Municipal Sludge Dewatering Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427837 | Date : Oct, 2025 | Pages : 244 | Region : Global | Publisher : MRU

Municipal Sludge Dewatering Equipment Market Size

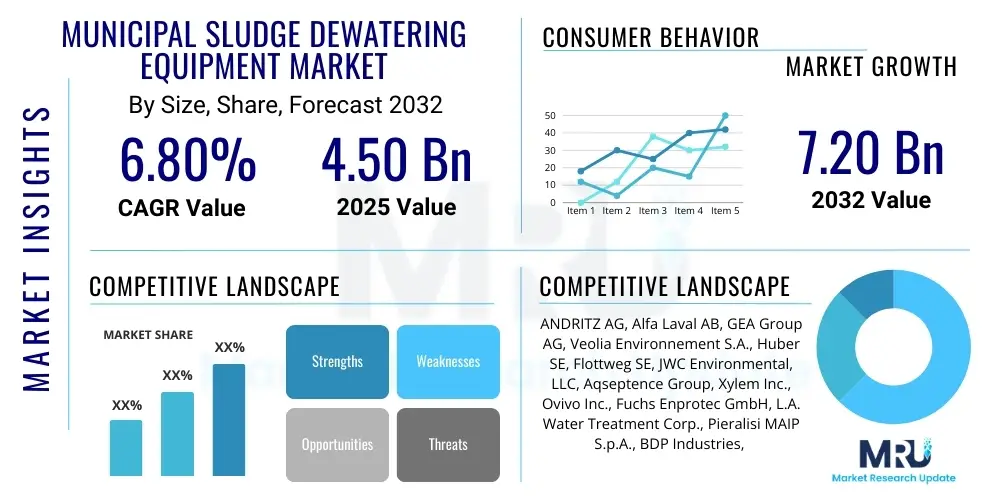

The Municipal Sludge Dewatering Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 4.50 billion in 2025 and is projected to reach USD 7.20 billion by the end of the forecast period in 2032. This growth is driven by increasing environmental regulations, expanding urban populations, and the critical need for efficient wastewater treatment infrastructure globally. The markets expansion reflects a sustained investment in sustainable sludge management practices and the adoption of advanced dewatering technologies to minimize waste volume and reduce disposal costs.

The municipal sludge dewatering equipment sector plays a pivotal role in the broader wastewater treatment industry, offering essential solutions for managing the substantial quantities of sludge generated during the purification process. Market size projections are underpinned by a rigorous analysis of historical growth trends, current technological advancements, and future policy landscapes influencing wastewater management. Factors such as governmental mandates for cleaner water bodies, public health concerns, and the rising emphasis on resource recovery from sludge contribute significantly to the markets upward trajectory, ensuring continued demand for innovative dewatering solutions.

Municipal Sludge Dewatering Equipment Market introduction

The Municipal Sludge Dewatering Equipment Market encompasses the sale and deployment of machinery designed to reduce the water content in sludge generated from municipal wastewater treatment plants. This process is crucial for minimizing the volume and weight of sludge, thereby lowering transportation and disposal costs, and often preparing the sludge for further treatment, such as incineration, composting, or anaerobic digestion. Key equipment types include centrifuges, belt filter presses, screw presses, and plate and frame filter presses, each offering distinct advantages based on sludge characteristics, required dryness, and operational budget. The overarching goal is to transform liquid or semi-liquid sludge into a more manageable, solid cake.

The primary applications of municipal sludge dewatering equipment are found within municipal wastewater treatment facilities, where large volumes of water and solid waste are processed daily. Beyond volume reduction, dewatering facilitates easier handling, reduces environmental impact by limiting leachate, and can enable beneficial reuse of biosolids in agriculture or energy generation. The benefits extend to significant operational cost savings for municipalities, improved compliance with environmental discharge standards, and enhanced sustainability efforts. The market is propelled by stringent environmental regulations worldwide mandating effective sludge management, escalating urbanization leading to increased wastewater generation, growing awareness of resource recovery from waste, and technological advancements improving dewatering efficiency and automation.

Driving factors for market growth include the global impetus for clean water, which necessitates robust wastewater treatment infrastructure and subsequent sludge management. Population growth and industrial expansion directly correlate with increased wastewater volumes, demanding more efficient and higher-capacity dewatering solutions. Furthermore, the adoption of advanced dewatering technologies, such as those incorporating polymer dosing systems and automation, enhances operational effectiveness and attracts investment. The push for circular economy principles also encourages the dewatering of sludge for potential resource extraction, turning a waste product into a valuable resource.

Municipal Sludge Dewatering Equipment Market Executive Summary

The Municipal Sludge Dewatering Equipment Market is experiencing robust growth, driven by an confluence of stringent environmental regulations, rapid urbanization, and technological innovations aimed at optimizing sludge management processes. Business trends indicate a strong focus on automation, energy efficiency, and modular designs to address varying plant capacities and operational requirements. Key players are investing in research and development to introduce equipment that offers higher dry solids content, lower polymer consumption, and reduced operational footprints. The market also observes an increasing trend towards integrated solutions that combine dewatering with other sludge treatment technologies, providing comprehensive wastewater management systems. Service-oriented business models, including maintenance contracts and equipment leasing, are gaining traction, reflecting municipalities desire for cost-effective and reliable solutions without significant upfront capital expenditure.

Regional trends highlight significant growth opportunities in emerging economies across Asia Pacific, Latin America, and Africa, where rapid industrialization and urbanization are fueling demand for new and upgraded wastewater treatment facilities. Developed regions, particularly North America and Europe, are characterized by a focus on replacing aging infrastructure, upgrading to more efficient and sustainable technologies, and adhering to increasingly strict environmental discharge limits. European markets are particularly advanced in adopting technologies that enable resource recovery from sludge, aligning with the regions circular economy objectives. The Middle East is also emerging as a key growth region due to substantial investments in water infrastructure projects and a growing commitment to sustainable water management.

Segmentation trends indicate a strong preference for continuous dewatering technologies such as centrifuges and belt filter presses due to their high throughput and automated operation, particularly in large-scale municipal applications. Screw presses are gaining popularity for small to medium-sized plants owing to their lower energy consumption and quieter operation. Furthermore, the market is seeing a push for smart dewatering solutions that integrate with plant-wide control systems for remote monitoring, predictive maintenance, and optimized performance. The demand for compact and mobile dewatering units is also growing, especially for temporary operations, emergency response, or decentralized treatment facilities, reflecting the diverse needs of municipal wastewater management stakeholders.

AI Impact Analysis on Municipal Sludge Dewatering Equipment Market

Common user questions regarding AIs impact on municipal sludge dewatering equipment revolve around concerns about operational efficiency, predictive maintenance capabilities, data-driven optimization of dewatering processes, and the potential for enhanced automation to reduce manual intervention. Users frequently inquire about how AI can improve the dryness of sludge cake, minimize chemical consumption (e.g., polymers), and predict equipment failures before they occur. There is also interest in understanding AIs role in integrating dewatering units seamlessly within larger wastewater treatment plant control systems and its potential to optimize energy usage, contributing to lower operational costs and greater sustainability. The overarching expectation is that AI will transform dewatering from a reactive process to a more proactive, intelligent, and cost-effective operation.

- AI-driven predictive maintenance minimizes equipment downtime and extends operational lifespan.

- Optimization of polymer dosing and chemical usage through real-time data analysis, reducing operational costs.

- Enhanced automation and remote monitoring capabilities, leading to reduced manual labor and improved safety.

- Real-time performance adjustments based on incoming sludge characteristics, maximizing dewatering efficiency.

- Data analytics for energy consumption optimization, contributing to lower carbon footprint.

- Integration with plant-wide SCADA systems for holistic process control and management.

DRO & Impact Forces Of Municipal Sludge Dewatering Equipment Market

The Municipal Sludge Dewatering Equipment Market is significantly shaped by a combination of key drivers, restraints, opportunities, and pervasive impact forces. Primary drivers include increasingly stringent environmental regulations governing wastewater discharge and sludge disposal, which compel municipalities to adopt more efficient dewatering technologies to meet compliance standards and reduce environmental pollution. Rapid global urbanization and population growth lead to higher volumes of wastewater generation, creating an escalating demand for robust and high-capacity sludge treatment solutions. Furthermore, the rising operational costs associated with sludge transportation and disposal act as a strong incentive for municipalities to invest in dewatering equipment that reduces sludge volume and weight. Technological advancements, such as improved equipment designs and automation features, also continuously drive market adoption by offering enhanced efficiency and lower lifecycle costs.

Despite the strong drivers, several restraints impede market growth. The high initial capital expenditure required for purchasing and installing sophisticated dewatering equipment can be a significant barrier for municipalities, especially those with limited budgetary allocations. The operational complexity associated with maintaining and optimizing advanced dewatering systems, including the need for specialized personnel and consistent chemical supply, also presents challenges. Furthermore, the variability in sludge characteristics, which can fluctuate based on influent wastewater composition and treatment processes, often requires custom solutions or frequent operational adjustments, adding to complexity and cost. Public perception and acceptance of sludge reuse practices, alongside the availability of cost-effective disposal alternatives, can also influence investment decisions.

Opportunities for market expansion are abundant, particularly in emerging economies that are undergoing rapid infrastructure development and implementing modern wastewater treatment standards for the first time. The growing emphasis on resource recovery from sludge, including biogas production from anaerobic digestion of dewatered sludge or phosphorus recovery, opens new avenues for innovation and equipment demand. Advancements in smart technologies, including AI and IoT integration, offer opportunities for developing more intelligent, autonomous, and energy-efficient dewatering solutions. Moreover, the increasing adoption of public-private partnerships (PPPs) in wastewater infrastructure projects can help overcome financial barriers and accelerate the deployment of advanced dewatering technologies. The development of modular and portable dewatering units also presents an opportunity to serve decentralized treatment facilities and provide flexible solutions.

Segmentation Analysis

The Municipal Sludge Dewatering Equipment market is segmented across various critical dimensions, including product type, capacity, and application, reflecting the diverse needs and operational scales within municipal wastewater management. This segmentation provides a granular view of market dynamics, enabling stakeholders to identify specific growth areas and tailor their offerings. The choice of dewatering equipment is highly dependent on factors such as the volume of sludge to be processed, the desired dryness level, available footprint, operational budget, and specific regulatory requirements. Understanding these segments is crucial for strategic market positioning and product development, ensuring solutions meet the precise demands of different municipal facilities globally.

- By Product Type:

- Belt Filter Press: Known for continuous operation and relatively low energy consumption.

- Centrifuge: Offers high throughput and effective dewatering, suitable for large plants.

- Screw Press: Characterized by low speed, low energy consumption, and quiet operation.

- Plate and Frame Filter Press: Provides very dry cake, but typically batch operation.

- Other Dewatering Equipment (e.g., Rotary Drum Thickeners, Drying Beds): Complementary or niche solutions.

- By Capacity:

- Small Capacity (up to 5 m3/hr): Suitable for smaller treatment plants or specific municipal needs.

- Medium Capacity (5-20 m3/hr): Common for mid-sized municipal wastewater treatment facilities.

- Large Capacity (above 20 m3/hr): Designed for major metropolitan wastewater treatment plants.

- By Application:

- Municipal Wastewater Treatment Plants: The primary end-user segment.

- Centralized Sludge Treatment Facilities: Dedicated facilities processing sludge from multiple sources.

Municipal Sludge Dewatering Equipment Market Value Chain Analysis

The value chain for the Municipal Sludge Dewatering Equipment Market begins with upstream activities involving the sourcing and processing of raw materials such as steel, polymers, and electronic components. Key suppliers in this stage include metal manufacturers, chemical producers, and specialized component providers. The quality and cost-effectiveness of these raw materials directly impact the manufacturing process and the final products durability and performance. Manufacturers of dewatering equipment also rely on specialized engineering firms for design, research, and development, ensuring that the equipment meets evolving efficiency, reliability, and regulatory standards. Effective management of this upstream segment is critical for maintaining competitive pricing and ensuring the availability of high-quality inputs.

Midstream activities primarily encompass the manufacturing, assembly, and testing of the dewatering equipment. This stage involves complex engineering, precision fabrication, and stringent quality control to produce robust and high-performing machinery. Manufacturers often integrate advanced technologies, such as automation, IoT sensors, and predictive analytics, into their equipment to enhance operational efficiency and reduce maintenance requirements. Following manufacturing, the equipment is distributed to municipal clients through various channels. Direct distribution involves manufacturers selling directly to municipalities, often supported by their own sales and technical support teams. This approach allows for direct communication, customization, and comprehensive after-sales service.

Downstream activities involve the installation, commissioning, operation, and maintenance of the dewatering equipment at municipal wastewater treatment plants. This stage often includes training municipal staff, providing technical support, and offering spare parts and upgrade services. Indirect distribution channels typically involve third-party distributors, system integrators, and engineering, procurement, and construction (EPC) firms. These intermediaries often have established regional networks and expertise in local markets, helping manufacturers reach a broader customer base, especially in regions where direct presence is challenging. The efficiency of the entire value chain, from raw material sourcing to post-installation support, is crucial for market success, customer satisfaction, and ensuring the long-term operational effectiveness of municipal sludge dewatering processes.

Municipal Sludge Dewatering Equipment Market Potential Customers

The primary potential customers and end-users of municipal sludge dewatering equipment are municipal wastewater treatment plants (WWTPs). These facilities are responsible for collecting, treating, and discharging wastewater from residential, commercial, and institutional sources within a given jurisdiction. The continuous generation of sludge as a byproduct of the wastewater treatment process necessitates the constant operation of dewatering equipment. As urban populations expand and environmental regulations become more stringent globally, the demand from these plants, both for new installations and for upgrades to existing infrastructure, remains consistently high. Investment decisions in these facilities are often driven by public health concerns, environmental compliance mandates, and the need for cost-effective sludge management solutions to reduce disposal volumes and associated expenses.

Beyond traditional wastewater treatment plants, centralized sludge treatment facilities represent another significant customer segment. These facilities are designed to consolidate and process sludge from multiple smaller treatment plants or industrial sources, offering economies of scale in dewatering and subsequent treatment (e.g., anaerobic digestion, composting, incineration). Such centralized approaches are becoming more common in densely populated areas or regions with fragmented wastewater infrastructure, providing efficient regional sludge management. These facilities require high-capacity, robust dewatering equipment capable of handling diverse sludge characteristics and large volumes, often integrating advanced automation and control systems to optimize operations.

Additionally, private sector operators managing municipal wastewater treatment under public-private partnership (PPP) models are important potential customers. These private entities are often tasked with delivering efficient, cost-effective, and compliant wastewater services, driving their investment in advanced dewatering technologies to meet performance targets and ensure long-term operational sustainability. Engineering, Procurement, and Construction (EPC) firms involved in designing and building new wastewater treatment infrastructure or upgrading existing ones also act as crucial intermediaries, specifying and procuring dewatering equipment on behalf of municipal clients. These diverse customer segments underscore the broad applicability and essential nature of municipal sludge dewatering equipment within the global water and wastewater industry.

Municipal Sludge Dewatering Equipment Market Key Technology Landscape

The Municipal Sludge Dewatering Equipment Market is characterized by a dynamic technology landscape, driven by continuous innovation aimed at enhancing efficiency, reducing operational costs, and improving environmental performance. A cornerstone technology is the centrifuge, which employs high-speed rotation to separate solids from liquids. Modern centrifuges feature advanced control systems, often incorporating variable frequency drives (VFDs) and sophisticated scroll designs, to optimize performance based on real-time sludge characteristics. Belt filter presses represent another mature technology, utilizing mechanical pressure and gravity drainage across a porous belt to dewater sludge. Recent advancements in belt filter presses focus on improved belt washing systems, automated tensioning, and robust construction materials to enhance reliability and reduce maintenance.

Screw presses have gained significant traction due to their low energy consumption, minimal noise, and ability to handle various sludge types. Technological improvements in screw presses include variable pitch screws, pre-thickening zones, and automatic self-cleaning mechanisms, which contribute to higher dewatering efficiency and reduced operator intervention. Plate and frame filter presses, while often batch-oriented, are valued for achieving very high dry solids content. Innovations in this segment include automated plate shifting, membrane plates for enhanced dewatering, and efficient cake discharge systems, making them more competitive for specific applications requiring extremely dry sludge cake. The integration of polymer dosing systems, critical for flocculating sludge particles to improve dewatering efficiency, has also seen advancements with precise dosing controls and online monitoring of polymer effectiveness.

Beyond core mechanical technologies, the market is increasingly incorporating digitalization and automation. This includes the integration of Internet of Things (IoT) sensors for real-time monitoring of process parameters such as sludge flow, solids content, and polymer concentration. Artificial intelligence (AI) and machine learning (ML) algorithms are being deployed to optimize operational settings, predict maintenance needs, and reduce chemical consumption, leading to more autonomous and efficient dewatering processes. Smart control systems and SCADA integration allow for remote operation, performance analytics, and seamless data exchange with other plant components. Furthermore, research into novel dewatering methods, such as electro-osmotic dewatering and acoustic dewatering, while still emerging, aims to offer even higher efficiencies and lower energy footprints in the long term, pushing the boundaries of current dewatering capabilities.

Regional Highlights

- North America: A mature market characterized by stringent environmental regulations, substantial investments in infrastructure upgrades, and a strong emphasis on adopting advanced, energy-efficient dewatering technologies. The U.S. and Canada are leading in R&D and implementation of smart solutions.

- Europe: Driven by strict EU directives on wastewater treatment and sludge disposal, with a strong focus on circular economy principles and resource recovery from sludge. Germany, France, and the UK are key players, showing high adoption of sophisticated dewatering systems.

- Asia Pacific: The fastest-growing market due to rapid urbanization, industrialization, and increasing government spending on new wastewater treatment infrastructure in countries like China, India, and Southeast Asian nations. Demand for both high-capacity and cost-effective solutions is high.

- Latin America: Emerging market with increasing investments in water and sanitation infrastructure, particularly in Brazil, Mexico, and Argentina. The region presents significant growth opportunities as environmental awareness and regulatory enforcement improve.

- Middle East & Africa: Growing market spurred by significant infrastructure projects, water scarcity concerns, and government initiatives to modernize wastewater treatment facilities. UAE, Saudi Arabia, and South Africa are key countries investing in advanced dewatering solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Municipal Sludge Dewatering Equipment Market.- ANDRITZ AG

- Alfa Laval AB

- GEA Group AG

- Veolia Environnement S.A.

- Huber SE

- Flottweg SE

- JWC Environmental, LLC

- Aqseptence Group (Bilfinger Water Technologies GmbH)

- Xylem Inc.

- Ovivo Inc.

- Fuchs Enprotec GmbH

- L.A. Water Treatment Corp.

- Pieralisi MAIP S.p.A.

- BDP Industries, Inc.

Frequently Asked Questions

What is municipal sludge dewatering equipment used for?

Municipal sludge dewatering equipment is used to reduce the water content in sludge generated during municipal wastewater treatment, making it easier and more cost-effective to transport, dispose of, or reuse.

What are the main types of dewatering equipment?

The main types include belt filter presses, centrifuges, screw presses, and plate and frame filter presses, each suited for different sludge characteristics and operational requirements.

How do dewatering technologies contribute to environmental sustainability?

Dewatering reduces the volume and weight of sludge, thereby lowering transportation emissions, minimizing landfill space, and facilitating resource recovery for beneficial reuse or energy generation, enhancing overall environmental sustainability.

What factors drive the growth of the dewatering equipment market?

Key drivers include stringent environmental regulations, rapid urbanization, increasing wastewater generation, rising sludge disposal costs, and continuous technological advancements in dewatering efficiency and automation.

How does AI impact municipal sludge dewatering operations?

AI impacts dewatering by enabling predictive maintenance, optimizing polymer dosing, automating operational adjustments, and integrating with plant control systems for enhanced efficiency, cost reduction, and improved performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager