Non-Glass Capacitive Sensors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430193 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Non-Glass Capacitive Sensors Market Size

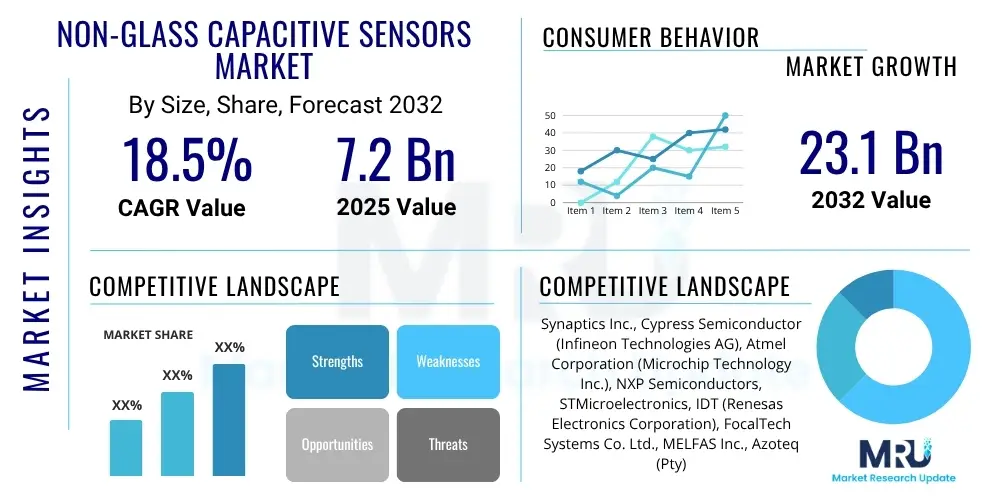

The Non-Glass Capacitive Sensors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at USD 7.2 Billion in 2025 and is projected to reach USD 23.1 Billion by the end of the forecast period in 2032. This robust growth is primarily driven by the increasing demand for flexible, durable, and highly responsive touch interfaces across a multitude of industries.

Non-Glass Capacitive Sensors Market introduction

The Non-Glass Capacitive Sensors Market encompasses a range of touch and proximity sensing technologies that utilize flexible, non-glass substrates such as polymer films, printed circuit boards (PCBs), or other synthetic materials. Unlike traditional glass-based capacitive sensors, these innovative solutions offer unparalleled flexibility, conformability, and ruggedness, making them ideal for applications where glass is impractical due to its brittleness, weight, or rigid form factor. These sensors detect changes in capacitance caused by the proximity of a conductive object, typically a human finger, enabling intuitive and responsive human-machine interaction. Their inherent adaptability allows for integration into complex, curved, or dynamic surfaces, opening up new design possibilities in product development.

Product descriptions of non-glass capacitive sensors highlight their construction using various flexible conductive materials and dielectric layers, often manufactured through advanced printing or roll-to-roll processes. Key materials include indium tin oxide (ITO) on PET film, silver nanowires, carbon nanotubes, and conductive polymers, all designed to offer excellent conductivity and optical clarity when required. Major applications span a wide array of sectors, including consumer electronics (wearables, flexible displays), automotive (in-cabin controls, touch surfaces), medical devices (wearable health monitors, diagnostic equipment), industrial automation (rugged HMIs), and smart home devices. The versatility of these sensors allows for creation of transparent, opaque, or even stretchable interfaces, adapting to diverse functional and aesthetic requirements.

The benefits derived from non-glass capacitive sensors are numerous, including enhanced durability against impact and shattering, significant weight reduction, superior form factor flexibility, and improved resistance to environmental factors like moisture and dust. These advantages are pivotal in driving market adoption, particularly in segments demanding robust and integrated solutions. Key driving factors for the market's expansion include the global trend towards device miniaturization, the escalating adoption of the Internet of Things (IoT), the surging demand for advanced human-machine interfaces (HMIs) in automotive and industrial sectors, and the rapid innovation in flexible electronics and smart textiles. The continuous evolution of material science and manufacturing processes further fuels the market's growth, enabling more cost-effective and high-performance sensor solutions.

Non-Glass Capacitive Sensors Market Executive Summary

The Non-Glass Capacitive Sensors Market is experiencing significant momentum, propelled by technological advancements and evolving consumer preferences for intuitive and durable electronic interfaces. The market's upward trajectory is underpinned by several key business trends, including the increasing integration of flexible sensors into next-generation smart devices, a heightened focus on creating seamless human-machine interfaces, and the widespread adoption of IoT across various verticals. Companies are investing heavily in research and development to enhance sensor performance, improve manufacturing efficiency, and explore new material compositions, striving for thinner, more robust, and highly sensitive solutions. This competitive landscape is fostering innovation, leading to a broader array of applications and an expanding market reach for non-glass technologies.

Regional trends indicate that Asia Pacific continues to be a dominant force in the non-glass capacitive sensors market, primarily due to its robust manufacturing base for consumer electronics and a rapidly growing automotive sector. Countries like China, South Korea, and Japan are at the forefront of adopting and developing these technologies. North America and Europe are also significant contributors, driven by strong R&D capabilities, a high demand for advanced automotive systems, sophisticated medical devices, and industrial automation solutions. Latin America and the Middle East & Africa regions are emerging as promising markets, demonstrating increasing adoption rates as industrialization and digitalization initiatives gain traction, particularly in smart cities and automotive advancements. These regional dynamics highlight a geographically diverse yet interconnected market landscape.

Segment trends within the non-glass capacitive sensors market reveal a strong emphasis on touch interfaces, including multi-touch and gesture recognition, as well as proximity sensing for touchless interactions. The consumer electronics segment, encompassing smartphones, tablets, wearables, and home appliances, remains a primary growth driver due to the continuous demand for sleek, durable, and advanced user experiences. The automotive sector is witnessing substantial growth with the integration of these sensors into infotainment systems, interior controls, and even exterior features for enhanced safety and design flexibility. Furthermore, the medical and industrial segments are increasingly adopting non-glass solutions for portable diagnostic devices, patient monitoring, and rugged industrial control panels, valuing their durability and hygienic properties. These segment-specific advancements are collectively shaping the market's overall growth and diversification.

AI Impact Analysis on Non-Glass Capacitive Sensors Market

The impact of Artificial Intelligence (AI) on the Non-Glass Capacitive Sensors Market is a critical area of interest for users, who frequently inquire about AI's potential to enhance sensor accuracy, enable predictive functionalities, and optimize data interpretation. Users are keen to understand how AI algorithms can process complex input patterns from these flexible sensors to deliver more intelligent and context-aware responses, particularly in advanced human-machine interfaces and IoT ecosystems. There is a strong expectation that AI will not only refine the user experience by making sensor interactions more intuitive but also contribute significantly to the manufacturing processes, improving calibration, quality control, and reducing production costs through intelligent automation.

AI's integration is transforming non-glass capacitive sensors by moving beyond simple touch detection to sophisticated pattern recognition, allowing for multi-modal sensing and improved noise cancellation. For instance, AI can differentiate between intentional touches and accidental brushes, or even interpret complex gestures, thereby expanding the functionality of these sensors in smart devices and automotive interiors. Furthermore, in industrial and medical applications, AI-driven analytics can provide real-time insights from sensor data, enabling predictive maintenance for equipment or advanced patient monitoring. This capability to derive deeper meaning from raw sensor data fundamentally elevates the value proposition of non-glass capacitive technologies, making them smarter, more reliable, and more adaptable to dynamic environments.

- Enhanced Data Interpretation: AI algorithms process complex sensor inputs to derive richer insights and patterns.

- Predictive Functionality: AI enables sensors to anticipate user actions or system needs, leading to proactive responses.

- Context-Aware Sensing: Facilitates understanding of environmental and user context for more intelligent interactions.

- Improved Human-Machine Interface (HMI): Enables advanced gesture recognition, haptic feedback integration, and personalized user experiences.

- Autonomous System Integration: Supports the development of self-regulating systems by providing intelligent sensory input.

- Manufacturing Optimization: AI assists in precision calibration, quality control, and defect detection during production, enhancing efficiency.

- Energy Efficiency: AI can optimize sensor operation cycles, leading to reduced power consumption in always-on applications.

DRO & Impact Forces Of Non-Glass Capacitive Sensors Market

The Non-Glass Capacitive Sensors Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and competitive impact forces. A primary driver is the accelerating demand for flexible and conformable electronic components, essential for the proliferation of wearable technology, flexible displays, and advanced automotive interiors. The continuous expansion of the Internet of Things (IoT) ecosystem also fuels market growth, as non-glass sensors offer the durability and slim form factors required for diverse connected devices. Advancements in material science, particularly in conductive polymers and thin-film technologies, have enabled the production of high-performance, cost-effective non-glass sensors, further stimulating their adoption across multiple industrial applications.

Despite the strong growth drivers, the market faces several restraints. The relatively higher manufacturing costs associated with advanced flexible substrates and specialized production processes, compared to traditional glass-based sensors, can deter adoption in price-sensitive segments. Technical complexities related to signal integrity, shielding, and integration into existing electronic architectures also present challenges for manufacturers and system integrators. Moreover, a lack of widespread standardization across different flexible sensor technologies can impede interoperability and slow down market penetration. These factors necessitate continuous innovation to reduce costs and simplify integration processes for broader market acceptance.

Significant opportunities exist within emerging applications such as smart textiles, implantable medical devices, and large-area interactive surfaces in commercial and public spaces. The increasing focus on creating more intuitive and aesthetically pleasing product designs also presents a fertile ground for non-glass sensors to thrive due to their design freedom. The competitive landscape is shaped by impact forces, including the bargaining power of buyers who demand customized and cost-effective solutions, and the bargaining power of suppliers providing specialized raw materials and manufacturing equipment. The threat of new entrants is moderate, driven by high R&D investments and intellectual property requirements, while the threat of substitutes, particularly from other sensing technologies like resistive or optical sensors, remains a continuous challenge, pushing non-glass sensor manufacturers to innovate consistently. Intense competitive rivalry among existing players, striving for technological leadership and market share, further defines the market's dynamic.

Segmentation Analysis

The Non-Glass Capacitive Sensors Market is comprehensively segmented to provide granular insights into its diverse components, aiding in targeted market strategies and understanding specific growth trajectories. This segmentation typically considers various parameters such as the type of substrate used, the specific application areas, the end-use industries leveraging these sensors, and the geographical regions where they are adopted. Such a detailed breakdown allows stakeholders to identify high-growth niches, assess competitive landscapes within distinct categories, and tailor product development to meet specific industry requirements, thus maximizing market potential and optimizing resource allocation. The market's heterogeneous nature necessitates a multi-dimensional approach to segmentation to capture its full scope.

Key segments by type often include film-based sensors, which utilize flexible polymer films like PET or PEN as substrates, and PCB-based sensors, where capacitive elements are integrated onto flexible printed circuit boards. Each type offers distinct advantages in terms of flexibility, durability, and integration complexity, catering to different performance and cost requirements. Application-wise, the market is broadly divided into categories such as touch sensing, proximity sensing, material sensing, and even gesture recognition. Touch sensing, covering single-touch and multi-touch capabilities, dominates much of the market due to its widespread use in user interfaces across consumer electronics and automotive infotainment systems. Proximity sensing is crucial for touchless controls and object detection, finding applications in industrial safety and smart home devices.

Further segmentation by end-use industry highlights the varied adoption across sectors. The consumer electronics segment is a primary driver, integrating non-glass capacitive sensors into smartphones, tablets, wearables, and smart appliances for intuitive user interaction. The automotive industry utilizes these sensors for interior controls, steering wheel integration, and advanced driver-assistance systems (ADAS) due to their robust and conformable nature. The medical sector employs them in wearable health monitors, diagnostic tools, and surgical equipment, valuing their hygiene and precise sensing capabilities. Industrial automation applications leverage their durability for human-machine interfaces (HMIs) and controls in harsh environments. Regional segmentation divides the market into major geographical areas, each with unique economic and technological drivers influencing market growth and demand patterns.

- By Type

- Film-based Capacitive Sensors

- PCB-based Capacitive Sensors

- Fabric/Textile-based Capacitive Sensors

- Flexible Hybrid Electronic (FHE) Capacitive Sensors

- By Application

- Touch Sensing (Single-touch, Multi-touch, Force Sensing)

- Proximity Sensing

- Gesture Recognition

- Material Sensing

- Level Sensing

- Humidity Sensing

- By End-Use Industry

- Consumer Electronics (Smartphones, Tablets, Wearables, Smart Appliances, Home Automation)

- Automotive (Infotainment Systems, Interior Controls, Steering Wheels, Exterior Sensors)

- Medical & Healthcare (Wearable Health Monitors, Diagnostic Devices, Surgical Tools, Patient Monitoring)

- Industrial (HMIs, Robotics, Process Control, Safety Systems)

- Aerospace & Defense

- Retail & Hospitality

- Smart Packaging

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Non-Glass Capacitive Sensors Market

The value chain for the Non-Glass Capacitive Sensors Market is a complex and interconnected network, beginning with the sourcing of specialized raw materials and extending to the final integration into end-user products. The upstream segment of the value chain involves critical suppliers of conductive materials such as silver nanowires, carbon nanotubes, indium tin oxide (ITO), and conductive polymers. These suppliers provide the foundational elements that dictate the performance and flexibility of the sensors. Additionally, manufacturers of flexible substrates like PET, PEN, polyimide, and various textile materials play a crucial role, as the choice of substrate directly impacts the sensor's physical properties and application suitability. This initial phase is characterized by significant R&D efforts in material science to achieve optimal conductivity, transparency, and durability.

Moving downstream, the midstream segment encompasses the core manufacturing and fabrication processes of the non-glass capacitive sensors. This involves specialized printing technologies such as screen printing, inkjet printing, and gravure printing, which are employed to deposit conductive patterns onto flexible substrates. Advanced photolithography and laser patterning techniques are also utilized for high-precision sensor designs. Sensor manufacturers then assemble these flexible layers, often integrating control electronics, connectors, and protective coatings. This stage requires significant expertise in microfabrication, material handling, and quality control to ensure the reliability and performance of the final sensor modules. Innovation in manufacturing processes is key to reducing costs and enabling mass production of complex sensor designs.

The final stage, the downstream segment, involves the distribution channels and the integration of these sensors into various end-user applications. Original Equipment Manufacturers (OEMs) in consumer electronics, automotive, medical, and industrial sectors are the primary buyers, integrating non-glass capacitive sensors into their products to create advanced user interfaces. Distribution channels can be direct, where sensor manufacturers sell directly to large-scale OEMs requiring customized solutions and extensive technical support. Indirect channels involve distributors and value-added resellers who cater to smaller businesses or provide off-the-shelf sensor components. The choice of channel often depends on the scale of the customer, the complexity of the sensor solution, and the geographical reach required. The increasing trend towards direct engagement with OEMs for highly specialized and integrated solutions highlights the importance of close collaboration throughout the value chain.

Non-Glass Capacitive Sensors Market Potential Customers

The Non-Glass Capacitive Sensors Market caters to a broad spectrum of potential customers, primarily comprising Original Equipment Manufacturers (OEMs) across various high-growth industries. These end-users are continually seeking innovative, durable, and highly integrated sensing solutions to enhance product functionality, user experience, and aesthetic appeal. Key buyers are typically product development teams and procurement departments within manufacturing companies that value the unique advantages of non-glass capacitive sensors, such as their flexibility, slim form factor, and robustness, which glass-based alternatives cannot offer. The diverse application possibilities mean that customer needs vary significantly, ranging from simple touch buttons to complex multi-touch surfaces with haptic feedback, necessitating a versatile product offering from sensor manufacturers.

In the consumer electronics segment, potential customers include manufacturers of smartphones, smartwatches, fitness trackers, smart home appliances, and various other portable devices. These companies are driven by the need for sleek designs, improved durability against drops, water resistance, and advanced interactive capabilities like gesture control and seamless integration into flexible displays. The automotive industry represents another substantial customer base, with vehicle manufacturers and Tier 1 suppliers seeking non-glass sensors for interior controls, infotainment systems, steering wheel interfaces, and even exterior sensing applications. Their motivations stem from a desire for modern vehicle aesthetics, reduced weight, enhanced safety features, and robust components that can withstand demanding environmental conditions within a vehicle cabin.

Beyond consumer and automotive, the medical and industrial sectors are increasingly vital potential customers. Medical device manufacturers are adopting non-glass capacitive sensors for wearable health monitors, diagnostic equipment, and surgical instruments, valuing their hygienic properties, comfort for patients, and precision. In industrial automation, manufacturers of machinery, control panels, and robotics are integrating these sensors for robust human-machine interfaces (HMIs) that can endure harsh operational environments, offering resistance to chemicals, dust, and vibrations. Other emerging customer segments include smart packaging, smart textiles, and aerospace industries, all seeking flexible, lightweight, and high-performance sensing solutions to drive innovation in their respective product lines and address unique operational challenges.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 7.2 Billion |

| Market Forecast in 2032 | USD 23.1 Billion |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Synaptics Inc., Cypress Semiconductor (Infineon Technologies AG), Atmel Corporation (Microchip Technology Inc.), NXP Semiconductors, STMicroelectronics, IDT (Renesas Electronics Corporation), FocalTech Systems Co. Ltd., MELFAS Inc., Azoteq (Pty) Ltd., Cirque Corporation, ELAN Microelectronics Corporation, Samsung Electro-Mechanics, Interlink Electronics, TDK Corporation, Alps Alpine Co. Ltd., General Electric, Texas Instruments, Eaton Corporation, Hoffmann + Krippner GmbH, Molex LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Non-Glass Capacitive Sensors Market Key Technology Landscape

The technology landscape for the Non-Glass Capacitive Sensors Market is characterized by continuous innovation across material science, manufacturing processes, and integration methodologies. At its core, the advancement of flexible conductive materials such as silver nanowires, carbon nanotubes, conductive polymers, and thin-film ITO replacements is paramount. These materials enable the creation of highly transparent, stretchable, and durable sensor electrodes that can be seamlessly integrated into various non-rigid substrates. The development of new dielectric materials with improved properties for sensitivity and noise reduction is also a significant area of focus. These material innovations are critical for achieving the high performance and reliability required in demanding applications where traditional glass sensors fall short.

Manufacturing technologies play an equally crucial role, with advancements in roll-to-roll (R2R) printing, inkjet printing, and screen printing enabling cost-effective and high-volume production of flexible sensor arrays. These printing methods facilitate precise patterning of conductive inks and pastes onto polymer films, offering significant advantages in terms of scalability and design flexibility. Furthermore, sophisticated signal processing algorithms and integrated circuit (IC) designs are essential for translating raw capacitance changes into accurate touch, proximity, or gesture data. Technologies for multi-touch recognition, force sensing, and haptic feedback integration are continually evolving, enhancing the user experience and expanding the functional capabilities of non-glass capacitive sensors beyond basic interaction to more immersive and intuitive interfaces.

Looking ahead, the technological landscape is moving towards the integration of non-glass capacitive sensors with Flexible Hybrid Electronics (FHE) and stretchable electronics, allowing for their embedding into fabrics, biomedical implants, and complex curved surfaces. Low-power consumption designs are also critical, particularly for battery-operated wearables and IoT devices, driving innovations in power management ICs and energy-harvesting solutions. The confluence of these technologies with Artificial Intelligence (AI) and machine learning (ML) is paving the way for context-aware sensing, predictive functionalities, and enhanced data analytics, making non-glass capacitive sensors more intelligent and adaptable. This ongoing technological evolution is not only expanding the application scope but also improving the performance, durability, and cost-effectiveness of these versatile sensors.

Regional Highlights

- North America: This region is a significant market for non-glass capacitive sensors, driven by robust R&D activities, the early adoption of advanced technologies, and a strong presence of key players in the automotive and medical device industries. The demand for flexible and durable HMIs in automotive interiors, coupled with the rapid innovation in wearable health technologies, fuels market growth. High consumer disposable income also contributes to the demand for premium consumer electronics incorporating these advanced sensors. The United States, in particular, leads in developing and integrating cutting-edge sensor technologies into a wide array of products.

- Europe: Characterized by stringent regulatory standards and a strong focus on industrial automation and high-end automotive manufacturing, Europe presents a substantial market. Countries like Germany, France, and the UK are pioneers in smart factory initiatives and advanced medical equipment, where the durability and precision of non-glass capacitive sensors are highly valued. The region is also a hub for design-conscious consumer electronics, driving the demand for aesthetically pleasing and functionally superior touch interfaces. Sustainable manufacturing practices and eco-friendly material development also influence the market here.

- Asia Pacific (APAC): APAC dominates the global non-glass capacitive sensors market, primarily due to its position as a global manufacturing hub for consumer electronics. Countries such as China, South Korea, Japan, and Taiwan are at the forefront of producing smartphones, tablets, and wearables, extensively utilizing non-glass sensors. Rapid urbanization, increasing disposable income, and the expansion of the automotive and industrial sectors further contribute to market growth. Significant investments in infrastructure development and the widespread adoption of IoT technologies are also propelling the demand for these flexible sensing solutions in the region.

- Latin America: While an emerging market, Latin America shows promising growth, driven by increasing industrialization, rising consumer electronics adoption, and a burgeoning automotive manufacturing sector, especially in countries like Brazil and Mexico. The demand for cost-effective yet durable sensing solutions in these developing economies is boosting the adoption of non-glass technologies. Investments in smart city initiatives and public infrastructure upgrades are also opening new avenues for flexible sensor applications. The market here is still developing but poised for considerable expansion.

- Middle East & Africa (MEA): This region is experiencing steady growth in the non-glass capacitive sensors market, largely influenced by economic diversification efforts and significant investments in infrastructure, smart buildings, and technologically advanced industries. Countries in the GCC region are focusing on developing high-tech sectors, including automotive and smart cities, which require sophisticated and robust HMI solutions. The growing healthcare sector and increasing consumer adoption of smart devices also contribute to the rising demand, though market penetration is still relatively nascent compared to other regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Non-Glass Capacitive Sensors Market.- Synaptics Inc.

- Cypress Semiconductor (Infineon Technologies AG)

- Atmel Corporation (Microchip Technology Inc.)

- NXP Semiconductors

- STMicroelectronics

- IDT (Renesas Electronics Corporation)

- FocalTech Systems Co. Ltd.

- MELFAS Inc.

- Azoteq (Pty) Ltd.

- Cirque Corporation

- ELAN Microelectronics Corporation

- Samsung Electro-Mechanics

- Interlink Electronics

- TDK Corporation

- Alps Alpine Co. Ltd.

- General Electric

- Texas Instruments

- Eaton Corporation

- Hoffmann + Krippner GmbH

- Molex LLC

Frequently Asked Questions

What are non-glass capacitive sensors?

Non-glass capacitive sensors are advanced sensing devices that utilize flexible, non-rigid substrates like polymer films, PCBs, or textiles instead of traditional glass. They detect changes in capacitance caused by proximity or touch, offering benefits such as flexibility, durability, and a lightweight form factor. These sensors are ideal for applications requiring conformable and robust interfaces that cannot accommodate brittle glass.

What are the primary advantages of non-glass capacitive sensors over traditional glass-based sensors?

The main advantages include superior flexibility and conformability, allowing integration into curved or irregular surfaces. They offer enhanced durability, being shatterproof and more resistant to impact, scratches, and harsh environments. Additionally, non-glass sensors are typically lighter and thinner, facilitating product miniaturization and innovative design aesthetics in various electronic devices.

In which industries are non-glass capacitive sensors most commonly used?

Non-glass capacitive sensors find extensive use across several industries. Key sectors include consumer electronics (smartphones, wearables, smart home devices), automotive (in-cabin controls, infotainment systems), medical and healthcare (wearable health monitors, diagnostic tools), and industrial automation (rugged human-machine interfaces and control panels).

How does AI enhance the functionality of non-glass capacitive sensors?

AI significantly enhances sensor functionality by enabling advanced data interpretation, leading to more accurate gesture recognition and context-aware sensing. It facilitates predictive maintenance, optimizes sensor performance, and improves noise cancellation. AI also supports the development of more intelligent and autonomous systems by processing complex sensory inputs for refined human-machine interactions and efficient manufacturing processes.

What are the key technological advancements driving the non-glass capacitive sensor market?

Key technological advancements include innovations in flexible conductive materials (e.g., silver nanowires, carbon nanotubes), advanced printing and roll-to-roll manufacturing processes for cost-effective production, and sophisticated signal processing algorithms. Furthermore, developments in flexible hybrid electronics (FHE) and low-power designs, coupled with the integration of AI and machine learning, are crucial drivers for market growth and expanded application possibilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager