Non-Condensing Low Temperature Industrial Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429026 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Non-Condensing Low Temperature Industrial Boiler Market Size

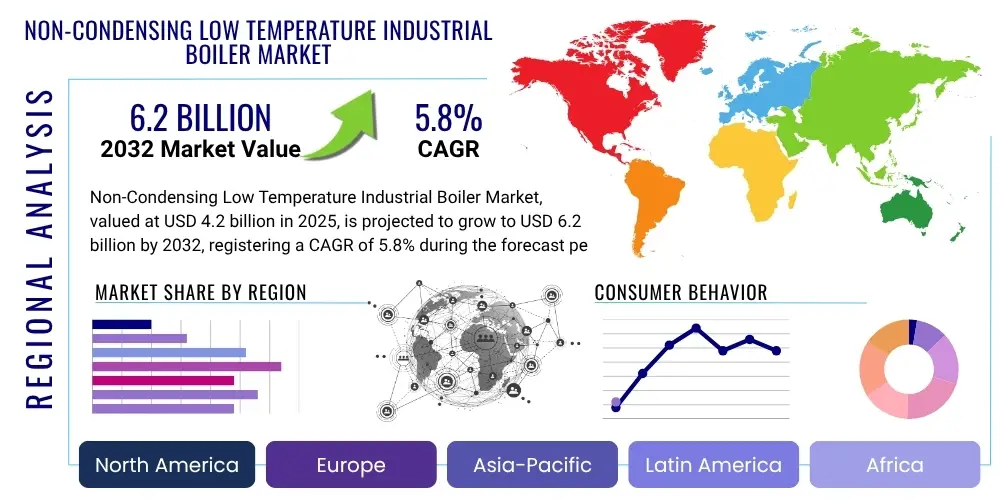

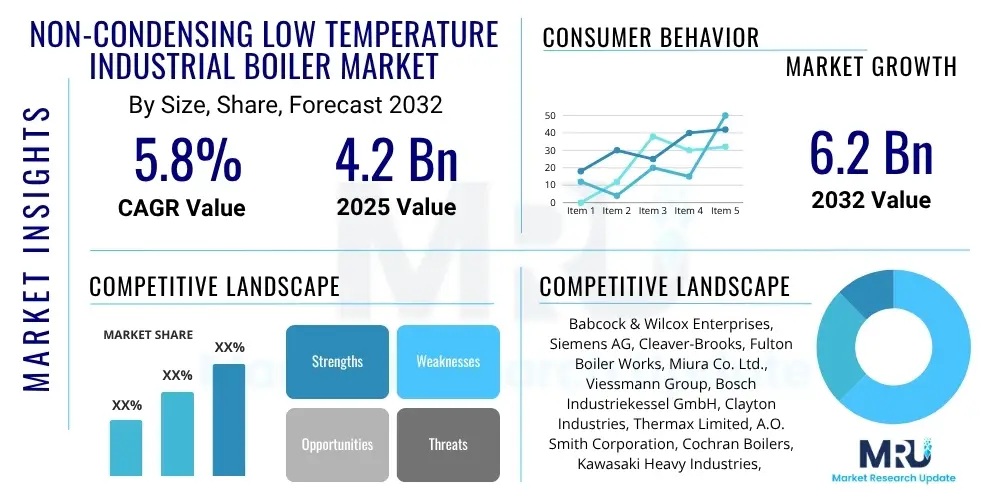

The Non-Condensing Low Temperature Industrial Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 4.2 billion in 2025 and is projected to reach USD 6.2 billion by the end of the forecast period in 2032.

Non-Condensing Low Temperature Industrial Boiler Market introduction

The Non-Condensing Low Temperature Industrial Boiler Market encompasses a specialized segment of heating solutions designed for industrial processes that do not require high-temperature steam or hot water. These boilers operate efficiently at lower temperatures, typically avoiding flue gas condensation, making them suitable for a range of applications where energy recovery from condensation is either not feasible or economically justifiable. Their simpler design and operational characteristics contribute to lower capital expenditure and maintenance costs, presenting an attractive proposition for various industries seeking reliable and cost-effective heating solutions.

Products within this market typically include fire-tube and water-tube designs, utilizing diverse fuel sources such as natural gas, oil, biomass, and electricity. Major applications span across process heating, hot water generation for sanitary purposes, and space heating in industrial facilities. Industries like food and beverage, pharmaceuticals, textiles, chemical processing, and pulp and paper are primary users, relying on these boilers for consistent and controlled heat supply for their manufacturing operations.

The benefits associated with non-condensing low-temperature industrial boilers include enhanced operational simplicity, a lower initial investment compared to their high-temperature counterparts, and reduced complexity in terms of maintenance. Key driving factors for this market's growth include the ongoing industrialization in emerging economies, the need for cost-effective thermal energy solutions, the replacement of aging boiler infrastructure, and the continuous demand for energy efficiency improvements in various manufacturing sectors globally.

Non-Condensing Low Temperature Industrial Boiler Market Executive Summary

The Non-Condensing Low Temperature Industrial Boiler Market is characterized by a steady expansion driven by resilient industrial growth and a persistent focus on operational efficiencies. Business trends indicate a shift towards modular and compact boiler designs that facilitate easier installation and offer flexibility in scaling operations. Manufacturers are increasingly integrating advanced control systems to optimize fuel consumption and minimize emissions, aligning with evolving environmental regulations and corporate sustainability objectives. Digitalization and the adoption of IoT for remote monitoring and predictive maintenance are also becoming prevalent, enhancing boiler reliability and reducing downtime for industrial end-users.

Regional trends reveal significant growth opportunities in the Asia Pacific due to rapid industrialization and expansion across manufacturing sectors, particularly in China and India. North America and Europe, while mature markets, demonstrate demand driven by the replacement of outdated boiler systems with newer, more efficient non-condensing low-temperature units. Latin America and the Middle East and Africa regions are experiencing moderate growth, spurred by infrastructure development and investments in various industrial segments, including oil and gas, and food processing.

Segment trends highlight the continued dominance of natural gas-fired boilers owing to their clean-burning properties and widespread availability. However, biomass-fired boilers are gaining traction as industries seek to diversify their energy mix and reduce their carbon footprint. The market also observes a consistent demand for boilers across various capacity ranges, with small to medium-capacity units seeing particular uptake in decentralized heating applications. End-user segments such as food and beverage, chemicals, and pharmaceuticals remain significant contributors, constantly seeking robust and reliable heating for critical processes.

AI Impact Analysis on Non-Condensing Low Temperature Industrial Boiler Market

User inquiries frequently revolve around how Artificial Intelligence (AI) can revolutionize the operational efficiency and predictive capabilities within the non-condensing low-temperature industrial boiler domain. Common concerns include the extent to which AI can optimize fuel consumption, automate maintenance schedules, or predict potential failures. There is a strong expectation that AI will lead to smarter, more autonomous boiler systems, enhancing overall plant productivity and reducing energy costs, while simultaneously addressing potential challenges such as data privacy, cybersecurity, and the integration complexity with legacy systems. The summarization of these questions indicates a clear user interest in AI as a transformative technology for boiler performance, reliability, and sustainability.

- Predictive maintenance scheduling, reducing unplanned downtime by analyzing operational data.

- Real-time performance optimization, dynamically adjusting combustion parameters for maximum fuel efficiency.

- Energy consumption forecasting and load management, aligning boiler output with demand to minimize waste.

- Anomaly detection, identifying unusual operational patterns indicative of potential faults before escalation.

- Autonomous control adjustments, enabling boilers to self-regulate based on environmental and process variables.

- Enhanced safety protocols through AI-driven risk assessments and immediate alert generation.

- Automated diagnostics and troubleshooting assistance for maintenance personnel.

DRO & Impact Forces Of Non-Condensing Low Temperature Industrial Boiler Market

The Non-Condensing Low Temperature Industrial Boiler Market is significantly influenced by a confluence of drivers, restraints, and opportunities, shaping its growth trajectory. Key drivers include the ongoing industrial expansion across various manufacturing sectors globally, particularly in developing economies, which necessitates robust and reliable heating infrastructure. Additionally, the increasing emphasis on energy efficiency to mitigate rising fuel costs and achieve sustainability goals is compelling industries to invest in modern, optimized boiler systems. Stricter environmental regulations aimed at reducing carbon emissions also indirectly boost the market, as newer boiler technologies offer improved combustion and lower pollutant outputs compared to older models.

However, the market also faces considerable restraints. The substantial initial capital investment required for new boiler installations or major upgrades can be a significant barrier for smaller and medium-sized enterprises. The availability and increasing adoption of alternative heating technologies, such as heat pumps, electric heaters, and highly efficient condensing boilers in specific applications, also pose a competitive challenge. Furthermore, global economic slowdowns or uncertainties can defer industrial investment decisions, impacting market growth. The complexity of integrating advanced boiler systems with existing plant infrastructure and the shortage of skilled labor for installation and maintenance can also hinder broader adoption.

Despite these challenges, numerous opportunities exist for market players. The integration of non-condensing low-temperature industrial boilers with smart factory and Industrial Internet of Things (IIoT) ecosystems presents a significant avenue for growth, enabling advanced monitoring, control, and predictive capabilities. The development of hybrid boiler systems that combine different fuel types or integrate with renewable energy sources offers potential for market diversification. Furthermore, the burgeoning industrialization in emerging markets continues to create demand for new installations, while the vast installed base in mature economies offers ample opportunities for retrofitting existing units with advanced controls and efficiency enhancements, leveraging government incentives for energy upgrades.

Segmentation Analysis

The Non-Condensing Low Temperature Industrial Boiler Market is comprehensively segmented to provide a detailed understanding of its diverse landscape. This segmentation allows for precise analysis of market dynamics, identifying key areas of demand and supply across various product attributes, operational characteristics, and end-user applications. Understanding these segments is crucial for stakeholders to tailor products, marketing strategies, and investment decisions effectively. The market is typically broken down by factors such as the type of fuel used, the boiler's heating capacity, its primary application, and the specific industrial sectors it serves, each presenting unique growth patterns and technological requirements.

- Fuel Type:

- Natural Gas

- Oil

- Coal

- Biomass

- Electric

- Others (e.g., waste heat recovery)

- Capacity:

- Less than 10 MMBtu/hr

- 10-50 MMBtu/hr

- Greater than 50 MMBtu/hr

- Application:

- Process Heating

- Hot Water Generation

- Space Heating

- End-User:

- Food and Beverage

- Chemical

- Pharmaceutical

- Textile

- Pulp & Paper

- Automotive

- Power Generation (Auxiliary)

- District Heating

- Others (e.g., Rubber & Plastics, Metal Processing)

Value Chain Analysis For Non-Condensing Low Temperature Industrial Boiler Market

The value chain for the Non-Condensing Low Temperature Industrial Boiler Market is a complex ecosystem, starting from raw material procurement and extending through manufacturing, distribution, installation, and post-sales support. The upstream segment involves the sourcing of essential raw materials such as steel, copper, insulation materials, and specialized components like burners, pumps, valves, and control systems. Suppliers of these core components and sub-assemblies play a critical role in determining the quality, cost, and ultimately, the performance of the final boiler system. Relationships with reliable and cost-effective upstream partners are vital for manufacturers to maintain competitive pricing and product integrity.

Midstream activities primarily encompass the design, engineering, and assembly of the industrial boilers by various manufacturers. This stage involves significant R&D investment to develop efficient, compliant, and technologically advanced boiler systems. Downstream activities focus on the delivery, installation, commissioning, and ongoing maintenance of the boilers at the end-user facilities. This segment involves a network of engineering, procurement, and construction (EPC) firms, specialized installation contractors, and service providers who ensure optimal operation and longevity of the installed units. After-sales services, including spare parts supply, routine maintenance, and emergency repairs, are crucial for customer satisfaction and long-term revenue generation.

The distribution channel for non-condensing low-temperature industrial boilers can be broadly categorized into direct and indirect routes. Direct sales are often employed for large-scale, complex projects where manufacturers engage directly with major industrial clients, offering customized solutions and comprehensive project management. Indirect channels, on the other hand, involve a network of distributors, resellers, and original equipment manufacturers (OEMs) who integrate boilers into broader industrial systems. These channels are crucial for reaching a wider customer base, particularly for standardized or smaller capacity boilers, providing local market presence, logistical support, and immediate technical assistance to end-users.

Non-Condensing Low Temperature Industrial Boiler Market Potential Customers

The Non-Condensing Low Temperature Industrial Boiler Market serves a broad spectrum of industrial end-users, all requiring efficient and reliable process heating or hot water generation at specific temperature ranges. These customers typically operate facilities where consistent thermal energy is critical for production processes, space heating, or sanitation. The diversity of industrial applications necessitates a range of boiler capacities and fuel types, making the market highly segmented by end-user industry. Understanding the specific needs and operational constraints of these potential customers is paramount for manufacturers and service providers to develop targeted solutions and effective market penetration strategies.

Major end-user segments include the food and beverage industry, which utilizes boilers for pasteurization, sterilization, cooking, and cleaning processes in dairies, breweries, and food processing plants. The chemical and pharmaceutical sectors rely on these boilers for precise temperature control in reactions, drying, and distillation. Textile mills use them for dyeing, drying, and fabric treatment, while pulp and paper manufacturers employ them for drying paper sheets and process heating in various stages of pulp production. These industries represent significant buyers due to their continuous operational demands and high energy consumption for thermal processes.

Beyond these core sectors, other significant potential customers include automotive manufacturing plants for paint drying and facility heating, district heating systems providing centralized heat to commercial and residential complexes, and various other light and heavy manufacturing industries. Even power generation facilities may utilize these boilers for auxiliary heating purposes or as standby units. The common thread among all these potential customers is the need for a robust, efficient, and often cost-effective source of low-to-medium temperature thermal energy, underscoring the broad applicability and enduring demand for non-condensing low-temperature industrial boilers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.2 billion |

| Market Forecast in 2032 | USD 6.2 billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Babcock & Wilcox Enterprises, Siemens AG, Cleaver-Brooks, Fulton Boiler Works, Miura Co. Ltd., Viessmann Group, Bosch Industriekessel GmbH, Clayton Industries, Thermax Limited, A.O. Smith Corporation, Cochran Boilers, Kawasaki Heavy Industries, ATTSU, Superior Boiler Works, York-Shipley Global, Weil-McLain, Burnham Commercial, Lochinvar LLC, Vaillant Group, Danfoss |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Non-Condensing Low Temperature Industrial Boiler Market Key Technology Landscape

The technology landscape for non-condensing low-temperature industrial boilers is continuously evolving, driven by the imperative for greater efficiency, reduced emissions, and enhanced operational intelligence. Modern boiler systems incorporate sophisticated combustion control systems that optimize air-to-fuel ratios, leading to more complete combustion and minimizing fuel consumption. Technologies such as variable frequency drives (VFDs) for fans and pumps allow for precise control over energy input, matching boiler output more closely with demand fluctuations, thus significantly improving overall system efficiency and reducing parasitic loads.

Beyond combustion, significant advancements are seen in heat recovery and monitoring. Economizers are increasingly integrated to preheat feedwater using exhaust gases, further enhancing thermal efficiency. Flue gas recirculation (FGR) systems are also being employed to reduce nitrogen oxide (NOx) emissions, aligning with tightening environmental regulations. Furthermore, the adoption of advanced materials in boiler construction improves durability and corrosion resistance, extending the operational lifespan and reducing maintenance frequency.

The most transformative technological trend is the widespread integration of digital technologies. IoT-enabled sensors provide real-time data on critical operating parameters, including temperature, pressure, flow rates, and flue gas composition. This data is fed into intelligent control systems and cloud-based platforms, enabling remote monitoring, predictive maintenance analytics, and automated fault detection. Such digitalization not only enhances operational reliability and safety but also empowers facility managers with actionable insights to optimize energy usage and reduce operational expenditures, making boilers smarter and more responsive to industrial demands.

Regional Highlights

- North America: This region represents a mature market characterized by stringent environmental regulations and a strong emphasis on upgrading aging infrastructure. Demand is primarily driven by replacement cycles and the adoption of more energy-efficient models to comply with energy performance standards and reduce operating costs. The focus is on integrating advanced controls and digital solutions for enhanced boiler performance.

- Europe: Europe is another developed market with a robust regulatory framework promoting energy efficiency and low emissions. The growth is fueled by the need for compliant boiler technologies, the expansion of district heating networks, and increasing investments in biomass and other renewable fuel-fired boilers as part of decarbonization strategies. Germany, the UK, and France are key contributors.

- Asia Pacific (APAC): The APAC region is a primary growth engine for the non-condensing low-temperature industrial boiler market, driven by rapid industrialization, urbanization, and significant investments in manufacturing sectors across countries like China, India, and Southeast Asian nations. The demand here is for new installations to support expanding industrial capacities, alongside a growing awareness of energy efficiency.

- Latin America: This region exhibits moderate growth, influenced by infrastructure development and the expansion of key industries such as food and beverage, and mining. Investments in modern boiler systems are aimed at improving operational efficiency and supporting industrial output, though economic volatility can sometimes impact market momentum. Brazil and Mexico are leading markets.

- Middle East and Africa (MEA): The MEA market is experiencing gradual growth, primarily spurred by investments in the oil and gas sector, petrochemicals, and various manufacturing projects. The demand for industrial boilers is linked to industrial diversification efforts and the need for reliable process heating in a region with abundant fossil fuel resources but also increasing interest in efficiency.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Non-Condensing Low Temperature Industrial Boiler Market.- Babcock & Wilcox Enterprises

- Siemens AG

- Cleaver-Brooks

- Fulton Boiler Works

- Miura Co. Ltd.

- Viessmann Group

- Bosch Industriekessel GmbH

- Clayton Industries

- Thermax Limited

- A.O. Smith Corporation

- Cochran Boilers

- Kawasaki Heavy Industries

- ATTSU

- Superior Boiler Works

- York-Shipley Global

- Weil-McLain

- Burnham Commercial

- Lochinvar LLC

- Vaillant Group

- Danfoss

Frequently Asked Questions

What are the primary benefits of non-condensing low-temperature industrial boilers?

The main benefits include lower initial capital costs, simpler design and operation, reduced maintenance requirements, and reliable heat supply for applications not needing high-temperature steam or where flue gas condensation is undesirable, making them cost-effective for specific industrial needs.

Which industries are the major end-users of these boilers?

Key end-user industries include food and beverage (for pasteurization, cooking, sterilization), pharmaceuticals (for process heating, drying), chemical processing, textile manufacturing, pulp and paper, and various light and heavy manufacturing sectors requiring consistent low-to-medium temperature thermal energy.

How do non-condensing boilers differ from condensing boilers?

Non-condensing boilers operate at temperatures above the flue gas dew point, preventing condensation and recovering sensible heat. Condensing boilers, conversely, recover latent heat from flue gas condensation, achieving higher efficiencies but requiring corrosion-resistant materials and higher return water temperatures.

What are the key drivers for market growth?

Market growth is primarily driven by global industrial expansion, the increasing demand for energy-efficient heating solutions, the replacement of aging boiler infrastructure, and the continuous need for reliable process heating in diverse manufacturing and processing industries worldwide.

How is energy efficiency improved in modern non-condensing boilers?

Modern non-condensing boilers enhance efficiency through advanced combustion control systems for optimal air-to-fuel ratios, integration of economizers for waste heat recovery, variable frequency drives for parasitic load reduction, and smart controls for load matching and real-time operational adjustments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager