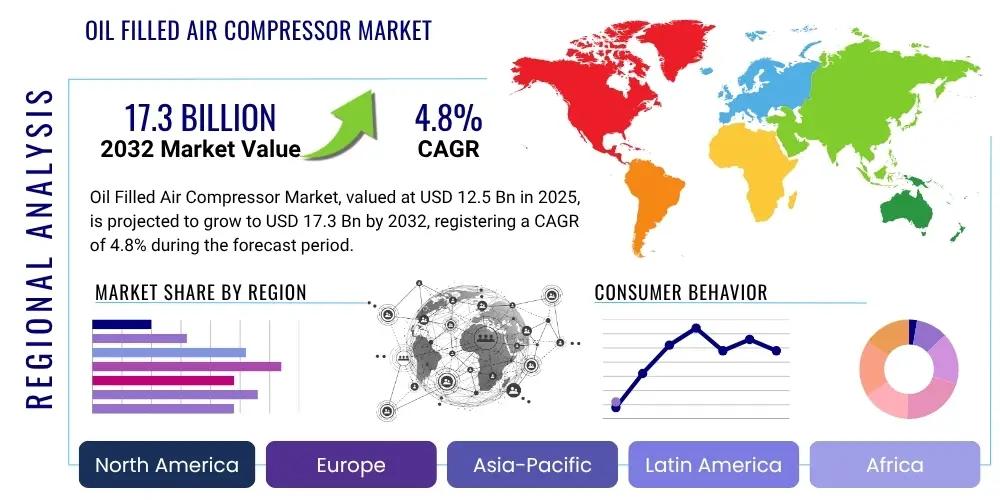

Oil Filled Air Compressor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429439 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Oil Filled Air Compressor Market Size

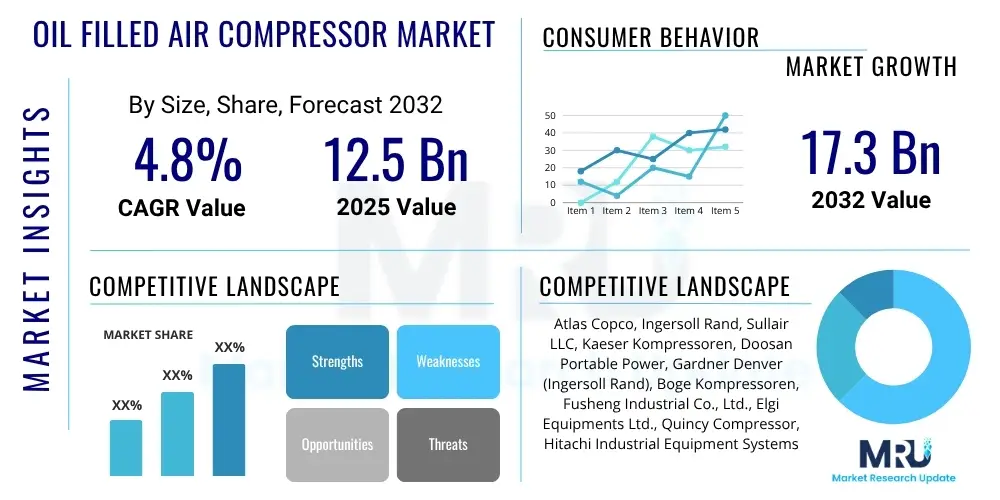

The Oil Filled Air Compressor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at $12.5 Billion in 2025 and is projected to reach $17.3 Billion by the end of the forecast period in 2032.

Oil Filled Air Compressor Market introduction

The Oil Filled Air Compressor Market encompasses a vast and essential segment of the industrial equipment landscape, providing critical compressed air solutions across a multitude of sectors. These compressors are distinguished by their use of oil for various vital functions, including lubrication of internal moving parts, sealing air gaps to enhance compression efficiency, and effective heat dissipation to maintain optimal operating temperatures. This oil-based design inherently contributes to the robust construction and operational longevity of these machines, making them a preferred choice for heavy-duty, continuous applications where reliability and consistent performance are paramount. Their ability to withstand demanding industrial environments is a key differentiator, ensuring stable operation even under strenuous conditions, which is crucial for maintaining productivity in various manufacturing and processing plants.

The product portfolio within the oil filled air compressor market is diverse, including reciprocating (piston) compressors, rotary screw compressors, and, to a lesser extent, centrifugal compressors. Each type is tailored for specific operational scales and pressure requirements. Rotary screw compressors, for instance, are widely adopted for their continuous duty cycles, high efficiency, and consistent airflow, making them ideal for large industrial operations. Reciprocating compressors, conversely, are often chosen for intermittent use or applications requiring very high pressures or in smaller workshops due to their robust design and relatively lower initial cost. The benefits of these systems are manifold, ranging from enhanced machine durability and reduced internal wear to improved overall efficiency and often quieter operation when properly maintained, presenting a compelling value proposition to industrial end-users globally.

Major applications for oil filled air compressors span numerous industries, forming the backbone of many production processes. In the manufacturing sector, they power pneumatic tools, facilitate automated assembly lines, drive material handling systems, and are essential for spray painting and surface finishing. The automotive industry relies heavily on these compressors for tasks such as tire inflation, vehicle assembly, paint shops, and powering impact wrenches. The construction sector utilizes them for operating jackhammers, demolition tools, and other heavy pneumatic equipment on job sites. Furthermore, their utility extends to general industrial maintenance, oil and gas operations, mining, and various other fields where dependable high-pressure air is indispensable for critical tasks, driving consistent demand across mature and emerging markets alike due to ongoing industrial expansion and modernization efforts.

Oil Filled Air Compressor Market Executive Summary

The global Oil Filled Air Compressor Market is currently demonstrating a significant growth trajectory, underpinned by persistent industrial expansion and a rising global emphasis on manufacturing capabilities. Key business trends highlight a pronounced shift towards integrating advanced technologies such as Variable Speed Drives (VSD) for superior energy efficiency and the incorporation of smart monitoring systems that leverage the Internet of Things (IoT) for enhanced operational visibility and predictive maintenance. This technological evolution directly addresses the increasing demand for sustainable and cost-effective industrial solutions. Furthermore, strategic consolidations and collaborative ventures among leading market players are becoming more frequent, as companies strive to expand their geographical footprint, diversify their product portfolios, and strengthen their competitive standing within a dynamic global marketplace.

Regional dynamics are playing a crucial role in shaping market development, with the Asia Pacific (APAC) region emerging as the primary growth engine. This surge is largely attributable to rapid industrialization, substantial government investments in infrastructure development, and the robust growth of manufacturing sectors in economies like China, India, and Southeast Asian nations. These regions benefit from expanding production capacities and a growing adoption of automated industrial processes, which inherently drive the demand for reliable compressed air systems. Meanwhile, mature markets in North America and Europe continue to exhibit steady demand, primarily driven by the replacement of aging infrastructure with newer, more energy-efficient models, and stringent regulatory frameworks that mandate higher environmental and operational standards, pushing innovation in compressor design and performance.

An in-depth analysis of segment trends reveals that rotary screw compressors continue to dominate the market share due to their inherent efficiency, continuous duty cycle capabilities, and suitability for large-scale industrial operations. However, reciprocating compressors maintain a vital niche, particularly in smaller workshops, for intermittent tasks, or in applications requiring very high pressures, owing to their robust and straightforward design. From an end-user perspective, the manufacturing sector remains the largest consumer, reflecting its broad reliance on compressed air for diverse production processes. Significant growth is also observed in the construction and automotive sectors, propelled by global infrastructure projects and sustained vehicle production. The market is also witnessing increasing demand for specialized, portable oil-filled compressors, catering to flexible operational needs in diverse field applications and temporary setups, thereby broadening the market's reach and application versatility across various industrial verticals.

AI Impact Analysis on Oil Filled Air Compressor Market

Common user inquiries concerning the impact of Artificial Intelligence (AI) on the Oil Filled Air Compressor Market predominantly focus on how AI can revolutionize operational paradigms, particularly in terms of efficiency, reliability, and maintenance protocols. Users are keen to understand AI's potential in facilitating predictive maintenance, thereby minimizing costly unscheduled downtime and extending equipment lifespan by anticipating failures. There is also significant interest in AI's role in optimizing energy consumption through intelligent load management and adaptive control systems that can respond dynamically to varying air demands. Furthermore, questions often arise about the integration challenges, data security implications, and the specialized skill sets required to fully leverage AI-driven insights within industrial settings, reflecting both anticipation and pragmatic concerns regarding this transformative technology. The underlying expectation is that AI will make these indispensable industrial machines smarter, more autonomous, and significantly more cost-effective to operate over their lifecycle.

- Enhanced predictive maintenance models using machine learning to analyze vibration, temperature, and pressure data for early anomaly detection.

- Optimized energy management through AI algorithms that dynamically adjust compressor output to precisely match demand, reducing wasted energy.

- Automated fault diagnosis and root cause analysis, accelerating troubleshooting and reducing repair times.

- Real-time performance monitoring and remote control facilitated by AI-powered IoT platforms, providing continuous operational insights.

- Intelligent scheduling of maintenance activities, parts replacement, and lubricant changes based on actual usage patterns rather than fixed intervals.

- Improved operational safety by predicting component wear or potential failures before they escalate into hazardous situations.

- Personalized performance tuning and adaptive control for specific application requirements, maximizing efficiency and output for diverse industrial tasks.

- Supply chain optimization for critical spare parts by forecasting demand based on AI-driven maintenance schedules.

- Development of self-optimizing compressors capable of autonomous adjustments for peak performance under varying conditions.

DRO & Impact Forces Of Oil Filled Air Compressor Market

The Oil Filled Air Compressor Market is profoundly shaped by a complex interplay of Drivers, Restraints, Opportunities, and a variety of Impact Forces that dictate its growth trajectory and competitive landscape. A primary driver is the accelerating pace of global industrialization, particularly in emerging economies where new manufacturing facilities and infrastructure projects continuously escalate the demand for reliable and robust compressed air systems. The increasing adoption of automation across diverse industries, from automotive to packaging, heavily relies on pneumatic tools and systems, thereby creating a sustained and expanding need for high-performance compressors. Furthermore, the persistent demand for energy-efficient industrial equipment, coupled with ongoing technological advancements that make oil-filled compressors more efficient and quieter, acts as a significant catalyst, prompting industries to upgrade their existing fleets and invest in newer models for improved operational economics.

Despite these strong growth drivers, the market navigates several notable restraints. Paramount among these are the increasingly stringent environmental regulations, particularly those concerning oil carryover and noise pollution, which compel manufacturers to invest heavily in advanced filtration, oil-water separation technologies, and noise reduction solutions. These compliance costs can sometimes translate to higher product prices, affecting market accessibility for some smaller enterprises. Another significant restraint is the relatively higher maintenance requirements of oil-filled compressors, involving regular oil changes, filter replacements, and separator maintenance, which can contribute to higher operational expenditure for end-users compared to oil-free alternatives. Moreover, the growing preference for oil-free compressors in highly sensitive applications, such as medical, pharmaceutical, and certain food and beverage processing, poses a competitive challenge, limiting the expansion of oil-filled market share in these specialized, high-growth niches.

Conversely, the market is rich with opportunities that promise substantial future growth. The widespread integration of IoT and AI technologies into compressor systems presents a transformative opportunity for predictive maintenance, remote diagnostics, and real-time performance optimization, significantly enhancing equipment uptime and operational efficiency. The ongoing global boom in infrastructure development, including commercial constructions, energy projects, and mining operations, offers vast untapped markets for oil-filled air compressors, particularly for heavy-duty and portable applications. Manufacturers can also capitalize on the rising demand for customized compressor solutions tailored to specific industry needs, along with focusing on delivering comprehensive after-sales services and robust customer support to differentiate their offerings. Innovations in material science for compressor components and the development of more environmentally benign lubricants further create avenues for market expansion, allowing companies to meet evolving regulatory standards and cater to an increasingly sustainability-conscious customer base.

Segmentation Analysis

The Oil Filled Air Compressor Market is meticulously segmented across various dimensions to provide a comprehensive understanding of its intricate structure and diverse application landscape. This detailed segmentation enables market participants to identify specific niches, tailor product development strategies, and optimize marketing efforts towards distinct customer groups. The categorization considers fundamental attributes such as the compressor's operational mechanism, the technology governing its speed, the method of lubrication employed, the pressure levels it can achieve, its power output, and the specific industrial sectors it serves. Each of these segments exhibits unique demand characteristics, growth patterns, and competitive dynamics, reflecting the varied requirements of industrial processes globally. A thorough analysis of these segments is crucial for strategic planning and informed decision-making within the highly competitive compressed air industry.

- By Type: This segment differentiates compressors based on their operational mechanism.

- Reciprocating: Piston-driven compressors suitable for intermittent duty and high-pressure applications.

- Rotary Screw: Employs two meshing helical screws to compress air, ideal for continuous operation and high-volume industrial use.

- Centrifugal: Utilizes a rotating impeller to accelerate air, primarily used in very large industrial applications for high flow rates.

- By Technology: Focuses on the drive system's sophistication.

- Fixed Speed: Operates at a constant motor speed, providing consistent airflow but less efficient for fluctuating demand.

- Variable Speed Drive (VSD): Adjusts motor speed to match air demand, significantly improving energy efficiency and reducing operational costs.

- By Lubrication Method: Defines how oil is distributed within the compressor.

- Splash Lubrication: Simpler method where crankshaft movement splashes oil onto components.

- Pressure Lubrication: Utilizes a pump to deliver oil under pressure to critical parts, offering more controlled and efficient lubrication.

- By Pressure: Categorizes compressors based on their maximum output pressure.

- Low Pressure (Up to 150 PSI): Common for general workshop tools and smaller applications.

- Medium Pressure (151-1000 PSI): Suitable for a wider range of industrial tasks and pneumatic systems.

- High Pressure (Above 1000 PSI): Used for specialized applications like industrial gas compression or certain heavy-duty tools.

- By Power: Groups compressors by their motor horsepower.

- Up to 50 HP: Typically used in small to medium-sized workshops and light industrial applications.

- 51-200 HP: Suited for medium to large manufacturing plants and heavier industrial processes.

- Above 200 HP: Employed in very large industrial complexes, heavy manufacturing, and specialized heavy industries.

- By End-User Industry: Identifies the primary sectors utilizing these compressors.

- Manufacturing: Widespread use in assembly lines, fabrication, painting, and general production.

- Automotive: Essential for vehicle manufacturing, repair shops, and tire services.

- Construction: Powers pneumatic tools for demolition, drilling, and site preparation.

- Energy: Applications in power generation, oil & gas exploration, and processing.

- Oil & Gas: Critical for offshore platforms, refineries, and various upstream and downstream operations.

- Food & Beverage (Limited Applications): Used where air purity is not ultra-critical, or with specialized filtration.

- Mining: Powers drilling equipment, ventilation systems, and material handling.

- Textile: Used in pneumatic weaving looms and other textile machinery.

- General Industrial: Covers a broad array of other industrial uses not specifically categorized, reflecting widespread applicability.

Value Chain Analysis For Oil Filled Air Compressor Market

The value chain for the Oil Filled Air Compressor Market is a multi-stage process, beginning with extensive upstream activities crucial for product quality and cost efficiency. This initial phase involves the meticulous sourcing of raw materials, which includes specialized metals like high-grade steel and aluminum for compressor casings, rotors, and pressure vessels, as well as copper for motors and electrical components. Alongside these, essential consumables such as synthetic and mineral lubricants, various types of air and oil filters, and high-performance seals are procured. Key upstream participants are component manufacturers specializing in electric motors, air ends, control systems, and cooling components. Strong, long-term relationships with these suppliers are vital, as the quality and timely delivery of these foundational elements directly impact the performance, reliability, and ultimately, the market competitiveness of the final air compressor unit.

Moving through the value chain, the core manufacturing and assembly stage represents the transformation of these raw materials and components into a finished product. This involves sophisticated engineering design, precision machining of parts, meticulous assembly processes, and rigorous quality control testing to ensure each compressor meets stringent performance and safety standards. Manufacturers often invest heavily in advanced production technologies and automation to optimize this stage, reduce production costs, and enhance product consistency. After the manufacturing process, downstream activities become critical, encompassing logistics, distribution, sales, installation, and comprehensive after-sales support. Effective logistics ensure timely delivery to diverse customer locations, while robust distribution channels are instrumental in extending market reach and facilitating customer access to products.

The distribution channels in the Oil Filled Air Compressor Market typically employ a dual approach: direct and indirect. Direct sales channels are often utilized for large industrial clients or projects requiring custom-engineered solutions, where manufacturers can offer specialized technical consultation, direct project management, and bespoke service contracts. This approach fosters deep customer relationships and allows for tailored solutions. Indirect channels, comprising an extensive network of authorized distributors, local dealers, and value-added resellers, are essential for penetrating regional markets, reaching small and medium-sized enterprises (SMEs), and providing localized sales and support. These partners often offer installation services, routine maintenance, and immediate spare parts supply, enhancing customer convenience. The robustness of after-sales services, including technical support, warranty provisions, preventative maintenance programs, and the ready availability of spare parts, significantly contributes to customer satisfaction, brand loyalty, and the overall lifecycle value of the compressor, forming a crucial differentiator in a competitive market.

Oil Filled Air Compressor Market Potential Customers

Potential customers for oil filled air compressors constitute a vast and diverse ecosystem of industrial and commercial entities across the globe, all united by a common need for reliable, robust, and consistent sources of compressed air. These end-users are primarily found in sectors where the operational environment is often demanding, and the performance characteristics of oil-lubricated compressors—such as their durability, extended operational lifespan, and capability for continuous, heavy-duty cycles—are highly valued. While air purity is a consideration, these customers often prioritize raw power, reliability, and cost-effectiveness over absolute oil-free air, which is the domain of different compressor types. The versatility of oil-filled systems means they cater to a broad range of applications, from driving simple pneumatic tools to powering complex automated machinery.

The manufacturing sector stands out as the largest and most significant customer segment. Industries ranging from automotive assembly and metal fabrication to textile production and general industrial goods rely heavily on compressed air for powering machinery, operating pneumatic clamps and tools, facilitating spray painting, and even for packaging and material handling systems. For example, in an automotive plant, oil-filled compressors are indispensable for tasks like engine assembly, body panel shaping, and powering paint booths where stringent oil-free air might be less critical than consistent high pressure. Similarly, in large-scale fabrication shops, they provide the necessary power for grinders, cutters, and other tools, contributing directly to production efficiency and output.

Beyond manufacturing, the construction and mining industries represent substantial customer bases. On construction sites, oil-filled portable compressors are critical for operating a variety of pneumatic tools such as jackhammers, rock drills, and concrete vibrators, providing the necessary power for demolition, excavation, and structural work. In the mining sector, these compressors are vital for powering drilling equipment, ventilation systems, and various material extraction processes in harsh and remote conditions where durability is paramount. Other significant customers include petrochemical plants, general workshops, service industries requiring constant air supply, and agricultural operations. The diverse and extensive nature of these end-user applications ensures a broad and sustained demand for oil filled air compressors, driven by ongoing industrial activity and infrastructure development worldwide.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $12.5 Billion |

| Market Forecast in 2032 | $17.3 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Ingersoll Rand, Sullair LLC, Kaeser Kompressoren, Doosan Portable Power, Gardner Denver (Ingersoll Rand), Boge Kompressoren, Fusheng Industrial Co., Ltd., Elgi Equipments Ltd., Quincy Compressor, Hitachi Industrial Equipment Systems Co., Ltd., Kobelco Compressors America, Inc., Champion Pneumatic, Parker Hannifin Corporation, Chicago Pneumatic (Atlas Copco), CompAir (Gardner Denver), Mattei Compressors, AERZEN, Bauer Kompressoren, Alup Kompressoren (Atlas Copco) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Oil Filled Air Compressor Market Key Technology Landscape

The Oil Filled Air Compressor Market is undergoing significant transformation driven by continuous technological advancements aimed at enhancing performance, energy efficiency, and operational intelligence. A cornerstone of this evolution is the widespread adoption and refinement of Variable Speed Drive (VSD) technology. VSD compressors dynamically adjust their motor speed and, consequently, their air output to precisely match the fluctuating demand of industrial processes. This capability dramatically reduces energy consumption compared to traditional fixed-speed compressors, which often run at full capacity regardless of actual demand, leading to considerable energy waste. The integration of VSD technology is crucial for industries striving to lower operational costs, reduce their carbon footprint, and comply with increasingly stringent energy efficiency regulations, making it a key competitive differentiator for manufacturers.

Another pivotal area of innovation lies in the realm of advanced control systems and digital connectivity, fundamentally altering how compressors are monitored and managed. Modern oil-filled compressors are increasingly equipped with sophisticated Programmable Logic Controllers (PLCs) and integrated with IoT (Internet of Things) sensors, enabling real-time data collection on critical operational parameters such as pressure, temperature, flow rates, and energy consumption. These data streams are then often transmitted to cloud-based platforms, where advanced analytics and Artificial Intelligence (AI) algorithms process them to provide actionable insights. This technological synergy facilitates predictive maintenance, allowing potential equipment failures to be identified and addressed before they lead to costly downtime, and enables remote monitoring and control, offering operators greater flexibility and responsiveness in managing their compressed air systems.

Furthermore, ongoing research and development in materials science and component design contribute significantly to the improved durability, reliability, and efficiency of oil-filled compressors. Innovations include optimized rotor profiles for rotary screw compressors, which enhance volumetric efficiency and reduce energy input per unit of compressed air. Improvements in filtration technologies are also critical, ensuring higher air quality, extending the lifespan of internal components, and minimizing oil carryover into the compressed air system, thereby helping industries meet environmental standards. The development of advanced, synthetic lubricants with longer service intervals and better thermal stability further reduces maintenance needs and enhances performance. Collectively, these technological advancements are propelling the oil filled air compressor market towards more intelligent, sustainable, and high-performing solutions that cater to the evolving demands of modern industrial environments globally.

Regional Highlights

- North America: This region represents a mature and technologically advanced market. Demand is primarily driven by the replacement of older systems with newer, energy-efficient models, and the stringent regulatory environment pushing for low emissions and noise levels. Key industries include automotive, aerospace, and general manufacturing, particularly in the United States and Canada, which show consistent investment in modern industrial infrastructure.

- Europe: Similar to North America, Europe is a highly developed market characterized by strong demand for high-efficiency, low-noise, and environmentally compliant oil-filled compressors. Countries like Germany, Italy, the UK, and France are significant contributors, with a focus on advanced manufacturing, pharmaceuticals (with specialized filtration), and robust industrial automation. Strict EU directives on energy consumption and emissions heavily influence product development and market trends.

- Asia Pacific (APAC): Positioned as the fastest-growing region globally, APAC is experiencing exponential demand fueled by rapid industrialization, massive infrastructure development projects, and the expansion of manufacturing bases, particularly in China, India, and countries within ASEAN. Lower labor costs and government initiatives to boost domestic production also attract significant foreign direct investment, driving the adoption of industrial machinery, including oil-filled air compressors, across diverse sectors like textiles, electronics, and automotive.

- Latin America: This region is an emerging market showing considerable growth, particularly in economies such as Brazil, Mexico, and Argentina. The demand for oil-filled air compressors is propelled by increasing foreign investments in manufacturing, expanding mining operations, and burgeoning construction activities. Economic diversification and industrial modernization efforts are creating new opportunities, though market penetration can be influenced by local economic stability and trade policies.

- Middle East and Africa (MEA): The MEA region is witnessing steady growth, driven by significant investments in the oil and gas sector, large-scale construction projects, and ongoing efforts towards industrial diversification. Countries like Saudi Arabia, UAE, and South Africa are leading the adoption of industrial equipment. The need for robust and durable compressors capable of operating in harsh climatic conditions, typical of this region, further supports the demand for oil-filled variants.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Oil Filled Air Compressor Market.- Atlas Copco

- Ingersoll Rand

- Sullair LLC

- Kaeser Kompressoren

- Doosan Portable Power

- Gardner Denver (Ingersoll Rand)

- Boge Kompressoren

- Fusheng Industrial Co., Ltd.

- Elgi Equipments Ltd.

- Quincy Compressor

- Hitachi Industrial Equipment Systems Co., Ltd.

- Kobelco Compressors America, Inc.

- Champion Pneumatic

- Parker Hannifin Corporation

- Chicago Pneumatic (Atlas Copco)

- CompAir (Gardner Denver)

- Mattei Compressors

- AERZEN

- Bauer Kompressoren

- Alup Kompressoren (Atlas Copco)

- Pneumatech (Atlas Copco)

- FS-Curtis

- FS-Elliott

Frequently Asked Questions

What is an oil filled air compressor and how does it work?

An oil filled air compressor uses oil to lubricate, seal, and cool the internal components, such as pistons or rotors. This oil ensures smooth operation, minimizes friction and wear, improves compression efficiency by sealing gaps, and dissipates heat, enabling continuous heavy-duty performance and extending the compressor's operational life in demanding industrial environments.

What are the primary applications and benefits of using oil filled air compressors in industrial settings?

Oil filled air compressors are widely used in manufacturing, automotive, construction, and mining industries to power pneumatic tools, assembly lines, spray painting, and heavy machinery. Their key benefits include superior durability, higher pressure and flow capabilities, extended equipment lifespan due to reduced wear, and enhanced heat dissipation for reliable, continuous operation in robust industrial environments.

How do oil filled air compressors compare to oil-free compressors in terms of performance and cost?

Oil filled compressors typically offer higher power, greater durability, and lower initial purchase costs, making them suitable for heavy industrial tasks where small amounts of oil in the airstream are acceptable. Oil-free compressors, while more expensive initially and sometimes less robust, are essential for sensitive applications like food and beverage or pharmaceuticals, where absolute air purity is critical and any oil contamination is unacceptable.

What impact does Variable Speed Drive (VSD) technology have on oil filled air compressor efficiency?

Variable Speed Drive (VSD) technology significantly enhances the efficiency of oil filled air compressors by allowing the motor to adjust its speed precisely to match the real-time air demand. This capability prevents the compressor from running at full capacity unnecessarily, leading to substantial energy savings, reduced operational costs, and a smaller carbon footprint, especially in applications with fluctuating compressed air requirements.

What maintenance considerations are important for oil filled air compressors?

Regular maintenance for oil filled air compressors is crucial for optimal performance and longevity, including routine oil changes, replacement of oil and air filters, and servicing of oil/air separators. Adhering to manufacturer-recommended schedules for these tasks, alongside periodic inspections of belts, hoses, and valves, helps prevent downtime, ensures air quality, and maintains energy efficiency over the equipment's lifespan.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager