Palletizer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427725 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Palletizer Market Size

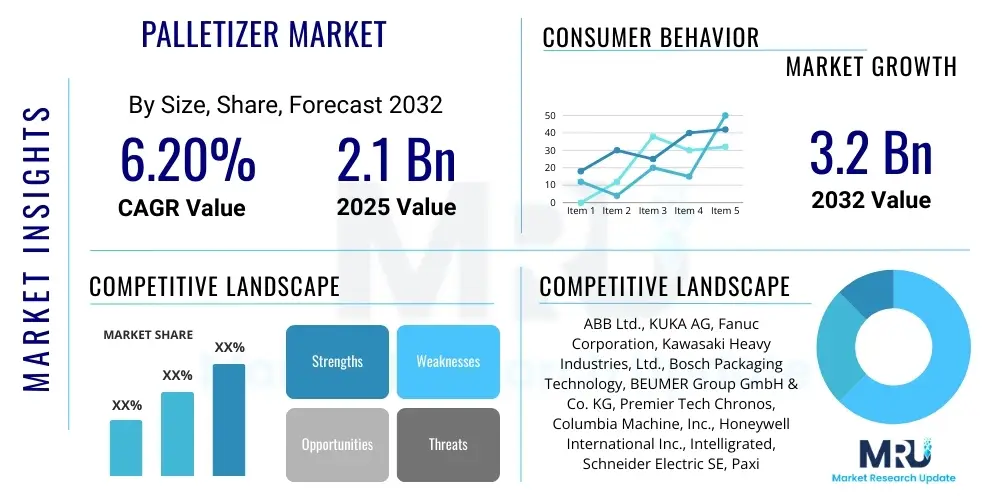

The Palletizer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at USD 2.1 billion in 2025 and is projected to reach USD 3.2 billion by the end of the forecast period in 2032.

Palletizer Market introduction

The Palletizer Market encompasses automated or semi-automated machinery designed to stack and arrange products onto pallets for storage, warehousing, and transportation. These systems are crucial for streamlining end-of-line packaging processes, enhancing operational efficiency, and reducing manual labor requirements in various industries. Palletizers handle a diverse range of products, including boxes, bags, cartons, and bundled goods, ensuring stable and organized loads for subsequent logistics. Their primary function is to optimize space utilization, improve safety, and accelerate throughput in manufacturing and distribution environments.

Major applications for palletizers span across the food and beverage, pharmaceutical, chemical, consumer goods, and logistics sectors, where consistent and high-volume packaging is paramount. Benefits derived from the adoption of palletizing solutions include significant reductions in labor costs, minimized risk of workplace injuries associated with heavy lifting, improved pallet stability for safer transport, and increased speed and accuracy of operations. These advantages directly contribute to enhanced productivity and a more efficient supply chain. The automation offered by palletizers addresses critical industrial needs for scalability and reliability in packaging operations.

Driving factors propelling the Palletizer Market include the escalating demand for automation across industries to counter rising labor costs and shortages, the rapid expansion of e-commerce necessitating faster and more efficient warehousing and distribution, and the increasing focus on workplace safety and ergonomics. Additionally, advancements in robotics and control technologies, coupled with the growing emphasis on Industry 4.0 principles, are further stimulating market growth by enabling more sophisticated and adaptable palletizing solutions capable of handling diverse product types and varying production scales. The push for greater operational efficiency and cost-effectiveness remains a core catalyst.

Palletizer Market Executive Summary

The Palletizer Market is experiencing robust growth, driven by an overarching trend towards automation and optimization in manufacturing and logistics. Business trends indicate a strong focus on custom solutions that integrate seamlessly with existing production lines, alongside a rising demand for collaborative robots and flexible palletizing systems capable of handling diverse product SKUs. Companies are increasingly investing in advanced analytics and IoT capabilities to monitor palletizer performance, predict maintenance needs, and enhance overall equipment effectiveness (OEE). Sustainability initiatives are also influencing design, with a preference for energy-efficient models and reduced material waste.

Regional trends highlight Asia-Pacific as the fastest-growing market, fueled by expanding manufacturing capabilities, rapid industrialization, and significant investments in e-commerce infrastructure, particularly in countries like China and India. North America and Europe continue to be strong markets, characterized by high adoption of advanced robotic palletizers and a continuous drive for innovation in automation technologies to combat labor shortages and enhance competitiveness. Emerging economies in Latin America and the Middle East are also showing increasing potential as industrial and logistics sectors mature, adopting palletizing solutions to improve supply chain efficiencies.

Segment trends underscore the dominance and rapid expansion of robotic palletizers due to their flexibility, precision, and ability to handle complex stacking patterns, gradually surpassing conventional mechanical systems. The food and beverage industry remains the largest end-user segment, propelled by high production volumes and stringent hygiene requirements, while the pharmaceutical and logistics sectors are also exhibiting substantial growth. High-speed palletizers are seeing increased adoption to meet the demands of large-scale production, and there is a growing interest in hybrid systems that combine the benefits of both conventional and robotic technologies for optimized performance across various applications.

AI Impact Analysis on Palletizer Market

Common user questions regarding AIs impact on the Palletizer Market frequently revolve around how artificial intelligence can enhance efficiency, reduce errors, and provide greater flexibility in palletizing operations. Users are keen to understand the practical applications of AI, such as its role in optimizing stacking patterns, enabling predictive maintenance, and integrating with advanced vision systems for quality control. Concerns often include the complexity of implementing AI solutions, the initial investment required, and the need for skilled personnel to manage and maintain these sophisticated systems. Expectations are high for AI to deliver significant improvements in throughput, adaptability to varying product types, and overall operational intelligence, thereby transforming traditional palletizing processes into more autonomous and data-driven systems.

The integration of AI in palletizing solutions represents a transformative shift, moving beyond traditional automation to intelligent automation that learns, adapts, and optimizes in real-time. This evolution allows palletizers to handle unprecedented levels of complexity and variability, addressing critical challenges faced by manufacturers and logistics providers. AI-powered systems can analyze vast amounts of data from sensors and production schedules to make informed decisions, ensuring that products are stacked efficiently and accurately while minimizing waste and downtime. The capability for continuous improvement through machine learning algorithms signifies a paradigm shift in how end-of-line packaging processes are managed and executed, leading to more resilient and responsive supply chains.

Moreover, AIs ability to enhance human-machine collaboration is opening new avenues for efficiency and safety. Collaborative robots (cobots) equipped with AI can work alongside human operators, taking on repetitive or ergonomically challenging tasks while humans focus on supervision, maintenance, or more complex problem-solving. This symbiotic relationship not only boosts productivity but also creates a safer working environment by reducing the physical strain on workers. The long-term impact of AI on the palletizer market is projected to be profound, driving innovation in system design, operational intelligence, and overall supply chain integration, making palletizing an increasingly smart and adaptive component of industrial automation.

- AI-powered vision systems for precise product identification, orientation, and quality inspection, reducing errors and ensuring correct stacking.

- Intelligent path planning and optimization algorithms that determine the most efficient stacking patterns for diverse product sizes and shapes, maximizing pallet utilization and stability.

- Predictive maintenance capabilities, leveraging machine learning to analyze operational data and anticipate equipment failures, minimizing downtime and extending machine lifespan.

- Adaptive learning for handling product variability, allowing palletizers to adjust automatically to changes in product dimensions, weights, or packaging materials without manual reprogramming.

- Integration with Warehouse Management Systems (WMS) and Manufacturing Execution Systems (MES) for real-time data exchange, enabling dynamic scheduling and inventory optimization.

- Enhanced safety features through AI-driven proximity sensors and anomaly detection, improving human-robot interaction and preventing accidents in automated environments.

- Reduced energy consumption through optimized operational cycles and intelligent load management, contributing to more sustainable manufacturing practices.

DRO & Impact Forces Of Palletizer Market

The Palletizer Market is significantly shaped by a confluence of drivers, restraints, and opportunities, all influenced by various impact forces. A primary driver is the pervasive global trend towards industrial automation, fueled by rising labor costs, a scarcity of manual labor, and the imperative for increased operational efficiency. The exponential growth of e-commerce has further intensified demand for rapid and accurate palletizing solutions to manage high-volume logistics in warehouses and distribution centers. Additionally, growing emphasis on workplace safety and ergonomics is pushing industries to replace manual heavy lifting with automated palletizing systems, thereby reducing injury risks and improving working conditions. These drivers collectively create a strong impetus for market expansion, prompting industries to invest in advanced automation technologies to maintain competitiveness and scalability.

Despite these strong growth drivers, the market faces several restraints. The high initial capital investment required for advanced robotic and automated palletizing systems can be a significant barrier for small and medium-sized enterprises (SMEs), limiting their adoption. Technical complexity associated with integrating these sophisticated systems into existing production lines, along with the need for specialized programming and maintenance expertise, poses challenges for many businesses. Furthermore, the lack of adequately skilled personnel to operate and maintain these advanced palletizers can hinder their effective deployment and utilization, potentially slowing down market penetration in certain regions. These factors necessitate careful strategic planning and investment in training to overcome market entry and operational hurdles.

Opportunities within the Palletizer Market are abundant, particularly in emerging economies where industrialization and e-commerce growth are accelerating, creating new demand for automation. The increasing trend towards customization and flexibility in manufacturing offers a significant opportunity for palletizer manufacturers to develop modular and reconfigurable systems that can adapt to diverse product lines and production requirements. Moreover, the deeper integration of palletizers with broader digital ecosystems, such as Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP), and Manufacturing Execution Systems (MES), presents a pathway for creating highly optimized and interconnected supply chains. The continuous evolution of technology, including advanced robotics, AI, and IoT, further opens doors for innovative solutions that can address specific industry needs and expand market reach. These opportunities pave the way for sustained market evolution and diversification.

Segmentation Analysis

The Palletizer Market is comprehensively segmented by type, end-user industry, capacity, and operation, reflecting the diverse range of applications and technological capabilities available. This segmentation helps in understanding the specific needs of various sectors and the most suitable palletizing solutions for different operational scales and product types. Analyzing these segments provides a clear picture of market dynamics, growth areas, and the evolution of palletizing technology to meet specialized demands across the industrial landscape. Each segment represents a unique set of drivers and competitive factors, influencing product development and market strategies.

- By Type:

- Conventional Palletizers: Traditional mechanical systems, typically offering lower flexibility but reliable performance for high-volume, uniform product stacking. Includes layer-type and robotic arm-type variations without advanced AI integration.

- Robotic Palletizers: Utilize industrial robots for stacking, offering high flexibility, precision, and adaptability to handle varied product sizes and complex stacking patterns. Increasingly integrating advanced vision and AI capabilities.

- Hybrid Palletizers: Combine elements of both conventional and robotic systems, designed to offer a balance of speed, flexibility, and cost-effectiveness for specific applications.

- By End-User Industry:

- Food and Beverage: Largest segment, driven by high-volume production of packaged foods, beverages, dairy, and confectionery, requiring hygienic and efficient handling.

- Pharmaceutical: Requires precise, gentle handling and strict adherence to regulatory standards for medicines, medical devices, and other sterile products.

- Chemicals: Involves handling of various chemical products, often in bags, drums, or boxes, requiring robust and sometimes corrosive-resistant systems.

- Logistics and Warehousing: Driven by the need for efficient handling and organization of goods in distribution centers, e-commerce fulfillment centers, and third-party logistics (3PL) providers.

- Consumer Goods: Includes diverse products like personal care items, household goods, and electronics, requiring flexible systems to manage varied packaging.

- Automotive: Used for palletizing components, parts, and finished goods, supporting just-in-time delivery and manufacturing processes.

- Others: Includes building materials, agriculture, textiles, and other manufacturing sectors with specific palletizing needs.

- By Capacity:

- Low-Speed Palletizers: Suitable for smaller production volumes, typically processing up to 10 cases per minute, often used in batch production or smaller facilities.

- Medium-Speed Palletizers: Designed for moderate production rates, handling between 10 and 30 cases per minute, common in mid-sized manufacturing operations.

- High-Speed Palletizers: Engineered for large-scale operations, capable of processing over 30 cases per minute, crucial for high-volume industries like food and beverage.

- By Operation:

- Automatic Palletizers: Fully automated systems requiring minimal human intervention, from product reception to pallet discharge, typically integrated with upstream and downstream equipment.

- Semi-Automatic Palletizers: Require some level of human involvement, such as loading empty pallets or removing full ones, offering a balance between automation and manual control, often preferred by SMEs.

Palletizer Market Value Chain Analysis

The value chain for the Palletizer Market involves a complex interplay of upstream suppliers, manufacturers, integrators, and downstream customers, all contributing to the final delivery and operation of palletizing solutions. Upstream analysis focuses on the sourcing of critical components and raw materials necessary for manufacturing palletizer systems. This includes suppliers of robotics and automation components such as robotic arms, control systems, sensors, motors, and vision systems, as well as providers of structural materials like steel and aluminum. The quality and availability of these components directly impact the cost-effectiveness, performance, and reliability of the final palletizer product. Strong relationships with reliable component suppliers are vital for maintaining production efficiency and managing supply chain risks, particularly given the global nature of component sourcing.

Downstream analysis in the Palletizer Market centers on the distribution channels and the end-users who ultimately purchase and deploy these systems. Once manufactured, palletizers are typically distributed through a combination of direct sales, where manufacturers sell directly to large enterprises or provide bespoke solutions, and indirect channels, which involve a network of distributors, value-added resellers (VARs), and system integrators. These intermediaries often provide localized sales, installation, training, and after-sales support, which are crucial for market penetration and customer satisfaction. The efficiency of these distribution networks is critical for reaching a broad customer base and ensuring timely delivery and service.

The distribution channel encompasses both direct and indirect approaches. Direct sales are prevalent for large, complex, or customized projects where direct consultation and engineering support are necessary. This allows manufacturers to build deep relationships with key clients and ensure precise alignment with their operational requirements. Indirect channels, on the other hand, leverage specialized integrators who can combine palletizers with other packaging equipment, conveyors, and software to provide complete, turnkey automated lines. These integrators play a crucial role in providing comprehensive solutions tailored to specific industry needs, offering expertise in system design, installation, and ongoing maintenance. The choice of distribution strategy often depends on the target market, the complexity of the solution, and the desired level of customer engagement and support.

Palletizer Market Potential Customers

The potential customers for the Palletizer Market are diverse and span across nearly all manufacturing, processing, and logistics industries that handle goods in bulk or packaged form. These end-users are primarily driven by the need to automate repetitive and labor-intensive end-of-line packaging tasks, improve operational efficiency, enhance workplace safety, and optimize space utilization. Key buyers of palletizing solutions include large-scale manufacturers seeking to increase throughput and reduce labor costs, as well as small to medium-sized enterprises (SMEs) looking for flexible and cost-effective automation options to remain competitive. The increasing complexity of supply chains and the rapid growth of e-commerce are also expanding the customer base to include a wider array of distribution centers and third-party logistics providers.

Specifically, the food and beverage industry represents a significant segment of potential customers, ranging from dairies, breweries, and soft drink manufacturers to producers of packaged snacks, cereals, and baked goods. These entities require high-speed, hygienic, and reliable palletizing systems to manage immense volumes of products. Similarly, the pharmaceutical sector, with its stringent regulatory requirements and need for precise handling of sensitive products, is a crucial customer segment, investing in solutions that ensure product integrity and traceability. The chemical industry, dealing with hazardous or heavy materials, also heavily relies on palletizers for safe and efficient handling of bags, drums, and containers.

Beyond these, the consumer goods sector, encompassing personal care products, household items, and electronics, seeks flexible palletizers capable of handling a wide variety of product shapes and sizes. The logistics and warehousing industry, including e-commerce fulfillment centers and general distribution hubs, are increasingly adopting advanced robotic palletizers to manage inventory more efficiently and accelerate order fulfillment. Furthermore, industries such as automotive (for parts and components), building materials, and agriculture also represent substantial customer segments, each with unique requirements for robust and adaptable palletizing solutions. Ultimately, any entity involved in high-volume product packaging and distribution stands as a potential buyer for palletizer technologies.

Palletizer Market Key Technology Landscape

The Palletizer Market is undergoing continuous technological evolution, driven by advancements in robotics, artificial intelligence, and industrial automation. At the core of this landscape are sophisticated robotic systems, which include articulated robots, gantry robots, and collaborative robots (cobots). Articulated robots offer high flexibility and speed for complex stacking patterns, while gantry robots provide stability and precision for heavy loads over larger work envelopes. Cobots, designed to work safely alongside humans without extensive guarding, are gaining traction for their adaptability in dynamic environments and their ability to address labor challenges. These robotic platforms are increasingly modular, allowing for easier integration and reconfiguration to meet specific production demands.

Beyond the mechanical aspects, the integration of Artificial Intelligence (AI) and Machine Learning (ML) is profoundly transforming palletizer capabilities. AI-powered vision systems are becoming standard, enabling precise product detection, orientation, and quality control, ensuring correct stacking and identifying defective products in real-time. Machine learning algorithms optimize stacking patterns, reducing trial-and-error and improving pallet stability and utilization, especially for mixed-SKU palletizing. Predictive maintenance, another AI application, uses data analytics to monitor equipment health and anticipate failures, thereby minimizing downtime and extending the lifespan of the machinery. This intelligent automation moves palletizers from purely mechanical devices to smart, adaptive systems.

Furthermore, the Industrial Internet of Things (IIoT) plays a crucial role by enabling connectivity and data exchange across the palletizing system and the broader production line. Sensors embedded in palletizers collect vast amounts of data on performance, energy consumption, and operational status, which can be analyzed to identify bottlenecks, optimize processes, and facilitate remote monitoring and control. Human-Machine Interfaces (HMIs) with intuitive touchscreens and graphical user interfaces (GUIs) are simplifying operation and programming, making these complex machines more accessible. Advanced safety features, including laser scanners, light curtains, and pressure-sensitive mats, are enhancing workplace safety, ensuring compliance with international standards and fostering a secure environment for human-robot collaboration. This confluence of technologies creates highly efficient, flexible, and intelligent palletizing solutions.

Regional Highlights

- North America: This region is characterized by high adoption rates of advanced robotic and automated palletizing systems, driven by high labor costs, a strong emphasis on workplace safety, and continuous innovation in automation technologies. The presence of major manufacturing hubs, a robust e-commerce sector, and significant investment in smart factory initiatives contribute to the regions prominent market share. The United States and Canada are leading the way in integrating AI and IoT into palletizing solutions, focusing on efficiency, flexibility, and data-driven operations.

- Europe: Europe represents a mature market for palletizers, propelled by stringent regulatory standards for workplace safety, a strong manufacturing base, and a focus on sustainable and energy-efficient automation. Countries such as Germany, Italy, and France are at the forefront of developing sophisticated and customized palletizing solutions, particularly for the food and beverage, pharmaceutical, and automotive industries. The region emphasizes precision engineering, high reliability, and seamless integration with existing production lines, often leveraging advanced robotics and vision systems.

- Asia-Pacific: Poised for the fastest growth, the Asia-Pacific market is fueled by rapid industrialization, expanding manufacturing capabilities, and the booming e-commerce sector, especially in countries like China, India, Japan, and South Korea. Increasing disposable incomes, growing demand for packaged goods, and government initiatives promoting automation and manufacturing efficiency are significant drivers. The region offers a vast and diverse customer base, from large multinational corporations to emerging local manufacturers, creating substantial demand for both conventional and advanced robotic palletizers.

- South America: This emerging market is experiencing gradual growth in the adoption of palletizing solutions, driven by efforts to modernize manufacturing infrastructure, improve supply chain efficiencies, and enhance competitiveness in the global market. Countries such as Brazil, Argentina, and Mexico are investing in automation to address labor challenges and increase productivity, particularly in the food processing, beverage, and consumer goods sectors. While currently smaller, the region presents long-term growth potential as industrialization progresses.

- Middle East and Africa (MEA): The MEA region is witnessing increasing investments in industrial and logistics infrastructure, spurred by economic diversification efforts and growing consumer markets. Countries in the Gulf Cooperation Council (GCC) are particularly active in adopting advanced automation, including palletizers, to support large-scale construction, food and beverage production, and emerging e-commerce operations. Challenges such as geopolitical instability and varying levels of industrial development mean growth is selective but promising, particularly in logistics and processing sectors seeking efficiency gains.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Palletizer Market.- ABB Ltd.

- KUKA AG

- Fanuc Corporation

- Kawasaki Heavy Industries, Ltd.

- Bosch Packaging Technology (Syntegon Technology GmbH)

- BEUMER Group GmbH & Co. KG

- Premier Tech Chronos

- Columbia Machine, Inc.

- Honeywell International Inc.

- Intelligrated (Honeywell)

- Schneider Electric SE

- Paxiom Group

- A-B-C Packaging Machine Corporation

- Cermex (Tetra Pak)

- Maschinenfabrik Mollers GmbH

Frequently Asked Questions

What is a palletizer and why is it important for industrial operations?

A palletizer is an automated or semi-automated machine designed to stack products onto pallets in a stable and organized manner for storage, transportation, or warehousing. It is crucial for industrial operations because it significantly increases efficiency, reduces manual labor costs, minimizes workplace injuries associated with heavy lifting, and ensures consistent, stable loads, which are vital for an optimized supply chain and safe logistics.

How do robotic palletizers differ from conventional palletizers?

Robotic palletizers utilize articulated industrial robots to perform stacking, offering high flexibility, precision, and adaptability to handle various product types and complex stacking patterns. Conventional palletizers, typically mechanical layer-type or gantry systems, are generally less flexible but can achieve very high speeds for uniform products. Robotic systems often integrate advanced vision and AI, providing greater versatility for mixed-SKU environments.

What industries are the primary users of palletizing solutions?

The primary users of palletizing solutions span a wide range of industries including food and beverage, pharmaceuticals, chemicals, consumer goods, and logistics/warehousing. These sectors require efficient, high-volume handling and precise stacking of products to meet production demands, ensure product integrity, and streamline their distribution processes.

What are the key benefits of investing in an automated palletizer?

Investing in an automated palletizer offers numerous benefits, including significant labor cost reduction, improved workplace safety by eliminating manual heavy lifting, increased throughput and operational speed, enhanced consistency and accuracy in stacking, and better utilization of pallet space. These advantages collectively lead to higher productivity, reduced operational expenses, and a more competitive manufacturing or logistics operation.

How does AI impact the future of palletizing technology?

AI is profoundly impacting the future of palletizing technology by enabling advanced capabilities such as intelligent path planning for optimal stacking, predictive maintenance to minimize downtime, AI-powered vision systems for superior quality control and product identification, and adaptive learning for handling product variability. This integration transforms palletizers into smarter, more autonomous, and highly flexible systems capable of optimizing complex logistical challenges and improving overall operational intelligence.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager