Natural Fiber Insulation Materials Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430885 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Natural Fiber Insulation Materials Market Size

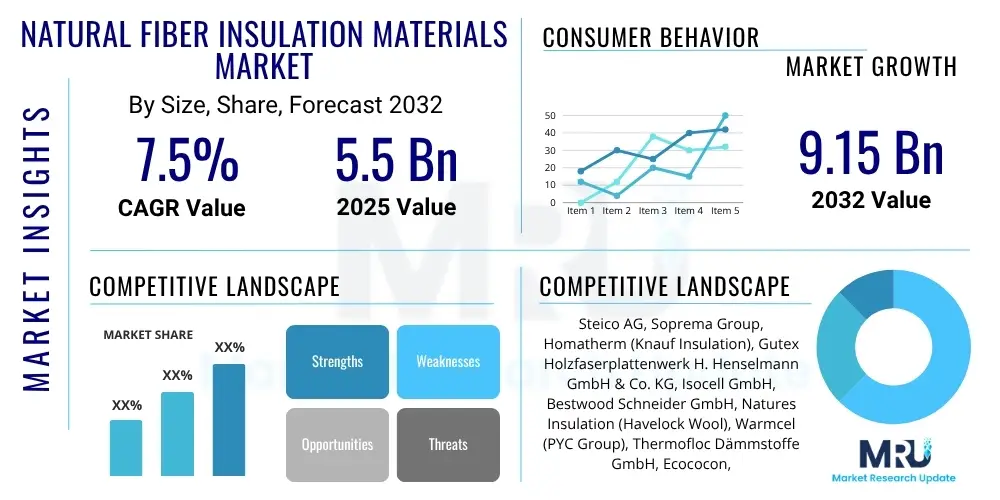

The Natural Fiber Insulation Materials Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at $5.5 Billion in 2025 and is projected to reach $9.15 Billion by the end of the forecast period in 2032.

Natural Fiber Insulation Materials Market introduction

The Natural Fiber Insulation Materials Market is experiencing robust growth driven by an increasing global emphasis on sustainable construction practices and energy efficiency. These materials, derived from renewable natural resources such as wood fiber, cellulose, hemp, sheep wool, and cotton, offer environmentally friendly alternatives to conventional synthetic insulation products. They are characterized by their low embodied energy, breathability, non-toxicity, and excellent thermal and acoustic performance, making them highly desirable in modern building applications.

Product descriptions typically highlight their renewable nature, recyclability, and ability to improve indoor air quality compared to synthetic counterparts. Key applications span a wide range of construction types, including residential homes, commercial buildings, and various industrial structures. Their versatility allows for use in walls, roofs, floors, and for specialized acoustic insulation, addressing diverse needs within the building sector.

The primary benefits driving their adoption include superior thermal regulation, significant reductions in energy consumption, sound dampening properties, and their contribution to healthier indoor environments. Moreover, they align perfectly with stringent environmental regulations and green building certifications, while mitigating the impact of rising energy costs by enhancing building envelope performance. These factors collectively position natural fiber insulation as a critical component in the future of sustainable architecture and construction.

Natural Fiber Insulation Materials Market Executive Summary

The Natural Fiber Insulation Materials Market is poised for substantial expansion, underpinned by evolving business trends that prioritize sustainability, circular economy principles, and innovative product development. Industry stakeholders are increasingly investing in research and development to enhance material performance, improve manufacturing processes, and broaden the application scope of these eco-friendly insulation solutions. There is a discernible shift towards integrating these materials into mainstream construction projects, moving beyond niche green building applications, signaling a maturing market landscape.

Regional trends indicate Europe and North America as frontrunners in market adoption, driven by stringent energy efficiency mandates, robust green building initiatives, and heightened consumer environmental awareness. These regions benefit from established regulatory frameworks and supportive government policies that incentivize sustainable construction. Concurrently, the Asia Pacific region is emerging as a significant growth hub, propelled by rapid urbanization, a burgeoning construction sector, and a gradual increase in the awareness and demand for sustainable building materials, though starting from a lower base compared to Western markets.

In terms of segment trends, cellulose and wood fiber insulation continue to dominate the market due to their widespread availability, cost-effectiveness, and proven performance. However, there is growing interest and increasing market penetration of other natural fibers such as hemp, sheep wool, and even recycled textile waste, particularly as technological advancements address previous performance limitations. The market is also seeing greater demand for integrated insulation solutions that offer both thermal and acoustic benefits, further diversifying the product offerings within this dynamic sector.

AI Impact Analysis on Natural Fiber Insulation Materials Market

Users frequently inquire about artificial intelligence's potential to revolutionize the Natural Fiber Insulation Materials market, focusing on optimizing efficiency, enhancing product characteristics, and improving market responsiveness. Key themes encompass how AI can streamline raw material sourcing, predict market demand, automate quality control processes, and facilitate the development of novel material compositions. Concerns often revolve around the initial investment required for AI integration, data privacy, and the need for specialized expertise to implement and manage AI-driven systems effectively within traditional manufacturing environments. Expectations are high for AI to deliver substantial improvements in sustainability, cost-effectiveness, and overall product innovation, helping the industry overcome existing challenges and accelerate growth.

- AI can optimize the sourcing and logistics of raw natural fibers, predicting supply chain disruptions and enabling more efficient procurement from sustainable sources to minimize waste and transport costs.

- Predictive analytics powered by AI can forecast market demand for various natural fiber insulation products, allowing manufacturers to adjust production schedules, optimize inventory levels, and reduce overproduction.

- AI-driven image recognition and sensor technologies can implement real-time quality control during manufacturing, identifying defects or inconsistencies in material density, uniformity, and composition with greater accuracy than manual inspections.

- Advanced algorithms can accelerate research and development by simulating new fiber blends and binder formulations, predicting their thermal, acoustic, and mechanical properties, thereby reducing the need for extensive physical prototyping and speeding up innovation cycles.

- AI can enhance manufacturing process efficiency by monitoring machine performance, identifying bottlenecks, and implementing predictive maintenance schedules, leading to reduced downtime, lower operational costs, and improved output consistency.

- Utilizing machine learning to analyze building performance data can help architects and builders select the most appropriate natural fiber insulation materials for specific climate zones and structural designs, ensuring optimal energy efficiency.

DRO & Impact Forces Of Natural Fiber Insulation Materials Market

The Natural Fiber Insulation Materials Market is propelled by several robust drivers, most notably the escalating global imperative for sustainable development and stringent energy efficiency regulations in the construction sector. Growing environmental awareness among consumers and building professionals is fostering a preference for eco-friendly products that offer low embodied carbon and contribute to healthier indoor environments. Additionally, the fluctuating and often rising costs of conventional synthetic insulation materials make natural fiber alternatives increasingly competitive, particularly as green building certifications become more widespread and accessible, providing tangible economic incentives for their adoption.

However, the market also faces notable restraints, including the comparatively higher initial material and installation costs of natural fiber insulation when directly compared to some traditional synthetic options, which can deter cost-sensitive projects. There remains a significant challenge in overcoming limited market awareness and ingrained perceptions about the performance and durability of natural materials in certain regions, requiring considerable educational efforts. Furthermore, the supply chain for some natural fibers can be subject to agricultural variability and regional availability, potentially leading to inconsistencies in supply and price fluctuations, complicating large-scale adoption.

Opportunities for growth are abundant, driven by continuous advancements in manufacturing technologies that improve the performance, cost-efficiency, and ease of installation of natural fiber products. Expanding into nascent and emerging construction markets, particularly in developing economies with rising urbanization and nascent sustainability agendas, presents significant avenues for market penetration. Government incentives for green building, coupled with the ongoing renovation and retrofitting of existing building stock to meet modern energy standards, offer substantial growth potential. Moreover, the development of novel fiber blends and hybrid materials with enhanced properties will unlock new applications and boost market confidence.

Segmentation Analysis

The Natural Fiber Insulation Materials Market is comprehensively segmented to address the diverse needs of the construction industry, reflecting the variety of raw materials, applications, and end-user types. This granular segmentation allows for a precise understanding of market dynamics, identifying specific growth areas and tailoring product development to cater to distinct demand profiles. The primary segments include categories based on the fiber type used, the specific building application, and the end-use sector, each presenting unique characteristics and market drivers that influence demand and adoption rates across different geographies and construction projects.

Understanding these segments is crucial for manufacturers, suppliers, and policymakers to develop targeted strategies, optimize resource allocation, and foster innovation. For instance, the demand for wood fiber insulation might be strong in regions with abundant forestry resources and established woodworking industries, while hemp-based insulation might see traction where agricultural policies support its cultivation. Similarly, residential and commercial building applications have distinct requirements for thermal, acoustic, and fire performance, influencing the choice of natural fiber insulation materials and driving product differentiation within the market.

- By Fiber Type:

- Wood Fiber: Widely used for its thermal mass and breathability, often in board or batt form.

- Cellulose: Made from recycled paper, known for its excellent thermal performance and sound absorption, typically blown-in or dense-packed.

- Hemp: Offers high tensile strength, resistance to pests, and good moisture regulation, available in batt or loose-fill forms.

- Sheep Wool: Excellent thermal and acoustic properties, naturally breathable, fire-resistant, and sustainable.

- Cotton: Often derived from recycled textile waste, providing good insulation and sound dampening.

- Flax: Similar to hemp, offering good thermal performance and environmental benefits.

- Others (e.g., Kenaf, Jute): Emerging fibers with specialized properties or regional significance, contributing to market diversification.

- By Application:

- Wall Insulation: Crucial for thermal envelope performance in both exterior and interior walls.

- Roof Insulation: Essential for preventing heat loss or gain through the building's top surface.

- Floor Insulation: Enhances thermal comfort and reduces energy transfer from the ground or between levels.

- Acoustic Insulation: Specifically designed to reduce noise transmission in residential, commercial, and industrial settings.

- Pipe Insulation: Used to prevent heat loss from hot water pipes or condensation on cold pipes.

- By End-Use:

- Residential Buildings: Focus on energy efficiency, comfort, and healthy indoor environments for homes.

- Commercial Buildings: Emphasis on energy savings, compliance with building codes, and occupant comfort in offices, retail, and public spaces.

- Industrial Buildings: Requirements for thermal stability, process efficiency, and sometimes acoustic control in manufacturing facilities or warehouses.

- Renovation & Retrofit: Application in upgrading existing buildings to meet modern energy standards and improve sustainability.

- New Construction: Integration into newly built structures as part of green building design principles from the outset.

Value Chain Analysis For Natural Fiber Insulation Materials Market

The value chain for the Natural Fiber Insulation Materials Market begins with upstream activities focused on the sustainable sourcing and initial processing of raw natural fibers. This phase involves agricultural cultivation for fibers like hemp, flax, and cotton, forestry management for wood fiber, and responsible collection of recycled paper for cellulose insulation. Key activities at this stage include harvesting, primary processing (e.g., retting for bast fibers, pulping for wood), and basic refinement to prepare the fibers for insulation manufacturing. Ensuring ethical sourcing and traceability is paramount, as it directly impacts the environmental footprint and market acceptance of the final product.

Moving downstream, the value chain encompasses the manufacturing processes where raw fibers are transformed into insulation products. This involves shredding, blending, adding fire retardants (often natural or low-toxicity), binders (often bio-based), and forming the materials into batts, boards, or loose-fill. Following manufacturing, products enter the distribution channels, which include direct sales to large construction projects, sales through wholesalers and specialized building material distributors, and increasingly, online retail platforms. Logistics and warehousing play a critical role in efficiently moving these often bulky materials from production facilities to various markets.

The distribution of natural fiber insulation materials typically involves both direct and indirect channels. Direct distribution often targets large-scale commercial or public projects where manufacturers engage directly with contractors, architects, or developers to provide customized solutions and bulk orders. Indirect channels involve a network of building material retailers, hardware stores, and specialized green building suppliers, catering to smaller contractors, renovators, and DIY homeowners. Effective management of these diverse channels, including strong partnerships with distributors and a robust online presence, is crucial for market penetration and reaching a broad customer base, ultimately connecting the product to its end-users and buyers.

Natural Fiber Insulation Materials Market Potential Customers

The primary potential customers and end-users of Natural Fiber Insulation Materials represent a diverse group within the construction and building sectors, united by a growing demand for sustainable, high-performance, and environmentally responsible building solutions. These include individual homeowners and residential developers who prioritize energy efficiency, healthy indoor living environments, and a reduced carbon footprint for their properties. The increasing awareness of sustainable living and the long-term benefits of natural materials, such as improved air quality and reduced reliance on fossil fuels for heating and cooling, significantly drive their purchasing decisions.

Beyond the residential segment, a substantial portion of potential customers includes commercial builders, contractors, and architectural firms engaged in designing and constructing commercial, institutional, and public buildings. These entities are increasingly required to meet stringent green building certifications like LEED, BREEAM, or Passive House standards, for which natural fiber insulation materials are ideal. Their procurement decisions are often influenced by regulatory compliance, corporate sustainability goals, operational cost savings through energy efficiency, and the public image associated with green construction practices, making natural fiber insulation a strategic choice.

Furthermore, government agencies, particularly those focused on public infrastructure and housing projects, constitute a growing customer base, driven by mandates for sustainable procurement and public sector leadership in environmental stewardship. Renovation and retrofit specialists also represent a key segment, as a significant global effort is underway to upgrade existing building stock for improved energy performance and sustainability. These diverse end-users and buyers collectively underscore the broad and expanding market for natural fiber insulation, reflecting a fundamental shift towards more eco-conscious and energy-efficient construction practices across the entire building lifecycle.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $5.5 Billion |

| Market Forecast in 2032 | $9.15 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Steico AG, Soprema Group, Homatherm (Knauf Insulation), Gutex Holzfaserplattenwerk H. Henselmann GmbH & Co. KG, Isocell GmbH, Bestwood Schneider GmbH, Natures Insulation (Havelock Wool), Warmcel (PYC Group), Thermofloc Dämmstoffe GmbH, Ecococon, Celenit S.p.A., Pavatex by Soprema, Unilin Insulation, Bauder Ltd., Isonat by Soprema, Recyceld Insulation (Greenfiber), Igloo Cellulose, Fiberon, NatureWorks LLC, Biofilta. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Natural Fiber Insulation Materials Market Key Technology Landscape

The Natural Fiber Insulation Materials Market is continuously evolving through technological advancements aimed at enhancing product performance, improving manufacturing efficiency, and ensuring sustainability. Mechanical processing technologies, such as defibration, shredding, and carding, are fundamental in preparing raw natural fibers for insulation production, optimizing fiber length and structure for optimal thermal and acoustic properties. Innovations in thermal bonding and needle-punching techniques are crucial for creating dimensionally stable and durable insulation batts and boards without relying heavily on synthetic binders, thus preserving the natural and eco-friendly characteristics of the materials.

Chemical treatments play a significant role in addressing inherent challenges of natural fibers, particularly concerning fire resistance, moisture management, and pest deterrence. While maintaining the natural integrity of the product, advancements in non-toxic or low-toxicity fire retardants, such as borate-based compounds or ammonium polyphosphate, are essential for meeting stringent building safety codes. Similarly, hydrophobic treatments that allow the material to breathe while resisting water absorption, along with natural pest deterrents, are critical areas of ongoing research and development to broaden the applicability and longevity of these materials in diverse climates and environments.

Furthermore, the integration of advanced manufacturing processes, including automated production lines and robotics, is enhancing precision, consistency, and scalability in the production of natural fiber insulation. The adoption of AI-driven process control systems allows for real-time monitoring and adjustment of manufacturing parameters, leading to optimized material usage, reduced waste, and improved product quality. Material engineering continues to focus on developing hybrid natural fiber composites and exploring innovative binder solutions derived from bio-based sources, pushing the boundaries of performance and sustainability in the natural fiber insulation market, creating new opportunities for competitive differentiation and market growth.

Regional Highlights

- North America: This region is a significant market for natural fiber insulation, driven by growing environmental awareness, a strong emphasis on energy efficiency, and a robust green building movement. Countries like the United States and Canada are seeing increased adoption due to supportive government incentives for sustainable construction, rising consumer demand for healthy indoor environments, and the expansion of certifications such as LEED. The market here benefits from a well-established construction sector and a gradual shift away from traditional synthetic materials, particularly in residential and light commercial applications.

- Europe: Europe stands as the leading market for natural fiber insulation materials, propelled by some of the world's most stringent energy performance regulations for buildings and a long-standing commitment to sustainability. Nations such as Germany, France, the UK, and the Scandinavian countries have embraced these materials due to their superior thermal performance, low embodied carbon, and alignment with circular economy principles. Strong policy support, well-developed supply chains for wood fiber and cellulose, and a high level of consumer and industry awareness contribute to the region's dominance and continued growth in both new construction and extensive renovation projects.

- Asia Pacific (APAC): The Asia Pacific region is rapidly emerging as a high-growth market for natural fiber insulation. This growth is primarily fueled by rapid urbanization, significant infrastructure development, and a burgeoning construction sector across countries like China, India, Japan, and Australia. While adoption rates have historically been lower than in Europe, increasing awareness of environmental issues, a growing middle class demanding higher quality housing, and the implementation of green building initiatives are driving demand. The challenge remains in overcoming initial cost perceptions and establishing robust supply chains for locally sourced natural fibers.

- Latin America: This region presents an developing market for natural fiber insulation, characterized by increasing awareness of sustainable building practices and a growing focus on energy efficiency in new construction projects. Countries like Brazil and Mexico are witnessing gradual adoption, influenced by international sustainability trends and a desire to reduce operational costs in buildings. Local availability of natural fibers and the potential for job creation in their processing are attractive factors, though market penetration is still in its early stages and often dependent on government support and educational campaigns.

- Middle East and Africa (MEA): The MEA region is a relatively nascent but promising market for natural fiber insulation. The extreme climatic conditions, particularly the high temperatures, drive a strong need for efficient thermal insulation to reduce cooling loads and energy consumption. While synthetic insulation has traditionally dominated, growing sustainability agendas, large-scale green development projects (e.g., in UAE and Saudi Arabia), and an increasing focus on sustainable urban planning are creating opportunities for natural alternatives. Challenges include limited local production capabilities and a need for greater awareness of natural fibers' specific benefits in harsh environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Natural Fiber Insulation Materials Market.- Steico AG

- Soprema Group

- Homatherm (Knauf Insulation)

- Gutex Holzfaserplattenwerk H. Henselmann GmbH & Co. KG

- Isocell GmbH

- Bestwood Schneider GmbH

- Natures Insulation (Havelock Wool)

- Warmcel (PYC Group)

- Thermofloc Dämmstoffe GmbH

- Ecococon

- Celenit S.p.A.

- Pavatex by Soprema

- Unilin Insulation

- Bauder Ltd.

- Isonat by Soprema

- Recyceld Insulation (Greenfiber)

- Igloo Cellulose

- Fiberon

- NatureWorks LLC

- Biofilta

Frequently Asked Questions

What are the primary benefits of natural fiber insulation?

Natural fiber insulation offers multiple benefits, including superior thermal performance that reduces energy consumption for heating and cooling, excellent acoustic dampening properties, and improved indoor air quality due to its non-toxic, breathable nature. These materials are also sustainable, renewable, and often biodegradable, contributing to a lower environmental footprint throughout a building's lifecycle. Their hygroscopic properties can help manage moisture, reducing the risk of mold and enhancing structural integrity.

How do natural fiber insulation materials compare to synthetic alternatives?

Natural fiber insulation materials generally boast a lower embodied energy, are renewable, and contribute positively to indoor air quality, unlike many synthetic alternatives which are petroleum-based and can off-gas VOCs. While some synthetic materials might offer higher R-values per inch or superior moisture resistance in specific applications, natural fibers typically excel in breathability, moisture buffering, and acoustic performance. Natural options also align better with green building certifications and broader sustainability goals, offering a compelling eco-conscious choice.

Are natural fiber insulation materials resistant to fire and pests?

While natural fibers are inherently combustible, they are typically treated with natural or low-toxicity fire retardants during manufacturing to meet stringent building safety codes, making them resistant to ignition and slowing flame spread. Regarding pests, some natural fibers like sheep wool have natural deterrents, and others like cellulose or hemp are often treated with borate compounds that effectively deter insects and rodents. Proper installation and moisture control are also crucial in mitigating any pest or mold risks, ensuring long-term performance.

What is the lifespan of natural fiber insulation?

When properly installed and maintained within a dry and well-ventilated building envelope, natural fiber insulation materials can have a lifespan comparable to, or even exceeding, that of the building structure itself, often lasting 50 years or more. Factors influencing longevity include protection from moisture, pests, and significant structural movements. Their inherent durability and resistance to degradation under ideal conditions make them a long-term investment in a building's energy efficiency and comfort, requiring minimal replacement or repair over decades.

Which types of buildings are best suited for natural fiber insulation?

Natural fiber insulation is highly suitable for a wide range of buildings, including residential homes, commercial offices, public buildings, and schools, particularly where occupant health, energy efficiency, and environmental sustainability are key priorities. They are ideal for passive house constructions, ecological buildings, and renovation projects aiming to upgrade existing structures to modern energy standards. Their versatility allows for effective use in walls, roofs, floors, and for acoustic applications, making them a preferred choice for architects and builders committed to green building practices across diverse climates.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager