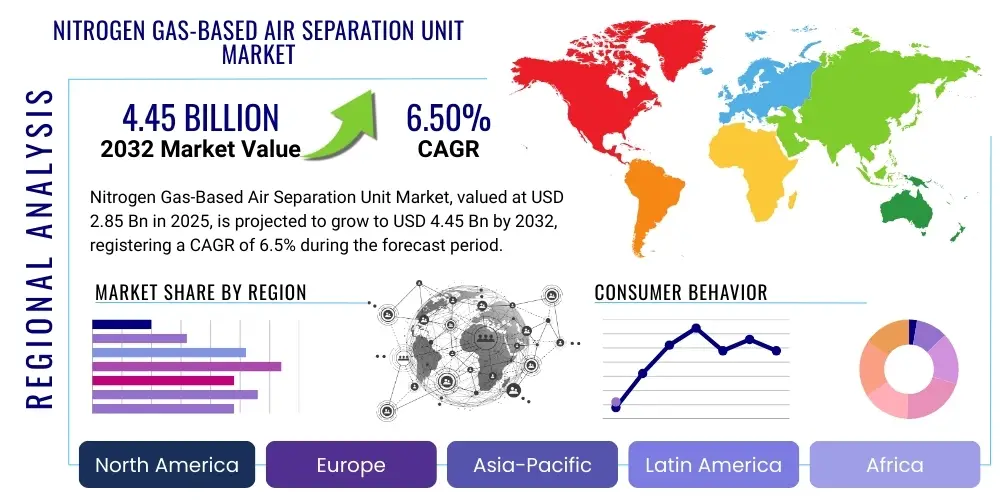

Nitrogen Gas-Based Air Separation Unit Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427455 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Nitrogen Gas-Based Air Separation Unit Market Size

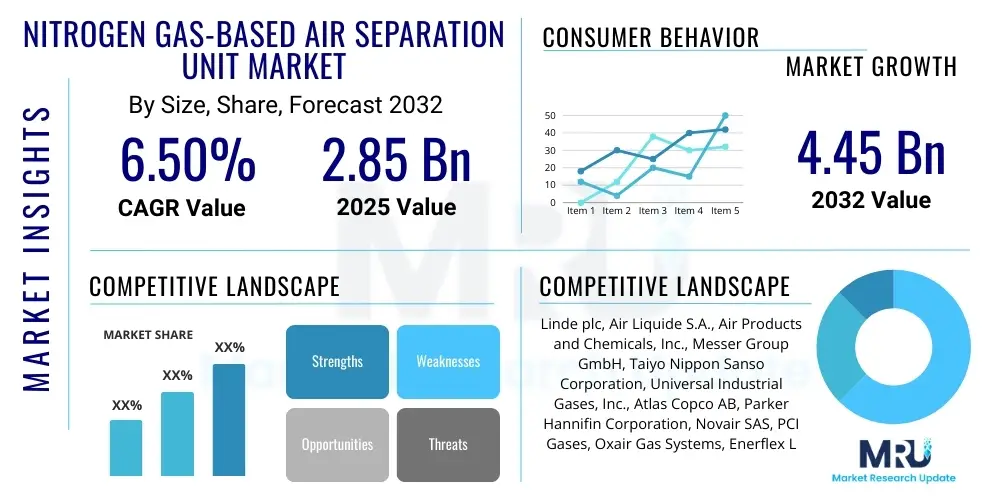

The Nitrogen Gas-Based Air Separation Unit Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 2.85 Billion in 2025 and is projected to reach USD 4.45 Billion by the end of the forecast period in 2032.

Nitrogen Gas-Based Air Separation Unit Market introduction

The Nitrogen Gas-Based Air Separation Unit (ASU) Market encompasses the design, manufacture, installation, and servicing of systems that produce high-purity nitrogen by separating it from atmospheric air. These units are critical across numerous industrial sectors, providing a reliable and cost-effective source of nitrogen gas tailored to specific application requirements. The core technology leverages principles such as cryogenic distillation, pressure swing adsorption (PSA), and membrane separation to achieve varying levels of purity and capacity. Nitrogen, being an inert gas, finds extensive use where oxygens presence is detrimental or where a non-reactive environment is required for safety, preservation, or process optimization.

Product descriptions of nitrogen ASUs typically highlight their operational efficiency, purity output ranging from 95% to 99.999%, and modular design adaptability for on-site generation. Major applications span a wide spectrum of industries including electronics for inert atmospheres during manufacturing, food and beverage for packaging and preservation to extend shelf life, chemical and petrochemical sectors for blanketing and purging, pharmaceuticals for sterile environments and ingredient protection, and metal fabrication for laser cutting and heat treatment processes. The benefits of using nitrogen ASUs include enhanced process safety, reduced reliance on external gas suppliers, significant cost savings over time compared to bulk gas purchases, and a lower carbon footprint due to on-demand production. Furthermore, the ability to control nitrogen purity and flow rates on-site offers unparalleled operational flexibility.

The market is primarily driven by the continuous expansion of industrial manufacturing activities globally, particularly in emerging economies, alongside an increasing demand for high-purity nitrogen in advanced manufacturing processes. Stringent safety regulations in various industries, which mandate the use of inert gas for preventing explosions and fires, also contribute significantly to market growth. Technological advancements leading to more energy-efficient and compact ASU designs, coupled with the growing preference for on-site nitrogen generation over traditional merchant supply models, further propel market expansion. The versatility of nitrogen across diverse applications, from preserving delicate electronic components to enhancing food freshness, ensures a sustained demand for these critical air separation technologies.

Nitrogen Gas-Based Air Separation Unit Market Executive Summary

The Nitrogen Gas-Based Air Separation Unit market is experiencing robust growth, driven by escalating industrial demands and technological advancements. Key business trends indicate a strong shift towards on-site nitrogen generation solutions, offering greater operational control, cost efficiencies, and reduced logistical complexities for end-users. Manufacturers are increasingly focusing on developing modular, energy-efficient ASUs equipped with advanced automation and remote monitoring capabilities, catering to diverse capacity requirements and emphasizing sustainable operations. Strategic partnerships and acquisitions are also common as companies seek to expand their geographic reach and enhance their technological portfolios, consolidating market leadership and fostering innovation.

Regionally, Asia-Pacific continues to be the most dominant and fastest-growing market, primarily fueled by rapid industrialization, burgeoning electronics manufacturing, chemical processing, and food & beverage sectors in countries like China, India, and Southeast Asian nations. North America and Europe, while mature, demonstrate steady demand driven by the modernization of existing industrial infrastructure, stringent safety and environmental regulations, and the adoption of high-purity nitrogen in advanced manufacturing and healthcare. The Middle East and Africa, alongside Latin America, present significant growth opportunities due to developing industrial bases and increasing investments in infrastructure and oil & gas, which require substantial volumes of nitrogen for various operations.

Segment trends highlight a strong demand for Pressure Swing Adsorption (PSA) and membrane separation technologies due to their lower capital expenditure and operational flexibility for small to medium-scale nitrogen production, especially for applications not requiring ultra-high purity. However, cryogenic ASUs maintain their dominance for large-scale, ultra-high purity nitrogen requirements in industries like chemicals, metallurgy, and electronics. The food and beverage, electronics, and pharmaceutical sectors are emerging as pivotal application segments, exhibiting accelerated growth due to their critical need for high-purity nitrogen for inerting, packaging, and processing. The market is also witnessing a trend towards integrated solutions that combine nitrogen generation with other industrial gas services, providing comprehensive offerings to end-users.

AI Impact Analysis on Nitrogen Gas-Based Air Separation Unit Market

User inquiries regarding Artificial Intelligence (AI) in the Nitrogen Gas-Based Air Separation Unit market frequently center on how AI can enhance operational efficiency, reduce energy consumption, and improve predictive maintenance capabilities. There is significant interest in understanding AIs role in optimizing the complex processes involved in air separation, such as real-time control of parameters, anomaly detection, and ensuring consistent gas purity. Users are also concerned with the practical implementation challenges, including data integration, cybersecurity risks, and the need for skilled personnel to manage AI-driven systems. Overall, the expectation is that AI will revolutionize the operational lifecycle of ASUs, leading to substantial cost savings and improved reliability, thereby making nitrogen generation more sustainable and economically viable for a broader range of industrial applications.

- AI-driven predictive maintenance optimizes ASU uptime and reduces unexpected failures by analyzing sensor data to forecast equipment malfunctions, scheduling maintenance proactively.

- Real-time process optimization algorithms, powered by AI, fine-tune operational parameters such as flow rates, pressure, and temperature to maximize nitrogen output purity and minimize energy consumption.

- Enhanced energy management through AI can monitor and adjust power usage based on demand fluctuations and electricity costs, significantly lowering operational expenses for nitrogen production.

- AI-enabled safety monitoring systems provide early detection of abnormal operating conditions or potential hazards, improving plant safety and ensuring compliance with industrial regulations.

- Automated control systems integrated with AI algorithms allow for more precise and responsive management of nitrogen generation, adapting dynamically to changes in raw air quality or end-user demand.

DRO & Impact Forces Of Nitrogen Gas-Based Air Separation Unit Market

The Nitrogen Gas-Based Air Separation Unit (ASU) market is significantly shaped by a confluence of drivers, restraints, and opportunities, alongside various impact forces. Key drivers include the relentless expansion of industrial sectors globally, particularly electronics, food & beverage, chemicals, and pharmaceuticals, which require high-purity nitrogen for diverse applications ranging from inerting and purging to packaging and processing. The increasing emphasis on workplace safety and environmental compliance also propels demand for nitrogen as an inerting agent, preventing combustion and managing hazardous reactions. Furthermore, the economic benefits of on-site nitrogen generation, offering independence from external suppliers and reduced long-term costs, are strong motivators for adoption. Technological advancements in ASU design, leading to more compact, energy-efficient, and modular units, also contribute to market growth by making these systems accessible to a wider range of industries and scales of operation.

Conversely, the market faces several restraints that could impede its growth trajectory. The high initial capital expenditure required for installing ASUs, especially large-scale cryogenic units, can be a significant barrier for smaller enterprises or those with limited budgets. The energy-intensive nature of air separation processes, particularly cryogenic distillation, translates into substantial operating costs, making the market susceptible to fluctuating energy prices. Operational complexities, including the need for specialized technical expertise for maintenance and troubleshooting, further add to the total cost of ownership. Moreover, stringent regulatory frameworks related to industrial gas production and handling, while promoting safety, can also introduce hurdles in terms of compliance and operational adjustments. The availability of alternative nitrogen supply methods, such as liquid nitrogen delivery, presents a competitive restraint, particularly for applications with intermittent or lower volume requirements.

Despite these challenges, the market is rife with opportunities. The burgeoning industrial growth in developing economies, coupled with increasing investments in infrastructure and manufacturing capabilities, creates fertile ground for ASU adoption. The growing trend towards sustainable manufacturing and green industrial practices offers an opportunity for suppliers of energy-efficient ASUs and those exploring novel, less energy-intensive nitrogen generation technologies. Expanding applications in niche sectors such as additive manufacturing, healthcare, and advanced materials processing also open new revenue streams. The development of advanced analytics and AI-driven control systems for ASUs presents an opportunity to further optimize performance, reduce operational costs, and enhance system reliability. From an impact forces perspective, the bargaining power of buyers is moderately high due to several suppliers and diverse technological options, while the bargaining power of suppliers for critical components is moderate. The threat of new entrants is low due to high capital requirements and technological expertise, and the threat of substitutes, primarily bulk liquid nitrogen, is moderate. Competitive rivalry among established players is intense, driving continuous innovation and market differentiation.

Segmentation Analysis

The Nitrogen Gas-Based Air Separation Unit market is comprehensively segmented to provide granular insights into its diverse components, technologies, applications, and regional dynamics. This segmentation helps in understanding the market structure, identifying growth pockets, and formulating targeted strategies based on specific operational needs and industrial requirements. The primary segmentation categories include technology type, purity level, production capacity, application sector, and end-user base. Each segment reflects distinct market characteristics, driving forces, and competitive landscapes, catering to a broad spectrum of industrial demands for nitrogen gas.

Further analysis within these segments reveals varying adoption rates and market maturity. For instance, while cryogenic technology dominates the large-scale, ultra-high purity market, non-cryogenic technologies like PSA and membrane separation are gaining traction for their cost-effectiveness and flexibility in smaller to medium-scale on-site generation. The growing demand for specialized nitrogen purities in critical applications, such as semiconductor manufacturing, highlights the importance of purity-based segmentation. Understanding these segments allows market players to tailor their product offerings, marketing efforts, and distribution channels to effectively meet the evolving needs of different industrial verticals and geographical regions, ultimately contributing to sustained market growth and competitive advantage.

- By Technology:

- Cryogenic Air Separation Units

- Non-Cryogenic Air Separation Units

- Pressure Swing Adsorption (PSA)

- Membrane Separation

- Vacuum Pressure Swing Adsorption (VPSA)

- By Purity:

- High Purity Nitrogen (99% - 99.99%)

- Ultra High Purity Nitrogen (>99.999%)

- By Production Capacity:

- Small Scale (Below 1,000 Nm3/hr)

- Medium Scale (1,000 - 10,000 Nm3/hr)

- Large Scale (Above 10,000 Nm3/hr)

- By Application:

- Chemical & Petrochemical

- Food & Beverage

- Electronics

- Pharmaceutical & Healthcare

- Metal Fabrication & Metallurgy

- Oil & Gas

- Automotive & Transportation

- Others (e.g., Waste Water Treatment, Power Generation)

- By End-Use Mode:

- On-site Generation

- Merchant Gas Supply (Indirect)

Nitrogen Gas-Based Air Separation Unit Market Value Chain Analysis

The value chain for the Nitrogen Gas-Based Air Separation Unit (ASU) market is a complex ecosystem involving several distinct stages, from raw material procurement to final product delivery and aftermarket services. At the upstream level, the value chain commences with the sourcing of critical components and raw materials necessary for manufacturing ASUs. This includes specialized machinery such as compressors, expanders, heat exchangers, adsorbers for PSA units, and membranes for membrane separation systems. Suppliers of these highly engineered components play a crucial role in the overall quality, efficiency, and cost-effectiveness of the final ASU product. Engineering firms specializing in industrial gas technologies are also vital upstream participants, providing design, research, and development expertise that underpins the innovation and technological advancement of nitrogen generation systems. Their ability to deliver customized, energy-efficient, and reliable designs directly impacts the competitive standing of ASU manufacturers.

Moving downstream, the value chain involves the manufacturing, assembly, and testing of the ASUs, followed by their distribution, installation, and ongoing maintenance. Manufacturers integrate the sourced components, applying their proprietary technologies and processes to produce a complete nitrogen generation system. The distribution channels are critical for market reach and customer accessibility. Direct distribution involves manufacturers selling and installing ASUs directly to end-users, often for large-scale or highly customized projects, allowing for close customer relationships and tailored solutions. Indirect distribution channels primarily involve third-party distributors, system integrators, and engineering, procurement, and construction (EPC) contractors, who facilitate sales, provide local support, and integrate ASUs into larger industrial complexes. These indirect channels are particularly effective for reaching smaller and medium-sized enterprises or for projects requiring comprehensive industrial solutions beyond just gas generation.

Post-installation, the value chain extends to comprehensive aftermarket services, which include routine maintenance, spare parts supply, technical support, and operational optimization. These services are crucial for ensuring the long-term reliability and efficiency of the ASUs, contributing significantly to customer satisfaction and loyalty. The end-users, encompassing a wide array of industries such as electronics, food & beverage, chemicals, and pharmaceuticals, represent the final link in the value chain, directly benefiting from the on-site generation of high-purity nitrogen. The operational model, whether on-site generation or merchant gas supply, significantly influences the downstream dynamics. On-site ASUs offer end-users direct control over their nitrogen supply, while merchant gas supply, often facilitated by large industrial gas companies, provides nitrogen via bulk delivery or pipelines, typically serving customers who prefer not to manage their own generation equipment. The efficiency and synergy across all these stages are paramount for delivering value, optimizing costs, and ensuring a robust and responsive market for nitrogen gas-based air separation units.

Nitrogen Gas-Based Air Separation Unit Market Potential Customers

Potential customers for Nitrogen Gas-Based Air Separation Units encompass a broad spectrum of industrial sectors, all of which require a reliable and cost-effective source of high-purity nitrogen for various critical processes. These end-users are driven by the need to create inert atmospheres, prevent oxidation, ensure product purity, enhance safety, or extend shelf life. The demand originates from industries where oxygens presence is detrimental or where a non-reactive gas is essential for optimal operations. For instance, the electronics industry, particularly semiconductor and display panel manufacturers, relies heavily on ultra-high purity nitrogen to prevent contamination during manufacturing, soldering, and packaging of sensitive components, ensuring product integrity and performance. The pharmaceutical and biotechnology sectors utilize nitrogen for sterile environments, blanketing sensitive compounds, lyophilization, and inerting storage tanks to preserve the efficacy and purity of active pharmaceutical ingredients and finished drugs.

The food and beverage industry represents another significant customer segment, employing nitrogen for modified atmosphere packaging (MAP) to extend the freshness and shelf life of perishable goods like snacks, coffee, and produce. Nitrogen purging is also vital in breweries and wineries to remove oxygen, preventing spoilage and maintaining product quality. In the chemical and petrochemical industries, nitrogen is indispensable for inerting storage tanks, pipelines, and reactors to prevent explosions and fires, purge lines of combustible gases, and serve as a carrier gas or for catalyst regeneration. Metal fabrication and metallurgy industries, including laser cutting, heat treatment, and brazing, use nitrogen to create an inert atmosphere that prevents oxidation, improves cut quality, and enhances material properties. Furthermore, the oil and gas sector utilizes nitrogen for various applications such as pipeline inerting, well stimulation, and enhanced oil recovery, leveraging its inert and non-corrosive properties. The growing adoption of advanced manufacturing techniques, such as additive manufacturing, also increases the demand for controlled inert atmospheres provided by ASUs.

Nitrogen Gas-Based Air Separation Unit Market Key Technology Landscape

The Nitrogen Gas-Based Air Separation Unit (ASU) market is characterized by a dynamic technological landscape dominated by several established and evolving methods for nitrogen production. The most prominent technology is cryogenic distillation, which involves cooling ambient air to extremely low temperatures, causing it to liquefy. Subsequent fractional distillation separates nitrogen from other atmospheric gases like oxygen and argon based on their different boiling points. Cryogenic ASUs are highly efficient for producing ultra-high purity nitrogen in large volumes, making them indispensable for industries such such as chemicals, metallurgy, and electronics that demand exceptional purity and high throughput. While they require significant initial capital investment and are energy-intensive, their ability to deliver consistent, high-grade nitrogen on a massive scale ensures their continued importance in the market.

Complementing cryogenic technology are non-cryogenic methods, which offer more flexible and cost-effective solutions for small to medium-scale nitrogen generation. Pressure Swing Adsorption (PSA) is a widely adopted non-cryogenic technology that separates nitrogen by adsorbing oxygen, carbon dioxide, and water vapor onto a molecular sieve at high pressure. When pressure is released, the adsorbed impurities are desorbed, leaving high-purity nitrogen. PSA systems are known for their rapid start-up, lower capital costs compared to cryogenic units, and ease of operation, making them popular in applications like food packaging, tire inflation, and laser cutting where ultra-high purity is not always paramount. Membrane separation is another non-cryogenic technology that uses semi-permeable hollow fiber membranes to separate nitrogen. Air is passed through the membrane, where oxygen and water vapor permeate faster than nitrogen, allowing nitrogen to be collected at the outlet. Membrane systems are compact, require minimal maintenance, and are suitable for lower purity nitrogen requirements, often used in fire prevention and inerting applications.

The technological landscape is also seeing advancements aimed at improving energy efficiency, modularity, and integration with digital control systems. Vacuum Pressure Swing Adsorption (VPSA) technology is an evolution of PSA, offering enhanced energy efficiency by operating part of the cycle under vacuum. On-site generation technologies, regardless of the core separation method, are becoming increasingly sophisticated, incorporating advanced automation, remote monitoring, and predictive maintenance capabilities. This allows end-users greater control over their nitrogen supply, reduced operational costs, and improved reliability. Innovations also focus on developing hybrid systems that combine the benefits of different technologies, as well as exploring novel materials for membranes and adsorbents to achieve higher separation efficiency and lower operational footprints. The continuous drive for greater sustainability and cost-effectiveness across industrial operations ensures ongoing research and development in nitrogen generation technologies, maintaining a dynamic and competitive environment.

Regional Highlights

- North America: The North American market for Nitrogen Gas-Based Air Separation Units is characterized by a mature industrial base and a strong emphasis on technological innovation and environmental compliance. Demand is robust across diverse sectors including electronics, food processing, pharmaceuticals, and oil & gas. The region benefits from significant investments in advanced manufacturing technologies and the modernization of existing industrial infrastructure, which drives the adoption of energy-efficient and highly automated ASUs. The presence of key market players and a well-developed supply chain further solidifies its market position.

- Europe: Europe represents a significant market, driven by stringent environmental regulations, a well-established industrial framework, and a focus on sustainable manufacturing practices. Countries like Germany, France, and the UK are major contributors, with strong demand from the chemical, automotive, and food & beverage industries. The region is witnessing a trend towards modular and compact ASUs, reflecting the need for flexible and space-efficient solutions. Investments in renewable energy and green hydrogen production also indirectly contribute to nitrogen demand for inerting and purging processes.

- Asia-Pacific: The Asia-Pacific region is the largest and fastest-growing market for Nitrogen Gas-Based Air Separation Units globally. This explosive growth is attributed to rapid industrialization, burgeoning manufacturing sectors (especially electronics, automotive, and textiles), and significant investments in infrastructure development, particularly in countries such as China, India, Japan, and South Korea. The increasing disposable income and changing consumer lifestyles are boosting the food & beverage and pharmaceutical industries, leading to higher demand for nitrogen for packaging and processing. The regions competitive manufacturing landscape also favors cost-effective, on-site nitrogen generation solutions.

- Latin America: The Latin American market is experiencing steady growth, propelled by the expansion of its industrial base, particularly in sectors such as food & beverage, mining, and oil & gas. Countries like Brazil, Mexico, and Argentina are key contributors to market demand. While currently smaller than other regions, increasing foreign direct investment and government initiatives to boost industrial output are creating new opportunities for ASU deployment. The adoption of advanced manufacturing technologies is also on the rise, supporting the need for reliable nitrogen supply.

- Middle East & Africa: This region presents considerable growth potential, primarily driven by extensive investments in the oil & gas sector, petrochemical industries, and infrastructure development. Nitrogen is crucial for various applications in oil & gas, including inerting, purging, and enhanced oil recovery. Rapid urbanization and economic diversification efforts are also fostering the growth of other industrial sectors, such as food processing and manufacturing, which contribute to the demand for nitrogen ASUs. Increasing awareness regarding industrial safety and the need for reliable gas supply further boosts market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nitrogen Gas-Based Air Separation Unit Market.- Linde plc

- Air Liquide S.A.

- Air Products and Chemicals, Inc.

- Messer Group GmbH

- Taiyo Nippon Sanso Corporation

- Universal Industrial Gases, Inc.

- Atlas Copco AB

- Parker Hannifin Corporation (DOMNICK HUNTER)

- Novair SAS

- PCI Gases

- Oxair Gas Systems

- Enerflex Ltd.

- INGERSOLL RAND

- NOXERIOR S.R.L.

- GENERON

- South-Tek Systems

Frequently Asked Questions

What is a Nitrogen Gas-Based Air Separation Unit (ASU)?

A Nitrogen Gas-Based Air Separation Unit (ASU) is an industrial system designed to produce high-purity nitrogen gas by separating it from atmospheric air. It utilizes various technologies, primarily cryogenic distillation or non-cryogenic methods like Pressure Swing Adsorption (PSA) and membrane separation, to isolate nitrogen for diverse industrial applications.

How do Nitrogen ASUs work?

Nitrogen ASUs typically work by taking in ambient air, filtering it, and then separating its components. Cryogenic ASUs cool air to liquefaction, then distill nitrogen based on boiling points. Non-cryogenic ASUs, like PSA, use adsorbent materials to selectively remove oxygen and other gases, leaving purified nitrogen. Membrane ASUs use semi-permeable membranes to allow faster permeation of oxygen, leaving nitrogen behind.

What are the primary applications of nitrogen generated by ASUs?

Nitrogen generated by ASUs is widely used across various industries. Key applications include creating inert atmospheres in electronics manufacturing, preserving freshness in food and beverage packaging, blanketing and purging in chemical and pharmaceutical processes, and providing a non-oxidizing environment in metal fabrication and laser cutting. It is essential for safety, product integrity, and process optimization.

What are the main advantages of on-site nitrogen generation?

On-site nitrogen generation offers several advantages, including significant cost savings over time compared to purchasing bulk liquid or cylinder nitrogen, greater control over gas purity and supply, reduced logistical complexities and associated safety risks, and a lower environmental footprint due to reduced transportation. It provides an independent and reliable nitrogen source tailored to specific operational demands.

What is the market outlook for Nitrogen Gas-Based Air Separation Units?

The market outlook for Nitrogen Gas-Based Air Separation Units is highly positive, projecting sustained growth driven by global industrial expansion, increasing demand for high-purity nitrogen across critical sectors, and technological advancements enhancing efficiency and flexibility. The shift towards on-site generation and the need for reliable, cost-effective inert gas solutions will continue to fuel market expansion through the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager