Nuclear Robots Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429456 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Nuclear Robots Market Size

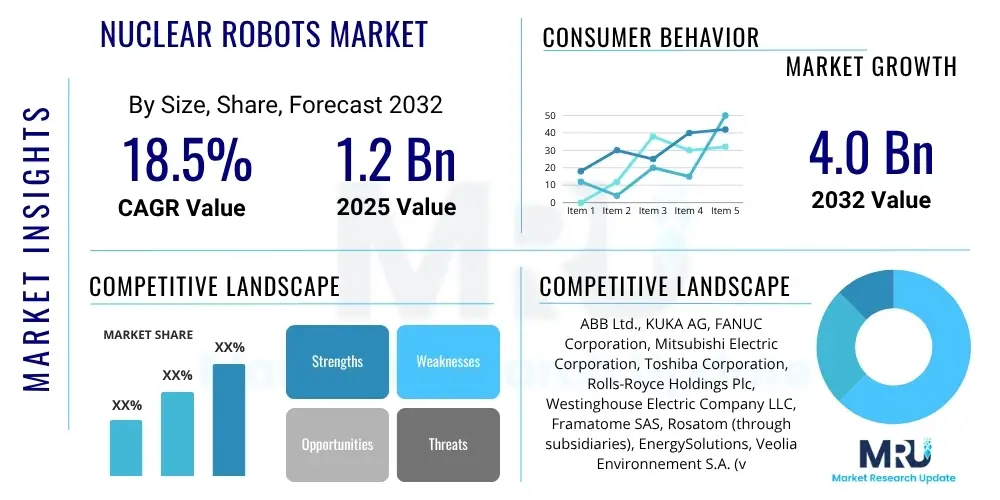

The Nuclear Robots Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at USD 1.2 Billion in 2025 and is projected to reach USD 4.0 Billion by the end of the forecast period in 2032.

Nuclear Robots Market introduction

The Nuclear Robots Market encompasses the design, development, and deployment of robotic systems specifically engineered to operate in hazardous nuclear environments. These robots are crucial for enhancing safety, improving efficiency, and reducing human exposure to radiation during various stages of the nuclear lifecycle, including power generation, decommissioning, waste management, and research. Their robust construction, often incorporating radiation-hardened components and specialized sensors, allows them to perform tasks that are dangerous, difficult, or impossible for human workers.

Product descriptions within this market range from highly articulated robotic arms designed for precise manipulation of radioactive materials to autonomous mobile robots capable of extensive inspection, surveillance, and monitoring across vast nuclear facilities. Key benefits include minimizing occupational hazards, enabling continuous operations in high-radiation zones, facilitating remote and intricate repairs, and ultimately contributing to the overall integrity and safety of nuclear installations. The market is experiencing significant growth, driven by an aging global nuclear infrastructure requiring extensive maintenance and decommissioning, alongside the construction of new nuclear power plants and the increasing adoption of advanced automation technologies. These robotic solutions provide an indispensable tool for managing the inherent risks associated with nuclear energy, ensuring compliance with stringent safety regulations and operational excellence.

Major applications of nuclear robots include routine inspection of reactor vessels and spent fuel pools, remote maintenance and repair of contaminated equipment, critical tasks in nuclear decommissioning, advanced handling of radioactive waste, and security surveillance in sensitive areas. The primary driving factors for market expansion include the imperative for enhanced worker safety, the prohibitive costs and risks associated with human intervention in contaminated areas, technological advancements in robotics and artificial intelligence, and a growing global emphasis on sustainable energy sources that include nuclear power, despite its challenges. As nuclear facilities worldwide continue to operate and new technologies such as Small Modular Reactors (SMRs) emerge, the demand for sophisticated and reliable nuclear robotic solutions is expected to intensify, solidifying their role as essential assets in the nuclear industry.

Nuclear Robots Market Executive Summary

The Nuclear Robots Market is experiencing dynamic growth, propelled by a confluence of business trends, evolving regional demands, and significant segmental advancements. Business trends highlight a strong shift towards automation and remote operations to mitigate radiation exposure and improve operational efficiency in nuclear power plants, waste management facilities, and decommissioning sites. There is a growing emphasis on developing versatile, modular, and collaborative robotic systems that can adapt to diverse and unpredictable nuclear environments, minimizing downtime and human intervention. Furthermore, the integration of artificial intelligence and machine learning is revolutionizing robotic capabilities, enabling predictive maintenance, autonomous navigation, and sophisticated data analysis, which are crucial for enhancing safety and reducing operational costs across the nuclear lifecycle. The market is also seeing increased investment in research and development aimed at improving radiation hardening, power longevity, and dexterity of robotic platforms, indicating a robust innovation pipeline.

Regional trends reveal distinct market drivers across different geographies. Asia Pacific is poised for substantial growth due to a surge in new nuclear power plant constructions, particularly in China and India, alongside modernization efforts in existing facilities, driving demand for inspection, maintenance, and security robots. North America and Europe, while having fewer new builds, present significant opportunities in nuclear decommissioning, waste management, and the long-term maintenance of aging infrastructure, necessitating advanced robotic solutions for hazardous tasks. These regions are also leading in the adoption of advanced research and development initiatives for next-generation nuclear robotics, driven by stringent regulatory frameworks and a focus on environmental safety. Latin America, the Middle East, and Africa are gradually expanding their nuclear energy programs, albeit at a slower pace, creating emerging markets for specialized nuclear robotic services and technologies as they prioritize safe and efficient operations.

Segmental trends indicate robust expansion in remote operated vehicles (ROVs) and autonomous mobile robots (AMRs) for tasks such as visual inspection, radiation mapping, and environmental monitoring. The maintenance and repair segment is witnessing high demand for articulated robotic arms and specialized manipulators capable of performing intricate tasks in confined and high-radiation spaces. Decommissioning and waste management applications are driving innovation in heavy-duty demolition robots and specialized material handling systems, designed to safely dismantle and process contaminated structures. Moreover, security and surveillance applications are increasingly utilizing drones and ground-based autonomous robots equipped with advanced sensors for perimeter monitoring and threat detection within nuclear facilities. The market is also seeing a rise in demand for hybrid solutions that combine multiple functionalities, catering to the complex and multifaceted requirements of the nuclear industry and fostering specialized service providers.

AI Impact Analysis on Nuclear Robots Market

The integration of Artificial Intelligence (AI) into the Nuclear Robots Market is a transformative force, directly addressing core concerns such as safety, operational efficiency, and the reduction of human error. Common user questions frequently revolve around how AI can enhance the autonomy and reliability of robots in highly hazardous environments, the potential for AI-driven predictive maintenance to prevent costly outages, and the ethical implications of autonomous decision-making in critical nuclear operations. Users are keen to understand if AI can significantly minimize human exposure to radiation, whether it can improve data analysis for faster incident response, and how cybersecurity risks associated with AI-enabled systems are being mitigated. There is a clear expectation that AI will unlock new levels of precision, speed, and analytical capability for nuclear robots, while also raising concerns about the need for robust verification, validation, and human oversight mechanisms to ensure ultimate safety and regulatory compliance.

AI's influence is primarily seen in its ability to enable more sophisticated perception, reasoning, and autonomous action for nuclear robots. By processing vast amounts of sensor data, AI algorithms can perform real-time anomaly detection, identify potential equipment failures before they occur, and optimize task execution paths to minimize energy consumption and operational time. This capability extends beyond basic automation, allowing robots to adapt to unpredictable environmental changes, navigate complex layouts without direct human input, and even learn from previous missions to improve future performance. The focus is on creating intelligent robotic systems that can augment human capabilities, providing critical insights and performing high-risk tasks with unparalleled accuracy and consistency. This augmentation not only elevates safety standards but also significantly enhances the overall operational effectiveness and longevity of nuclear facilities, making them more resilient to unforeseen challenges.

The key themes emerging from user inquiries underscore a strong demand for AI to provide advanced analytical capabilities, automate complex decision-making processes, and ensure the integrity and security of nuclear operations. While the benefits of AI in terms of enhanced safety, predictive power, and operational efficiency are widely acknowledged, there are also legitimate concerns regarding the robustness of AI algorithms, the potential for cyber vulnerabilities, and the regulatory frameworks required to govern truly autonomous systems in such critical infrastructure. The industry is actively working towards striking a balance between leveraging AI's transformative potential and ensuring fail-safe operations, robust human-in-the-loop protocols, and stringent testing methodologies to build confidence in these advanced robotic solutions. This ensures that AI serves as a powerful tool to complement, rather than replace, human expertise and oversight in the nuclear domain.

- Enhanced autonomous navigation and path planning in complex, confined, and hazardous environments.

- Predictive maintenance capabilities through AI-driven data analysis, identifying equipment anomalies before failure.

- Real-time anomaly detection and decision support for operators, improving incident response and safety.

- Optimized task execution and manipulation for precise repairs and handling of radioactive materials.

- Improved data fusion from multiple sensors (visual, thermal, radiation) for comprehensive situational awareness.

- Machine learning for pattern recognition in inspection data, reducing human fatigue and improving accuracy.

- Development of digital twins for simulation, testing, and training of AI-powered robotic systems.

- Increased efficiency in waste sorting and categorization using AI-driven visual recognition.

- Augmented human-robot collaboration through intuitive interfaces and shared autonomy.

- Enhanced cybersecurity measures for AI systems to prevent unauthorized access or manipulation.

DRO & Impact Forces Of Nuclear Robots Market

The Nuclear Robots Market is shaped by a critical interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include the paramount need to enhance safety and reduce human exposure to hazardous radiation, an aging global nuclear infrastructure demanding frequent inspection and maintenance, and a persistent shortage of skilled human labor willing to work in such dangerous conditions. Furthermore, the continuous advancements in robotics, sensor technology, and artificial intelligence are enabling robots to perform increasingly complex and delicate tasks with greater precision and reliability, making them indispensable tools. The growing global emphasis on clean energy, which includes nuclear power as a low-carbon option, also indirectly fuels investment in technologies that improve the safety and efficiency of nuclear operations, thereby boosting the demand for specialized robots.

However, significant restraints temper the market's growth trajectory. The high initial capital investment required for developing, purchasing, and deploying radiation-hardened robotic systems is a considerable barrier, especially for smaller operators. The inherently complex and stringent regulatory frameworks governing nuclear facilities impose lengthy certification processes and design constraints, increasing time-to-market and development costs. Technical challenges such as designing robots capable of sustained operation in high-radiation fields, ensuring reliable power sources for extended missions, developing sophisticated dexterity for intricate tasks, and guaranteeing secure communication in electromagnetically noisy environments remain significant hurdles. Public perception concerns regarding the safety and security of nuclear energy can also indirectly impact investment and adoption rates for related technologies, including robotics.

Despite these challenges, substantial opportunities exist within the market. The massive undertaking of nuclear decommissioning, particularly for older power plants worldwide, represents a long-term, high-value application for heavy-duty and specialized demolition robots. The emergence of Small Modular Reactors (SMRs) and advanced reactor designs offers new avenues for integrated robotic systems designed for their unique operational and maintenance requirements. Innovation in advanced nuclear waste management, including sorting, packaging, and long-term storage, is another fertile ground for robotic solutions. Moreover, the increasing integration of AI, machine learning, and digital twin technologies promises to unlock new levels of autonomy, predictive capabilities, and cost-effectiveness for nuclear robots, broadening their scope and making them more attractive investments. The increasing demand for enhanced security and surveillance in nuclear facilities also presents a continuous opportunity for autonomous monitoring robots.

Segmentation Analysis

The Nuclear Robots Market is comprehensively segmented to provide a detailed understanding of its diverse components and applications. This segmentation allows for targeted analysis of growth areas, technological preferences, and end-user demands, reflecting the multifaceted nature of robotic deployment in nuclear environments. The market is primarily categorized by the type of robot, its operational modality, the specific application it serves, and the end-user industry, each playing a crucial role in defining market dynamics and investment priorities. Understanding these distinctions is vital for stakeholders to identify niches, develop tailored solutions, and capitalize on emerging trends across the nuclear sector.

Each segment within the market responds to distinct functional requirements and technological advancements. For instance, the type of robot often dictates its mobility and reach, with wheeled and tracked robots excelling in ground-based inspection, while aerial and underwater robots provide unique perspectives for difficult-to-reach areas. The operational segmentation highlights the shift towards greater autonomy, driven by AI and advanced control systems, which directly impacts safety and efficiency. Furthermore, the application-based segmentation clearly delineates the critical roles robots play across the nuclear lifecycle, from routine monitoring to complex decommissioning activities, illustrating the broad utility and indispensable nature of these specialized machines. This granular view facilitates strategic planning and resource allocation for both manufacturers and end-users, ensuring that robotic solutions are precisely aligned with specific industry needs and regulatory mandates.

- By Type

- Wheeled Robots

- Legged Robots

- Tracked Robots

- Aerial Robots (Drones)

- Underwater Robots (ROVs)

- Articulated Robotic Arms

- Hybrid Systems

- By Operation

- Remote Operated (Teleoperated)

- Semi-Autonomous

- Autonomous

- By Application

- Inspection and Monitoring

- Maintenance and Repair

- Decommissioning and Dismantling

- Waste Management and Handling

- Security and Surveillance

- Fuel Handling

- Sampling and Characterization

- By End-User

- Nuclear Power Plants

- Nuclear Waste Storage Facilities

- Research and Development Facilities

- Defense and Homeland Security

- Medical Isotope Production Facilities

- By Component

- Hardware (Robotic Arms, Mobile Platforms, Sensors, Actuators, Cameras, End-Effectors)

- Software (Control Systems, AI/ML Algorithms, Data Analytics, Navigation Software)

- Services (Integration, Maintenance, Training, Decommissioning Services)

Value Chain Analysis For Nuclear Robots Market

The value chain for the Nuclear Robots Market is a complex ecosystem, starting from the foundational research and development of specialized components to the ultimate deployment and maintenance of sophisticated robotic systems in hazardous environments. Upstream activities are critical, involving a highly specialized network of suppliers providing radiation-hardened electronics, advanced sensors, robust actuators, specialized materials capable of withstanding extreme conditions, and high-performance computing units. These components are often custom-designed to meet the stringent requirements of nuclear applications, demanding significant R&D investment and expertise in radiation physics and materials science. Software developers also play a vital upstream role, creating intricate control algorithms, AI and machine learning frameworks for autonomous operations, and data analytics platforms essential for the robots' functionality and intelligence.

Midstream activities involve the core manufacturing and assembly of the robotic systems, where these specialized components are integrated into fully functional robots, including mobile platforms, articulated arms, and custom end-effectors. This stage often includes extensive testing for radiation tolerance, mechanical durability, and software reliability to ensure compliance with nuclear safety standards. Downstream activities focus on the delivery, integration, and ongoing support of these robots. This involves system integrators who customize and deploy robots for specific nuclear facilities, service providers offering specialized operational and maintenance support, and training programs to ensure end-users can effectively operate and manage their robotic assets. The success of these downstream functions hinges on strong collaboration between manufacturers, integrators, and nuclear operators to ensure seamless integration into existing infrastructure and operational protocols.

Distribution channels in the Nuclear Robots Market are highly specialized, typically involving direct sales from manufacturers to nuclear facility operators or government agencies due to the bespoke nature and high value of these systems. Partnerships with established nuclear engineering firms or specialized robotics integrators are common, leveraging their existing relationships and expertise within the nuclear sector. Indirect channels might include long-term service contracts where a third-party provider deploys and manages a fleet of robots for a nuclear facility, effectively leasing the robotic capabilities rather than selling the hardware outright. The entire value chain emphasizes rigorous quality control, regulatory compliance, and a deep understanding of nuclear safety culture, underscoring the high-stakes environment in which these advanced robotic solutions operate. Both direct engagement and strategic indirect collaborations are essential for penetrating this niche yet critical market.

Nuclear Robots Market Potential Customers

The primary potential customers and end-users for nuclear robots are institutions and organizations operating within or closely associated with the nuclear energy sector, where the need for enhanced safety, efficiency, and remote operation is paramount. Nuclear power plant operators constitute the largest segment of potential buyers, as they continuously require sophisticated robotic systems for routine inspections, preventative maintenance, emergency response, and security surveillance within their operational facilities. Their demand is driven by the imperative to minimize human exposure to radiation, comply with stringent international safety regulations, and optimize operational continuity and asset longevity. These customers seek highly reliable, precision-engineered robots capable of performing complex tasks in contaminated and hazardous zones, thereby reducing operational risks and long-term costs associated with human labor in dangerous environments.

Beyond active power generation, nuclear waste storage and processing facilities represent a significant customer base. These entities require specialized robots for the safe handling, sorting, packaging, and long-term monitoring of radioactive waste, which often involves highly contaminated and complex materials. Robots are crucial here for reducing human intervention in areas with sustained high radiation levels, ensuring secure containment, and facilitating efficient waste management processes. The long-term nature of nuclear waste management translates into a continuous demand for robust, durable, and adaptable robotic solutions that can operate for decades, performing tasks that are inherently too dangerous or impractical for human workers to undertake directly. This segment emphasizes the need for systems with advanced manipulation capabilities and autonomous navigation in unstructured or changing environments.

Furthermore, government agencies involved in nuclear decommissioning, defense, and homeland security also stand as key potential customers. Decommissioning projects for retired nuclear facilities or former weapons sites demand heavy-duty, often custom-built, robotic systems for dismantling, decontamination, and waste removal, where human access is severely restricted. Defense ministries utilize nuclear robots for managing and securing nuclear stockpiles, inspecting reactors on naval vessels, and responding to nuclear emergencies. Research and development facilities, including national laboratories and academic institutions conducting nuclear physics or materials science research, also employ specialized robots for handling radioactive samples, performing experiments in hot cells, and developing new nuclear technologies. These diverse applications underscore the broad utility and indispensable nature of robotic technology across the entire nuclear ecosystem, making these entities prime targets for manufacturers and service providers in the nuclear robotics market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.2 Billion |

| Market Forecast in 2032 | $4.0 Billion |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., KUKA AG, FANUC Corporation, Mitsubishi Electric Corporation, Toshiba Corporation, Rolls-Royce Holdings Plc, Westinghouse Electric Company LLC, Framatome SAS, Rosatom (through subsidiaries), EnergySolutions, Veolia Environnement S.A. (via Kurion), Mirion Technologies Inc., Boston Dynamics, Sarcos Technology and Robotics Corporation, iRobot Corporation, Gecko Robotics Inc., OC Robotics, Kraft TeleRobotics, General Atomics, Lockheed Martin Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Nuclear Robots Market Key Technology Landscape

The Nuclear Robots Market is underpinned by a sophisticated array of advanced technologies designed to overcome the unique challenges of nuclear environments. Central to this landscape is radiation hardening, which involves engineering electronic components, materials, and systems to withstand intense ionizing radiation without degradation, ensuring prolonged operational life and reliability in highly contaminated zones. Alongside this, advanced sensor fusion capabilities are critical, integrating data from various sensor types such as LiDAR, ultrasonic, thermal, chemical, and radiological detectors to create a comprehensive understanding of the robot's surroundings and the specific hazards present. This multi-modal sensing allows for precise navigation, obstacle avoidance, and accurate identification of radioactive sources, even in visually obscured or complex environments. The development of robust, high-bandwidth, and secure communication systems, often incorporating fiber optics or shielded wireless protocols, is also vital for maintaining reliable remote control and data transfer over long distances, preventing signal degradation in electromagnetically challenging nuclear facilities.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is rapidly transforming the operational capabilities of nuclear robots, moving them towards greater autonomy and intelligence. AI algorithms enable sophisticated autonomous navigation, allowing robots to self-localize, map environments, and plan optimal paths without continuous human intervention, especially beneficial in areas with restricted access. ML powers predictive maintenance routines, where robots analyze operational data to anticipate component failures, thereby reducing downtime and preventing costly incidents. Furthermore, advanced manipulation capabilities, involving dexterous robotic grippers and specialized end-effectors with force feedback systems, are crucial for performing intricate tasks like valve turning, cable cutting, or delicate sample collection, mimicking human precision while maintaining a safe distance. These technologies are continually evolving, pushing the boundaries of what robots can achieve in previously inaccessible or highly hazardous nuclear zones, significantly augmenting human capacity and safety protocols.

Beyond these core elements, other crucial technologies include modular design principles, which allow robots to be easily reconfigured or repaired by swapping out components, enhancing versatility and reducing maintenance complexity. Digital twin technology is increasingly employed, creating virtual replicas of nuclear facilities and robotic systems to simulate missions, test new algorithms, and train operators in a safe, controlled environment before real-world deployment. Swarm robotics, while still nascent, holds promise for coordinating multiple simpler robots to perform distributed sensing or collaborative tasks more efficiently. Non-destructive testing (NDT) techniques, integrated directly into robotic platforms, enable real-time assessment of structural integrity and material conditions without damaging components. These technological advancements collectively contribute to making nuclear robots more robust, intelligent, and capable, cementing their indispensable role in ensuring the safety, efficiency, and long-term sustainability of the global nuclear industry, addressing challenges from operational maintenance to complex decommissioning efforts.

Regional Highlights

- North America: The North American market, particularly the United States and Canada, demonstrates strong demand for nuclear robots driven primarily by the ongoing maintenance and life extension of aging nuclear power plants, as well as significant investments in nuclear decommissioning projects. The region is also a hub for technological innovation, with active research into advanced robotics, AI, and remote-controlled systems for nuclear applications. The emergence of Small Modular Reactor (SMR) development programs creates new opportunities for specialized robotic systems designed for their unique modularity and operational profiles. Stringent regulatory frameworks and a high emphasis on worker safety further accelerate the adoption of robotic solutions to minimize human exposure to radiation and improve operational efficiency.

- Europe: Europe represents a mature market with a substantial installed base of nuclear reactors, many of which are nearing the end of their operational lifespans or are undergoing decommissioning. This scenario makes Europe a leading region for nuclear decommissioning robotics and waste management solutions. Countries like the UK, France, and Germany are at the forefront of developing and deploying advanced robotic systems for dismantling, waste characterization, and hazardous material handling. Furthermore, strong regulatory bodies and public scrutiny over nuclear safety drive continuous innovation and investment in robotic technologies that enhance safety and environmental protection. Research collaborations and cross-border initiatives also contribute to technological advancements and widespread adoption across the continent.

- Asia Pacific (APAC): The Asia Pacific region is projected to be the fastest-growing market for nuclear robots, primarily fueled by extensive new nuclear power plant construction programs in countries such as China, India, and South Korea. Rapid industrialization and increasing energy demand are driving significant investments in nuclear energy infrastructure, consequently boosting the demand for robots for construction assistance, routine inspection, maintenance, and security surveillance. Japan, with its experience in post-Fukushima cleanup and decommissioning, also contributes to the market through specialized robotics research and deployment for disaster recovery and complex hazardous environments. The region's proactive approach to adopting advanced technologies and scaling industrial automation further supports market expansion.

- Latin America: The Latin American nuclear robots market is in its nascent stage but shows potential for growth, particularly in countries like Argentina and Brazil, which have established nuclear energy programs. The demand is primarily focused on inspection, maintenance, and security applications for existing reactors. As these nations look to expand their nuclear energy capabilities or address aging infrastructure, the adoption of robotic solutions for safety and efficiency is expected to increase. Strategic partnerships and technology transfers from more developed nuclear regions will be crucial for the market's evolution in Latin America.

- Middle East and Africa (MEA): The MEA region is emerging as a significant market, driven by strategic investments in nuclear energy infrastructure, particularly in the UAE (Barakah Nuclear Power Plant) and Saudi Arabia, as part of their diversification from fossil fuels. These new plants require state-of-the-art robotic systems for operational monitoring, maintenance, and security from their inception. As nuclear energy programs develop, the demand for specialized robots for inspection, fuel handling, and waste management will grow. The region's focus on adopting advanced technologies to ensure the highest safety standards in its nascent nuclear industry creates a strong pull for sophisticated robotic solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Nuclear Robots Market.- ABB Ltd.

- KUKA AG

- FANUC Corporation

- Mitsubishi Electric Corporation

- Toshiba Corporation

- Rolls-Royce Holdings Plc

- Westinghouse Electric Company LLC

- Framatome SAS

- Rosatom (through subsidiaries such as Atomenergomash)

- EnergySolutions

- Veolia Environnement S.A. (via its subsidiary Kurion)

- Mirion Technologies Inc.

- Boston Dynamics (indirectly through advanced mobile platforms)

- Sarcos Technology and Robotics Corporation

- iRobot Corporation (historically involved in defense/industrial robots)

- Gecko Robotics Inc.

- OC Robotics (now part of GE Inspection Robotics)

- Kraft TeleRobotics

- General Atomics

- Lockheed Martin Corporation (defense and advanced tech applications)

Frequently Asked Questions

What are Nuclear Robots and what do they do?

Nuclear robots are specialized robotic systems designed to operate in highly hazardous nuclear environments, including areas with high radiation levels, extreme temperatures, or confined spaces. They perform critical tasks such as inspection, maintenance, repair, decommissioning, waste handling, and security surveillance, significantly reducing human exposure to radiation and enhancing safety and efficiency in nuclear facilities.

How does AI impact the safety of nuclear operations with robots?

AI significantly enhances the safety of nuclear operations by enabling robots to perform advanced tasks autonomously or semi-autonomously, reducing the need for human presence in dangerous zones. AI-driven predictive maintenance can identify potential equipment failures before they occur, while enhanced navigation and anomaly detection improve response times to incidents, thereby preventing accidents and minimizing risks.

What are the main applications of robots in nuclear facilities?

The main applications of robots in nuclear facilities include routine inspection of reactor components, remote maintenance and repair of contaminated equipment, critical tasks in nuclear decommissioning and dismantling, safe handling and processing of radioactive waste, and continuous security surveillance and monitoring of sensitive areas. They also assist in fuel handling and sampling procedures.

What are the key challenges in developing and deploying nuclear robots?

Key challenges include the high initial cost of radiation-hardened components and systems, complex and stringent regulatory compliance requirements, technical difficulties in ensuring long-term operational reliability in extreme environments, developing advanced dexterity for intricate tasks, and managing secure communication channels in electromagnetically noisy conditions. Public perception and acceptance also play a role.

Which regions are leading the adoption of nuclear robotics technology?

North America and Europe are leaders in the adoption of nuclear robotics, primarily due to their aging nuclear infrastructure and extensive decommissioning projects, coupled with strong regulatory emphasis on safety. The Asia Pacific region is experiencing the fastest growth, driven by new nuclear power plant constructions and modernization efforts in countries like China and India, making it a rapidly expanding market for these advanced robotic solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager