Pallet Jacks Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427608 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Pallet Jacks Market Size

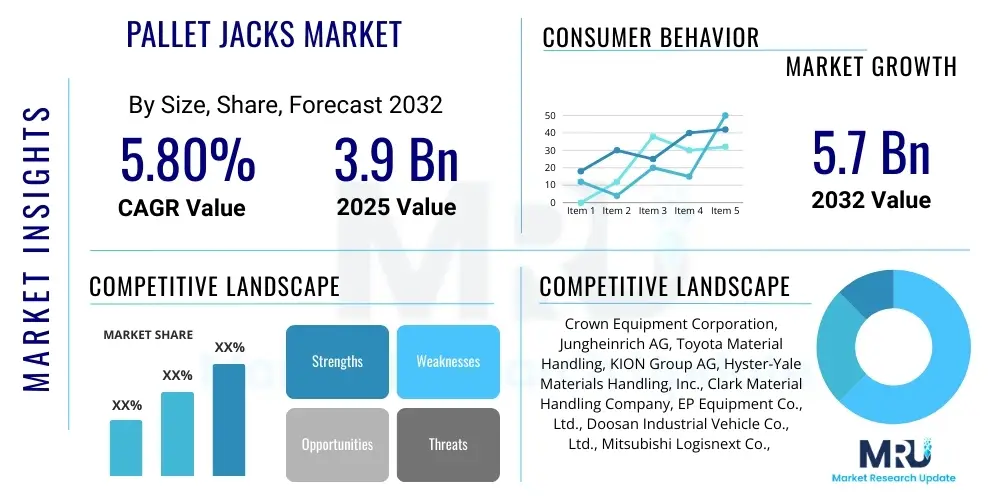

The Pallet Jacks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 3.9 Billion in 2025 and is projected to reach USD 5.7 Billion by the end of the forecast period in 2032. This substantial growth is primarily driven by the continuous expansion of global e-commerce, the increasing emphasis on warehouse automation, and the rising demand for efficient material handling solutions across various industrial sectors.

Pallet Jacks Market introduction

The Pallet Jacks Market encompasses a range of material handling equipment designed for lifting and moving pallets within warehouses, distribution centers, manufacturing facilities, and retail environments. These essential tools facilitate the horizontal transportation of goods, significantly enhancing operational efficiency and reducing manual labor requirements. Products typically include manual, electric, and semi-electric pallet jacks, each offering distinct advantages tailored to specific operational needs and load capacities. Major applications span across logistics and supply chain operations, retail backrooms, pharmaceutical storage, and food and beverage distribution, where their versatility and maneuverability are highly valued. The primary benefits of employing pallet jacks include improved productivity, enhanced worker safety through reduced physical strain, and optimized space utilization in storage areas. The markets growth is substantially driven by the rapid expansion of global e-commerce necessitating faster order fulfillment, increasing industrialization in developing economies, and the growing demand for automated and semi-automated material handling solutions to counteract labor shortages and improve operational throughput.

Pallet Jacks Market Executive Summary

The Pallet Jacks Market is undergoing significant transformation, characterized by several key business and technological trends. Businesses are increasingly adopting electric and semi-electric pallet jacks due to their enhanced efficiency, ergonomic benefits, and reduced operational fatigue compared to manual alternatives. The integration of advanced features such as lithium-ion batteries, telematics, and improved safety sensors is becoming more prevalent, signaling a shift towards smarter, more connected material handling solutions. From a regional perspective, Asia-Pacific is emerging as a dominant force, fueled by rapid industrial growth, expanding manufacturing sectors, and burgeoning e-commerce industries in countries like China and India. North America and Europe, while mature markets, continue to demonstrate steady demand, driven by modernization efforts in existing warehouses and a focus on operational safety and efficiency improvements. In terms of segment trends, the electric pallet jack segment is experiencing accelerated growth, largely attributed to its higher productivity and suitability for intensive operations, while manual pallet jacks retain their market share for light-duty, cost-sensitive applications. Overall, the markets trajectory is upward, propelled by the imperative for streamlined logistics and robust supply chain management.

AI Impact Analysis on Pallet Jacks Market

The advent of Artificial Intelligence (AI) is poised to significantly transform the Pallet Jacks Market, addressing common user questions about automation, efficiency, and predictive capabilities. Users frequently inquire about how AI can enhance the performance and safety of pallet jacks, reduce downtime, and contribute to more autonomous material handling systems. The key themes revolve around AIs potential to enable smarter operational decision-making, facilitate predictive maintenance, and integrate pallet jacks more seamlessly into broader smart warehouse ecosystems. AIs influence extends to optimizing material flow, improving route planning, and enhancing the overall safety of warehouse operations by anticipating potential hazards. This integration promises to elevate pallet jacks from simple material handling equipment to intelligent, data-driven assets within the modern supply chain. The primary concerns users have often center on the complexity of integrating AI, initial investment costs, and the cybersecurity implications of connected devices, alongside the impact on existing human labor roles. However, the overarching expectation is that AI will unlock new levels of efficiency and operational intelligence.

- AI-driven predictive maintenance can forecast equipment failures, reducing unplanned downtime and optimizing maintenance schedules for pallet jacks.

- Route optimization algorithms powered by AI can determine the most efficient paths for electric and autonomous pallet jacks, minimizing travel time and energy consumption within a facility.

- Integration of AI with vision systems allows pallet jacks to navigate complex environments, detect obstacles, and enhance collision avoidance, significantly improving safety.

- AI facilitates real-time data analysis from telematics devices on pallet jacks, providing insights into operational performance, utilization rates, and driver behavior.

- Development of semi-autonomous and fully autonomous pallet jacks, capable of performing tasks with minimal human intervention, driven by advanced AI navigation and decision-making.

- AI can optimize battery management for electric pallet jacks, extending battery life and ensuring optimal charging cycles based on usage patterns.

- Enhanced inventory management through AI-enabled pallet jacks that can automatically scan, track, and report on pallet locations and contents, reducing manual errors.

DRO & Impact Forces Of Pallet Jacks Market

The Pallet Jacks Market is influenced by a complex interplay of drivers, restraints, and opportunities, all shaped by various internal and external impact forces. A primary driver is the relentless expansion of global e-commerce, which necessitates highly efficient and rapid material handling processes in warehouses and distribution centers to meet escalating consumer demands. Concurrently, increasing industrialization and urbanization in emerging economies are fueling the construction of new logistics infrastructure and manufacturing plants, thereby boosting the demand for essential equipment like pallet jacks. The growing emphasis on workplace safety and ergonomics also propels the adoption of electric and semi-electric pallet jacks, which reduce physical strain on workers compared to traditional manual options. Furthermore, persistent labor shortages in the logistics sector incentivize companies to invest in equipment that enhances worker productivity and operational autonomy.

However, the market faces notable restraints that could impede its growth. The relatively high initial investment cost associated with advanced electric and semi-electric pallet jacks, particularly those with sophisticated features like lithium-ion batteries or telematics, can be a barrier for small and medium-sized enterprises (SMEs). Moreover, the intense competition from more advanced material handling solutions such as Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) in larger, more automated facilities presents a challenge, as some enterprises might opt for full automation over semi-automated solutions. Maintenance costs and the need for skilled technicians to operate and repair advanced pallet jacks also add to the total cost of ownership, which can be a deterrent for budget-conscious organizations. Geopolitical instability and economic downturns can further restrict capital expenditure on new equipment, thereby slowing market expansion.

Despite these challenges, significant opportunities abound for the Pallet Jacks Market. The ongoing trend towards warehouse automation and smart logistics presents a fertile ground for integrating more intelligent and connected pallet jack solutions. Developing regions, characterized by their nascent but rapidly expanding industrial bases, offer immense untapped potential for market penetration. Furthermore, the increasing focus on sustainability and energy efficiency creates opportunities for manufacturers to innovate with eco-friendly designs and power sources, such as advanced battery technologies and regenerative braking systems. Collaboration with technology providers to embed IoT capabilities, telematics, and AI into pallet jacks will also unlock new value propositions, improving fleet management, predictive maintenance, and overall operational visibility. The continuous evolution of ergonomic designs and user-friendly interfaces will further enhance market appeal.

- Drivers:

- Rapid growth of the global e-commerce sector and associated warehousing needs.

- Increasing industrialization and expansion of manufacturing activities worldwide.

- Growing focus on workplace safety and ergonomics, promoting electric models.

- Shortage of skilled labor in the logistics and material handling industries.

- Demand for efficient and cost-effective material handling solutions in various sectors.

- Restraints:

- High initial investment costs for advanced electric and semi-electric pallet jacks.

- Competition from advanced automation solutions like AGVs and AMRs in large-scale operations.

- Maintenance expenses and the requirement for specialized technical support.

- Potential for economic slowdowns affecting capital expenditure in industrial sectors.

- Opportunities:

- Integration with smart warehouse technologies and IoT for enhanced efficiency.

- Market expansion in emerging economies with developing industrial infrastructures.

- Development of environmentally friendly and energy-efficient pallet jack models.

- Technological advancements in battery technology (e.g., lithium-ion) and telematics.

- Customization and specialized designs for niche applications and extreme conditions.

Segmentation Analysis

The Pallet Jacks Market is comprehensively segmented across various dimensions to provide a granular understanding of its dynamics, identifying key areas of growth and market penetration strategies. These segmentation criteria typically include product type, load capacity, end-use industry, and power source, each offering unique insights into consumer preferences and operational requirements. Understanding these segments is crucial for manufacturers and suppliers to tailor their product offerings and marketing strategies effectively. For instance, the distinction between manual and electric pallet jacks highlights the trade-offs between cost-effectiveness for light duties versus efficiency and ergonomics for heavier, more frequent operations. Similarly, segmenting by end-use industries reveals specific demands, such as hygiene requirements in food and beverage or precision handling in pharmaceuticals, guiding product innovation.

Segmentation by load capacity is essential for addressing diverse material handling needs, from light retail stock movement to heavy industrial loads. The evolution of battery technology, particularly the adoption of lithium-ion batteries, has also created a significant segmentation within electric pallet jacks, affecting performance, charging times, and overall operational cost. These granular classifications enable market players to identify specific market niches and develop targeted solutions that address the nuanced requirements of different customer groups. The analysis of these segments also provides a clear picture of market maturity and saturation in various areas, allowing for strategic planning and resource allocation. Furthermore, geographical segmentation helps in understanding regional consumption patterns, regulatory environments, and economic factors influencing purchasing decisions.

The strategic analysis of these market segments aids in forecasting future growth trends and identifying competitive advantages. For example, the increasing demand for automation and enhanced safety features within specific industrial applications like manufacturing and logistics is driving innovation within the electric pallet jack segment. Similarly, the continued reliance on basic, robust manual pallet jacks in smaller businesses or for occasional use maintains a consistent demand for this foundational segment. By analyzing the interplay between these segments, businesses can optimize their product portfolios, identify promising investment opportunities, and develop more resilient and responsive market strategies in a rapidly evolving global economy.

- By Type:

- Manual Pallet Jacks

- Electric Pallet Jacks (Walkie, Rider)

- Semi-Electric Pallet Jacks

- By Load Capacity:

- Less than 2,000 lbs

- 2,000 lbs to 5,000 lbs

- More than 5,000 lbs

- By End-Use Industry:

- Warehousing and Logistics

- Retail and E-commerce

- Manufacturing

- Food and Beverage

- Pharmaceuticals

- Others (e.g., Construction, Chemical)

- By Power Source (for Electric/Semi-Electric):

- Lead-Acid Batteries

- Lithium-Ion Batteries

Pallet Jacks Market Value Chain Analysis

The value chain for the Pallet Jacks Market is a complex network of interconnected activities, beginning with the sourcing of raw materials and culminating in the delivery and post-sales support of the finished product to the end-user. Upstream activities involve the procurement of essential components and raw materials such as steel, high-grade plastics, hydraulic systems, electric motors, batteries, and electronic controls. Key suppliers in this stage include metal fabricators, battery manufacturers, hydraulic component specialists, and electronics providers. The quality and cost-effectiveness of these foundational inputs significantly influence the final products performance and market competitiveness. Strong relationships with reliable suppliers are critical for ensuring consistent quality, managing costs, and mitigating supply chain disruptions.

Midstream in the value chain, manufacturers play a pivotal role in designing, assembling, and testing pallet jacks. This phase involves precision engineering, integration of various components, and stringent quality control processes to ensure durability, safety, and compliance with industry standards. Innovation in design, such as ergonomic handles, advanced braking systems, and modular components, adds significant value here. Research and development efforts are concentrated on improving efficiency, extending battery life, and incorporating smart features like telematics. The manufacturing process often involves a combination of automated and manual assembly lines, focusing on lean principles to optimize production efficiency and reduce waste.

Downstream activities encompass distribution, sales, and aftermarket services. Pallet jacks reach end-users through a combination of direct sales channels, authorized dealerships, and robust distributor networks. These distribution channels are crucial for market penetration, offering geographical reach, local inventory, and immediate customer support. Aftermarket services, including maintenance, repairs, spare parts availability, and training, are vital for customer satisfaction and long-term brand loyalty. These services not only extend the lifespan of the equipment but also generate recurring revenue streams. The efficiency of the entire value chain, from raw material sourcing to post-sales support, directly impacts the market positioning and profitability of pallet jack manufacturers, making continuous optimization a strategic imperative.

Pallet Jacks Market Potential Customers

The Pallet Jacks Market serves a broad spectrum of potential customers across various industries, all requiring efficient and reliable solutions for horizontal material handling. The most significant customer base resides within the warehousing and logistics sector, encompassing third-party logistics (3PL) providers, freight forwarders, and distribution centers of all sizes. These operations rely heavily on pallet jacks for loading and unloading trucks, transporting goods within vast facilities, and organizing inventory in racking systems. The rapid growth of global supply chains and the increasing volume of goods handled necessitate robust and adaptable equipment, making these entities prime buyers for both manual and electric models to streamline their complex operational flows and enhance throughput.

Another substantial segment of potential customers includes the retail and e-commerce industries. From large big-box stores and supermarkets to smaller retail outlets and dedicated e-commerce fulfillment centers, pallet jacks are indispensable for managing incoming stock, replenishing shelves, and preparing online orders for shipment. The need for quick and ergonomic movement of goods in often confined backroom spaces or high-volume picking areas makes compact and maneuverable pallet jacks particularly attractive. Furthermore, the manufacturing sector represents a consistent demand source, with factories utilizing pallet jacks for moving raw materials to production lines, transporting work-in-progress, and staging finished goods for dispatch. Companies involved in automotive, electronics, heavy machinery, and consumer goods manufacturing frequently invest in pallet jacks to support their continuous production cycles and internal logistics.

Beyond these core sectors, the food and beverage industry, pharmaceuticals, and chemical sectors also constitute significant potential customers. In food and beverage, hygiene and efficient cold chain management drive demand for specialized pallet jacks suitable for temperature-controlled environments or wash-down applications. The pharmaceutical industry requires precision handling and strict inventory control, often favoring electric pallet jacks for their smooth operation and safety features. Even industries like construction, where materials need to be moved across sites, or agricultural businesses for transporting packaged produce, find essential uses for robust pallet jacks. This diverse demand across numerous verticals underscores the universal utility and market breadth of pallet jacks as fundamental material handling tools.

Pallet Jacks Market Key Technology Landscape

The Pallet Jacks Market is continually evolving, driven by technological advancements aimed at enhancing efficiency, safety, ergonomics, and overall operational intelligence. A significant technological shift has been the widespread adoption of lithium-ion battery technology, particularly for electric and semi-electric pallet jacks. These batteries offer distinct advantages over traditional lead-acid counterparts, including faster charging times, longer runtimes, zero maintenance, and a longer lifespan, contributing to increased uptime and lower total cost of ownership. The integration of advanced motor technologies, such as AC drive motors, further improves energy efficiency and provides smoother, more powerful performance, reducing wear and tear while enhancing maneuverability in demanding warehouse environments.

Another critical area of technological innovation is the incorporation of telematics and Internet of Things (IoT) sensors. Telematics systems allow for real-time monitoring of pallet jack fleets, providing valuable data on usage patterns, battery status, operational hours, and even impacts. This data enables fleet managers to optimize utilization, implement predictive maintenance strategies, and identify areas for operational improvement and driver training. IoT sensors further enhance this capability by providing granular data on machine health, environmental conditions, and location tracking, facilitating a more connected and intelligent material handling ecosystem. These technologies not only improve asset management but also contribute significantly to workplace safety by monitoring operator behavior and equipment condition.

Ergonomic design principles are also at the forefront of technological development in pallet jacks, focusing on user comfort and injury prevention. This includes the development of ergonomically designed handles, adjustable tiller heads, power steering, and cushioned operator platforms for rider models, all aimed at reducing operator fatigue and increasing productivity during long shifts. Furthermore, safety features such as automatic braking, anti-roll back systems, pedestrian detection, and advanced warning systems are being integrated through sophisticated sensor technology and control algorithms. The nascent stages of autonomous navigation and remote-control capabilities, leveraging AI and advanced mapping, are also emerging, hinting at a future where pallet jacks can operate with even greater independence and efficiency within smart warehouse infrastructures, revolutionizing traditional material handling paradigms.

Regional Highlights

- North America: This region represents a mature market with a strong emphasis on automation, safety, and efficiency. The growing e-commerce sector and a well-established logistics infrastructure drive demand for advanced electric and semi-electric pallet jacks. Investments in warehouse modernization and the adoption of cutting-edge material handling technologies are prevalent, with a focus on integrating telematics and ergonomic designs.

- Europe: Similar to North America, Europe is a mature market characterized by stringent safety regulations and a high demand for energy-efficient and environmentally friendly material handling solutions. Germany, the UK, and France are key contributors, driven by manufacturing, retail, and a robust logistics network. The adoption of lithium-ion powered pallet jacks and automated features is steadily increasing across the continent.

- Asia-Pacific: Poised for rapid growth, the Asia-Pacific region is the fastest-growing market for pallet jacks, primarily fueled by massive industrialization, expanding manufacturing bases, and explosive e-commerce growth in countries like China, India, and Southeast Asian nations. Increased foreign direct investment, developing logistics infrastructure, and a large labor force contribute to the widespread adoption of both manual and electric pallet jacks.

- Latin America: This region is an emerging market experiencing steady growth, driven by increasing trade activities, foreign investments in manufacturing, and the development of new distribution centers. Brazil and Mexico are leading markets, with a growing demand for cost-effective and durable pallet jacks. The market is gradually transitioning from manual to semi-electric and electric options as businesses modernize their operations.

- Middle East & Africa: The market in the Middle East and Africa is characterized by ongoing infrastructure development projects, growth in the retail and logistics sectors, and diversification efforts away from oil-dependent economies. Countries like UAE, Saudi Arabia, and South Africa are key markets, showing increasing adoption of modern material handling equipment, though manual pallet jacks still hold a significant share due to cost considerations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pallet Jacks Market.- Crown Equipment Corporation

- Jungheinrich AG

- Toyota Material Handling

- KION Group AG (Linde Material Handling, STILL)

- Hyster-Yale Materials Handling, Inc.

- Clark Material Handling Company

- EP Equipment Co., Ltd.

- Doosan Industrial Vehicle Co., Ltd.

- Mitsubishi Logisnext Co., Ltd.

- Combilift Ltd.

- Ningbo Ruyi Joint Stock Co., Ltd. (Xilin)

- Big Joe Lift Trucks

Frequently Asked Questions

What is a pallet jack and what are its primary uses?

A pallet jack, also known as a pallet truck, is a fundamental piece of material handling equipment used for lifting and moving pallets and their loaded goods horizontally. Its primary uses include loading and unloading trucks, transporting inventory within warehouses, distribution centers, and retail stores, and facilitating efficient stock movement in various industrial settings.

What are the different types of pallet jacks available?

Pallet jacks are primarily categorized into three types: manual pallet jacks, which rely on hydraulic hand pumps for lifting and manual effort for movement; electric pallet jacks (walkie and rider models), which use an electric motor for both lifting and propulsion; and semi-electric pallet jacks, which typically feature electric drive but manual lift.

What are the key benefits of using electric pallet jacks over manual ones?

Electric pallet jacks offer several key benefits over manual versions, including significantly reduced operator fatigue, enhanced efficiency for moving heavier loads over longer distances, faster operational speeds, and improved ergonomics. They contribute to higher productivity and can be equipped with advanced features like telematics and lithium-ion batteries for superior performance and reduced downtime.

How does AI impact the future of pallet jacks in warehouses?

AI is set to revolutionize pallet jacks by enabling features such as predictive maintenance to reduce downtime, route optimization for more efficient material flow, and enhanced safety through advanced obstacle detection and collision avoidance. AI also facilitates the development of semi-autonomous and fully autonomous pallet jacks, integrating them into intelligent warehouse ecosystems for greater automation and operational insights.

What factors should be considered when choosing a pallet jack?

When selecting a pallet jack, critical factors to consider include the typical load capacity required, the distances goods need to be transported, the type of environment (e.g., cold storage, narrow aisles), operational frequency, available budget, and specific ergonomic or safety features needed. The power source (manual, lead-acid, or lithium-ion) and maintenance requirements are also significant considerations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager