Onshore Artificial Lift System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430266 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Onshore Artificial Lift System Market Size

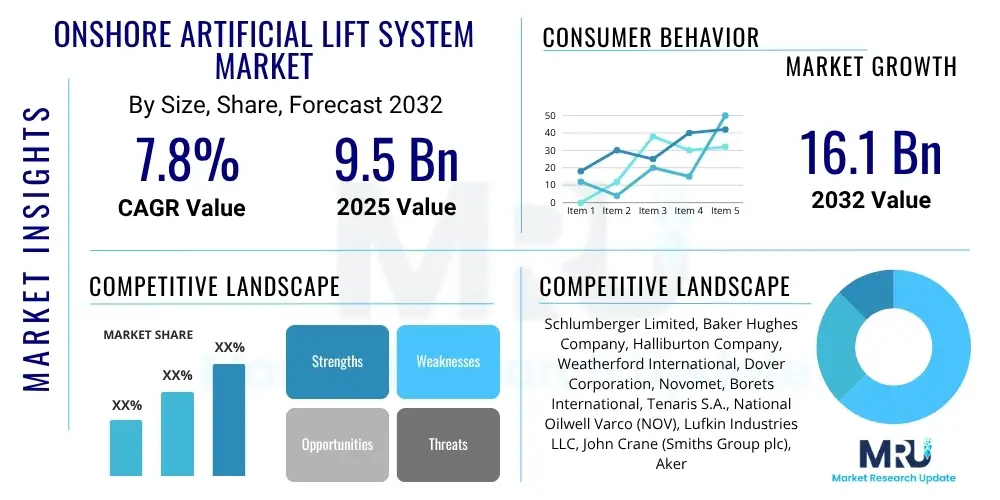

The Onshore Artificial Lift System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at $9.5 Billion in 2025 and is projected to reach $16.1 Billion by the end of the forecast period in 2032.

Onshore Artificial Lift System Market introduction

The Onshore Artificial Lift System Market encompasses a critical sector within the oil and gas industry, dedicated to enhancing the production of crude oil and natural gas from wells where natural reservoir pressure is insufficient. As oil and gas reservoirs mature, their intrinsic pressure declines, necessitating mechanical assistance to bring hydrocarbons to the surface. Artificial lift systems are engineered solutions designed to increase the flow of liquids and gases by providing supplementary energy to the wellbore fluid column, thereby maintaining economic production rates and extending the operational life of a well. These systems are indispensable for maximizing recovery from existing onshore assets, addressing the inherent challenges of declining production, and ensuring sustained energy supply.

The product portfolio within this market is diverse, comprising various mechanical and gas-based systems, each tailored to specific well conditions, fluid properties, and operational requirements. Key product types include Electric Submersible Pumps (ESPs), Rod Pumps (Sucker Rod Pumps), Gas Lift systems, Progressive Cavity Pumps (PCPs), and Plunger Lift systems. ESPs are dynamic displacement pumps suitable for high-volume production, while Rod Pumps are positive displacement systems widely used in low-to-medium flow rate wells. Gas Lift injects gas into the wellbore to reduce fluid density, and PCPs are effective for viscous fluids. These systems find their major applications across conventional and unconventional onshore oil and gas fields, playing a pivotal role in maintaining consistent hydrocarbon flow from the reservoir to the surface facilities.

The primary benefits of implementing onshore artificial lift systems include significantly improved oil and gas recovery rates, extended economic life of wells, and optimized production efficiency. These systems mitigate the challenges posed by decreasing reservoir pressure and increasing water cut, ensuring that wells remain productive even after their natural flow capabilities diminish. Driving factors for market growth include the global demand for energy, the increasing number of mature oilfields requiring intervention, technological advancements leading to more efficient and reliable lift solutions, and a growing focus on enhanced oil recovery (EOR) techniques. Furthermore, the development of unconventional reserves, such as shale oil and gas, often necessitates artificial lift from the outset, further bolstering market expansion.

Onshore Artificial Lift System Market Executive Summary

The Onshore Artificial Lift System Market is undergoing significant evolution, driven by a confluence of business trends focusing on operational efficiency, cost optimization, and enhanced hydrocarbon recovery. Operators are increasingly adopting advanced monitoring and automation technologies to improve the performance and reliability of artificial lift systems. This includes the integration of real-time data analytics, remote control capabilities, and predictive maintenance solutions, which are crucial for minimizing downtime and maximizing production. There is a strong business emphasis on life cycle cost reduction, pushing manufacturers and service providers to innovate in areas like energy efficiency, modular design, and simplified maintenance procedures. Furthermore, the consolidation of service providers and strategic partnerships are shaping competitive dynamics, enabling companies to offer integrated solutions and expand their market reach.

Regionally, the market exhibits varied growth trajectories influenced by factors such as maturity of oilfields, investment climates, and regulatory landscapes. North America, particularly the United States, stands as a dominant region due to its extensive mature oil and gas fields, robust shale plays, and early adoption of advanced artificial lift technologies. The Middle East and Africa are witnessing substantial investments in EOR projects and field expansions, driving demand for high-performance artificial lift solutions. Asia Pacific is emerging as a growth hotspot, propelled by increasing energy consumption, new exploration activities, and the need to enhance production from aging wells in countries like China and India. Latin America, with its vast hydrocarbon resources and ongoing upstream activities, also presents significant opportunities, although economic and political stability can influence market dynamics.

Segment-wise, the market sees robust activity across different artificial lift methods. Electric Submersible Pumps (ESPs) and Rod Pumps continue to hold significant market share due to their versatility and proven effectiveness across a wide range of well conditions. ESPs are favored for high-volume applications and deep wells, while Rod Pumps remain a cost-effective and reliable choice for lower production rates. Gas Lift systems are gaining traction in areas with readily available gas supply and specific reservoir characteristics, offering flexibility in operation. Progressive Cavity Pumps (PCPs) are specialized for handling highly viscous fluids and sandy conditions, finding niche applications. The trend indicates a move towards more intelligent and adaptive lift systems, where the choice is optimized not just by well characteristics but also by real-time data, aiming for maximum efficiency and minimized environmental footprint.

AI Impact Analysis on Onshore Artificial Lift System Market

The integration of Artificial Intelligence (AI) into the Onshore Artificial Lift System Market is a transformative development, addressing common user questions about optimizing production, reducing operational costs, and improving equipment reliability. Users frequently inquire about how AI can enhance predictive maintenance, the extent of efficiency gains, the potential for autonomous operations, and the overall return on investment. The key themes revolve around leveraging AI for better decision-making, minimizing human intervention, and future-proofing operations. AI's influence is seen in its ability to process vast amounts of sensor data, identify subtle anomalies, and forecast equipment failures, thereby shifting maintenance strategies from reactive to predictive. This leads to significant improvements in uptime, reduced expenditure on emergency repairs, and optimized energy consumption across the entire artificial lift lifecycle. Concerns often relate to data security, the initial investment required for AI infrastructure, and the need for a skilled workforce to manage these advanced systems.

- Predictive maintenance and anomaly detection for equipment failure prevention.

- Real-time optimization of lift system parameters (e.g., pump speed, gas injection rate) for maximum production.

- Autonomous well management and control, reducing human intervention and operational costs.

- Enhanced data analysis for reservoir characterization and production forecasting.

- Improved safety by automating hazardous tasks and detecting abnormal operating conditions.

- Reduced energy consumption through smart control algorithms.

- Optimization of chemical injection and other auxiliary processes.

- Better resource allocation and supply chain management for spare parts.

DRO & Impact Forces Of Onshore Artificial Lift System Market

The Onshore Artificial Lift System Market is significantly shaped by a dynamic interplay of drivers, restraints, opportunities, and external impact forces. The primary drivers fueling market expansion include the incessant global demand for energy, which necessitates maximizing production from existing hydrocarbon reserves, especially mature onshore fields experiencing natural decline in reservoir pressure. As conventional extraction methods become less effective, the reliance on artificial lift systems to maintain economic production rates intensifies. Furthermore, continuous technological advancements, such as the development of more efficient pumps, smart sensors, and advanced control systems, are making artificial lift solutions more cost-effective and reliable, encouraging wider adoption. Growing investments in enhanced oil recovery (EOR) projects, particularly in mature basins, also act as a crucial catalyst, as many EOR techniques require artificial lift to bring the treated fluids to the surface.

Conversely, several restraints impede the market's growth trajectory. Volatility in crude oil prices remains a significant challenge; periods of low oil prices can lead to reduced capital expenditure in upstream activities, directly impacting the demand for new installations and maintenance of artificial lift systems. The high initial capital expenditure associated with installing certain advanced artificial lift technologies can deter smaller operators. Additionally, stringent environmental regulations, particularly regarding carbon emissions and wastewater management, compel operators to adopt more environmentally friendly but potentially costlier solutions, sometimes delaying or restricting project approvals. Operational complexities, including managing diverse well conditions and ensuring system reliability in harsh environments, also pose considerable challenges for market participants.

Despite these restraints, abundant opportunities exist for market participants. The rapid development of unconventional reserves, such as shale oil and gas, frequently requires artificial lift from the very beginning of production, opening up new avenues for market penetration. The ongoing trend towards digitalization, automation, and the integration of AI and IoT offers substantial opportunities to enhance the efficiency, predictive capabilities, and remote management of artificial lift operations, leading to optimized performance and reduced downtime. Moreover, the development and adoption of artificial lift systems powered by renewable energy sources (e.g., solar-powered pumpjacks) present a niche but growing opportunity, aligning with global sustainability goals and offering long-term operational cost savings. The increasing focus on asset integrity and life extension for aging infrastructure further stimulates demand for advanced monitoring and refurbishment services within the artificial lift segment.

Segmentation Analysis

The Onshore Artificial Lift System Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation facilitates targeted market analysis, allowing stakeholders to identify specific growth areas and operational requirements across different technologies, applications, and regional landscapes. The market's structure reflects the varied operational demands and geological characteristics encountered in onshore oil and gas production globally. Each segment addresses distinct challenges and offers unique advantages, contributing to the overall market's resilience and adaptability. Understanding these segments is crucial for strategic planning, product development, and market entry strategies for both established players and new entrants.

- By Type:

- Rod Pump

- Electric Submersible Pump (ESP)

- Gas Lift

- Plunger Lift

- Progressive Cavity Pump (PCP)

- Hydraulic Pumping System

- Jet Pump

- Other Types

- By Mechanism:

- Positive Displacement

- Dynamic Displacement

- By Application:

- Oil Production

- Gas Production

- Water Management

- By Well Type:

- Vertical Wells

- Horizontal Wells

- Directional Wells

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Onshore Artificial Lift System Market

The value chain for the Onshore Artificial Lift System Market is a complex network involving various stages from raw material procurement to end-use services, each adding incremental value to the final product and service offering. At the upstream level, the chain begins with the sourcing of specialized raw materials such as high-strength metals for pump components, advanced polymers for seals and coatings, and sophisticated electronics for sensors and control units. Key suppliers include steel manufacturers, specialized alloy producers, and electronic component vendors. This stage is crucial as the quality and performance of the artificial lift systems heavily depend on the integrity and durability of these foundational materials. Component manufacturing then transforms these raw materials into specific parts like pump impellers, motors, control panels, rods, and valves, often requiring precision engineering and specialized fabrication processes.

Moving downstream, the value chain encompasses the assembly of these components into complete artificial lift systems, followed by rigorous testing to ensure operational reliability and efficiency. This stage often involves sophisticated manufacturing facilities and skilled labor. Once the systems are manufactured, they are distributed to the end-users, primarily oil and gas exploration and production (E&P) companies. The distribution channels can be categorized into direct and indirect routes. Direct sales typically involve large-scale contracts with major oil companies, where manufacturers provide bespoke solutions and direct installation support. Indirect channels involve a network of third-party distributors, authorized resellers, and oilfield service companies that procure systems from manufacturers and then provide integrated solutions, including installation, commissioning, and ongoing operational support to a broader range of operators, including smaller independent firms.

The final and crucial stages in the value chain involve post-sale services, including field installation, maintenance, repair, and ongoing operational support. Given the critical nature of artificial lift systems in maintaining production, robust maintenance and service capabilities are paramount. This includes regular inspections, preventative maintenance, troubleshooting, and rapid response to equipment failures. Many manufacturers offer comprehensive service contracts, and specialized oilfield service companies play a significant role in this segment, often providing a full spectrum of services from initial setup to decommissioning. The integration of digital technologies, such as IoT sensors and AI-driven predictive maintenance platforms, is increasingly enhancing the efficiency and effectiveness of these downstream services, enabling remote monitoring and proactive interventions, thereby optimizing the entire lifecycle cost and performance for the end-user.

Onshore Artificial Lift System Market Potential Customers

The primary potential customers and end-users of Onshore Artificial Lift Systems are entities deeply involved in the exploration, development, and production of onshore oil and gas resources. These include a wide spectrum of players within the upstream energy sector, all sharing the common objective of maximizing hydrocarbon recovery and optimizing well performance. National Oil Companies (NOCs) form a significant customer segment, as they often manage extensive domestic reserves and prioritize long-term production stability for national energy security. Their projects are typically large-scale and require reliable, high-performance artificial lift solutions to maintain output from mature fields and develop new ones. These companies often seek comprehensive solutions that include not only equipment but also long-term service and support contracts, valuing established relationships with proven suppliers.

International Oil Companies (IOCs) represent another key customer group, known for their global operational footprints and technological leadership. IOCs often operate complex, high-value projects and are early adopters of advanced artificial lift technologies, including those incorporating automation, digitalization, and AI for optimized performance. They prioritize efficiency, safety, and environmental compliance, driving demand for sophisticated and reliable systems. Independent oil and gas operators, ranging from large publicly traded companies to smaller private firms, also constitute a substantial customer base. These independents often focus on specific regions or unconventional plays and require flexible, cost-effective artificial lift solutions that can be rapidly deployed and adapted to diverse well conditions. Their purchasing decisions are often highly sensitive to capital expenditure and operational costs, making efficient and affordable systems particularly attractive.

Beyond the direct E&P companies, oilfield service providers are also significant buyers and influencers in this market. While not end-users of the hydrocarbons, these companies often purchase artificial lift equipment from manufacturers to integrate into their broader service offerings. They then provide these systems, along with installation, maintenance, and operational expertise, as part of a complete solution package to the E&P companies. This indirect channel allows manufacturers to reach a wider array of smaller operators and provide specialized services. Furthermore, equipment leasing companies and engineering, procurement, and construction (EPC) firms involved in large-scale field development projects can also be considered potential customers, facilitating the deployment of artificial lift technologies within broader infrastructure initiatives.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $9.5 Billion |

| Market Forecast in 2032 | $16.1 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schlumberger Limited, Baker Hughes Company, Halliburton Company, Weatherford International, Dover Corporation, Novomet, Borets International, Tenaris S.A., National Oilwell Varco (NOV), Lufkin Industries LLC, John Crane (Smiths Group plc), Aker Solutions ASA, General Electric (GE) Oil & Gas, Valiant Artificial Lift Solutions, JJ Tech, Access ESP, Upwing Energy, Summit ESP, Exterran Corporation, ChampionX Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Onshore Artificial Lift System Market Key Technology Landscape

The technology landscape for the Onshore Artificial Lift System Market is characterized by a relentless pursuit of efficiency, reliability, and intelligence, driven by the need to maximize hydrocarbon recovery in increasingly complex and mature environments. Core technological advancements revolve around the materials science of pump components, the sophistication of control systems, and the pervasive integration of digital technologies. Innovations in materials, such as corrosion-resistant alloys and advanced elastomers, significantly extend the lifespan of downhole equipment, reducing intervention frequency and associated operational costs, especially in corrosive well conditions or those with high sand content. Precision engineering in pump design further enhances hydraulic efficiency, allowing for higher flow rates and reduced energy consumption. Variable Speed Drives (VSDs) are a critical technology, enabling operators to precisely control the speed and output of electric submersible pumps (ESPs) and rod pumps, thereby optimizing production in real-time based on reservoir conditions and demand fluctuations. This adaptability leads to substantial energy savings and prolongs equipment life by operating within optimal performance envelopes.

Beyond mechanical and electrical improvements, the most profound shift in the technology landscape is the widespread adoption of digital technologies, often encapsulated under the umbrella of Industry 4.0. The deployment of Internet of Things (IoT) sensors downhole and at the wellhead provides real-time data on critical parameters such as pressure, temperature, flow rates, vibration, and motor performance. This constant stream of data is fed into sophisticated analytics platforms, often leveraging cloud computing for processing and storage. Advanced data analytics, powered by Artificial Intelligence (AI) and Machine Learning (ML) algorithms, are then used to interpret this data, identify patterns, and predict potential equipment failures before they occur. This transition from reactive to predictive maintenance significantly reduces downtime, minimizes catastrophic failures, and optimizes maintenance schedules, leading to substantial cost savings and improved operational continuity. AI also facilitates the optimization of lift parameters, such as gas injection rates in gas lift systems or stroke length and speed in rod pumps, ensuring the system operates at peak efficiency.

Automation and remote control systems further define the modern technology landscape, allowing operators to monitor and adjust artificial lift systems from central control rooms, often miles away from the well site. This capability not only enhances operational efficiency but also improves safety by reducing personnel exposure to hazardous field conditions. Autonomous operations, guided by AI, are becoming a reality, where systems can make self-correcting adjustments based on real-time data and predefined operational envelopes without human intervention. Additionally, software solutions for production optimization, well modeling, and simulation are integral, helping engineers design, evaluate, and fine-tune artificial lift strategies before and during deployment. The ongoing evolution of these technologies is not only extending the economic viability of aging wells but also making the exploration and production of challenging unconventional resources more feasible and profitable.

Regional Highlights

- North America: This region dominates the Onshore Artificial Lift System Market, driven by the extensive presence of mature oil and gas fields and the prolific development of shale plays, particularly in the United States and Canada. High levels of technological adoption, significant investments in EOR projects, and a robust service infrastructure contribute to its market leadership. The focus on maximizing production from vast unconventional reserves ensures sustained demand for advanced and efficient artificial lift solutions.

- Middle East & Africa: Characterized by some of the world's largest hydrocarbon reserves, this region is witnessing substantial investments in expanding production capabilities and enhancing recovery from existing mega-fields. National oil companies are driving demand for high-performance artificial lift systems, often integrated with advanced digital solutions, to optimize output and extend the lifespan of their assets. Ongoing exploration and development activities, coupled with significant foreign investment, underpin market growth.

- Asia Pacific (APAC): The APAC market is poised for significant growth, fueled by rising energy demand, increasing upstream investments in countries like China, India, and Indonesia, and a growing emphasis on improving production from aging conventional wells. The adoption of modern artificial lift technologies is accelerating as operators seek to enhance recovery rates and reduce operational costs. The region presents substantial opportunities for technology providers due to its developing energy infrastructure and expanding exploration activities.

- Europe: While having fewer new large-scale onshore discoveries, Europe's market for artificial lift systems is driven by the need to maintain production from mature fields and optimize recovery from existing gas assets. Strict environmental regulations and a focus on operational efficiency and sustainability often lead to the adoption of advanced, energy-efficient, and digitally integrated solutions. The region also benefits from a strong base of technology developers and service providers.

- Latin America: This region possesses vast untapped hydrocarbon potential and a significant number of mature fields, particularly in countries like Brazil, Argentina, and Mexico. Investments in artificial lift systems are increasing to combat natural production declines and exploit challenging reserves, including heavy oil and deep conventional deposits. Economic and political factors can influence the pace of adoption, but the long-term potential for market growth remains substantial due to considerable resource endowments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Onshore Artificial Lift System Market.- Schlumberger Limited

- Baker Hughes Company

- Halliburton Company

- Weatherford International

- Dover Corporation

- Novomet

- Borets International

- Tenaris S.A.

- National Oilwell Varco (NOV)

- Lufkin Industries LLC

- John Crane (Smiths Group plc)

- Aker Solutions ASA

- General Electric (GE) Oil & Gas

- Valiant Artificial Lift Solutions

- JJ Tech

- Access ESP

- Upwing Energy

- Summit ESP

- Exterran Corporation

- ChampionX Corporation

Frequently Asked Questions

What are the primary types of artificial lift systems used onshore?

The primary types of onshore artificial lift systems include Rod Pumps, Electric Submersible Pumps (ESPs), Gas Lift systems, Plunger Lift systems, and Progressive Cavity Pumps (PCPs). Each type is designed for specific well conditions and production requirements, offering varied benefits in terms of efficiency, cost, and fluid handling capabilities.

How does an artificial lift system enhance oil and gas recovery?

Artificial lift systems enhance oil and gas recovery by providing supplementary energy to the wellbore, effectively compensating for declining natural reservoir pressure. They help lift hydrocarbons to the surface, maintain optimal flow rates, and prevent wells from becoming uneconomical to operate, thereby extending the productive life of the reservoir and maximizing overall recovery.

What role does digital technology play in modern artificial lift operations?

Digital technology, including IoT sensors, AI, and machine learning, plays a crucial role in modern artificial lift operations by enabling real-time monitoring, predictive maintenance, and automated optimization. These technologies help reduce downtime, lower operational costs, improve safety, and ensure that systems operate at peak efficiency by adapting to changing well conditions.

What are the key challenges in the Onshore Artificial Lift System Market?

Key challenges in the Onshore Artificial Lift System Market include the volatility of crude oil prices, which can impact investment decisions; high initial capital expenditure for advanced systems; stringent environmental regulations; and the operational complexities associated with varying well conditions and maintaining equipment reliability in harsh environments.

Which regions are experiencing significant growth in the Onshore Artificial Lift System Market?

North America, particularly the United States, continues to be a dominant market due to extensive shale plays and mature fields. The Middle East and Africa are growing rapidly due to significant investments in EOR. Asia Pacific is emerging as a strong growth market driven by increasing energy demand and efforts to optimize production from aging wells.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager