Packaging Nets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430553 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Packaging Nets Market Size

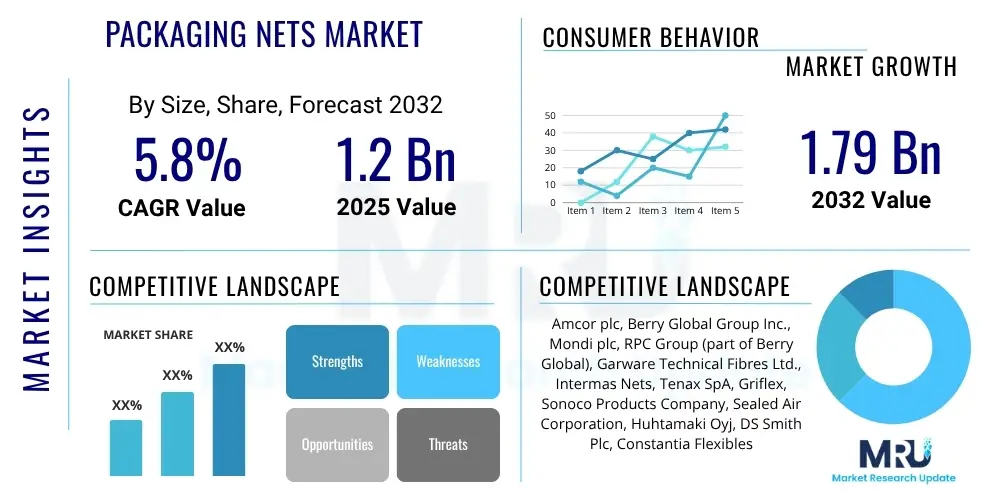

The Packaging Nets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at $1.2 Billion in 2025 and is projected to reach $1.79 Billion by the end of the forecast period in 2032.

Packaging Nets Market introduction

The Packaging Nets Market encompasses a diverse range of netting solutions primarily utilized for the secure and efficient handling, storage, and transportation of various goods. These nets are engineered to provide ventilation, product visibility, and protection while ensuring item stability, particularly for perishable products and irregularly shaped industrial components. The market's growth is intrinsically linked to the expanding global logistics network, the increasing volume of e-commerce transactions, and the evolving demands of industries that require robust yet breathable packaging. The inherent flexibility and cost-effectiveness of packaging nets make them a preferred choice across numerous sectors.

Packaging nets are typically manufactured from materials such as polypropylene (PP), polyethylene (PE), and increasingly, bio-based polymers, offering a range of strengths, mesh sizes, and elastic properties. Their product description highlights their lightweight nature, resistance to tearing, and ability to conform to different product shapes, which is crucial for maximizing load stability and preventing damage during transit. These nets come in various forms, including pallet netting, produce nets, and extruded sleeves, each designed for specific application requirements. The versatility in material and design allows for customization to meet stringent industry standards and client specifications, ensuring optimal performance for diverse packaging needs.

Major applications for packaging nets span across the agriculture sector for fruits, vegetables, and ornamental plants, the industrial sector for securing heavy machinery parts, coils, and fragile components, and the logistics industry for pallet stabilization during warehousing and shipping. The benefits are multifold, including enhanced product shelf-life due to improved air circulation, reduced product spoilage, efficient inventory management through clear visibility, and significant cost savings compared to alternative packaging methods. Key driving factors include the escalating demand for fresh and minimally processed food products, the expansion of global supply chains requiring secure transit solutions, and the increasing adoption of automated packaging systems that benefit from the consistent form factor of net packaging, alongside a growing focus on sustainable and recyclable packaging options.

Packaging Nets Market Executive Summary

The Packaging Nets Market is experiencing robust expansion, driven by significant shifts in global business trends, evolving regional dynamics, and innovative segment developments. Business trends indicate a strong move towards automation in warehousing and logistics, which necessitates packaging solutions that are compatible with robotic handling and high-speed operations. Furthermore, there is an increasing emphasis on sustainable packaging materials, pushing manufacturers to explore recyclable, biodegradable, and compostable net options. Customization and specialized performance features, such as UV resistance or anti-fungal properties, are also becoming critical competitive differentiators, catering to niche market demands and enhancing product value propositions for end-users seeking tailored solutions for unique challenges.

Regional trends play a pivotal role in shaping the market landscape. Asia Pacific is emerging as a dominant region, propelled by its rapidly expanding manufacturing base, burgeoning e-commerce sectors, and vast agricultural output. This region exhibits a high demand for cost-effective and efficient packaging solutions for both domestic consumption and export. North America and Europe, while mature markets, are leading in terms of technological innovation, adoption of advanced materials, and strict regulatory frameworks promoting environmental responsibility. These regions are characterized by a strong focus on high-performance nets and the integration of smart packaging technologies. Latin America, the Middle East, and Africa are showing significant growth potential, driven by improving infrastructure, increasing international trade activities, and a rising focus on food security and supply chain optimization, creating new avenues for market penetration and expansion.

Segmentation trends highlight the increasing importance of material innovation and application-specific solutions. While traditional plastic nets (polypropylene and polyethylene) continue to hold a substantial market share due to their cost-effectiveness and durability, the fastest-growing segment is expected to be bio-based and recyclable nets, responding to consumer and regulatory pressures for environmental sustainability. Pallet wrapping remains the largest application segment, critical for logistics efficiency, closely followed by nets for fresh produce packaging, which benefits from the ventilation properties. The industrial sector's demand for specialized nets for heavy-duty applications also contributes significantly. The market is thus poised for a dynamic future, with product development heavily influenced by environmental considerations and operational efficiencies across diverse end-use industries.

AI Impact Analysis on Packaging Nets Market

Users frequently inquire about how Artificial Intelligence can revolutionize the packaging nets industry, particularly concerning manufacturing efficiency, supply chain optimization, and sustainability. Key themes include the potential for AI to automate quality control, predict material requirements, and enhance design for specific applications. Concerns often revolve around the initial investment in AI infrastructure and the need for skilled labor to manage AI-driven systems. Expectations are high for AI to significantly reduce waste, improve product quality consistency, and provide real-time insights into market demand and production processes, thereby making the packaging nets market more agile and responsive to environmental and operational challenges. The integration of AI is seen as a crucial step towards smarter, more efficient, and sustainable packaging solutions.

- AI-driven predictive analytics optimize raw material procurement, reducing waste and inventory costs.

- Automated quality control systems using AI vision inspect nets for defects, ensuring high product consistency and reducing human error.

- Machine learning algorithms enhance manufacturing processes by optimizing extrusion and weaving parameters for improved net strength and material usage.

- AI-powered supply chain management provides real-time tracking and forecasting, improving delivery efficiency and reducing transit damages for netted goods.

- Generative AI assists in designing custom net patterns and structures that maximize protection and ventilation for specific product types.

- AI facilitates the development of smart packaging nets with integrated sensors for monitoring product conditions during transit, particularly for perishables.

- Data analysis by AI helps identify optimal recycling pathways and sustainable material alternatives, furthering environmental initiatives within the industry.

DRO & Impact Forces Of Packaging Nets Market

The Packaging Nets Market is propelled by several robust drivers, including the relentless expansion of global e-commerce, which mandates efficient and protective packaging for a vast array of goods. The increasing demand for fresh and perishable food products globally also acts as a significant catalyst, as nets offer superior ventilation and visibility compared to opaque alternatives, extending shelf life and reducing spoilage. Furthermore, the rising industrial output and complex logistics operations worldwide necessitate reliable pallet stabilization and product containment solutions, areas where packaging nets excel due to their strength and adaptability. Their cost-effectiveness relative to other packaging materials also makes them an attractive option for businesses looking to optimize operational expenditures without compromising product integrity.

However, the market faces notable restraints that could temper its growth trajectory. Fluctuations in raw material prices, particularly for petrochemical-derived polymers like polypropylene and polyethylene, introduce cost volatility for manufacturers, which can impact pricing strategies and profit margins. The increasing environmental scrutiny regarding plastic waste and pollution poses a significant challenge, driving a push for more sustainable yet equally functional alternatives. This pressure from environmental regulations and growing consumer preference for eco-friendly products creates a dilemma for manufacturers dependent on traditional plastic nets. Additionally, intense competition from alternative packaging solutions such as stretch films, shrink wraps, and corrugated boxes, each with their own set of advantages, necessitates continuous innovation in the packaging nets sector to maintain market share.

Despite these restraints, ample opportunities exist for market expansion and innovation. The development and adoption of biodegradable, compostable, and recyclable packaging net materials represent a major growth avenue, aligning with global sustainability goals and regulatory shifts. Integration of smart technologies, such as RFID tags or QR codes, into packaging nets can offer enhanced traceability and real-time monitoring of goods, particularly for high-value or temperature-sensitive products. Emerging markets in developing economies present untapped potential, as improving infrastructure and increasing consumer purchasing power drive demand for modern packaging solutions. Strategic partnerships with logistics providers and agricultural companies can also unlock new distribution channels and application areas, allowing for specialized product offerings that cater to evolving industry needs. These opportunities, when strategically leveraged, can significantly mitigate the impact of existing restraints and propel the market forward.

Segmentation Analysis

The Packaging Nets Market is comprehensively segmented based on various factors, including the material used for manufacturing, the specific product type, its primary application, the end-use industry it serves, and the form in which it is supplied. This segmentation provides a granular view of market dynamics, revealing key trends and growth opportunities within distinct categories. The diverse needs of industries ranging from agriculture to heavy manufacturing necessitate a broad spectrum of net specifications, driving innovation in material science and product design to meet specialized requirements for strength, breathability, and environmental impact. Understanding these segments is crucial for stakeholders to tailor their product offerings and market strategies effectively.

- Material Type:

- Polypropylene (PP)

- Polyethylene (PE)

- Polyester

- Bio-based Materials (e.g., PLA, Cellulose-based)

- Other Polymers

- Product Type:

- Extruded Nets (e.g., fruit and vegetable bags, pallet wraps)

- Woven Nets (e.g., heavy-duty pallet nets, industrial covers)

- Knitted Nets (e.g., fine mesh for delicate produce)

- Sleeves (e.g., for bottles, components)

- Application:

- Pallet Wrapping and Stabilization

- Produce Packaging (Fruits, Vegetables, Seafood)

- Industrial Packaging (Automotive parts, Metal coils, Machinery)

- Consumer Goods Packaging

- Poultry and Meat Packaging

- End-Use Industry:

- Agriculture

- Food and Beverage

- Logistics and Transportation

- Industrial Manufacturing

- Building and Construction

- Retail

- Form:

- Rolls

- Bags

- Sleeves

Value Chain Analysis For Packaging Nets Market

The value chain for the Packaging Nets Market commences with upstream analysis, involving the sourcing and processing of raw materials. This segment is dominated by petrochemical companies that supply polymers such as polypropylene, polyethylene, and polyester, which are the fundamental building blocks for most packaging nets. In addition, manufacturers of specialized additives (e.g., UV stabilizers, colorants) and machinery for extrusion, weaving, and knitting also form part of the upstream activities. The quality and cost of these raw materials significantly influence the final product's performance and market price, making strong supplier relationships and efficient procurement strategies crucial for net manufacturers. As sustainability gains prominence, the sourcing of bio-based polymers and recycled content also forms a growing part of this upstream segment.

Moving downstream, the value chain encompasses the manufacturing processes where raw polymers are transformed into finished packaging nets through various techniques like extrusion, weaving, and knitting. These manufacturers, often referred to as converters, then supply their products to a diverse range of end-users. The distribution channels play a critical role in connecting these manufacturers with their potential customers. Direct distribution involves manufacturers selling directly to large industrial clients, agricultural cooperatives, or major logistics firms that purchase in bulk and may require customized net solutions. This channel allows for closer client relationships and tailored service offerings. Indirect distribution, on the other hand, involves intermediaries such as wholesalers, distributors, and packaging solution providers, who consolidate products from multiple manufacturers and distribute them to a wider array of smaller businesses or retail channels. Online platforms and e-commerce also represent a growing indirect channel, providing accessibility to a broader customer base for standard net products.

Both direct and indirect distribution strategies are vital for market penetration. Direct sales offer benefits such as higher margins, direct feedback, and greater control over customer service, often catering to specialized, high-volume orders. Indirect channels, while involving additional costs, provide extensive market reach, particularly to small and medium-sized enterprises (SMEs) and geographically dispersed customers, without the manufacturer needing to establish a vast distribution network. The choice of distribution channel often depends on the type of net product, the target customer segment, and the manufacturer's operational capabilities. Effective management of this multi-faceted value chain, from raw material sourcing to final delivery, is essential for optimizing costs, ensuring product quality, and maintaining a competitive edge in the Packaging Nets Market.

Packaging Nets Market Potential Customers

The Packaging Nets Market serves a broad and diverse range of potential customers, essentially encompassing any industry that requires efficient, protective, and often breathable solutions for product containment, stabilization, and transportation. End-users and buyers of packaging nets are primarily those involved in the handling and distribution of goods that benefit from ventilation, visibility, or secure bundling. A significant segment comprises the agricultural sector, including large-scale farms, fruit and vegetable growers, seafood processors, and agricultural cooperatives, which utilize nets for harvesting, packaging, and shipping fresh produce to maintain quality and extend shelf life.

Beyond agriculture, the logistics and transportation industry represents a crucial customer base, with warehousing companies, freight forwarders, and distribution centers relying on pallet netting to secure loads during transit and storage, preventing damage and improving handling efficiency. The industrial sector also constitutes a substantial portion of potential customers, including manufacturers of automotive parts, metal coils, machinery components, and other irregularly shaped or heavy items that require robust containment. Furthermore, food and beverage processing companies, particularly those dealing with perishable goods or bulk ingredients, leverage packaging nets for internal handling and external distribution. The retail sector, especially for bulk produce sections and certain consumer goods, also relies on these nets. Overall, any business involved in the manufacturing, processing, or distribution of products that need secure, breathable, and visible packaging solutions is a potential customer for the packaging nets market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.2 Billion |

| Market Forecast in 2032 | $1.79 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amcor plc, Berry Global Group Inc., Mondi plc, RPC Group (part of Berry Global), Garware Technical Fibres Ltd., Intermas Nets, Tenax SpA, Griflex, Sonoco Products Company, Sealed Air Corporation, Huhtamaki Oyj, DS Smith Plc, Constantia Flexibles GmbH, AptarGroup Inc., Netpak, RKW Group, Plastipak Holdings Inc., E. I. du Pont de Nemours and Company, Dow Inc., Sabic |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Packaging Nets Market Key Technology Landscape

The Packaging Nets Market is continuously evolving with significant advancements in its underlying technology landscape, driven by demands for increased efficiency, durability, and sustainability. Extrusion technology remains foundational, particularly for the production of plastic nets like those used for fruits, vegetables, and lightweight industrial packaging. Innovations in this area focus on multi-layer extrusion for enhanced strength, barrier properties, or integration of recycled content, as well as optimizing die designs to create finer meshes and more consistent net structures. Alongside extrusion, advanced weaving and knitting techniques are crucial for producing robust and specialized nets, such as heavy-duty pallet stabilization nets or fine-mesh nets for delicate produce. These technologies are seeing improvements in machine speed, precision, and the ability to process a wider range of yarn types, including increasingly common bio-based and recycled fibers. The integration of automation and robotics into these manufacturing processes is also a key technological trend, improving production speed, reducing labor costs, and ensuring consistent product quality.

Beyond core manufacturing, material science plays a pivotal role in the technology landscape of packaging nets. Research and development are focused on creating novel polymer blends that offer superior performance characteristics, such as increased tear resistance, enhanced elasticity, or specific temperature tolerances. A major thrust is the development of sustainable materials, including biodegradable polymers derived from renewable resources (e.g., PLA, cellulose-based materials) and advanced recycling technologies that enable the efficient recovery and re-use of plastic net waste. Surface treatment technologies are also gaining prominence, allowing for the application of coatings that provide UV protection, anti-fungal properties, or anti-slip characteristics, thereby extending the utility and performance of the nets in challenging environments or for sensitive products. Furthermore, the burgeoning field of smart packaging is influencing net design, with early explorations into integrating sensors or RFID tags directly into the net structure for real-time monitoring of product conditions or enhanced supply chain traceability. These technological advancements collectively contribute to a more versatile, efficient, and environmentally responsible packaging nets market, addressing the complex demands of modern logistics and consumer preferences.

The shift towards Industry 4.0 principles, including the Internet of Things (IoT) and artificial intelligence, is beginning to impact the packaging net production process. Manufacturers are implementing sensors on production lines to monitor machine performance, predict maintenance needs, and optimize energy consumption. Data analytics is used to refine manufacturing parameters, leading to less material waste and higher output quality. Digital printing technologies are also enabling more efficient branding and labeling directly on net packaging, offering customization without extensive additional processing steps. The amalgamation of these technologies is not only enhancing the functional attributes of packaging nets but also driving the operational efficiency and sustainability profile of the entire value chain, making net production more responsive, adaptive, and resource-efficient in response to evolving market demands.

Regional Highlights

- North America: This region demonstrates a strong market due to advanced logistics infrastructure, high adoption of automated warehousing, and increasing demand for fresh produce packaging. Stringent regulations for product safety and sustainability also drive innovation in net materials and design.

- Europe: Characterized by mature markets and a leading position in sustainable packaging initiatives, Europe sees significant growth in bio-based and recyclable nets. High demand from the agriculture sector and robust e-commerce penetration further bolster the market.

- Asia Pacific (APAC): As the fastest-growing region, APAC benefits from rapid industrialization, burgeoning e-commerce platforms, and a massive agricultural sector. Low manufacturing costs and increasing disposable incomes contribute to the region's expanding market share for packaging nets.

- Latin America: This region exhibits promising growth potential due to expanding food processing industries, increasing agricultural exports, and ongoing improvements in logistics and transportation infrastructure. Demand for cost-effective and efficient packaging is on the rise.

- Middle East and Africa (MEA): The MEA market is gradually expanding, driven by infrastructure development projects, initiatives to enhance food security, and diversification of economies. Increasing international trade and foreign investments also contribute to the adoption of modern packaging solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Packaging Nets Market.- Amcor plc

- Berry Global Group Inc.

- Mondi plc

- Garware Technical Fibres Ltd.

- Intermas Nets

- Tenax SpA

- Griflex

- Sonoco Products Company

- Sealed Air Corporation

- Huhtamaki Oyj

- DS Smith Plc

- Constantia Flexibles GmbH

- AptarGroup Inc.

- Netpak

- RKW Group

- Plastipak Holdings Inc.

- E. I. du Pont de Nemours and Company

- Dow Inc.

- Sabic

- Flexopack S.A.

Frequently Asked Questions

What are the primary uses of packaging nets?

Packaging nets are primarily used for securing, protecting, and ventilating products during storage, transit, and retail display. Their main applications include pallet wrapping to stabilize goods, packaging fresh produce like fruits and vegetables to ensure air circulation and extend shelf life, and bundling industrial components or irregularly shaped items for protection and ease of handling.

What materials are commonly used in manufacturing packaging nets?

The most common materials for packaging nets include polypropylene (PP) and polyethylene (PE) due to their versatility, strength, and cost-effectiveness. Polyester is also used for specialized applications requiring higher tensile strength. Increasingly, there is a growing trend towards bio-based materials like PLA (Polylactic Acid) and other cellulose-derived polymers, as well as recycled content, driven by sustainability initiatives and consumer demand for eco-friendly solutions.

Are packaging nets considered environmentally friendly?

The environmental friendliness of packaging nets depends largely on the material used and its end-of-life management. Traditional plastic nets raise concerns about waste and pollution. However, the industry is rapidly innovating towards more sustainable options, including nets made from recycled plastics, biodegradable polymers, and compostable materials. Many manufacturers are also focusing on designing nets that are fully recyclable within existing infrastructure, aiming to reduce their environmental footprint and align with circular economy principles.

How does the growth of e-commerce impact the packaging nets market?

The e-commerce boom significantly fuels the packaging nets market by increasing the demand for efficient, secure, and lightweight packaging solutions. As more goods are shipped directly to consumers, the need for robust pallet stabilization during logistics, and protective, breathable packaging for various products, including perishables, becomes critical. Packaging nets offer a cost-effective way to prevent damage during shipping, optimize space, and ensure product integrity throughout the extensive e-commerce supply chain.

What are the key innovations shaping the future of packaging nets?

Key innovations in packaging nets are centered on sustainability, performance enhancement, and smart integration. This includes the development of advanced bio-based and fully recyclable materials, improvements in extrusion and weaving technologies for stronger and lighter nets, and the incorporation of specialized additives for features like UV resistance or anti-fungal properties. Future innovations are also exploring the integration of smart technologies, such as RFID tags or sensors, within nets for enhanced traceability and real-time monitoring of goods, particularly for high-value or temperature-sensitive products, to provide comprehensive supply chain insights.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager