Oil-free Air Compressor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431052 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Oil-free Air Compressor Market Size

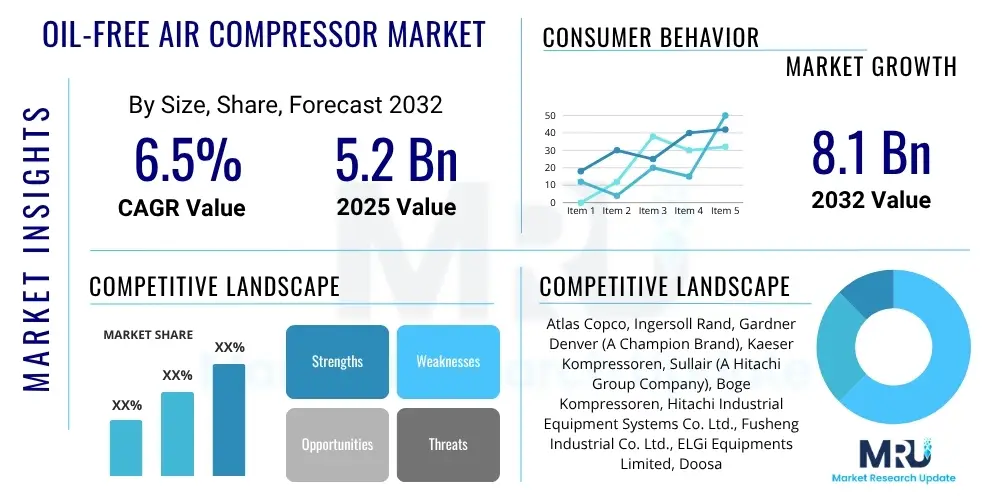

The Oil-free Air Compressor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 5.2 Billion in 2025 and is projected to reach USD 8.1 Billion by the end of the forecast period in 2032.

Oil-free Air Compressor Market introduction

The Oil-free Air Compressor Market is experiencing robust expansion driven by increasing industrial demands for contaminant-free compressed air across various sectors. Oil-free air compressors are specialized mechanical devices that compress air without the use of oil in the compression chamber, ensuring the delivered air is completely free of oil aerosols and vapors. This product category is crucial for applications where air purity is paramount to product quality, safety, and regulatory compliance, distinguishing it from traditional oil-lubricated compressors.

Major applications for oil-free air compressors span a broad range of industries, including food and beverage, pharmaceuticals, electronics manufacturing, healthcare, textiles, and chemical processing. These industries rely on pure compressed air for critical processes such as pneumatic conveying, instrumentation, packaging, fermentation, and breathing air. The primary benefits of utilizing oil-free technology include enhanced product integrity, reduced risk of contamination, lower maintenance costs associated with oil changes and downstream filtration, and compliance with stringent international quality standards like ISO 8573-1 Class 0.

Key driving factors for market growth include escalating global health and safety regulations, particularly in sensitive manufacturing environments, a growing emphasis on energy efficiency and sustainability in industrial operations, and the continuous expansion of industries that mandate high-purity air. Furthermore, technological advancements leading to more compact, quieter, and energy-efficient oil-free compressor designs are further stimulating market adoption. The inherent advantages of safeguarding end-products from oil contamination position oil-free air compressors as an indispensable component in modern industrial infrastructure.

Oil-free Air Compressor Market Executive Summary

The Oil-free Air Compressor Market is poised for significant growth, influenced by evolving business trends, distinct regional dynamics, and specialized segment advancements. Business trends indicate a strong shift towards sustainable manufacturing practices and a heightened focus on product quality and safety, driving widespread adoption of oil-free solutions. Market consolidation through strategic mergers and acquisitions is also observable, as key players seek to expand their product portfolios and geographical reach, alongside a continuous push for innovation in energy-efficient technologies and smart connectivity.

Regionally, the Asia Pacific (APAC) market is expected to exhibit the highest growth rate, fueled by rapid industrialization, burgeoning manufacturing sectors in countries like China and India, and increasing investments in pharmaceutical and food processing industries. Europe and North America, while mature, continue to demonstrate steady demand, primarily driven by stringent environmental regulations, advanced manufacturing facilities, and a strong emphasis on upgrading existing infrastructure with more efficient and compliant systems. Latin America and the Middle East & Africa are emerging markets, witnessing increased industrialization and infrastructure development, contributing to nascent but growing demand.

Segment trends highlight the dominance of rotary screw technology due to its efficiency and continuous operation capabilities, particularly in medium to large-scale industrial applications. The pharmaceutical and food & beverage sectors remain pivotal end-use segments, demanding the highest air purity standards. Furthermore, there is a rising demand for smaller capacity, portable oil-free compressors for specialized applications and burgeoning small to medium-sized enterprises. The integration of IoT and advanced control systems is transforming compressor operations, enabling predictive maintenance and optimized energy consumption across all segments, underscoring a broader industry movement towards smart, connected systems.

AI Impact Analysis on Oil-free Air Compressor Market

User inquiries concerning AI's influence on the Oil-free Air Compressor Market predominantly revolve around how artificial intelligence can enhance operational efficiency, enable predictive maintenance, and optimize energy consumption. Users are keen to understand the practical applications of AI in real-time monitoring, fault detection, and intelligent control systems that could minimize downtime and extend equipment lifespan. There is also significant interest in AI's role in data analysis for performance benchmarking, identifying operational anomalies, and supporting decision-making processes for resource allocation and energy management, ultimately leading to more sustainable and cost-effective operations within industrial settings.

- AI-driven predictive maintenance systems can forecast equipment failures, reducing unexpected downtime.

- Optimized energy consumption through AI algorithms that adjust compressor output based on real-time demand.

- Enhanced remote monitoring and diagnostics, allowing for proactive intervention and reduced service costs.

- Integration with smart factory ecosystems for seamless operation and data exchange.

- Automated performance tuning for peak efficiency and prolonged lifespan of components.

- Improved fault detection and root cause analysis, leading to faster repairs.

- Data analytics capabilities for identifying operational patterns and opportunities for improvement.

- Development of self-optimizing compressor systems that adapt to changing conditions.

- Virtual commissioning and digital twins for optimized system design and testing.

- Automated quality control for compressed air purity, ensuring compliance with industry standards.

DRO & Impact Forces Of Oil-free Air Compressor Market

The Oil-free Air Compressor Market is significantly shaped by a confluence of drivers, restraints, and opportunities, alongside various impact forces that dictate its trajectory. Key drivers include increasingly stringent environmental regulations and industrial standards requiring high air purity, particularly in sensitive sectors like food and beverage, pharmaceuticals, and electronics. The rising global emphasis on energy efficiency and sustainability further propels the adoption of oil-free solutions, as these systems typically offer lower energy consumption and reduced environmental footprint compared to their oil-lubricated counterparts. Additionally, the continuous expansion of manufacturing capacities in emerging economies and the modernization of industrial infrastructure in developed regions contribute substantially to market growth, driving demand for advanced compressed air solutions.

However, the market faces certain restraints that could temper its growth. The higher initial capital investment required for oil-free air compressors compared to oil-lubricated models can be a significant barrier for some small and medium-sized enterprises (SMEs). Perceived complexities in maintenance and the need for specialized technical expertise for servicing these advanced systems also present challenges. Intense competition from manufacturers offering oil-lubricated compressors with sophisticated filtration systems, which claim to achieve near oil-free air quality at a lower cost, adds further competitive pressure to the market, impacting pricing strategies and market share dynamics.

Despite these restraints, numerous opportunities abound for market players. The burgeoning demand from developing economies, coupled with ongoing technological advancements, offers substantial growth avenues. Innovations in connectivity, such as IoT integration and remote monitoring capabilities, present opportunities for value-added services and enhanced operational efficiency. Furthermore, the increasing adoption of oil-free compressors in niche applications, such as medical and dental facilities, as well as the potential for retrofitting existing systems with more efficient oil-free alternatives, are expected to unlock new revenue streams. These dynamic forces collectively influence market strategies, product development, and the overall competitive landscape within the oil-free air compressor sector.

Segmentation Analysis

The Oil-free Air Compressor Market is extensively segmented to reflect the diverse needs of various end-user industries and applications, providing a granular view of market dynamics. This segmentation facilitates a comprehensive understanding of the market's structure, allowing stakeholders to identify key growth areas and tailor their strategies effectively. The primary segmentation criteria include technology, power range, application, and geographic region, each offering unique insights into demand patterns and competitive landscapes.

Under technology, the market is categorized based on the specific compression mechanisms employed, which directly impact efficiency, cost, and suitability for different operational requirements. The power range segment delineates compressors based on their output capacity, catering to a spectrum of industrial scales from small workshops to large manufacturing plants. Application-based segmentation highlights the critical industries that are major consumers of oil-free compressed air, emphasizing the purity requirements and operational demands inherent to each sector. Geographic segmentation provides a regional perspective, showcasing market maturity, growth potential, and regulatory influences across different parts of the world. Each segment offers distinct opportunities and challenges, influencing product development and market penetration strategies.

- By Technology

- Rotary Screw

- Reciprocating

- Centrifugal

- Scroll

- Others (e.g., Rotary Vane, Claw)

- By Power Range

- Up to 50 kW

- 50-250 kW

- Above 250 kW

- By Application (End-Use Industry)

- Food and Beverage

- Pharmaceuticals

- Electronics and Semiconductors

- Healthcare (Medical & Dental)

- Oil and Gas

- Textiles

- Chemicals and Petrochemicals

- Automotive

- Water Treatment

- General Manufacturing

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Oil-free Air Compressor Market

The value chain for the Oil-free Air Compressor Market encompasses a complex network of activities, from raw material sourcing to end-user consumption, designed to deliver high-purity compressed air solutions. The upstream segment involves critical suppliers of raw materials and core components. This includes manufacturers of high-grade metals (steel, aluminum), specialized coatings, electric motors, control systems, filtration media, and advanced sealing materials essential for ensuring oil-free operation. These suppliers play a vital role in dictating the quality, performance, and cost-effectiveness of the final compressor unit, often engaging in long-term relationships with compressor manufacturers to ensure a consistent supply of specialized parts.

Midstream activities primarily involve the design, manufacturing, assembly, and quality assurance of the oil-free air compressors. This stage is characterized by significant research and development investments to innovate compressor technologies, enhance energy efficiency, and incorporate smart features like IoT connectivity and remote monitoring. Manufacturers often specialize in different compressor types, such as rotary screw, centrifugal, or scroll, and invest in advanced production facilities to meet stringent quality and performance benchmarks. This phase also includes the rigorous testing and certification processes necessary to ensure compliance with international standards for air purity and safety, particularly for sensitive applications.

The downstream segment focuses on distribution, sales, installation, and after-sales services to reach the end-user. Distribution channels for oil-free air compressors can be direct, involving manufacturers selling directly to large industrial clients or through their own sales networks, or indirect, leveraging a robust network of authorized distributors, dealers, and value-added resellers. These indirect channels often provide localized sales support, technical expertise, installation services, and crucial post-sale maintenance, repairs, and spare parts supply. The effectiveness of the distribution network is paramount for market penetration, customer satisfaction, and timely support, particularly for complex industrial equipment requiring specialized servicing.

Oil-free Air Compressor Market Potential Customers

The potential customer base for the Oil-free Air Compressor Market is remarkably diverse, spanning a wide array of industries where the integrity of products and processes is directly dependent on the purity of compressed air. These end-users are primarily driven by stringent regulatory requirements, the need to prevent contamination, and the pursuit of operational efficiency and cost savings associated with avoiding oil-related issues. The largest segments of potential buyers include the pharmaceutical industry, where oil-free air is critical for drug manufacturing, fermentation, and packaging to meet Good Manufacturing Practice (GMP) standards and ensure product safety and efficacy.

Similarly, the food and beverage industry represents a significant market for oil-free compressors. Here, compressed air is used in processes such as fermentation, pneumatic conveying of ingredients, packaging, and cleaning, where any oil contamination could lead to product spoilage, health risks, and severe reputational damage. Electronics and semiconductor manufacturers also heavily rely on oil-free air for precision cleaning, dust removal, and powering sensitive instruments, as even minute oil particles can severely damage delicate components and compromise product quality. Healthcare facilities, including hospitals and dental clinics, utilize oil-free air for medical devices, patient breathing air, and laboratory applications, prioritizing patient safety and compliance with medical standards.

Beyond these highly sensitive sectors, other significant potential customers include the oil and gas industry for instrumentation and control systems, chemical and petrochemical plants requiring pure air for processing and inerting, and textile manufacturers to prevent fabric staining. The automotive industry, particularly in painting and finishing processes, also increasingly adopts oil-free solutions to achieve flawless surfaces. Essentially, any industrial operation where compressed air comes into direct or indirect contact with final products, or where strict environmental and quality regulations are in place, represents a high-potential customer for oil-free air compressor manufacturers, demonstrating the broad applicability and critical necessity of this technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 5.2 Billion |

| Market Forecast in 2032 | USD 8.1 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Ingersoll Rand, Gardner Denver (A Champion Brand), Kaeser Kompressoren, Sullair (A Hitachi Group Company), Boge Kompressoren, Hitachi Industrial Equipment Systems Co. Ltd., Fusheng Industrial Co. Ltd., ELGi Equipments Limited, Doosan Portable Power, CompAir (A Gardner Denver Brand), Bauer Kompressoren GmbH, Quincy Compressor (A Generac Company), Parker Hannifin Corp., MATTEI Group, Chicago Pneumatic (An Atlas Copco Brand), Pneumatech (An Atlas Copco Brand), Kobelco Compressors, Cook Compression (A Dover Company), Sauer Compressors. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Oil-free Air Compressor Market Key Technology Landscape

The Oil-free Air Compressor Market is continually evolving, driven by significant advancements in technology aimed at enhancing efficiency, reliability, and ease of operation while maintaining the highest levels of air purity. One of the most prominent technological trends is the widespread adoption of Variable Speed Drive (VSD) technology. VSD compressors adjust their motor speed to match the air demand, leading to substantial energy savings by preventing the energy waste associated with off-load running. This intelligent control system is crucial for optimizing power consumption and reducing operational costs, making it a highly attractive feature for industrial end-users seeking sustainable solutions.

Another critical area of innovation lies in the integration of the Internet of Things (IoT) and advanced sensor technology. Modern oil-free compressors are increasingly equipped with smart sensors that monitor key operational parameters such as temperature, pressure, flow rate, and vibration in real-time. This data is then transmitted to cloud-based platforms for remote monitoring, predictive maintenance, and performance analytics. This connectivity enables operators to track compressor health, anticipate potential failures before they occur, optimize maintenance schedules, and improve overall system uptime, transforming reactive maintenance into proactive asset management.

Furthermore, advancements in materials science and compressor design are contributing to the market's technological landscape. This includes the development of more durable and efficient rotors, innovative sealing technologies that ensure complete separation of the compression chamber from the gearbox, and improved air-end designs that maximize volumetric efficiency. Energy recovery systems, which capture and reuse the heat generated during compression, are also gaining traction, further enhancing the energy efficiency profile of oil-free compressors. The continuous pursuit of quieter operation, reduced footprint, and modular designs also reflects the industry's commitment to delivering high-performance, user-friendly, and environmentally responsible compressed air solutions.

Regional Highlights

- North America: Characterized by a mature industrial base and stringent environmental regulations. High adoption rates in pharmaceuticals, food and beverage, and electronics due to strict quality controls. Focus on energy efficiency and replacing aging infrastructure drives consistent demand.

- Europe: A leading region for technological innovation and sustainability, with robust demand from manufacturing, chemical, and healthcare sectors. Strong regulatory frameworks, such as those imposed by the EU, promote the use of ISO 8573-1 Class 0 certified compressors. Germany, Italy, and the UK are key markets.

- Asia Pacific (APAC): The fastest-growing market, propelled by rapid industrialization, expanding manufacturing sectors, and increasing foreign direct investment in countries like China, India, and Southeast Asian nations. Rising demand for pure air in textiles, electronics, and pharmaceuticals due to burgeoning production capacities.

- Latin America: An emerging market with growing industrialization and infrastructure development, particularly in Brazil and Mexico. Increasing investments in food processing, automotive, and general manufacturing sectors are fueling the demand for oil-free compressed air.

- Middle East and Africa (MEA): Experiencing steady growth driven by investments in oil and gas, healthcare infrastructure, and food processing industries. Government initiatives to diversify economies away from oil are creating new manufacturing opportunities requiring high-purity air.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Oil-free Air Compressor Market.- Atlas Copco

- Ingersoll Rand

- Gardner Denver (A Champion Brand)

- Kaeser Kompressoren

- Sullair (A Hitachi Group Company)

- Boge Kompressoren

- Hitachi Industrial Equipment Systems Co. Ltd.

- Fusheng Industrial Co. Ltd.

- ELGi Equipments Limited

- Doosan Portable Power

- CompAir (A Gardner Denver Brand)

- Bauer Kompressoren GmbH

- Quincy Compressor (A Generac Company)

- Parker Hannifin Corp.

- MATTEI Group

- Chicago Pneumatic (An Atlas Copco Brand)

- Pneumatech (An Atlas Copco Brand)

- Kobelco Compressors

- Cook Compression (A Dover Company)

- Sauer Compressors

Frequently Asked Questions

What are the primary benefits of oil-free air compressors?

Oil-free air compressors deliver pure, contaminant-free air, eliminating the risk of product spoilage and operational disruptions caused by oil residues. Key benefits include enhanced product integrity, compliance with stringent purity standards (e.g., ISO 8573-1 Class 0), reduced maintenance costs due to fewer oil changes and filter replacements, and a more environmentally friendly operation.

Which industries are the main consumers of oil-free air compressors?

The main consumers of oil-free air compressors are industries requiring high-purity compressed air for their critical processes. These include the food and beverage industry, pharmaceuticals, electronics and semiconductor manufacturing, healthcare (medical and dental applications), and certain segments of the chemical and automotive sectors.

How does an oil-free air compressor differ from an oil-lubricated one?

The primary difference lies in the compression chamber design. Oil-free compressors use alternative methods, such as water or special coatings, to lubricate components or design elements that prevent oil from entering the air stream, ensuring the delivered air is entirely free of oil. Oil-lubricated compressors use oil for sealing, lubrication, and cooling in the compression process, requiring downstream filtration to remove oil contaminants.

What technological advancements are driving the oil-free air compressor market?

Key technological advancements include Variable Speed Drive (VSD) systems for energy efficiency, IoT integration for remote monitoring and predictive maintenance, advanced materials for improved durability, and innovative air-end designs that boost performance. These innovations enhance reliability, reduce operational costs, and promote sustainable practices.

What are the key regional growth drivers for oil-free air compressors?

Regional growth is driven by factors such as rapid industrialization and manufacturing expansion in Asia Pacific, stringent environmental regulations and high automation in Europe and North America, and increasing investments in critical infrastructure and sensitive industries across Latin America and the Middle East & Africa. Each region's unique economic and regulatory landscape contributes to its specific demand patterns.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager