting diverse industrial and consumer demands.

Regional Highlights

- North America: The North American market is characterized by a strong consumer preference for sustainable products and increasing corporate sustainability initiatives. Driven by significant demand from the food and beverage and electronics sectors, countries like the United States and Canada are witnessing consistent growth. Regulations promoting recycling and reducing plastic waste also contribute to market expansion. Investments in advanced manufacturing technologies and automation are common, aimed at enhancing production efficiency and product quality. The e-commerce boom further fuels demand for protective molded pulp inserts.

- Europe: Europe stands as a leader in the adoption of molded pulp packaging, primarily due to stringent environmental regulations and a robust circular economy framework. Countries such as Germany, the UK, and France are heavily investing in biodegradable and recyclable packaging solutions. The region benefits from high consumer awareness regarding environmental issues, coupled with government incentives and bans on single-use plastics. Innovation in barrier technologies and aesthetic designs is a key focus, expanding molded pulp's application in premium and sensitive product categories.

- Asia Pacific (APAC): The Asia Pacific region is projected to be the fastest-growing market, driven by rapid industrialization, increasing disposable incomes, and evolving consumer preferences for sustainable products in countries like China, India, Japan, and South Korea. Growing manufacturing bases in electronics and automotive, coupled with a burgeoning food processing industry, create immense demand. While plastic packaging remains prevalent, increasing environmental awareness and government initiatives are steadily shifting the preference towards molded pulp. Significant investment in new production facilities and technological upgrades is anticipated.

- Latin America: The Latin American market for molded pulp packaging is experiencing steady growth, albeit from a smaller base, primarily influenced by rising environmental consciousness and developing regulatory frameworks in countries like Brazil and Mexico. The food and beverage sector, particularly for egg and fruit packaging, is a major driver. Economic development and increasing foreign investment are contributing to the expansion of industrial and consumer goods sectors, creating new opportunities for sustainable packaging solutions.

- Middle East and Africa (MEA): The MEA region is an emerging market for molded pulp packaging, with growth being driven by urbanization, expanding retail sectors, and a nascent but growing focus on sustainability. While oil and gas dependent economies have been slower to adopt, countries like UAE and South Africa are showing increasing interest in eco-friendly alternatives. Investments in food security and packaging infrastructure are creating opportunities, particularly in protective packaging for agricultural produce and consumer goods. Regulatory push for waste reduction is gradually influencing market dynamics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Molded Pulp Packaging Market.- Huhtamaki

- DS Smith Plc

- UFP Technologies Inc.

- Sonoco Products Company

- The WestRock Company

- Pactiv Evergreen Inc.

- Hartmann A/S

- Fabri-Kal Corporation

- OrCon Industries Corporation

- Cellulose Converting Equipment Inc.

- FiberCel Packaging LLC

- Henry Molded Products Inc.

- EnviroPAK Corporation

- Keiding Inc.

- Pacific Pulp Molding Inc.

- BillerudKorsnas AB

- Smurfit Kappa Group Plc

- Mayr-Melnhof Karton AG

- Mondi Group

- Sappi Limited

Frequently Asked Questions

What is molded pulp packaging?

Molded pulp packaging is a sustainable packaging material made from recycled paperboard, newsprint, or virgin fibers, formed into various protective shapes using a molding process. It is biodegradable, recyclable, and commonly used for cushioning products.

What are the primary applications of molded pulp packaging?

Molded pulp packaging is widely used in the food and beverage industry for egg cartons and fruit trays, in electronics for protective inserts, in healthcare for medical devices, and for industrial and consumer goods to provide cushioning and containment.

What drives the growth of the molded pulp packaging market?

The market's growth is primarily driven by increasing environmental concerns, stringent government regulations against single-use plastics, and rising consumer demand for sustainable and eco-friendly packaging solutions across various industries.

What are the main types of molded pulp packaging?

The main types include thick wall for industrial use, transfer molded for items like egg cartons, thermoformed (thin-wall) for smooth consumer packaging, and processed molded pulp which includes coatings or treatments for enhanced properties.

How does AI impact the molded pulp packaging industry?

AI enhances the molded pulp industry through optimized production processes, improved quality control via visual inspection, predictive maintenance of machinery, efficient pulp preparation, and streamlined supply chain logistics, leading to cost reduction and sustainability gains.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager