Nano Composite Zirconia Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430157 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Nano Composite Zirconia Market Size

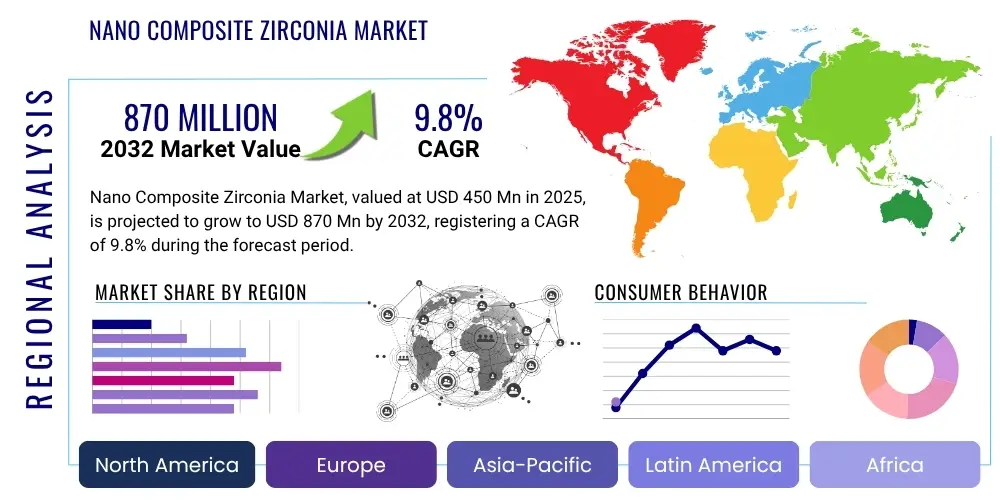

The Nano Composite Zirconia Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2025 and 2032. The market is estimated at USD 450 Million in 2025 and is projected to reach USD 870 Million by the end of the forecast period in 2032.

Nano Composite Zirconia Market introduction

The Nano Composite Zirconia (NCZ) market encompasses advanced ceramic materials that combine zirconia with other ceramic or metallic nanoparticles, engineered to significantly enhance mechanical properties such as toughness, strength, and wear resistance. These materials leverage nanotechnology to achieve superior performance characteristics, making them highly desirable across various high-tech applications where durability and biocompatibility are paramount. The inherent stability and aesthetic qualities of zirconia are further augmented by the composite structure, offering a versatile material solution.

Major applications for Nano Composite Zirconia span critical sectors including dental prosthetics, medical implants, high-performance structural ceramics, and specialized electronics. In dentistry, NCZ is vital for crowns, bridges, and implants due to its biocompatibility, exceptional flexural strength, and natural appearance. For medical implants, particularly orthopedic devices, its resistance to wear and compatibility with human tissue are key benefits. The market is primarily driven by the increasing global demand for advanced biomaterials in healthcare, continuous innovations in nanotechnology, and a growing emphasis on long-lasting, high-performance materials in industrial and consumer applications.

The benefits of Nano Composite Zirconia are manifold, including its remarkable fracture toughness, high flexural strength, excellent biocompatibility, and superior wear resistance compared to traditional ceramic materials. These advantages contribute to extended product life cycles, reduced maintenance, and improved functional outcomes. These compelling attributes, coupled with ongoing research and development efforts aimed at optimizing material properties and reducing production costs, are significant driving factors for market expansion across diverse end-use industries.

Nano Composite Zirconia Market Executive Summary

The Nano Composite Zirconia market is experiencing robust growth, propelled by a confluence of evolving business trends, significant regional dynamics, and strong segment-specific demands. Key business trends include an intensified focus on research and development to introduce novel NCZ formulations with enhanced properties, alongside strategic collaborations between material science companies and end-use manufacturers to accelerate product adoption and market penetration. There is a growing emphasis on sustainable production practices and cost-effective synthesis methods to broaden market accessibility.

Regional trends indicate that Asia Pacific is emerging as a dominant force, driven by rapid industrialization, increasing healthcare expenditure, and a burgeoning manufacturing sector in countries like China, India, and Japan. North America and Europe continue to be strong markets, characterized by advanced healthcare infrastructures, high adoption rates of sophisticated dental and medical procedures, and significant investments in material science research. These regions are also witnessing a shift towards premium, high-performance materials in their respective industrial applications.

From a segmentation perspective, the dental and medical application segments remain the primary revenue generators, fueled by an aging global population and rising awareness regarding the benefits of durable, biocompatible prosthetic and implant materials. The industrial and electronics segments are also showing promising growth, particularly as NCZ finds new applications in high-wear components, sensors, and solid oxide fuel cells. The market's overall trajectory is upward, underpinned by technological advancements and the increasing recognition of Nano Composite Zirconia's superior performance attributes across a wide array of demanding applications.

AI Impact Analysis on Nano Composite Zirconia Market

Users frequently inquire about the transformative potential of Artificial Intelligence in optimizing the synthesis, characterization, and application of Nano Composite Zirconia. The key themes revolve around how AI can accelerate material discovery, enhance manufacturing precision, predict material performance under various conditions, and enable personalized design for specific patient needs or industrial requirements. There is a strong expectation that AI will streamline research and development cycles, reduce material wastage, and unlock new functionalities for NCZ, ultimately leading to more efficient, cost-effective, and high-quality products.

- Accelerated discovery of novel Nano Composite Zirconia formulations through AI-driven material informatics.

- Predictive modeling for optimizing synthesis parameters, such as sintering temperatures and nanoparticle concentrations.

- Enhanced quality control and defect detection in NCZ manufacturing processes using machine vision and deep learning.

- Automated design and customization of NCZ components for dental prosthetics and medical implants based on patient-specific data.

- Simulation of mechanical properties and degradation behavior of NCZ, reducing the need for extensive physical testing.

- Optimization of supply chain and inventory management for NCZ raw materials and finished products.

- Development of smart NCZ materials with self-healing or adaptive properties through AI-guided material engineering.

DRO & Impact Forces Of Nano Composite Zirconia Market

The Nano Composite Zirconia market is shaped by a complex interplay of driving forces, inherent restraints, and emerging opportunities, all of which contribute to its overall impact. Key drivers include the escalating demand for high-performance, aesthetically pleasing, and biocompatible materials in the dental and medical industries, which are experiencing growth due to an aging global population and rising healthcare expenditures. Furthermore, continuous advancements in nanotechnology and material science enable the development of NCZ with enhanced properties, broadening its application scope and bolstering market growth.

Despite these significant drivers, the market faces several restraints. The high production cost associated with synthesizing high-purity nanoparticles and the complex, energy-intensive manufacturing processes required for NCZ components are major barriers. Stringent regulatory approval processes, particularly for medical and dental applications, add to the development timelines and costs. Limited awareness among certain industrial sectors about the superior benefits of NCZ compared to traditional materials also hinders broader adoption, requiring substantial market education efforts.

However, substantial opportunities exist for market expansion. The potential to diversify applications into emerging sectors such as aerospace, automotive, and energy offers new revenue streams. Developing more cost-effective and scalable synthesis methods, along with innovating customized NCZ solutions for niche markets, can unlock significant growth. Moreover, increasing investments in research and development by both public and private entities are paving the way for novel NCZ products and applications. The impact forces are generally positive, driven by technological innovation and evolving end-user demands, though regulatory and cost pressures necessitate strategic navigation.

Segmentation Analysis

The Nano Composite Zirconia market is comprehensively segmented to provide a detailed understanding of its diverse applications and material forms. This segmentation helps in analyzing market dynamics specific to various product types, end-use industries, and material forms, allowing stakeholders to identify key growth areas and tailor their strategies accordingly. The market is primarily categorized based on the specific type of stabilizer used in zirconia, the myriad of applications it serves, and the physical forms in which the material is supplied.

These distinct segments are crucial for understanding the varying demands and technical specifications across different industries. For instance, the requirements for dental crowns differ significantly from those for industrial cutting tools, necessitating specialized material compositions and processing techniques within each segment. The constant evolution in material science and engineering also leads to the emergence of new sub-segments and cross-segment applications, reflecting the dynamic nature of the market. This granular analysis facilitates targeted product development and market penetration strategies.

- By Type:

- Yttria Stabilized Zirconia (YSZ)

- Ceria Stabilized Zirconia (CSZ)

- Magnesia Stabilized Zirconia (MSZ)

- Calcium Stabilized Zirconia (CaSZ)

- Others (e.g., Alumina Toughened Zirconia ATZ)

- By Application:

- Dental

- Crowns

- Bridges

- Implants

- Dentures

- Orthodontic Brackets

- Medical

- Orthopedic Implants (Hip, Knee)

- Surgical Instruments

- Hearing Aids

- Drug Delivery Systems

- Industrial

- Cutting Tools

- Wear Parts and Liners

- Bearings

- Catalyst Supports

- Refractories

- Electronics

- Sensors (Oxygen Sensors)

- Solid Oxide Fuel Cells (SOFCs)

- Capacitors

- Substrates

- Others (e.g., Aerospace Components, Jewelry)

- Dental

- By Form:

- Powder

- Blocks and Blanks

- Pre-sintered Forms

- Fully Sintered Components

- Coatings

Value Chain Analysis For Nano Composite Zirconia Market

The value chain for the Nano Composite Zirconia market begins with the upstream procurement of essential raw materials, primarily zircon sand which is processed to yield high-purity zirconia, along with various rare earth oxides such as yttria, ceria, or magnesia used as stabilizers. These raw materials undergo sophisticated chemical and physical processing, including sol-gel, hydrothermal synthesis, or co-precipitation, to produce nano-sized zirconia powders with specific compositions and particle morphologies. This initial phase is critical for determining the final properties and performance of the Nano Composite Zirconia.

Further along the value chain, these nano zirconia powders are then utilized by specialized manufacturers to create intermediate forms such as blocks, blanks, or pre-sintered components through advanced ceramic processing techniques like pressing, slip casting, or additive manufacturing. These intermediate products are then supplied to downstream fabricators who perform final shaping, sintering (often using techniques like hot isostatic pressing or spark plasma sintering), and finishing operations to produce the final Nano Composite Zirconia components. This phase involves precision engineering to meet the stringent specifications required for medical, dental, or industrial applications.

The distribution channel plays a pivotal role in connecting manufacturers with end-users. Direct channels often involve large manufacturers supplying directly to major dental laboratories, medical device companies, or industrial clients with high volume requirements. Indirect channels include a network of specialized distributors and regional suppliers who cater to smaller clinics, dental practices, independent laboratories, and various industrial niche markets, providing logistical support, technical assistance, and localized inventory. This multi-faceted distribution strategy ensures broad market reach and efficient delivery of Nano Composite Zirconia products to a diverse customer base.

Nano Composite Zirconia Market Potential Customers

The primary potential customers for Nano Composite Zirconia are diverse and span several high-growth industries, each valuing the material's unique combination of strength, biocompatibility, and aesthetic qualities. The most prominent end-users are within the dental sector, encompassing dental laboratories and clinics that fabricate and install crowns, bridges, implants, and veneers. These customers prioritize materials that offer exceptional durability, a natural appearance, and patient comfort, all of which are characteristic features of NCZ, driving its widespread adoption in reconstructive and cosmetic dentistry.

Another significant customer segment is the medical device manufacturing industry, particularly companies specializing in orthopedic implants such as hip and knee replacements, as well as surgical instruments. For these applications, the excellent biocompatibility, low wear rates, and high fracture toughness of Nano Composite Zirconia are critical for long-term implant success and patient safety. The increasing demand for minimally invasive surgery and improved implant longevity further solidifies this sector as a major consumer of advanced zirconia ceramics.

Beyond healthcare, industrial manufacturers form a growing customer base. This includes companies in the aerospace, automotive, and general engineering sectors that require high-performance materials for cutting tools, wear-resistant components, bearings, and protective coatings operating in harsh environments. Furthermore, the electronics industry also represents a key segment, with potential customers including manufacturers of oxygen sensors, solid oxide fuel cells (SOFCs), and specialized electronic substrates that leverage zirconia's unique electrical and thermal properties at high temperatures. Research institutions and academic centers also frequently purchase NCZ for material science research and development.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 450 Million |

| Market Forecast in 2032 | USD 870 Million |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tosoh Corporation, Ivoclar Vivadent AG, 3M Company, Dentsply Sirona Inc., Zirkonzahn AG, VITA Zahnfabrik H. Rauter GmbH & Co. KG, Kuraray Noritake Dental Inc., Saint-Gobain Ceramic Materials, Coorstek Inc., Morgan Advanced Materials, CeramTec GmbH, H.C. Starck GmbH, Orient Abrasives Limited, American Elements, Sibelco, Metalor Technologies SA, Shofu Inc., Pritchard Dental, Shenzhen Upcera Dental Technology Co., Ltd., A.M.P.E.R.E. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nano Composite Zirconia Market Key Technology Landscape

The Nano Composite Zirconia market is underpinned by an array of sophisticated technological advancements in material synthesis, processing, and characterization. The production of high-quality nano zirconia powders relies on precision chemical synthesis methods such as sol-gel processing, hydrothermal synthesis, and co-precipitation. These techniques allow for tight control over particle size, morphology, and homogeneity, which are critical factors influencing the final mechanical and optical properties of the composite material. The ability to produce uniform nanoparticles with specific surface chemistries is fundamental to creating effective nano composites.

Following powder synthesis, advanced ceramic processing technologies are employed to form dense and high-strength Nano Composite Zirconia components. Sintering techniques play a crucial role, with conventional pressureless sintering often complemented by pressure-assisted methods like hot isostatic pressing (HIP) and spark plasma sintering (SPS). HIP enhances densification and eliminates porosity, while SPS offers rapid sintering at lower temperatures, leading to finer grain structures and improved mechanical performance. These sintering innovations are vital for achieving the desired material integrity and reducing manufacturing defects, particularly for critical applications like medical implants.

Furthermore, additive manufacturing (AM), particularly 3D printing techniques such as stereolithography (SLA) and binder jetting for ceramics, is gaining significant traction in the NCZ market. AM enables the fabrication of complex geometries and customized components with high precision, which is particularly beneficial for patient-specific dental prosthetics and intricate medical devices. Alongside these, advanced characterization techniques including high-resolution electron microscopy, X-ray diffraction, and mechanical testing systems are continuously evolved to ensure the quality, structural integrity, and performance of Nano Composite Zirconia materials, driving innovation and expanding application possibilities.

Regional Highlights

- North America: This region stands out due to its advanced healthcare infrastructure, high adoption rate of premium dental and medical materials, and significant investments in research and development. The presence of major market players and a robust regulatory framework also contribute to its prominent market share. Demand for high-quality, long-lasting dental restorations and orthopedic implants is consistently high.

- Europe: Europe represents a mature market with a strong emphasis on quality standards and technological innovation. Countries like Germany, France, and Italy are leaders in advanced ceramics research and manufacturing. The region benefits from an aging population driving demand for dental and medical prosthetics, coupled with a focus on high-performance industrial applications.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market, primarily fueled by increasing healthcare spending, a burgeoning population, and rising dental tourism, particularly in emerging economies such as China, India, and Southeast Asian countries. Rapid industrialization, expanding manufacturing bases, and growing awareness of advanced material benefits also contribute to substantial market expansion.

- Latin America: This region is an emerging market for Nano Composite Zirconia, characterized by increasing investments in healthcare infrastructure and a growing middle-class population demanding better medical and dental treatments. Market growth is driven by improving economic conditions and a gradual shift towards advanced material solutions.

- Middle East and Africa (MEA): The MEA region is witnessing steady growth, largely due to developing healthcare systems, increasing investment in medical tourism, and a rising prevalence of chronic diseases requiring advanced medical interventions. Adoption of Nano Composite Zirconia is gradually increasing as awareness and accessibility to high-performance materials improve across the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nano Composite Zirconia Market.- Tosoh Corporation

- Ivoclar Vivadent AG

- 3M Company

- Dentsply Sirona Inc.

- Zirkonzahn AG

- VITA Zahnfabrik H. Rauter GmbH & Co. KG

- Kuraray Noritake Dental Inc.

- Saint-Gobain Ceramic Materials

- Coorstek Inc.

- Morgan Advanced Materials

- CeramTec GmbH

- H.C. Starck GmbH

- Orient Abrasives Limited

- American Elements

- Sibelco

- Metalor Technologies SA

- Shofu Inc.

- Pritchard Dental

- Shenzhen Upcera Dental Technology Co., Ltd.

- A.M.P.E.R.E.

Frequently Asked Questions

What are the primary advantages of Nano Composite Zirconia over traditional dental materials?

Nano Composite Zirconia offers superior fracture toughness, high flexural strength, and excellent wear resistance compared to conventional ceramics. These properties lead to enhanced durability, longer lifespan, and reduced chipping or cracking in dental restorations, combined with excellent biocompatibility and aesthetic appeal.

Which industries are the largest consumers of Nano Composite Zirconia?

The dental and medical industries are the predominant consumers, utilizing Nano Composite Zirconia for dental crowns, bridges, implants, and various orthopedic prosthetics. However, industrial applications in cutting tools, wear parts, and electronics also represent significant and growing market segments.

What factors primarily drive the growth of the Nano Composite Zirconia market?

Key growth drivers include the increasing global demand for aesthetic and durable dental and medical solutions, advancements in nanotechnology enabling superior material properties, the rising geriatric population requiring implants, and growing research and development efforts in high-performance ceramics.

What are the main challenges faced by the Nano Composite Zirconia market?

Major challenges include the high cost of raw materials and complex, energy-intensive manufacturing processes. Stringent regulatory approval requirements, particularly for medical applications, and limited awareness among potential industrial users about its benefits also pose significant hurdles.

How is artificial intelligence influencing the Nano Composite Zirconia market?

AI is impacting the market by accelerating material discovery, optimizing synthesis parameters, enhancing quality control through predictive analytics, and enabling automated design of customized components. It helps streamline R&D, improve manufacturing efficiency, and unlock novel material functionalities for NCZ applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Nano Composite Zirconia Market Statistics 2025 Analysis By Application (Structual Ceramics, Functional Ceramics, Super Toughened Ceramics), By Type (Composite Zirconia, Nano Zirconia), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Nano Composite Zirconia Powder Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Composite Zirconia, Nano Zirconia), By Application (Structual Ceramics, Functional Ceramics, Super Toughened Ceramics, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager