Offshore Wind Turbine Blade Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429753 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Offshore Wind Turbine Blade Market Size

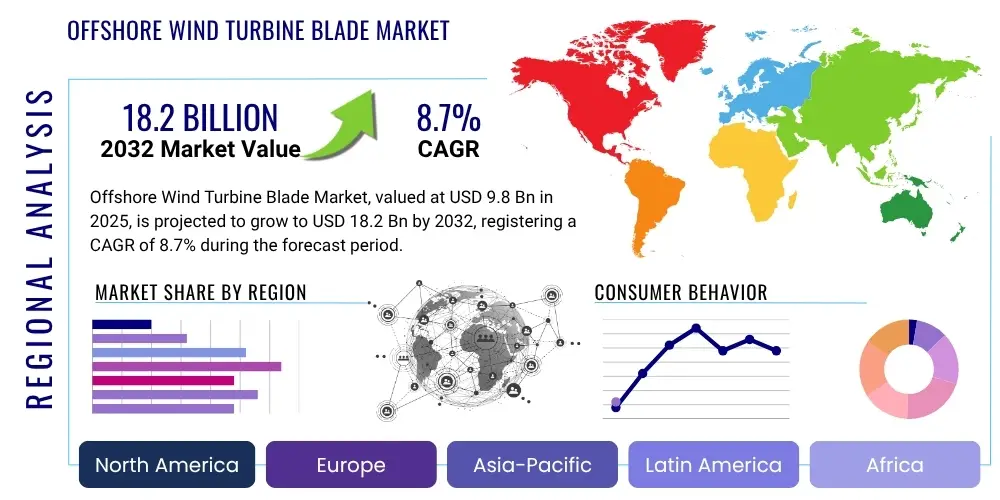

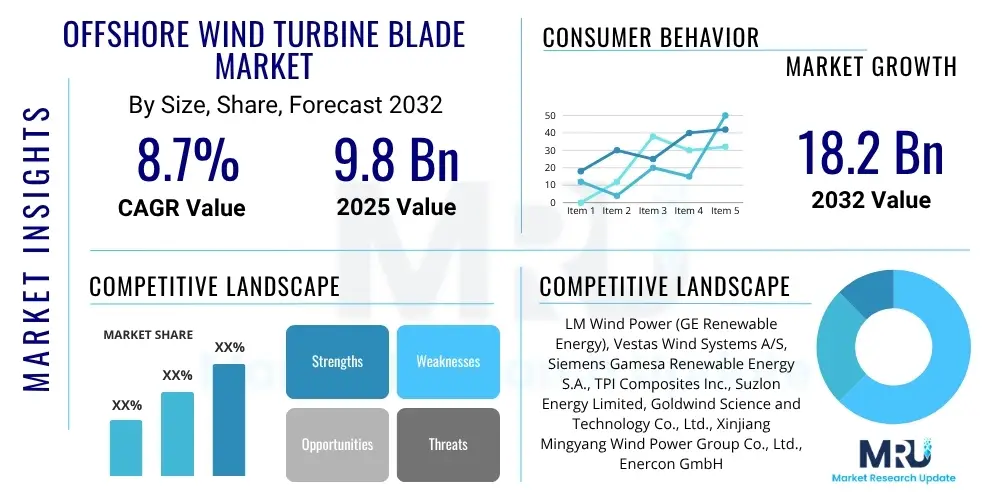

The Offshore Wind Turbine Blade Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2025 and 2032. The market is estimated at USD 9.8 Billion in 2025 and is projected to reach USD 18.2 Billion by the end of the forecast period in 2032.

Offshore Wind Turbine Blade Market introduction

The Offshore Wind Turbine Blade Market encompasses the design, manufacturing, and supply of blades specifically engineered for wind turbines deployed in marine environments. These critical components are integral to converting wind energy into electricity, playing a pivotal role in the global shift towards renewable energy sources. The product description highlights blades that are significantly longer, more robust, and designed to withstand the harsh conditions prevalent offshore, including saline air, strong winds, and corrosive elements. This demands advanced materials and sophisticated aerodynamic profiles to maximize energy capture and ensure longevity.

Major applications for offshore wind turbine blades primarily involve large-scale utility projects, where arrays of turbines form wind farms providing substantial contributions to national grids. These blades are crucial for energy independence initiatives and carbon emission reduction efforts. The benefits derived from the widespread adoption of these blades include a substantial increase in clean energy generation capacity, a reduction in reliance on fossil fuels, and the creation of economic opportunities within the renewable energy sector. Key driving factors propelling this market forward include ambitious government policies and subsidies promoting offshore wind development, escalating concerns over climate change, and continuous technological advancements improving turbine efficiency and reducing the levelized cost of energy (LCOE).

Offshore Wind Turbine Blade Market Executive Summary

The Offshore Wind Turbine Blade Market is experiencing robust growth driven by an accelerating global energy transition and significant policy support for renewable power generation. Business trends indicate a consolidation among key manufacturers, alongside intense research and development efforts focused on producing longer, lighter, and more durable blades using advanced composite materials. There is a growing emphasis on optimizing manufacturing processes for cost-efficiency and scalability, addressing supply chain challenges, and integrating smart technologies for enhanced performance monitoring. The industry is witnessing increased collaboration between material suppliers, blade manufacturers, and turbine OEMs to innovate and meet the escalating demands of offshore wind projects.

Regionally, Europe continues to lead the market with established offshore wind infrastructure and ambitious expansion plans, particularly in the North Sea and Baltic Sea. The Asia Pacific region, led by China, Taiwan, and Japan, represents the fastest-growing market, propelled by new project installations and significant investments. North America, particularly the United States, is emerging as a strong contender with substantial policy commitments and a pipeline of large-scale offshore wind developments. Segment trends highlight a clear move towards ultra-large blades exceeding 100 meters in length, crucial for maximizing energy output from next-generation turbines. Furthermore, innovation in materials and manufacturing techniques, including thermoplastic composites and additive manufacturing, is gaining traction to enhance blade performance and reduce environmental impact.

AI Impact Analysis on Offshore Wind Turbine Blade Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Offshore Wind Turbine Blade Market often revolve around how AI can enhance efficiency, reduce costs, and improve reliability. Users are keen to understand AI's role in optimizing blade design, predicting maintenance needs, streamlining manufacturing processes, and managing complex logistics. The key themes emerging from these inquiries include the potential for AI to revolutionize the lifecycle management of blades, from conceptualization to end-of-life, by enabling data-driven decision-making and automation. Concerns often include data privacy, the need for specialized skill sets, and the initial investment required for AI integration, alongside expectations for significant operational improvements and risk mitigation.

- AI-driven generative design for optimized aerodynamic profiles and structural integrity, leading to more efficient energy capture.

- Predictive maintenance analytics using sensor data to forecast blade fatigue, detect anomalies, and schedule proactive repairs, minimizing downtime.

- Enhanced manufacturing process control through machine learning algorithms for quality assurance, defect detection, and resource optimization in composite fabrication.

- Supply chain optimization and logistics management, utilizing AI to predict demand, manage inventory, and plan transportation routes for oversized components.

- Real-time performance monitoring and anomaly detection, allowing operators to adjust turbine settings for optimal performance and extend blade lifespan.

- Robotics and autonomous systems powered by AI for inspection, cleaning, and minor repairs of blades in harsh offshore environments, improving safety and reducing operational costs.

DRO & Impact Forces Of Offshore Wind Turbine Blade Market

The Offshore Wind Turbine Blade Market is primarily driven by the escalating global demand for clean energy and ambitious renewable energy targets set by governments worldwide. Decreasing levelized costs of energy (LCOE) for offshore wind, coupled with continuous technological advancements in turbine design and blade manufacturing, make offshore wind an increasingly competitive power source. Significant government subsidies, supportive regulatory frameworks, and international commitments to combat climate change further incentivize investment and expansion in this sector. The push for energy independence and security in many nations also plays a crucial role in driving offshore wind development, directly impacting the demand for high-performance turbine blades.

Restraints on market growth include the substantial upfront capital investment required for offshore wind projects, including turbine blades, which can be a barrier for new entrants or smaller developers. The complexities of establishing and maintaining offshore infrastructure, coupled with logistical challenges associated with transporting and installing extremely large blades, also pose significant hurdles. Environmental concerns, such as the potential impact on marine ecosystems and avian life, often lead to stringent regulatory approvals and protracted project development timelines. Supply chain vulnerabilities, including reliance on specific raw materials and specialized manufacturing capabilities, can also create bottlenecks and cost fluctuations.

Opportunities for the offshore wind turbine blade market are vast, particularly with the rapid development of floating offshore wind technology, which opens up new geographic areas with deeper waters previously inaccessible to fixed-bottom foundations. Innovations in advanced materials, such as lighter and more sustainable composites, offer prospects for improved blade performance and reduced environmental footprint. Emerging markets in Asia Pacific and North America present significant growth potential, as these regions ramp up their offshore wind capacities. The ongoing focus on circular economy principles in blade manufacturing, including recycling and reuse strategies, also presents opportunities for sustainable development and long-term market viability. Impact forces such as fluctuating raw material prices, global trade policies, and rapid technological obsolescence demand constant adaptation from market players.

Segmentation Analysis

The Offshore Wind Turbine Blade Market is comprehensively segmented to provide a detailed understanding of its diverse components and evolving dynamics. This segmentation helps in analyzing market trends, identifying key growth areas, and understanding the competitive landscape. The market is primarily categorized by material type, blade length, manufacturing process, and application, reflecting the technological advancements and varied requirements across the offshore wind industry. Each segment plays a crucial role in shaping the overall market trajectory, driven by specific technical innovations and economic factors.

- By Material Type

- Fiberglass Composites (GFRP)

- Carbon Fiber Composites (CFRP)

- Hybrid Composites (combining fiberglass and carbon fiber)

- Other Advanced Composites (e.g., thermoplastic composites)

- By Blade Length

- Up to 80 meters

- 80-100 meters

- Above 100 meters

- By Manufacturing Process

- Vacuum Infusion

- Pre-preg Fabrication

- Resin Transfer Molding (RTM)

- Other Advanced Manufacturing Techniques

- By Application

- Fixed-Bottom Offshore Wind Turbines

- Floating Offshore Wind Turbines

Value Chain Analysis For Offshore Wind Turbine Blade Market

The value chain for the Offshore Wind Turbine Blade Market is complex and extends across multiple stages, beginning with the sourcing of raw materials and culminating in the operation and maintenance of offshore wind farms. Upstream analysis involves the suppliers of critical raw materials such as fiberglass, carbon fiber, various resins (epoxy, polyester, vinyl ester), core materials (balsa wood, PVC foam, PET foam), and gel coats. These suppliers form the foundational layer, providing specialized materials that meet stringent performance requirements for strength, durability, and resistance to harsh marine environments. The quality and availability of these materials directly impact blade manufacturing costs and performance.

Moving further along the value chain, downstream analysis encompasses the processes of blade manufacturing, testing, assembly, and integration into complete wind turbines. Major turbine manufacturers often produce blades in-house or collaborate closely with specialized blade manufacturers. The distribution channel involves the logistics of transporting these enormous components from manufacturing facilities to port staging areas and then to the offshore installation sites, often requiring specialized vessels and lifting equipment. Direct sales typically occur between blade manufacturers or turbine OEMs and offshore wind farm developers or utility companies. Indirect channels may involve engineering, procurement, and construction (EPC) contractors who manage the entire project lifecycle, procuring blades as part of a broader turbine supply agreement.

Offshore Wind Turbine Blade Market Potential Customers

The primary potential customers and end-users of offshore wind turbine blades are entities deeply invested in large-scale renewable energy generation and infrastructure development. These include major utility companies and national power grid operators that are expanding their clean energy portfolios to meet escalating electricity demand and achieve sustainability targets. Offshore wind farm developers, ranging from established energy conglomerates to specialized renewable energy developers, constitute a significant customer base, as they are responsible for planning, constructing, and operating multi-billion-dollar wind energy projects globally. Their demand for advanced blades directly influences manufacturing capacities and technological innovation.

Additionally, independent power producers (IPPs) focused on supplying electricity to industrial consumers or niche markets represent another segment of buyers. Government energy agencies and state-owned enterprises, particularly in regions actively promoting offshore wind, also act as key customers, often through competitive tenders for project development. The growing number of international collaborations and joint ventures in offshore wind development means that partnerships between diverse companies, including oil and gas majors diversifying into renewables, are also significant buyers of these specialized blades. Ultimately, these customers are driven by the long-term economic viability, environmental benefits, and strategic importance of offshore wind power.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 9.8 Billion |

| Market Forecast in 2032 | USD 18.2 Billion |

| Growth Rate | 8.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LM Wind Power (GE Renewable Energy), Vestas Wind Systems A/S, Siemens Gamesa Renewable Energy S.A., TPI Composites Inc., Suzlon Energy Limited, Goldwind Science and Technology Co., Ltd., Xinjiang Mingyang Wind Power Group Co., Ltd., Enercon GmbH, Nordex SE, Senvion GmbH (now part of Siemens Gamesa), blades technology, Hexcel Corporation, Toray Industries Inc., Gurit Holding AG, Mitsubishi Heavy Industries, Dongfang Electric Corporation, Clipper Windpower, MHI Vestas Offshore Wind (now Vestas Offshore Wind), Eoltec. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Offshore Wind Turbine Blade Market Key Technology Landscape

The Offshore Wind Turbine Blade Market is characterized by a dynamic technology landscape, continually evolving to meet the demands for larger, more efficient, and more durable blades capable of withstanding extreme marine conditions. Advanced composite manufacturing techniques form the core of current production, including vacuum infusion, resin transfer molding (RTM), and pre-preg lay-up processes. These methods are crucial for creating blades with optimal strength-to-weight ratios, ensuring both structural integrity and aerodynamic performance. Innovations in materials, such as the increasing use of carbon fiber for its stiffness and lightness, often in hybrid configurations with fiberglass, are pivotal in extending blade lengths and improving energy capture efficiency without prohibitive weight increases.

Furthermore, aerodynamic design principles are continuously being refined, with sophisticated airfoil designs and specialized tips aimed at maximizing energy extraction and minimizing noise. Erosion protection coatings and lightning protection systems are critical technologies for ensuring blade longevity in harsh offshore environments, mitigating damage from rain, hail, saltwater, and electrical strikes. The emergence of smart blade technologies, integrating sensors for structural health monitoring, vibration dampening, and real-time performance optimization, is transforming operational maintenance and predictive analytics. Research into sustainable materials, including recyclable composites and bio-based resins, is also gaining traction, addressing environmental concerns and promoting a circular economy within the industry. These technological advancements collectively contribute to reducing the LCOE and enhancing the overall viability of offshore wind power.

Regional Highlights

- Europe

- Europe holds a dominant position in the offshore wind turbine blade market, driven by pioneering installations, strong government support, and ambitious renewable energy targets. Countries like the United Kingdom, Germany, Denmark, and the Netherlands have invested heavily in large-scale offshore wind farms, necessitating a robust supply chain for advanced blades. The region benefits from established manufacturing capabilities and significant research and development initiatives focused on next-generation blade technologies and floating offshore wind.

- Asia Pacific (APAC)

- The Asia Pacific region is experiencing the fastest growth in the offshore wind market, primarily led by China, Taiwan, and Japan. Rapid industrialization, increasing energy demand, and government incentives for clean energy production are propelling this growth. Significant investments in new offshore wind projects and the expansion of local manufacturing capabilities are making APAC a crucial hub for blade production and deployment. South Korea and Vietnam are also emerging as key players with substantial future potential.

- North America

- North America, particularly the United States, is an emerging but rapidly growing market for offshore wind turbine blades. Driven by federal and state-level renewable energy mandates, coupled with a vast coastline suitable for offshore wind development, the region is seeing considerable investment. The establishment of domestic supply chains and manufacturing facilities, alongside the deployment of several large-scale projects, indicates significant future expansion and market relevance.

- Latin America and Middle East & Africa (MEA)

- While smaller in market share compared to other regions, Latin America and MEA offer long-term growth potential. Countries like Brazil and South Africa possess significant offshore wind resources and are beginning to explore large-scale projects. Investments in these regions are often linked to national energy diversification strategies and are expected to grow as technology costs decrease and regulatory frameworks mature, leading to an eventual increase in demand for offshore wind turbine blades.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Offshore Wind Turbine Blade Market.- LM Wind Power (GE Renewable Energy)

- Vestas Wind Systems A/S

- Siemens Gamesa Renewable Energy S.A.

- TPI Composites Inc.

- Suzlon Energy Limited

- Goldwind Science and Technology Co., Ltd.

- Xinjiang Mingyang Wind Power Group Co., Ltd.

- Enercon GmbH

- Nordex SE

- blades technology

- Hexcel Corporation

- Toray Industries Inc.

- Gurit Holding AG

- Mitsubishi Heavy Industries

- Dongfang Electric Corporation

- Clipper Windpower

- Eoltec

- TECO Group

- Saertex GmbH & Co. KG

- 3M Company

Frequently Asked Questions

What are the primary drivers of growth in the Offshore Wind Turbine Blade Market?

The market is primarily driven by global renewable energy targets, decreasing levelized costs of energy (LCOE), robust government support and subsidies for offshore wind, and continuous technological advancements enhancing turbine efficiency and blade performance. Increasing concerns about climate change and the pursuit of energy independence also contribute significantly.

What are the key technological advancements shaping offshore wind turbine blades?

Key advancements include the use of advanced composite materials like carbon fiber for longer and lighter blades, sophisticated aerodynamic designs, smart blade technologies with integrated sensors for structural health monitoring, and improved manufacturing processes such as vacuum infusion and robotic fabrication. Erosion protection coatings and lightning protection systems are also crucial innovations.

What are the main challenges facing the Offshore Wind Turbine Blade Market?

Major challenges include the high upfront capital investment required for offshore wind projects, complex logistical hurdles associated with manufacturing and transporting oversized blades, environmental impact concerns, and the vulnerability of the supply chain to raw material price fluctuations. Permitting and regulatory complexities can also extend project timelines.

How do sustainable materials impact the offshore wind turbine blade industry?

Sustainable materials, such as recyclable composites and bio-based resins, are crucial for reducing the environmental footprint of blade manufacturing and improving end-of-life options. Their adoption addresses industry pressure for circularity, potentially lowering long-term waste management costs, enhancing brand image, and meeting evolving regulatory requirements for greener production.

What role does floating offshore wind technology play in the blade market?

Floating offshore wind technology is a significant opportunity, expanding the addressable market by enabling turbine deployment in deeper waters previously inaccessible to fixed-bottom structures. This opens up new coastal regions globally for wind energy development, necessitating specialized blade designs optimized for dynamic loads and the unique operational conditions of floating platforms, driving further innovation and demand.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager