Organic Rankine Cycle Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427555 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Organic Rankine Cycle Market Size

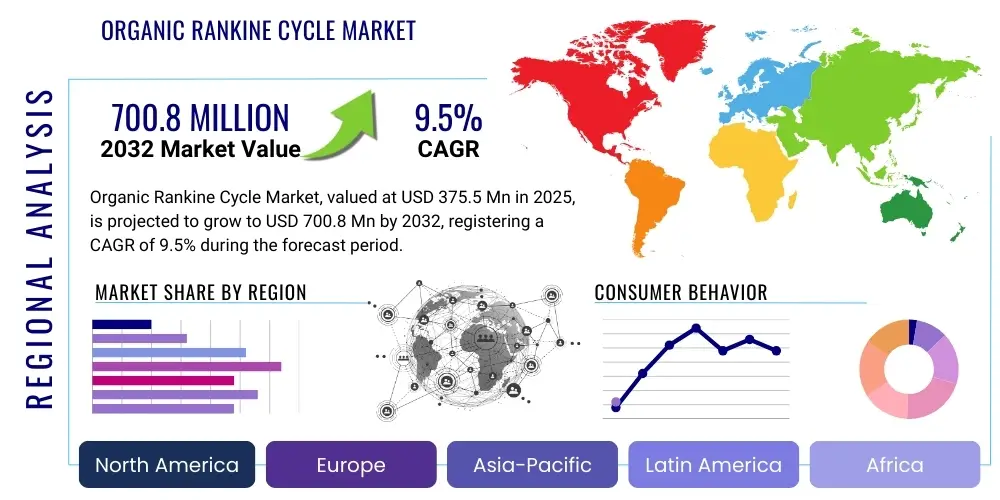

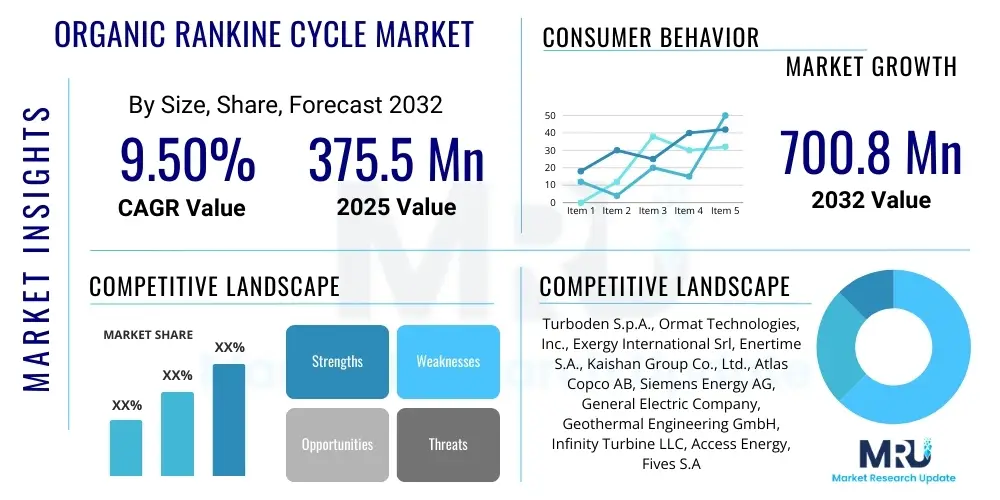

The Organic Rankine Cycle Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032. The market is estimated at USD 375.5 million in 2025 and is projected to reach USD 700.8 million by the end of the forecast period in 2032.

Organic Rankine Cycle Market introduction

The Organic Rankine Cycle (ORC) market encompasses the design, manufacturing, and deployment of systems that convert heat energy into mechanical work or electricity using an organic working fluid with a low boiling point. Unlike traditional steam Rankine cycles that use water, ORC systems utilize organic compounds such as hydrocarbons, refrigerants, or silicones, enabling efficient power generation from lower-temperature heat sources. This technology is particularly adept at harnessing industrial waste heat, geothermal energy, biomass combustion, and solar thermal heat, which are often not hot enough to efficiently operate conventional steam turbines.

ORC systems typically consist of four main components: an evaporator, an expander (turbine or screw expander), a condenser, and a pump. The organic fluid is heated in the evaporator, turning into a high-pressure vapor that expands through the expander to generate power. This vapor then passes to the condenser, where it cools and returns to a liquid state before being pumped back to the evaporator, completing the closed-loop cycle. The primary benefits of ORC technology include its ability to operate with varying and low-grade heat sources, lower maintenance requirements due to the absence of water-related corrosion and erosion, and its adaptability to remote or off-grid applications. It offers a robust and environmentally friendly solution for energy recovery and decentralized power generation, directly contributing to energy efficiency and carbon emission reduction goals.

Driving factors for the ORC market include the escalating global demand for clean energy, stringent environmental regulations promoting waste heat recovery, and the increasing focus on energy independence and decentralized power generation. Governments and industries are recognizing the economic and environmental advantages of converting previously wasted heat into valuable electricity, fostering significant investments in ORC solutions. The technologys versatility across diverse heat sources and its contribution to sustainable energy portfolios position it as a key component in the ongoing global energy transition.

Organic Rankine Cycle Market Executive Summary

The Organic Rankine Cycle (ORC) market is experiencing robust expansion driven by increasing industrial waste heat utilization, advancements in geothermal energy exploitation, and a global shift towards sustainable power generation. Business trends indicate a strong focus on modularization and standardization of ORC units to reduce costs and enhance deployment speed. Manufacturers are also engaging in strategic partnerships and collaborations to integrate ORC technology into broader energy solutions, such as combined heat and power (CHP) systems and hybrid renewable energy projects. Significant research and development efforts are concentrated on improving the efficiency of expanders, optimizing working fluids for specific temperature ranges, and developing smart control systems to maximize energy output under fluctuating conditions. The competitive landscape is characterized by both established energy players and specialized ORC technology providers vying for market share through innovation and competitive pricing.

Regionally, Europe continues to lead the market due to stringent environmental policies, a mature industrial base with substantial waste heat potential, and strong government incentives for renewable energy and energy efficiency. The Asia Pacific region is rapidly emerging as a significant growth hub, propelled by accelerated industrialization, a burgeoning demand for electricity, and a strategic emphasis on clean energy technologies in countries like China and India. North America is also witnessing steady growth, particularly in geothermal applications and the utilization of waste heat from oil and gas operations. These regional trends underscore a global commitment to decarbonization and the adoption of advanced energy recovery systems, with ORC technology playing a crucial role in diversified energy portfolios.

Segmentation trends highlight the dominance of waste heat recovery applications, driven by industries seeking to mitigate energy costs and reduce their carbon footprint. Small-to-medium scale ORC systems (typically below 10 MW capacity) are gaining traction due to their flexibility, ease of integration, and suitability for decentralized power generation. There is also a growing interest in ORC systems designed for lower temperature heat sources, opening up new opportunities in sectors previously unable to utilize conventional power generation technologies. The continuous innovation in working fluids, including those with lower global warming potential (GWP), is further enhancing the environmental profile and operational efficiency of ORC solutions across various applications and capacities.

AI Impact Analysis on Organic Rankine Cycle Market

User questions regarding the impact of Artificial Intelligence (AI) on the Organic Rankine Cycle (ORC) market frequently center on how AI can enhance operational efficiency, optimize design, and enable predictive maintenance. Users are keen to understand the practical applications of AI in improving energy conversion rates, reducing downtime, and managing complex system parameters under varying load conditions. Key themes include the potential for AI-driven real-time optimization of working fluid flow and temperature, the development of intelligent fault detection and diagnostics, and the role of machine learning in refining ORC system components for improved performance. Concerns often revolve around the data requirements for effective AI implementation, the cost implications of integrating AI solutions, and the need for specialized expertise to manage such advanced systems. Overall, there is a strong expectation that AI will unlock new levels of performance and cost-effectiveness for ORC technology, making it more competitive and widely adoptable.

- AI-powered predictive maintenance reduces downtime and extends component lifespan.

- Real-time performance optimization adjusts operational parameters for maximum efficiency.

- AI-driven design and simulation accelerate development of new ORC systems.

- Intelligent control systems adapt to fluctuating heat sources and demand.

- Enhanced fault detection and diagnostics prevent major system failures.

- Data analytics improve understanding of system behavior and identify areas for improvement.

- Automated energy management for hybrid ORC-renewable energy systems.

DRO & Impact Forces Of Organic Rankine Cycle Market

The Organic Rankine Cycle (ORC) market is significantly propelled by several key drivers. A primary driver is the global emphasis on energy efficiency and the imperative to reduce carbon emissions, pushing industries to adopt waste heat recovery solutions. The abundance of readily available low- and medium-grade waste heat from industrial processes, such as cement, steel, glass, and chemical manufacturing, represents a vast untapped resource that ORC technology can effectively convert into electricity. Furthermore, government mandates and incentives for renewable energy adoption and energy conservation, particularly in developed economies, strongly support the deployment of ORC systems for geothermal, biomass, and solar thermal applications. The rising cost of conventional electricity and the desire for energy independence also encourage industries and utilities to invest in decentralized power generation using ORC technology, reducing reliance on grid power and mitigating energy price volatility.

Despite the strong drivers, several restraints pose challenges to the ORC market. The high initial capital expenditure required for installing ORC systems can be a significant barrier, particularly for small and medium-sized enterprises, even with the long-term operational cost savings. The selection of suitable working fluids can be complex, involving considerations of thermodynamic properties, environmental impact (Global Warming Potential - GWP, Ozone Depletion Potential - ODP), safety, and cost. While new fluids are being developed, regulatory changes regarding specific refrigerants can create uncertainty. Moreover, the inherent complexity of integrating ORC systems into existing industrial infrastructure, especially for retrofitting older plants, can be technically challenging and require specialized engineering expertise. These factors contribute to a longer return on investment period, which can deter potential adopters.

Opportunities for growth in the ORC market are substantial, particularly in addressing the vast untapped potential of low-temperature waste heat sources, which are abundant across various industrial sectors and present a largely unexploited energy recovery avenue. The development of modular and standardized ORC units is creating new market niches by simplifying installation and reducing overall project costs, making the technology more accessible to a wider range of customers. Integration with hybrid renewable energy systems, combining ORC with solar thermal or biomass, offers enhanced efficiency and reliability for consistent power generation. Emerging economies, undergoing rapid industrialization and facing increasing energy demand, present significant growth potential as they seek sustainable and efficient energy solutions. Technological advancements in expander design, heat exchangers, and the development of next-generation working fluids are continually improving the efficiency and cost-effectiveness of ORC systems, expanding their applicability.

Segmentation Analysis

The Organic Rankine Cycle (ORC) market is analyzed across various segments, providing a comprehensive understanding of its structure and growth dynamics. These segments help in identifying key application areas, capacity demands, end-user preferences, and the role of different working fluids in optimizing ORC system performance. The segmentation analysis highlights the diverse range of applications for ORC technology, from large-scale industrial waste heat recovery to smaller, decentralized renewable energy projects, reflecting the versatility and adaptability of these systems in meeting varied energy needs.

- By Application: Waste Heat Recovery, Geothermal, Biomass, Solar Thermal, Others (e.g., Engine Waste Heat, Concentrated Solar Power).

- By Capacity: Small-scale (100 kWe to 1 MWe), Medium-scale (1 MWe to 10 MWe), Large-scale (>10 MWe).

- By End-User: Industrial, Power Plants, Commercial, Residential, Utilities.

- By Working Fluid: Hydrocarbons (e.g., n-pentane, n-butane), Silicones (e.g., MDM, D4), Refrigerants (e.g., R245fa, R134a), Fluorocarbons, Others (e.g., special blends).

Organic Rankine Cycle Market Value Chain Analysis

The value chain for the Organic Rankine Cycle (ORC) market begins with upstream activities focused on the procurement of essential raw materials and the manufacturing of specialized components. This involves suppliers of high-grade metals for heat exchangers and expander casings, manufacturers of turbomachinery components such as turbines and compressors, and providers of pumps, valves, and electrical generators. Research and development institutions also play a crucial upstream role in innovating new working fluids and optimizing system designs. These foundational elements are critical as the quality and performance of individual components directly impact the overall efficiency and reliability of the ORC system.

Midstream activities involve the system integration and assembly of these components into complete ORC units. This phase is typically undertaken by ORC system manufacturers who design, engineer, and fabricate the full system, ensuring seamless integration and operational efficiency. Engineering, Procurement, and Construction (EPC) firms often play a central role here, managing the project from initial design to commissioning. The distribution channel predominantly involves direct sales to large industrial clients or energy utility companies, where complex bespoke solutions are often required. Indirect channels include sales through regional distributors, specialized integrators, or value-added resellers who cater to smaller projects or specific geographic markets, offering localized support and installation services.

Downstream activities encompass the installation, commissioning, operation, and maintenance (O&M) services for ORC systems. These services are vital for ensuring the long-term performance and profitability of the installed units. Companies specializing in energy project development, utility providers, and independent power producers are key downstream players who purchase and operate these systems. Post-sales support, including spare parts supply, remote monitoring, and performance optimization, adds significant value throughout the operational lifespan of the ORC plant. The entire value chain is characterized by a high degree of technical expertise and a focus on delivering customized, efficient, and reliable energy recovery solutions.

Organic Rankine Cycle Market Potential Customers

The Organic Rankine Cycle (ORC) market targets a diverse range of potential customers across various sectors, primarily those with significant sources of waste heat or access to low-grade renewable thermal energy. Industrial facilities represent a substantial segment, particularly those in energy-intensive sectors such as steel manufacturing, cement production, glassmaking, chemical processing, and oil and gas refining. These industries generate vast amounts of process waste heat that can be efficiently converted into electricity using ORC systems, thereby reducing operational costs and improving energy self-sufficiency. For these end-users, ORC technology offers a compelling solution for energy recovery, directly contributing to their sustainability goals and compliance with environmental regulations.

Beyond industrial applications, the power generation sector is a key customer base. Geothermal power developers are significant users of ORC technology, especially for low-to-medium temperature geothermal reservoirs where traditional steam turbines are less efficient. Biomass power plants and facilities utilizing municipal solid waste for energy production also serve as important customers, employing ORC systems to generate electricity from the thermal energy derived from combustion. Additionally, solar thermal power plants, particularly those using concentrated solar power (CSP) technologies, increasingly integrate ORC solutions to convert solar-generated heat into electricity, enhancing the dispatchability and overall efficiency of renewable energy generation.

Utilities and independent power producers (IPPs) are increasingly exploring ORC technology for distributed power generation and grid stabilization, especially in regions transitioning towards cleaner energy grids. Commercial and large-scale residential complexes, particularly those employing district heating and cooling systems, may also emerge as potential customers for smaller ORC units, leveraging combined heat and power (CHP) configurations to improve overall energy efficiency. The common thread among these diverse potential customers is their need for efficient, reliable, and sustainable methods to convert available thermal energy into usable electricity, making ORC a versatile solution across a broad spectrum of energy applications.

Organic Rankine Cycle Market Key Technology Landscape

The Organic Rankine Cycle (ORC) market is characterized by a dynamic and evolving technology landscape, with continuous advancements aimed at improving efficiency, reducing costs, and expanding applicability. A critical area of innovation lies in expander technology, moving beyond traditional turbines to include highly efficient screw expanders, scroll expanders, and even piston-type expanders, each optimized for different power scales and working fluid properties. These developments focus on maximizing mechanical power output from a given thermal input, even at lower temperatures and pressures, thereby enhancing the overall energy conversion rate. Furthermore, the design and material science of heat exchangers are continuously being refined to improve heat transfer efficiency, reduce pressure drops, and minimize the physical footprint of ORC units, making them more compact and easier to integrate.

Another significant aspect of the technology landscape is the ongoing research and development in working fluids. The selection of the optimal organic fluid is paramount for ORC system performance, influencing efficiency, operating pressures, and environmental impact. Innovations include the development of new fluids with lower global warming potential (GWP) to meet evolving environmental regulations, as well as blends of fluids tailored to specific temperature ranges and operational conditions to enhance thermodynamic performance. The integration of advanced control systems, often leveraging artificial intelligence and machine learning, is also becoming a standard. These smart control systems enable real-time optimization of ORC parameters, predictive maintenance, and autonomous operation, which significantly improves reliability, reduces downtime, and ensures consistent high performance under varying heat source availability.

Beyond core component improvements, the technology landscape includes the growing trend towards modularization and standardization of ORC systems. This involves designing pre-engineered, skid-mounted units that can be quickly and cost-effectively deployed, reducing installation time and project complexity. Moreover, ORC technology is increasingly being integrated with other renewable energy sources, such as concentrated solar power and biomass boilers, to create hybrid systems that offer greater energy stability and output. Advanced manufacturing techniques, including additive manufacturing, are also being explored for producing complex, optimized components. These technological advancements collectively contribute to making ORC systems more efficient, economically viable, and adaptable to a wider array of low-to-medium temperature heat sources, solidifying their role in sustainable energy generation.

Regional Highlights

- Europe: Leading the market due to stringent environmental regulations, substantial industrial waste heat sources, and robust government support for renewable energy and energy efficiency initiatives. Countries like Germany, Italy, and France are at the forefront of ORC technology adoption and innovation.

- Asia Pacific: Emerging as the fastest-growing market, driven by rapid industrialization, increasing energy demand, and a strong focus on clean energy and waste heat recovery, particularly in China, India, and Japan. Government policies promoting sustainable development and investments in renewable energy infrastructure are key catalysts.

- North America: Experiencing steady growth, largely fueled by expanding geothermal energy projects, the utilization of waste heat from the oil and gas industry, and increasing investment in distributed power generation. Favorable government incentives and a growing awareness of energy efficiency contribute to market expansion.

- South America: Showing significant potential, especially in geothermal energy development and biomass applications, as countries seek to diversify their energy mix and harness indigenous renewable resources. Investments in industrial infrastructure also present opportunities for waste heat recovery.

- Middle East & Africa: An emerging market with growing interest in solar thermal power generation and industrial waste heat recovery. The regions abundant solar resources and expanding industrial base are driving initial explorations and pilot projects for ORC technology.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Organic Rankine Cycle Market.- Turboden S.p.A.

- Ormat Technologies, Inc.

- Exergy International Srl

- Enertime S.A.

- Kaishan Group Co., Ltd.

- Atlas Copco AB (partially through product offerings)

- Siemens Energy AG (through steam turbine and power generation solutions)

- General Electric Company (through power generation equipment)

- Geothermal Engineering GmbH

- Infinity Turbine LLC

- Access Energy (a division of Calnetix Technologies)

- Fives S.A.

- Opcon AB

- Triogen (A division of Turboden S.p.A.)

- Clean Energy Systems, Inc.

Frequently Asked Questions

What is an Organic Rankine Cycle (ORC) system?

An Organic Rankine Cycle (ORC) system is a closed-loop thermodynamic system that converts low-to-medium temperature heat into electricity using an organic working fluid with a low boiling point, instead of water or steam. It is highly efficient for various heat sources like waste heat, geothermal, biomass, and solar thermal energy.

What are the primary applications of ORC technology?

The primary applications of ORC technology include industrial waste heat recovery (e.g., from cement, steel, glass, chemical plants), geothermal power generation, biomass power generation, and solar thermal energy conversion. It is also used in engine waste heat recovery and combined heat and power (CHP) systems.

What are the main benefits of using ORC systems?

The main benefits of ORC systems include efficient power generation from low-temperature heat sources, reduced carbon emissions and fuel consumption, lower maintenance costs due to the use of organic fluids (preventing corrosion and erosion), high operational flexibility, and suitability for decentralized power generation and remote locations.

What are the key challenges facing the ORC market?

Key challenges include the high initial capital investment required for ORC systems, which can impact payback periods. Complexities in selecting optimal working fluids based on environmental and thermodynamic properties, and the technical challenges associated with integrating ORC units into existing industrial infrastructure, also pose significant hurdles.

How does ORC contribute to sustainability and decarbonization?

ORC technology significantly contributes to sustainability and decarbonization by converting waste heat, which would otherwise be released into the atmosphere, into valuable electricity, thereby improving energy efficiency and reducing the reliance on fossil fuels. It also enables the efficient utilization of various renewable heat sources like geothermal and biomass, further lowering greenhouse gas emissions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Waste Heat Recovery System Market Size Report By Type (Steam System, Organic Rankine Cycle System, Kalina Cycle System, Other), By Application (Petroleum Refining, Heavy Metal Production, Cement, Chemical, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Organic Rankine Cycle (ORC) System Market Statistics 2025 Analysis By Application (Combined Cycle Power Plant (CCPP), Waste Heat Recycling, Other), By Type (Driven by Biomass Boilers/Gasifiers, Driven by Waste Heat Sources), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Waste Heat Recovery Unit Market Statistics 2025 Analysis By Application (Petroleum Refining, Heavy Metal Production, Cement, Chemical), By Type (Steam System, Organic Rankine Cycle System, Kalina Cycle System, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Industrial Waste Heat Recovery Systems Market Statistics 2025 Analysis By Application (Petroleum Refining, Heavy Metal Production, Cement, Chemical), By Type (Steam System, Organic Rankine Cycle System, Kalina Cycle System, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Waste Heat Recovery Solutions Market Statistics 2025 Analysis By Application (Petroleum Refining, Heavy Metal Production, Cement, Chemical), By Type (Steam System, Organic Rankine Cycle System, Kalina Cycle System, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager