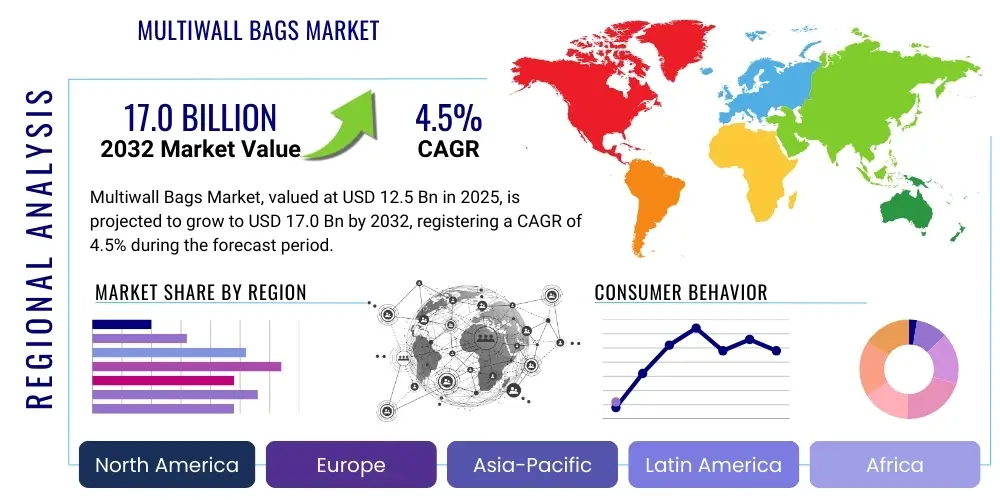

Multiwall Bags Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427534 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Multiwall Bags Market Size

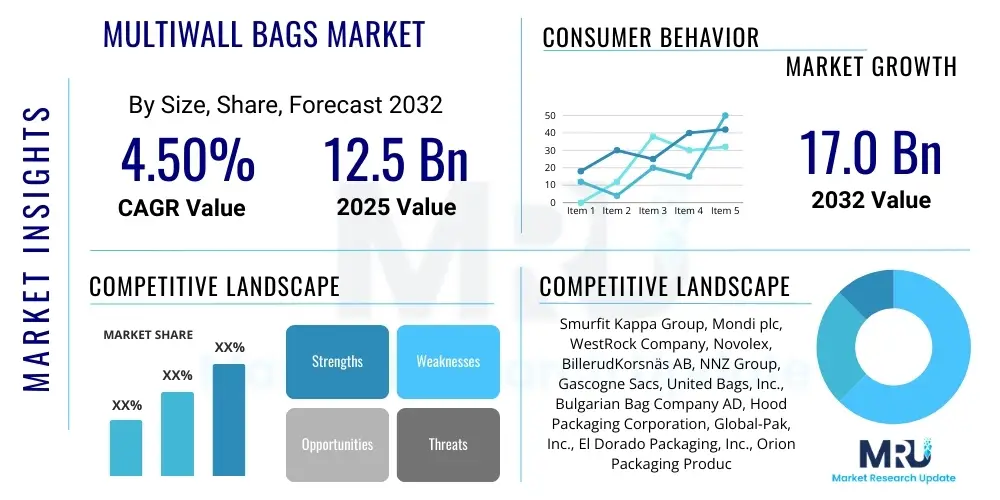

The Multiwall Bags Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2025 and 2032. The market is estimated at USD 12.5 Billion in 2025 and is projected to reach USD 17.0 Billion by the end of the forecast period in 2032. This sustained growth is primarily attributed to the expanding industrial output across various sectors, coupled with an increasing emphasis on efficient and durable packaging solutions for bulk materials. The demand is further bolstered by the burgeoning construction industry and agricultural sector globally, both of which are significant consumers of multiwall bags for cement, fertilizers, and animal feed.

The markets expansion is also influenced by advancements in packaging technology, allowing for enhanced barrier properties, improved printability, and greater sustainability, which cater to the evolving needs of end-use industries. Furthermore, the shift towards organized retail and e-commerce, particularly for industrial supplies and agricultural products, necessitates robust and protective packaging, thereby stimulating the adoption of multiwall bags. The inherent benefits of multiwall bags, such as their strength, breathability, and cost-effectiveness, continue to underpin their prevalent use across diverse applications, ensuring a stable growth trajectory over the forecast period.

Multiwall Bags Market introduction

Multiwall bags, often referred to as industrial bags, are advanced packaging solutions primarily composed of multiple layers of kraft paper, plastic films, or a combination thereof, designed for the robust containment and transportation of bulk, granular, or powdered materials. These engineered bags offer superior strength, tear resistance, and often moisture barrier properties, making them indispensable in industries where product integrity and protection are paramount. Their construction typically involves two to six plies of material, providing a formidable barrier against external elements and ensuring the safe delivery of contents from manufacturing to end-user. The diverse range of designs, including sewn open mouth, pinch bottom, and valve bags, allows for tailored solutions to meet specific handling and filling requirements of various products.

The major applications of multiwall bags span a wide array of industrial sectors, encompassing cement and building materials, food and beverages (e.g., flour, sugar, starch), chemicals, agriculture (e.g., fertilizers, seeds, animal feed), and minerals. Their robust nature makes them ideal for packaging heavy or abrasive materials, while specialized coatings and liners can be incorporated to protect moisture-sensitive or perishable goods. The primary benefits of utilizing multiwall bags include enhanced product protection, reduced spillage and waste, efficient storage and transportation, and improved brand visibility through high-quality printing capabilities. These advantages contribute significantly to supply chain optimization and cost-effectiveness for businesses operating with bulk commodities.

Key driving factors for the multiwall bags market include global industrialization and infrastructure development, which consistently fuel demand for building materials and agricultural inputs. The rising global population and subsequent increase in food production necessitate efficient packaging for food ingredients and animal feed. Furthermore, growing consumer awareness regarding sustainable packaging solutions is prompting manufacturers to innovate with recyclable and biodegradable materials, thereby creating new opportunities for market expansion. The increasing adoption of automated packaging lines across industries also favors multiwall bags due to their consistent form and ease of handling.

Multiwall Bags Market Executive Summary

The Multiwall Bags Market is currently experiencing dynamic shifts influenced by several key business, regional, and segment trends. Globally, there is a pronounced push towards sustainable packaging solutions, with an increasing number of manufacturers adopting recyclable, compostable, or recycled content for multiwall bags to align with corporate sustainability goals and evolving regulatory landscapes. This trend is driving innovation in material science and production processes, fostering a competitive environment where eco-friendly options are gaining significant market share. Simultaneously, the growth in e-commerce, especially for bulk and industrial goods, is accelerating the demand for durable, efficient, and protective packaging, positioning multiwall bags as a crucial component in last-mile delivery and warehousing logistics. Economic recovery and continued industrial expansion in emerging markets are also creating robust demand, as these regions scale up manufacturing and infrastructure projects.

From a regional perspective, Asia Pacific continues to dominate the multiwall bags market, driven by rapid industrialization, burgeoning construction activities, and a large agricultural base in countries like China, India, and Southeast Asian nations. North America and Europe are characterized by mature markets, where the emphasis is more on product innovation, automation in packaging, and the integration of smart packaging features. These regions are also leading in the adoption of advanced barrier technologies and sustainable materials, driven by stringent environmental regulations and consumer preferences. Latin America and the Middle East & Africa are showing promising growth potential, fueled by expanding agricultural sectors, infrastructure development, and increasing foreign investments in manufacturing, although these regions often face challenges related to supply chain infrastructure and raw material availability.

Segmentation trends reveal strong performance in the sewn open mouth bags segment due to their versatility and ease of filling, particularly in the food and agricultural sectors. The pinch bottom bags segment is also gaining traction for its superior sealing properties, which enhance product protection and hygiene, making them ideal for sensitive materials like chemicals and specialized food products. By material, paper-based multiwall bags remain a dominant choice, benefiting from their renewability and recyclability, while hybrid solutions incorporating plastic films are growing for applications requiring enhanced moisture or oxygen barriers. The cement and building materials application segment consistently holds a significant market share, buoyed by global urbanization and infrastructure projects, closely followed by the food & beverage and agriculture sectors, which demand high-volume, reliable packaging for staples and animal feed.

AI Impact Analysis on Multiwall Bags Market

Common user questions regarding AIs impact on the Multiwall Bags Market often revolve around operational efficiency, cost reduction, quality control, and supply chain optimization. Users frequently inquire about how AI can enhance manufacturing processes, such as predictive maintenance for machinery, automation of filling and sealing, and the optimization of material usage to minimize waste. Concerns about the initial investment required for AI integration versus the long-term return on investment are also prevalent. Additionally, there is significant interest in AIs role in demand forecasting, inventory management, and creating more resilient supply chains, especially in the context of fluctuating raw material prices and global logistical challenges. The potential for AI to support the development of sustainable packaging solutions through data analysis and material optimization is also a key area of inquiry, reflecting the industrys growing focus on environmental responsibility.

AIs influence is poised to be transformative, moving beyond basic automation to enable truly intelligent manufacturing and supply chain ecosystems. This includes the application of machine learning algorithms to analyze vast datasets from production lines, identifying inefficiencies, predicting equipment failures before they occur, and optimizing energy consumption. Such capabilities contribute directly to reducing operational costs and improving production uptime. Furthermore, AI-powered vision systems can enhance quality control by detecting even minute defects in bag construction or printing, ensuring consistently high product standards and reducing rejection rates. The integration of AI in designing new bag structures and selecting optimal materials based on performance requirements and sustainability metrics will also accelerate product innovation.

Moreover, AI plays a critical role in enhancing market responsiveness. By analyzing historical sales data, seasonal trends, and external factors like commodity prices or weather patterns, AI can generate highly accurate demand forecasts. This enables multiwall bag manufacturers to optimize raw material procurement, schedule production more efficiently, and manage inventory levels to prevent both stockouts and overstocking. This predictive capability significantly reduces waste, improves cash flow, and allows for more agile responses to market fluctuations. In the broader supply chain, AI can optimize logistics and transportation routes, further driving down costs and reducing carbon footprints, aligning with the industrys sustainability objectives.

- Enhanced predictive maintenance for manufacturing equipment, reducing downtime.

- Optimized production scheduling and resource allocation through data analytics.

- Improved quality control with AI-powered vision systems detecting defects.

- Accurate demand forecasting for raw materials and finished goods, minimizing waste.

- Streamlined inventory management and warehousing operations.

- Personalized product development based on market trends and customer needs.

- Supply chain risk mitigation and resilience through predictive analytics.

- Energy consumption optimization in manufacturing processes.

- Robotics integration for automated handling, filling, and palletizing processes.

DRO & Impact Forces Of Multiwall Bags Market

The Multiwall Bags Market is significantly shaped by a complex interplay of drivers, restraints, and opportunities, alongside various impact forces that influence its trajectory. Key drivers include the robust expansion of end-use industries such as construction, agriculture, and food processing, which continuously demand durable and efficient packaging for bulk goods. Global population growth, urbanization, and increasing disposable incomes in emerging economies further fuel demand for essential commodities, directly translating into higher consumption of multiwall bags. Additionally, the growing emphasis on sustainable packaging solutions is prompting manufacturers to innovate with eco-friendly materials and production processes, creating new avenues for market growth. The inherent benefits of multiwall bags, such as their strength, moisture resistance, and cost-effectiveness, also contribute to their sustained demand across diverse industrial applications.

However, the market faces notable restraints that can impede its growth. Volatility in raw material prices, particularly for kraft paper pulp and polymer resins, poses a significant challenge, directly impacting production costs and profit margins for manufacturers. Intense competition from alternative packaging solutions, such as Flexible Intermediate Bulk Containers (FIBCs), woven polypropylene bags, and bulk sacks, also restricts market expansion, especially for very large volumes or specialized applications. Furthermore, stringent environmental regulations in developed economies regarding plastic usage and waste management can lead to higher compliance costs and necessitate significant investment in research and development for sustainable alternatives. Logistical challenges, including transportation costs and infrastructure limitations in certain regions, can also affect the distribution and accessibility of multiwall bags.

Despite these restraints, substantial opportunities exist for market players to capitalize on. Innovations in biodegradable and compostable materials offer a promising avenue for sustainable product differentiation, appealing to environmentally conscious consumers and regulatory bodies. The integration of smart packaging technologies, such as RFID tags and QR codes, for enhanced traceability, anti-counterfeiting, and supply chain management, represents a significant growth opportunity. Moreover, the expansion into untapped markets in developing regions, coupled with the customization of multiwall bags to meet specific industry requirements (e.g., specialized barrier coatings for food safety or chemical resistance), provides fertile ground for market penetration and diversification. Strategic collaborations and mergers & acquisitions among key players can also strengthen market positions and foster technological advancements, driving overall market growth.

The impact forces influencing the multiwall bags market include factors such as the bargaining power of buyers and suppliers, the threat of new entrants and substitutes, and the intensity of competitive rivalry. The bargaining power of buyers is moderate to high, as end-use industries often purchase in bulk and have options between various packaging providers and material types. Conversely, the bargaining power of suppliers, especially for key raw materials like specialty paper and polymer resins, can be significant, impacting manufacturers costs. The threat of new entrants is relatively low due to the high capital investment required for manufacturing infrastructure and the need for specialized expertise. However, the threat of substitute products, as mentioned earlier, is substantial, constantly pushing multiwall bag manufacturers to innovate and differentiate their offerings. The competitive rivalry within the market is intense, characterized by a fragmented landscape with numerous global and regional players striving for market share through product innovation, pricing strategies, and service differentiation.

Segmentation Analysis

The Multiwall Bags Market is intricately segmented across various dimensions, including material type, bag type, and application, each catering to distinct industrial requirements and market dynamics. This detailed segmentation allows manufacturers to offer tailored packaging solutions that optimize product protection, handling efficiency, and cost-effectiveness for a diverse range of bulk goods. Understanding these segments is crucial for identifying specific growth pockets and developing targeted market strategies. The material type segment differentiates between paper-based, plastic-based, and hybrid bags, reflecting the diverse performance needs related to strength, moisture resistance, and sustainability. Each material offers unique advantages, driving their adoption in specific end-use sectors where their properties are most beneficial.

The bag type segmentation categorizes multiwall bags based on their structural design and sealing mechanisms, which dictate their suitability for different filling processes and product characteristics. Common types include sewn open mouth bags, pinch bottom bags, and valve bags, each designed to optimize the filling, sealing, and handling of various granular or powdered products. These design variations play a critical role in minimizing spillage, ensuring product integrity, and facilitating efficient packaging line operations. Finally, the application segment highlights the diverse end-use industries that rely on multiwall bags, ranging from heavy industrial sectors to sensitive food and agricultural domains, demonstrating the broad utility and adaptability of these packaging solutions.

The ongoing evolution within these segments is driven by technological advancements, regulatory pressures, and shifting consumer preferences towards more sustainable and efficient packaging. For instance, the demand for high-barrier paper multiwall bags is increasing in the food sector, driven by a need for extended shelf life and reduced plastic usage. Similarly, the construction industry continues to rely heavily on strong, moisture-resistant bags for cement and other building materials, while the agricultural sector seeks breathable and durable options for seeds, fertilizers, and animal feed. This multi-faceted segmentation underscores the versatility and indispensable role of multiwall bags in modern industrial supply chains, with continuous innovation ensuring their relevance and growth across various sectors.

- By Material Type:

- Kraft Paper

- Plastic (HDPE, LDPE, PP)

- Hybrid (Paper with Plastic Liners/Coatings)

- By Bag Type:

- Sewn Open Mouth Bags

- Pinch Bottom Bags

- Valve Bags (Internal & External)

- Pastel Bottom Bags

- By Application:

- Cement & Building Materials

- Food & Beverage (Flour, Sugar, Starch, Grains)

- Chemicals (Fertilizers, Resins, Polymers)

- Agriculture (Seeds, Animal Feed)

- Minerals & Mining

- Others (Pharmaceuticals, Consumer Goods)

Multiwall Bags Market Value Chain Analysis

The Multiwall Bags Markets value chain is a complex network spanning from raw material procurement to end-user consumption, encompassing several critical stages including upstream activities, manufacturing and conversion, distribution channels, and downstream consumption. Upstream analysis focuses on the sourcing of primary raw materials, predominantly paper pulp (for kraft paper) and polymer resins (for plastic films and coatings). Key suppliers in this segment include paper mills, chemical companies, and petrochemical producers. The quality, availability, and pricing volatility of these raw materials significantly impact the operational costs and competitive positioning of multiwall bag manufacturers. Strong relationships with reliable raw material suppliers are crucial for maintaining consistent production schedules and product quality.

Midstream activities involve the conversion of these raw materials into finished multiwall bags. This stage includes paper or plastic film extrusion, printing, lamination, and the assembly of multiple layers into the final bag structure. Manufacturers leverage various technologies for bag formation, such as sewing, adhesive bonding, and valve insertion, to produce different bag types tailored for specific applications. Research and development activities also play a vital role here, focusing on improving bag strength, barrier properties, sustainability, and print quality. Downstream analysis then examines the distribution channels and the ultimate end-users. Multiwall bags typically reach end-users through a combination of direct sales and indirect channels.

Direct sales often involve large-scale orders from major industrial clients such as cement manufacturers, large agricultural cooperatives, or chemical producers, allowing for customized solutions and direct negotiations. Indirect distribution channels include wholesalers, distributors, and packaging solution providers who cater to a broader range of smaller to medium-sized enterprises across various sectors. These intermediaries play a crucial role in market penetration and reaching a diverse customer base, particularly in geographically dispersed markets. The efficiency of these distribution networks, including logistics and warehousing, directly impacts market reach and customer satisfaction. The entire value chain is characterized by a drive for efficiency, cost reduction, and sustainability, as each stage seeks to add value while minimizing environmental impact.

Multiwall Bags Market Potential Customers

The Multiwall Bags Market serves a broad spectrum of potential customers, primarily comprising various industrial sectors that require robust, efficient, and protective packaging for their bulk, granular, or powdered products. The end-users of multiwall bags are typically businesses operating in manufacturing, agriculture, and infrastructure development, where the safe and reliable containment of materials is essential for their operations and supply chains. These customers seek packaging solutions that can withstand rigorous handling, provide adequate barrier protection against moisture, oxygen, and contaminants, and often offer opportunities for brand visibility through high-quality printing. The diverse needs across industries necessitate a range of multiwall bag types, from heavy-duty options for construction materials to food-grade bags for agricultural and food products.

A significant portion of potential customers comes from the construction and building materials industry, including cement manufacturers, gypsum producers, mortar mix companies, and other construction chemical suppliers. These entities require multiwall bags that are exceptionally strong, moisture-resistant, and capable of enduring harsh storage and transportation conditions. Another major customer base resides within the agricultural sector, encompassing seed producers, fertilizer manufacturers, animal feed companies, and grain processors. For these clients, multiwall bags must not only be durable but often need to be breathable, provide UV protection, and comply with food safety standards for edible products, ensuring product integrity and shelf life.

Furthermore, the food and beverage industry, particularly companies involved in bulk ingredients like flour, sugar, starch, and various grains, represents a substantial segment of potential customers. Here, the emphasis is on hygiene, food-grade materials, and effective sealing to prevent contamination and maintain product freshness. The chemical industry, including producers of industrial chemicals, resins, polymers, and mineral compounds, also relies heavily on multiwall bags that offer chemical resistance and secure containment to prevent leaks or spills. In essence, any industry dealing with the bulk packaging of dry, flowable materials that require strength, protection, and efficiency in handling is a potential customer for multiwall bags, underscoring the markets vast and varied client base.

Multiwall Bags Market Key Technology Landscape

The Multiwall Bags Market is continuously evolving through significant technological advancements aimed at enhancing product performance, manufacturing efficiency, and sustainability. A key aspect of the technology landscape revolves around advanced material science, particularly in developing innovative paper plies and plastic films that offer superior strength-to-weight ratios, improved barrier properties, and enhanced sustainability profiles. This includes the use of high-performance kraft papers with increased tear resistance, as well as multi-layer plastic films incorporating EVOH (Ethylene Vinyl Alcohol) or other specialized polymers for superior oxygen and moisture barrier capabilities. Innovations in bio-based and recycled content materials are also gaining traction, driven by environmental regulations and corporate sustainability goals, pushing the industry towards more circular economy practices. These material developments allow for lighter, yet stronger bags, reducing both material consumption and transportation costs.

Another crucial technological area is manufacturing and conversion processes. Modern multiwall bag production lines incorporate highly automated and precise machinery for printing, lamination, tube forming, and bottom closing. Advanced printing technologies, such as flexographic and rotogravure, enable high-resolution graphics and vibrant colors, offering enhanced branding opportunities for manufacturers. Automated filling and sealing systems for end-users are also driving demand for multiwall bags with consistent dimensions and superior sealing performance, ensuring efficient operation of high-speed packaging lines. Technologies like ultrasonic sealing for plastic plies and hot-melt adhesive applications for paper bags ensure robust and secure closures, crucial for preventing product loss and contamination during transit and storage. Precision control systems in these machines minimize waste and optimize resource utilization.

Beyond material and process innovations, the integration of smart technologies is beginning to reshape the multiwall bags market. This includes the incorporation of RFID tags, QR codes, and other digital markers directly onto the bags, facilitating enhanced traceability, inventory management, and anti-counterfeiting measures throughout the supply chain. These smart packaging solutions enable real-time tracking of products, provide valuable data on logistics, and offer consumers or industrial users access to product information. Furthermore, advancements in bag design software and simulation tools allow for virtual prototyping and optimization of bag structures, ensuring optimal performance for specific product requirements and handling conditions. These technological strides collectively contribute to more efficient, sustainable, and intelligent packaging solutions, enhancing the overall value proposition of multiwall bags.

Regional Highlights

The global Multiwall Bags Market exhibits significant regional variations in terms of consumption, production, and growth drivers, influenced by diverse economic landscapes, industrial development levels, and regulatory environments. Each major region contributes uniquely to the markets overall dynamics, reflecting local demands and supply capabilities. Understanding these regional highlights is crucial for market participants to identify growth opportunities, tailor their strategies, and allocate resources effectively across the globe. The mature markets in North America and Europe, for instance, are characterized by a focus on high-performance, sustainable, and aesthetically pleasing packaging, driven by stringent environmental regulations and a strong consumer preference for eco-friendly products. Innovation in materials and automation is key in these regions, catering to advanced manufacturing and logistics infrastructures.

Conversely, the Asia Pacific region stands out as the largest and fastest-growing market, propelled by rapid industrialization, urbanization, and substantial investments in infrastructure development. Countries like China and India, with their massive construction booms and expansive agricultural sectors, represent significant demand centers for multiwall bags. The increasing manufacturing output across various industries in Southeast Asian nations further bolsters this regional growth. Cost-effectiveness and the sheer volume of demand often dictate market trends here, though there is a growing shift towards improved quality and sustainability as economies mature. This region also benefits from a robust raw material supply chain, particularly for paper pulp and polymer production.

Latin America and the Middle East & Africa (MEA) are emerging as promising growth regions, driven by expanding agricultural activities, growing food processing industries, and ongoing infrastructure projects. While these regions may face challenges related to logistics and economic stability, increasing foreign investments and a rising middle class are stimulating demand for packaged goods, including those requiring multiwall bags. The demand in MEA is particularly influenced by the need for packaging solutions for cement, animal feed, and fertilizers, supporting local development and food security initiatives. Overall, while North America and Europe lead in innovation and sustainable practices, Asia Pacific remains the powerhouse of volume consumption, with Latin America and MEA presenting substantial future growth potential fueled by economic development and industrial expansion.

- Asia Pacific: Dominates the market due to rapid industrialization, extensive construction activities, and a large agricultural base in countries like China, India, and Indonesia.

- North America: Characterized by a focus on sustainable packaging solutions, advanced manufacturing processes, and high-quality, specialized multiwall bags for sophisticated applications.

- Europe: Driven by stringent environmental regulations, a strong emphasis on recyclability and biodegradable materials, and robust demand from the food, chemical, and construction sectors.

- Latin America: Exhibits significant growth potential fueled by expanding agricultural production, infrastructure development, and increasing industrial output, particularly in Brazil and Mexico.

- Middle East & Africa (MEA): Growing demand from the construction, agricultural, and petrochemical industries, coupled with increasing investments in manufacturing and processing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Multiwall Bags Market.- Smurfit Kappa Group

- Mondi plc

- WestRock Company

- Novolex (Ares Management Corporation)

- BillerudKorsnäs AB

- NNZ Group

- Gascogne Sacs

- United Bags, Inc.

- Bulgarian Bag Company AD

- Hood Packaging Corporation

- Global-Pak, Inc.

- El Dorado Packaging, Inc.

- Orion Packaging Products

- Premier Tech Ltd.

- Coveris Holdings S.A.

Frequently Asked Questions

What are multiwall bags primarily used for?

Multiwall bags are primarily used for packaging and transporting bulk, granular, or powdered materials across various industries, including cement, building materials, food and beverages (e.g., flour, sugar), chemicals, and agriculture (e.g., fertilizers, animal feed). Their robust multi-layered construction ensures product protection and efficient handling.

What are the key advantages of using multiwall bags?

Key advantages include superior strength, high tear resistance, and often excellent moisture barrier properties, which protect contents from external elements. They are also cost-effective for bulk packaging, offer good stackability, and provide a surface for high-quality branding and product information.

How do multiwall bags contribute to sustainability?

Multiwall bags contribute to sustainability through the increasing use of recyclable and renewable materials like kraft paper. Manufacturers are also innovating with biodegradable plastics and incorporating recycled content, along with optimizing bag designs to reduce material usage and minimize transportation emissions due to their lightweight nature.

What types of multiwall bags are available and what are their applications?

Common types include sewn open mouth bags for versatile manual or automated filling; pinch bottom bags, known for superior sealing and hygiene for sensitive products; and valve bags, designed for high-speed automated filling systems for cement or chemicals. Each type is optimized for specific product characteristics and packaging processes.

What recent innovations are impacting the multiwall bags market?

Recent innovations include advancements in barrier technologies for extended shelf life, development of bio-based and compostable materials for environmental benefits, integration of smart packaging features (RFID, QR codes) for traceability, and enhanced printing capabilities for improved brand visibility. Automation in production and filling lines also continues to evolve.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager