Motion Control Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430336 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Motion Control Market Size

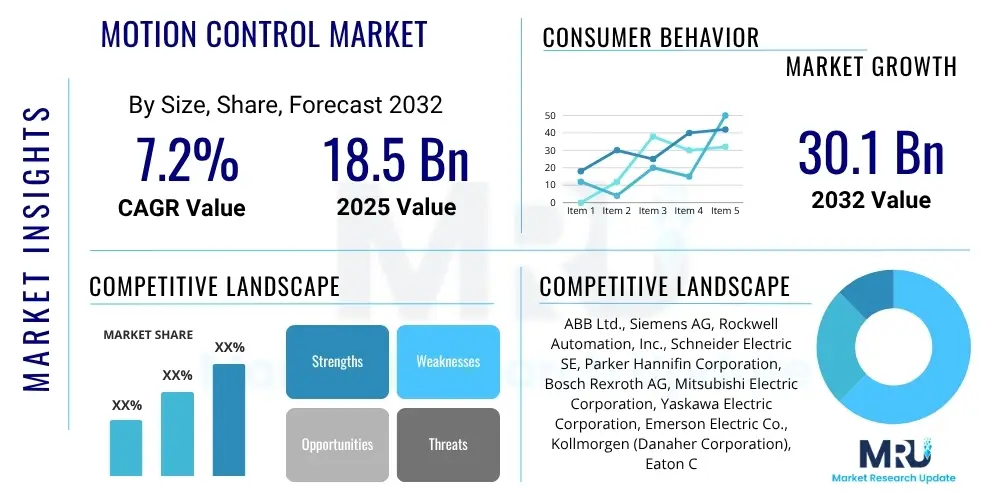

The Motion Control Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032. The market is estimated at $18.5 Billion in 2025 and is projected to reach $30.1 Billion by the end of the forecast period in 2032.

Motion Control Market introduction

The Motion Control Market encompasses systems and components that facilitate the controlled movement of machines and their parts, offering precision, speed, and reliability critical for modern industrial processes. These systems are fundamental to automation, enabling tasks that range from simple linear movements to complex, multi-axis coordination. The core components of motion control include motors, drives, controllers, and feedback devices, all working in concert to execute predefined movements with exceptional accuracy.

Major applications of motion control span across diverse industries such as manufacturing, robotics, packaging, semiconductor production, and healthcare. Its benefits are profound, including enhanced operational efficiency, improved product quality, reduced waste, and increased safety for human operators. The market is primarily driven by the escalating global demand for industrial automation, the proliferation of Industry 4.0 initiatives, and the continuous need for advanced manufacturing capabilities that require high levels of precision and speed. The integration of smarter, more flexible, and interconnected motion control solutions is pivotal for enterprises aiming to optimize their production lines and maintain a competitive edge in a rapidly evolving industrial landscape.

Motion Control Market Executive Summary

The Motion Control Market is undergoing significant transformation, driven by robust business trends centered on digitalization, sustainable manufacturing practices, and the increasing adoption of collaborative robotics. Enterprises are increasingly investing in motion control solutions to address rising labor costs, improve production throughput, and meet stringent quality control standards. This translates into a strong market push towards integrated, intelligent, and energy-efficient systems that can seamlessly communicate within a smart factory ecosystem. The focus on customized and flexible manufacturing is also shaping business strategies, leading to demand for modular and easily reconfigurable motion control architectures.

Regionally, Asia Pacific continues to dominate the market due to its robust manufacturing sector, particularly in countries like China, Japan, and South Korea, which are rapidly deploying automation technologies across various industries. North America and Europe are significant contributors, distinguished by their emphasis on technological innovation, research and development, and the early adoption of advanced motion control solutions, including those integrated with artificial intelligence and industrial internet of things (IIoT). Emerging markets in Latin America, the Middle East, and Africa are showing promising growth, fueled by industrialization efforts and increasing foreign direct investments in manufacturing infrastructure.

Segment-wise, the market is witnessing strong growth in AC servo systems, driven by their efficiency and precision in high-dynamic applications. The software component of motion control, including advanced human-machine interfaces (HMIs) and predictive maintenance analytics, is also gaining prominence, highlighting the shift towards more intelligent and data-driven operational control. The application of motion control in robotics, material handling, and packaging continues to be a primary revenue generator, while sectors such as healthcare and renewable energy present substantial future growth opportunities, underscoring the versatility and critical importance of motion control technology.

AI Impact Analysis on Motion Control Market

Users frequently inquire about how Artificial Intelligence (AI) is transforming motion control, focusing on aspects like predictive maintenance, enhanced precision, and the development of autonomous systems. Common questions revolve around the practical benefits of integrating AI into motion control, the challenges faced during implementation, and the future outlook for AI-driven motion control solutions. There is significant interest in understanding how AI can make motion control systems more intelligent, adaptive, and self-optimizing, moving beyond traditional pre-programmed sequences. Key themes emerging from these inquiries include the potential for AI to optimize complex motion paths, improve energy efficiency, enable real-time anomaly detection, and facilitate more intuitive human-machine collaboration, addressing concerns about system reliability and operational uptime.

- AI enables predictive maintenance by analyzing operational data from motion control components, foreseeing potential failures before they occur and minimizing downtime.

- Optimized motion profiles using AI algorithms lead to smoother, faster, and more energy-efficient movements, enhancing overall system performance and reducing wear and tear.

- Adaptive control systems powered by AI can dynamically adjust motion parameters in real-time to compensate for environmental changes, material variations, or unexpected loads, ensuring consistent precision.

- AI facilitates autonomous motion planning and execution for complex robotic tasks, allowing robots to learn from experience and perform sophisticated maneuvers without explicit programming.

- Improved human-robot collaboration is achieved through AI-driven interfaces that predict human intent and adapt robot movements, enhancing safety and efficiency in shared workspaces.

- Enhanced diagnostics and troubleshooting are supported by AI, which can rapidly identify root causes of malfunctions in motion control systems, streamlining maintenance processes.

- AI contributes to energy efficiency by analyzing usage patterns and optimizing motor and drive operations to consume less power during various stages of movement.

- Advanced quality inspection systems integrate AI with motion control to guide sensors and cameras for precise defect detection and product conformity assessment.

DRO & Impact Forces Of Motion Control Market

The Motion Control Market is significantly influenced by a confluence of drivers, restraints, and opportunities that shape its growth trajectory and competitive landscape. Key drivers include the escalating global demand for industrial automation, driven by the imperative to reduce labor costs, enhance manufacturing efficiency, and maintain consistent product quality. The rapid adoption of Industry 4.0 principles, characterized by smart factories, interconnected devices, and data-driven decision-making, further accelerates the deployment of advanced motion control solutions. Additionally, the growing focus on energy efficiency and sustainability in manufacturing processes is pushing companies towards more optimized and energy-conserving motion control systems.

Conversely, the market faces several restraints that could impede its expansion. The high initial capital investment required for implementing sophisticated motion control systems can be a significant barrier, especially for small and medium-sized enterprises. The inherent technical complexity of integrating various components and software, coupled with the need for specialized engineering expertise, also poses challenges. Furthermore, a persistent shortage of skilled professionals capable of operating, programming, and maintaining advanced motion control systems can slow down adoption rates. Cybersecurity concerns related to interconnected industrial systems present another hurdle, as breaches could lead to operational disruptions and data loss.

Opportunities for growth are abundant, particularly with the emergence of collaborative robots (cobots) and the broader trend of human-robot collaboration, which expands the application scope of motion control into more flexible and interactive environments. The continuous advancement in AI and IoT technologies provides avenues for developing more intelligent, predictive, and autonomous motion control systems. Furthermore, the expansion of motion control into new and niche application areas such as medical devices, logistics, agricultural automation, and renewable energy sectors offers diversified revenue streams. The increasing demand for customized motion control solutions, tailored to specific industry needs, also presents a lucrative pathway for market players to innovate and differentiate their offerings, while the competitive impact forces continue to drive innovation and product development to gain market share.

Segmentation Analysis

The Motion Control Market is comprehensively segmented across various dimensions, providing a granular view of its structure and growth potential. These segmentations are crucial for understanding market dynamics, identifying key growth areas, and formulating targeted business strategies. The market is primarily categorized by type, which includes both complete motion control systems and individual components, reflecting the diverse procurement needs of end-users. Further segmentation by application highlights the vast array of industrial and commercial uses, while segmentation by industry identifies the primary sectors driving demand for these advanced control technologies. This detailed breakdown enables a clear analysis of market trends and competitive positioning within each niche.

- By Type:

- Motion Control Systems

- Computerized Numerical Control (CNC)

- General Motion Control (GMC)

- Components

- Actuators

- Motors: AC Motors, DC Motors, Servo Motors, Stepper Motors

- Linear Actuators

- Rotary Actuators

- Drives

- AC Drives

- DC Drives

- Servo Drives

- Stepper Drives

- Motion Controllers

- PLC-based

- PC-based

- Standalone

- Sensors and Feedback Devices

- Encoders

- Resolvers

- Proximity Sensors

- Vision Sensors

- Software

- HMI (Human Machine Interface)

- SCADA (Supervisory Control and Data Acquisition)

- PLC Programming Software

- Motion Planning Software

- Simulation Software

- Other Components (e.g., Gearboxes, Brakes, Couplings, Cables)

- Actuators

- Motion Control Systems

- By Application:

- Robotics

- Material Handling (e.g., Conveyors, Automated Storage and Retrieval Systems AS/RS)

- Packaging and Labeling

- Assembly and Disassembly

- Metal Fabrication (e.g., Welding, Cutting, Bending)

- Printing and Paper

- Food and Beverage Processing

- Semiconductor and Electronics Manufacturing

- Medical and Laboratory Equipment

- Textile Machinery

- Automotive Manufacturing

- Aerospace and Defense

- Machine Tools

- Renewable Energy Systems (e.g., Wind Turbine Pitch Control)

- General Automation

- By Industry:

- Automotive

- Aerospace and Defense

- Semiconductor and Electronics

- Food and Beverage

- Packaging

- Healthcare and Medical

- Metal and Machinery Manufacturing

- Printing and Paper

- Textile

- Energy (Oil and Gas, Power Generation)

- Others (e.g., Construction, Logistics, Marine)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Motion Control Market

The value chain for the Motion Control Market begins with upstream activities involving the sourcing of raw materials and the manufacturing of discrete components. This includes suppliers of metals, semiconductors, rare earth elements, and other fundamental materials necessary for producing motors, drives, sensors, and controllers. Specialized component manufacturers then convert these raw materials into advanced electronic and mechanical parts, such as microcontrollers, power semiconductors, precision gears, and winding materials for motors. These manufacturers often specialize in specific components, ensuring high quality and technical sophistication, forming the foundational layer of the motion control ecosystem.

Further down the value chain, system integrators play a crucial role by combining these individual components into cohesive motion control systems tailored to specific industrial applications. These integrators design, program, and install solutions for various end-users, addressing complex automation challenges. The distribution channel is multifaceted, comprising both direct sales from major manufacturers to large industrial clients and indirect sales through a network of distributors, value-added resellers (VARs), and local agents. These indirect channels are vital for reaching smaller enterprises and providing localized support, technical assistance, and maintenance services. The efficiency of these distribution networks directly impacts market penetration and customer reach.

The downstream activities primarily involve the end-users who deploy these motion control systems in their production lines and operational facilities. These end-users span a broad spectrum of industries, leveraging motion control to enhance precision, speed, efficiency, and safety in their manufacturing, assembly, material handling, or processing operations. Ongoing maintenance, technical support, and periodic upgrades provided by manufacturers or their partners ensure the long-term performance and reliability of the installed systems. The integration of digital services, such as remote monitoring and predictive maintenance, is increasingly becoming a critical part of the downstream value proposition, enhancing customer satisfaction and operational uptime.

Motion Control Market Potential Customers

The primary potential customers and end-users of motion control products and systems are found across a diverse range of industrial sectors that require precise, repeatable, and high-speed mechanical movements. Manufacturing industries form the largest segment, with a critical need for automation to improve production efficiency and quality. This includes sectors such as automotive manufacturing, where motion control is vital for assembly lines, robotic welding, and painting processes. The electronics and semiconductor industries rely heavily on ultra-high precision motion control for wafer handling, chip mounting, and inspection systems, where even micron-level accuracy is essential for product yield and performance.

Beyond traditional manufacturing, the packaging and food and beverage industries are significant consumers, utilizing motion control for tasks like filling, sealing, labeling, and palletizing, ensuring consistent product presentation and hygiene. The healthcare and medical sector represents a growing customer base, with applications in diagnostic equipment, laboratory automation, robotic surgery, and prosthetics that demand highly accurate and reliable motion. Other key buyers include aerospace and defense, utilizing motion control for flight simulators, precision machining of components, and unmanned vehicle systems. Furthermore, the material handling and logistics sectors, including warehouses and distribution centers, are increasingly adopting motion control in automated guided vehicles (AGVs), automated storage and retrieval systems (AS/RS), and conveyor systems to optimize operational flow and throughput.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $18.5 Billion |

| Market Forecast in 2032 | $30.1 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Rockwell Automation, Inc., Schneider Electric SE, Parker Hannifin Corporation, Bosch Rexroth AG, Mitsubishi Electric Corporation, Yaskawa Electric Corporation, Emerson Electric Co., Kollmorgen (Danaher Corporation), Eaton Corporation plc, Delta Electronics, Inc., Festo AG & Co. KG, Oriental Motor Co., Ltd., FANUC Corporation, OMRON Corporation, Nidec Corporation, Dunkermotoren GmbH, Lenze SE, Beckhoff Automation GmbH & Co. KG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Motion Control Market Key Technology Landscape

The Motion Control Market is characterized by a dynamic and evolving technology landscape, continuously integrating innovations to enhance performance, connectivity, and intelligence. At its core, the technology relies heavily on advanced servo and stepper systems, which include precision motors (AC servo, DC servo, stepper motors) and their corresponding drives that manage power delivery and control. These systems are crucial for achieving the high levels of accuracy, speed, and torque required in modern industrial applications. Programmable Logic Controllers (PLCs) and Programmable Automation Controllers (PACs) serve as the brain of many motion control systems, coordinating complex sequences and integrating with other factory automation components. Human-Machine Interfaces (HMIs) are also critical, providing intuitive visualization and control capabilities for operators.

Connectivity is a paramount aspect, with industrial communication protocols such as EtherCAT, PROFINET, Ethernet/IP, and SERCOS III enabling high-speed, synchronized data exchange between controllers, drives, and other field devices. The proliferation of the Industrial Internet of Things (IIoT) is transforming motion control by enabling real-time data collection, remote monitoring, and cloud-based analytics, facilitating predictive maintenance and operational optimization. Furthermore, the integration of Artificial Intelligence (AI) and machine learning algorithms is emerging as a significant technological trend, allowing motion control systems to become more adaptive, self-learning, and capable of optimizing complex movement paths autonomously. Edge computing is also gaining traction, processing data closer to the source to reduce latency and enhance real-time decision-making, which is crucial for high-performance motion applications. This continuous technological evolution ensures motion control systems remain at the forefront of industrial automation capabilities.

Regional Highlights

- North America: This region is a leading adopter of advanced motion control technologies, driven by significant investments in industrial automation across diverse sectors like automotive, aerospace, and medical devices. The presence of key market players, robust R&D activities, and a strong emphasis on smart manufacturing initiatives contribute to its substantial market share.

- Europe: Europe represents a mature market with a strong focus on precision engineering, high-quality manufacturing, and sustainable production processes. Countries like Germany, Italy, and France are at the forefront of implementing sophisticated motion control solutions in robotics, machine tools, and packaging, propelled by Industry 4.0 strategies and stringent quality standards.

- Asia Pacific (APAC): The APAC region stands as the largest and fastest-growing market for motion control, primarily due to rapid industrialization, burgeoning manufacturing sectors, and extensive investments in automation by countries such as China, Japan, South Korea, and India. The robust growth in automotive, electronics, and semiconductor industries is a key driver for motion control adoption here.

- Latin America: This region is experiencing steady growth in the motion control market, fueled by increasing foreign investments in manufacturing and infrastructure development. Industries such as automotive, food and beverage, and packaging are gradually embracing automation to enhance productivity and competitiveness.

- Middle East and Africa (MEA): The MEA region is an emerging market, driven by diversification efforts away from oil-dependent economies and increasing investments in manufacturing and logistics. The adoption of motion control is primarily seen in sectors like oil and gas, construction, and nascent manufacturing industries seeking to modernize their operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Motion Control Market.- ABB Ltd.

- Siemens AG

- Rockwell Automation, Inc.

- Schneider Electric SE

- Parker Hannifin Corporation

- Bosch Rexroth AG (subsidiary of Robert Bosch GmbH)

- Mitsubishi Electric Corporation

- Yaskawa Electric Corporation

- Emerson Electric Co.

- Kollmorgen (Danaher Corporation)

- Eaton Corporation plc

- Delta Electronics, Inc.

- Festo AG & Co. KG

- Oriental Motor Co., Ltd.

- FANUC Corporation

- OMRON Corporation

- Nidec Corporation

- Dunkermotoren GmbH

- Lenze SE

- Beckhoff Automation GmbH & Co. KG

Frequently Asked Questions

What is motion control and why is it important in manufacturing?

Motion control involves precisely controlling the movement of machines and their components, crucial for automation. It is vital in manufacturing for achieving high precision, speed, efficiency, and consistent quality in production processes, reducing human error, and enhancing operational safety.

How is Industry 4.0 influencing the Motion Control Market?

Industry 4.0 is significantly driving the Motion Control Market by promoting smart factories, interconnected systems, and data-driven decision-making. It fosters demand for intelligent, flexible, and integrated motion control solutions that can communicate seamlessly, enabling features like predictive maintenance and real-time optimization.

What are the main components of a motion control system?

A typical motion control system consists of several key components: a motion controller (PLC-based, PC-based, or standalone), drives (e.g., servo drives, stepper drives), motors (e.g., AC servo motors, stepper motors), and feedback devices like encoders or resolvers, all working together to execute precise movements.

Which industries are the largest adopters of motion control technology?

The largest adopters of motion control technology include the automotive, electronics and semiconductor, packaging, food and beverage, robotics, and machine tools industries. These sectors heavily rely on precise automation to enhance productivity, product quality, and operational efficiency.

What are the future trends in the Motion Control Market?

Future trends in the Motion Control Market include increased integration with AI and IoT for predictive analytics and autonomous operation, greater adoption of collaborative robots, a focus on energy-efficient and sustainable solutions, enhanced cybersecurity measures, and the development of more modular and flexible system architectures for customized applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Motion Control Sensor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Linear Motion Control Valves Market Statistics 2025 Analysis By Application (Oil And Gas, Chemicals, Energy & Power Generation, Water Resources Management, Pharmaceuticals, Metals & Mining, Pulp & Paper, Food And Beverage), By Type (Gate Valves, Ball Valve, Diaphragm Valve, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Motion Control Sensors Market Statistics 2025 Analysis By Application (Robotics, Semiconductor machinery, Material handling, Packaging and labeling machinery), By Type (Position and displacement sensors, Proximity sensors, Speed sensors, Torque sensors), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Motion Control Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (General Motion Control (GMC), Computer Numerical Control (CNC)), By Application (Packaging, Material Handling, Metal Fabrication, Converting, Positioning), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Power Transmission And Motion Control Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Motors, Gearings, Clutches and Brakes, Belts and Chain Drivers, Hydraulics/Pneumatics), By Application (Mining, Automotive, Aerospace and Defense, Power Generation, Pulp and Paper, Oil and Gas), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager