Palletizing Robot Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429339 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Palletizing Robot Market Size

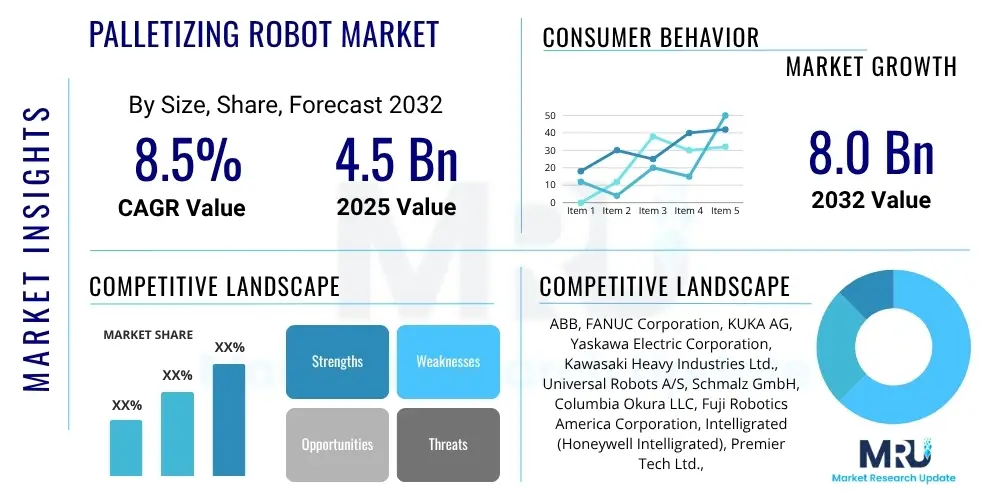

The Palletizing Robot Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 4.5 Billion in 2025 and is projected to reach USD 8.0 Billion by the end of the forecast period in 2032.

Palletizing Robot Market introduction

The Palletizing Robot Market encompasses sophisticated automated systems meticulously engineered to efficiently stack various products onto pallets, preparing them for storage, distribution, or direct shipment. These advanced robotic solutions are instrumental in modern manufacturing and logistics, providing a robust method to streamline repetitive and physically demanding tasks traditionally performed manually. By automating the palletizing process, industries can achieve significant improvements in operational throughput, accuracy, and overall workplace safety, directly addressing challenges associated with manual labor and potential injuries. The core functionality of a palletizing robot revolves around its ability to pick individual items or cases from a conveyor belt or production line and precisely place them in a pre-defined pattern onto a pallet, ensuring stability and optimal space utilization. This fundamental capability extends across a vast array of industries, establishing palletizing robots as a cornerstone of efficient end-of-line automation.

Product descriptions within this market segment typically cover a diverse range of robotic configurations, each designed to meet specific industrial requirements. This includes versatile articulated robots, renowned for their flexibility and broad reach; efficient SCARA robots, ideal for high-speed pick-and-place applications over a specific plane; robust gantry and Cartesian robots, offering high payload capacities and large operational envelopes for structured environments; and, increasingly, collaborative robots (cobots), engineered to work safely alongside human operators without extensive guarding. These robots are differentiated not only by their kinematic structure but also by their payload capacity, reach, speed, and the complexity of their integrated control and vision systems. Advanced palletizing robots frequently incorporate sophisticated machine vision technology, enabling them to identify, inspect, and precisely orient diverse items, even those with irregular shapes or varying dimensions. Such technological integration allows for highly adaptive and intelligent handling of products, a crucial aspect in fast-paced production environments. These systems significantly reduce manual intervention, thereby lowering labor costs, minimizing human error, and ensuring consistent output quality, all of which contribute to a more efficient and competitive operational landscape.

The major applications for palletizing robots span across a multitude of sectors including the burgeoning food and beverage industry, where hygienic and high-speed handling is paramount; the pharmaceutical industry, which demands extreme precision and adherence to strict regulatory standards; the automotive sector, handling heavy components with consistent accuracy; and the vast logistics and warehousing domain, essential for managing the enormous volumes of goods in e-commerce fulfillment centers. Other significant applications are found in the chemical industry for safe handling of hazardous materials, and in consumer goods manufacturing for high-volume, rapid packaging. The inherent benefits of deploying palletizing robots are manifold: they include dramatic increases in production efficiency and speed, substantial reductions in labor expenditures and associated overheads, markedly improved workplace safety by mitigating risks associated with manual lifting and repetitive strain injuries, and the guarantee of consistent, high-quality pallet configurations that minimize product damage during transit. The key driving factors propelling the growth of this market include the escalating global demand for industrial automation driven by a desire for operational excellence, the phenomenal growth of the e-commerce sector necessitating unparalleled logistical efficiency, persistent and widespread labor shortages across manufacturing and logistics sectors, and the continuous evolution of robotic and artificial intelligence technologies that make these systems more capable, adaptable, and cost-effective.

Palletizing Robot Market Executive Summary

The Palletizing Robot Market is experiencing a period of dynamic expansion, underpinned by a global paradigm shift towards enhancing industrial productivity and mitigating the inherent challenges of manual labor. Prevailing business trends underscore a pronounced industry focus on automation as a strategic imperative, particularly in processes that are repetitive, physically demanding, or ergonomically challenging. Enterprises are increasingly channeling investments into sophisticated robotic solutions that not only promise substantial improvements in operational efficiency and throughput but also significantly contribute to reducing long-term operational costs and bolstering supply chain resilience. The market's evolution is characterized by a demand for more versatile robots capable of handling a wider array of products with diverse characteristics, coupled with an increasing emphasis on seamless integration into existing and future smart factory ecosystems, aligning with the principles of Industry 4.0. This strategic adoption reflects a wider understanding among manufacturers and logistics providers that automation is key to maintaining competitive advantage in a globalized economy.

From a regional perspective, Asia Pacific continues to assert its dominance as the preeminent market for palletizing robots, a position solidified by its expansive manufacturing sector and rapid pace of industrial development, most notably in economic powerhouses such as China, Japan, and South Korea. This region benefits from significant government initiatives supporting automation, a large labor force increasingly inclined towards skilled roles, and burgeoning domestic and export demands. Concurrently, Europe and North America represent substantial and mature markets characterized by early and widespread adoption of advanced automation technologies. These regions are driven by elevated labor costs, a pervasive shortage of skilled manual labor, and a strong strategic commitment to innovation and digital transformation within manufacturing. European nations, particularly Germany and Italy, exemplify a proactive embrace of Industry 4.0 principles, integrating advanced robotics into highly automated production lines. North America, influenced by a surging e-commerce market, is rapidly deploying palletizing robots to enhance logistical efficiency and address labor availability issues, ensuring supply chain robustness.

Analysis of segment trends reveals several crucial shifts and areas of innovation within the Palletizing Robot Market. There is a palpable and accelerating shift towards the adoption of collaborative palletizing robots, or cobots, primarily due to their intrinsic safety features allowing them to operate in close proximity to human workers without extensive safety barriers. This characteristic renders them exceptionally suitable for flexible manufacturing environments and smaller operations that require adaptability and closer human-robot interaction. Beyond cobots, continuous advancements in robot control software, high-resolution vision systems, and the burgeoning application of artificial intelligence and machine learning are enabling robots to process more complex, mixed-SKU palletizing tasks with unparalleled precision and agility. These technological strides are broadening the applicability of palletizing robots to a greater variety of product types and operational scenarios. Furthermore, the market is witnessing an increasing demand for highly customized and modular robotic solutions that can be readily scaled, reconfigured, and adapted to meet dynamically evolving production requirements, offering businesses the agility necessary to respond to fluctuating market demands and product diversification.

AI Impact Analysis on Palletizing Robot Market

Discussions and user inquiries regarding the profound impact of Artificial Intelligence on the Palletizing Robot Market frequently center on how AI can fundamentally transform robotic capabilities, moving beyond mere programmed movements to truly intelligent operations. Users are keen to understand the extent to which AI can empower robots with enhanced autonomy, allowing them to adapt seamlessly to unpredictable scenarios such as varied product sizes, irregular shapes, or dynamic changes in production schedules without constant human intervention. A significant area of interest lies in AI's capacity to optimize complex pallet patterns, ensuring maximum space utilization and stability for diverse product loads, which is a critical factor for logistics efficiency. Furthermore, there is considerable focus on how AI-driven predictive maintenance can prevent costly downtime by anticipating mechanical failures, and how it can simplify robot programming and integration, making these advanced systems more accessible. Concerns often include the initial investment required for AI-integrated systems, the perceived complexity of implementation, and the necessity for a specialized workforce capable of managing and troubleshooting these intelligent platforms, alongside broader implications for human employment in industrial settings.

- Enhanced Vision Systems: AI-powered machine vision systems with deep learning algorithms significantly improve the robot's ability to accurately detect, identify, and categorize objects, even those with irregular shapes, varying textures, or complex orientations, leading to superior pick accuracy and adaptability.

- Adaptive Learning Algorithms: Machine learning enables robots to dynamically generate and optimize pallet patterns in real-time based on product dimensions, weight, and order specifications, ensuring efficient space utilization and load stability for mixed-SKU palletizing.

- Predictive Maintenance: AI-driven analytics continuously monitor robot performance data, detecting anomalies and predicting potential mechanical failures before they occur, thereby significantly reducing unplanned downtime and extending equipment lifespan through proactive servicing.

- Improved Human-Robot Collaboration: Advanced AI algorithms facilitate safer and more intuitive human-robot interaction in collaborative robot (cobot) applications, enhancing responsiveness to human presence and intentions, and allowing for seamless shared workspaces without extensive guarding.

- Optimized Path Planning and Motion Control: AI algorithms enable robots to calculate the most efficient and energy-optimal trajectories for picking and placing, minimizing cycle times, reducing energy consumption, and increasing overall operational speed and fluidity.

- Real-time Fault Detection and Self-correction: AI allows robots to detect operational errors or anomalies in real-time, such as dropped items or misalignments, and autonomously initiate corrective actions or alert operators, ensuring continuous and error-free operation.

- Automated Decision-Making: For complex logistical scenarios, AI empowers palletizing robots with the capacity for autonomous decision-making, such as re-routing or re-sequencing tasks to maintain optimal flow, especially in environments with dynamic inventory or order changes.

- Reduced Programming Complexity: AI-assisted programming tools and intuitive interfaces leverage machine learning to simplify the teaching and configuration process for new tasks, drastically reducing the time and expertise required for deployment and re-deployment.

DRO & Impact Forces Of Palletizing Robot Market

The Palletizing Robot Market is experiencing vigorous growth primarily propelled by a confluence of powerful drivers. Paramount among these is the escalating global demand for advanced automation technologies across diverse industrial sectors, driven by the imperative to enhance operational efficiencies and throughput. This is closely linked to the pervasive challenge of rising labor costs and a persistent shortage of skilled manual labor in manufacturing and logistics, compelling companies to invest in robotic solutions that can perform repetitive, labor-intensive tasks more consistently and cost-effectively. Furthermore, the exponential expansion of the e-commerce sector has significantly amplified the need for highly efficient and rapid logistics and warehousing operations, where automated palletizing systems are crucial for managing massive volumes of goods. The tangible benefits of improved workplace safety, achieved by minimizing human exposure to strenuous and potentially hazardous lifting tasks, also serve as a strong catalyst for adoption. These combined factors, alongside continuous innovation in robotics and control systems, collectively act as robust propellers for sustained market expansion.

Conversely, the market encounters several significant restraints that temper its growth trajectory. A primary impediment remains the substantial initial capital investment required for the procurement, installation, and integration of sophisticated palletizing robot systems. This considerable upfront cost can be a prohibitive barrier, particularly for small and medium-sized enterprises (SMEs) with limited capital budgets. The complexity involved in seamlessly integrating these advanced robotic solutions with existing legacy production infrastructures, along with the necessity for a highly skilled technical workforce for programming, maintenance, and troubleshooting, represents another considerable challenge. This often necessitates additional training or hiring, adding to the total cost of ownership. Moreover, the rapid pace of technological innovation within the robotics industry often leads to accelerated technological obsolescence, meaning companies must be prepared for continuous investment in system upgrades and replacements to maintain competitive advantage, which can deter cautious investors.

Despite these challenges, the Palletizing Robot Market is replete with promising opportunities that are poised to accelerate its evolution. The proliferation and increasing sophistication of collaborative robots (cobots) present a significant opportunity, as their inherent safety features allow them to operate alongside human workers without extensive physical guarding, thereby enhancing flexibility and expanding applicability to a wider array of tasks and production environments, including those with space constraints. The burgeoning industrialization in emerging economies across Asia Pacific, Latin America, and the Middle East and Africa offers vast untapped potential, as these regions seek efficient and modern manufacturing solutions. Furthermore, the growing trend towards highly customized, modular, and flexible robot solutions, capable of rapid reconfiguration to meet fluctuating production demands, is creating new avenues for innovation and market penetration. Coupled with ongoing advancements in Artificial Intelligence, machine learning, and sensor technologies, these opportunities are collectively shaping a dynamic and competitive landscape, where strategic partnerships, technological leadership, and scalable solutions are paramount for long-term success and market leadership, driving a continuous cycle of innovation and adoption.

Segmentation Analysis

The Palletizing Robot Market is meticulously segmented to provide a granular and comprehensive understanding of its intricate structure, allowing for precise market analysis and strategic planning. This segmentation methodically dissects the market across several critical dimensions, including the specific type of robot employed, the payload capacity it is designed to handle, the diverse applications it serves, the varied end-user industries that adopt these technologies, and the essential components that constitute a complete palletizing system. Each segment and sub-segment reflects unique technological requirements, distinct operational demands, and varying investment patterns, thereby offering deep insights into market dynamics, competitive landscapes, and future growth trajectories for different niches within the broader market. This detailed breakdown highlights the breadth and depth of the market's capabilities and its adaptability to a wide range of industrial challenges and opportunities.

- By Type

- Articulated Robots: Highly versatile robots with multiple rotary joints, offering exceptional flexibility and reach, making them suitable for complex palletizing patterns and varied product sizes across numerous industries. They represent a significant portion of the traditional market.

- SCARA Robots: Known for high-speed, precise horizontal movements, ideal for lighter loads and faster pick-and-place operations within a cylindrical workspace, commonly used in electronics and smaller consumer goods packaging.

- Gantry Robots: Also known as Cartesian robots, these operate along linear axes (X, Y, Z), offering very high payload capacities and large work envelopes, perfect for heavy-duty palletizing and depalletizing in structured environments like logistics warehouses and building materials.

- Cartesian Robots: Similar to gantry robots but often with a simpler linear structure, providing excellent precision and rigidity, suitable for tasks requiring straight-line movements and consistent stacking, often customized for specific applications.

- Collaborative Robots (Cobots): Designed to work safely alongside human operators without extensive safety guarding, offering enhanced flexibility, ease of programming, and quick redeployment, making them increasingly popular for varied tasks in SMEs and dynamic production lines.

- By Payload Capacity

- Low Payload (Up to 10 kg): Robots typically used for handling smaller, lighter products like individual consumer goods, pharmaceuticals, or delicate items, prioritizing speed and precision over strength.

- Medium Payload (10 kg to 100 kg): The most common category, suitable for a wide range of applications including case palletizing of food and beverage products, general manufacturing items, and mid-sized components.

- High Payload (Above 100 kg): Robots designed for heavy-duty tasks such as handling large bags of chemicals, bulk building materials, automotive components, or entire layers of products, emphasizing strength and stability.

- By Application

- Case Palletizing: The most prevalent application, involving stacking sealed boxes or cartons onto pallets in organized patterns for efficient storage and transport.

- Bag Palletizing: Specialized robots designed to handle flexible bags of granular materials, powders, or feeds, requiring unique gripping mechanisms and precise stacking to prevent damage.

- Depalletizing: The reverse process of palletizing, where robots systematically unload products from pallets onto conveyors or other processing lines, often utilizing vision systems for mixed-SKU handling.

- Mixed Palletizing: Advanced applications where robots create mixed pallets containing various product types and sizes to optimize space for specific customer orders or store layouts, requiring sophisticated software and vision.

- Tray Palletizing: Handling and stacking products presented in trays, common in food production (e.g., bakery items, fresh produce) or smaller electronics components, requiring gentle and precise manipulation.

- By End-User Industry

- Food and Beverage: High demand for hygiene, speed, and precision in handling packaged foods, beverages, dairy, and fresh produce, often requiring washdown capabilities.

- Pharmaceuticals: Extremely stringent requirements for accuracy, traceability, and sterile handling of medicines, vials, and medical devices, adhering to strict regulatory standards.

- Automotive: Used for palletizing heavy vehicle components, sub-assemblies, and finished parts, requiring high payload capacity and robust operation in demanding environments.

- Logistics and Warehousing: Critical for efficient order fulfillment, cross-docking, and distribution center operations, particularly in e-commerce, handling diverse products for rapid dispatch.

- Chemicals: Palletizing bags, drums, and containers of chemical products, often in hazardous environments, demanding robust and explosion-proof robot designs.

- Consumer Goods: Handling a vast array of packaged consumer products from personal care items to electronics, prioritizing speed, flexibility, and gentle handling for varied packaging.

- Building Materials: Palletizing heavy and bulky items such as bricks, tiles, cement bags, and insulation materials, requiring robots with very high payload capabilities and durable construction.

- Electronics: Precision handling of delicate electronic components, circuit boards, and finished devices, often with cleanroom specifications and high accuracy requirements.

- By Component

- Robot Arm: The mechanical manipulator comprising joints and links, responsible for the robot's movement and reach, forming the core physical structure of the palletizing system.

- Controller: The brain of the robot, housing the hardware and software that processes commands, executes programs, and controls the robot's motors and movements, ensuring coordinated operation.

- End Effectors (Grippers): Tools attached to the robot's wrist, such as vacuum grippers, clamp grippers, or magnetic grippers, specifically designed to pick and place various product types safely and efficiently.

- Software: Includes the robot operating system, programming interfaces, simulation software, and application-specific programs that define palletizing patterns, logic, and integration with other systems.

- Vision Systems: Cameras and image processing software that enable the robot to "see" and interpret its environment, facilitating accurate object detection, orientation, quality inspection, and dynamic adjustments for varied items.

- Sensors: Various sensors like force-torque sensors, proximity sensors, and safety sensors that provide real-time feedback to the controller, enhancing precision, safety, and adaptive capabilities.

- Conveyors: Integral parts of the palletizing cell, moving products to and from the robot, ensuring a continuous flow of materials and seamless integration with the robot's operation.

Value Chain Analysis For Palletizing Robot Market

The value chain for the Palletizing Robot Market represents a complex network of interconnected activities, commencing with the critical upstream segment that involves the meticulous sourcing and manufacturing of foundational raw materials and sophisticated core components. This initial stage relies heavily on specialized suppliers providing high-grade metals for structural integrity, advanced plastics for lightweight components, and a myriad of electronic parts crucial for robotic intelligence, including microcontrollers, high-precision sensors, and complex printed circuit boards. Essential mechanical components such as high-torque motors, precision gears, and durable bearings, which facilitate smooth and accurate robot movements, are also sourced from this segment. Furthermore, this upstream layer encompasses the development and production of cutting-edge software and artificial intelligence algorithms, which are increasingly becoming the intellectual backbone of modern, intelligent palletizing systems. Manufacturers of specialized end-effectors, such as customized grippers and vacuum cups designed for specific product handling, also constitute a vital part of this early stage, ensuring the robots can effectively manipulate a diverse range of items.

The midstream segment of the value chain is where the culmination of these components occurs, primarily involving the core activities of robot manufacturers. This crucial stage encompasses the advanced design, precision assembly, rigorous testing, and quality assurance of complete palletizing robot systems. Robot manufacturers integrate the myriad components sourced from upstream suppliers, develop and refine their proprietary control software, and conduct extensive simulations and physical tests to ensure that the robots meet stringent industry standards for performance, reliability, safety, and efficiency. This phase also frequently includes the customization of robotic systems to meet the unique operational requirements of specific clients, often leveraging modular designs and highly flexible programming capabilities. The ability to tailor solutions to diverse industrial applications, whether it involves specific payload capacities, reach requirements, or integration with existing factory layouts, is a significant value-add during this manufacturing and assembly stage, differentiating market players through specialized engineering and problem-solving.

The downstream activities represent the final stages of the value chain, focusing on the delivery, deployment, and sustained support of palletizing robots to end-users. Distribution channels are varied and critical, often involving direct sales teams for large-scale enterprise clients who require bespoke solutions and direct technical engagement. Additionally, a robust network of authorized distributors and, most importantly, highly specialized system integrators play a pivotal role. System integrators are crucial intermediaries, as they possess the expertise to design, configure, and implement comprehensive automated solutions tailored precisely to an end-user's unique production environment, often integrating the robot with conveyors, vision systems, and existing manufacturing execution systems (MES). Post-sales services, which include ongoing maintenance contracts, emergency repairs, essential software updates, and comprehensive operator training, are paramount for ensuring the long-term operational efficiency, reliability, and ultimate customer satisfaction of palletizing robot systems. Both direct and indirect distribution channels operate in tandem, with integrators often providing the necessary bridge for small and medium-sized enterprises (SMEs) that require extensive support in the complex journey of automation adoption, ensuring successful deployment and sustained performance throughout the robot's lifecycle.

Palletizing Robot Market Potential Customers

The market for palletizing robots caters to a broad and diverse spectrum of industries, all united by a common need for efficient, automated product handling for packaging, storage, and logistical operations. The quintessential potential customer is any large-scale manufacturing facility that operates with high production volumes of goods, where repetitive, laborious, and often ergonomically challenging tasks can be significantly streamlined through automation. These primary buyers are typically companies keenly focused on enhancing their overall operational efficiency, strategically reducing their reliance on manual labor, elevating their safety standards to protect their workforce, and achieving unparalleled consistency and quality in their end-of-line packaging processes. The drive to minimize human error, reduce product damage, and optimize throughput forms the core motivation for investing in these advanced robotic solutions, making them indispensable assets for maintaining competitive edge in fast-paced industrial environments.

Key end-user segments that represent significant potential customers include the vast food and beverage industry, which benefits immensely from the hygienic, precise, and high-speed handling capabilities of robots for diverse packaged products, fresh produce, and beverages. The pharmaceutical sector also stands as a critical customer segment, given its extremely stringent requirements for accuracy, traceability, and sterile handling of sensitive medications, vials, and medical devices, all while adhering to rigorous regulatory compliance standards. Automotive manufacturers are substantial users of palletizing robots for the efficient and consistent handling of heavy vehicle components, sub-assemblies, and finished parts within demanding production lines. Furthermore, the expansive logistics and warehousing sector, particularly in response to the explosive growth of e-commerce, forms a cornerstone of the customer base, utilizing robots to manage the enormous throughput of goods in distribution centers, facilitating rapid order fulfillment and dispatch.

Beyond the traditional large industrial enterprises, an increasingly important and rapidly growing segment of potential customers includes small and medium-sized enterprises (SMEs). As robot technology becomes more accessible, user-friendly, flexible, and cost-effective, SMEs are actively seeking automation solutions to overcome persistent labor challenges, enhance their competitive advantage in niche markets, and scale their operations without incurring the prohibitive costs traditionally associated with extensive manual labor. The innovative versatility of collaborative robots (cobots) plays a pivotal role in expanding this customer base, as their ability to operate safely alongside humans and their simplified programming capabilities make them an ideal fit for operations with limited floor space or those requiring dynamic human-robot interaction. Consequently, the market is continually broadening to encompass a wider range of businesses, from high-volume manufacturers to agile, specialized producers, all seeking to capitalize on the transformative power of robotic automation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.5 Billion |

| Market Forecast in 2032 | USD 8.0 Billion |

| Growth Rate | CAGR 8.5% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB, FANUC Corporation, KUKA AG, Yaskawa Electric Corporation, Kawasaki Heavy Industries Ltd., Universal Robots A/S, Schmalz GmbH, Columbia Okura LLC, Fuji Robotics America Corporation, Intelligrated (Honeywell Intelligrated), Premier Tech Ltd., BEUMER Group GmbH & Co. KG, Rethink Robotics, Mitsubishi Electric Corporation, Nachi-Fujikoshi Corp., Comau S.p.A., Estun Automation, Seiko Epson Corporation, Stäubli International AG, Omron Adept Technologies, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Palletizing Robot Market Key Technology Landscape

The Palletizing Robot Market is characterized by a rapidly evolving technological landscape, where continuous innovation is fundamental to enhancing system performance, operational flexibility, and seamless integration capabilities within diverse industrial ecosystems. At the heart of these advancements are sophisticated robotic kinematics, which encompass the intricate mechanical design and precise control algorithms dictating a robot's movement, reach, and operational accuracy. Modern palletizing systems are engineered to leverage multi-axis articulation, robust structural materials, and lightweight composite components to achieve increasingly higher payload capacities and faster cycle times. This engineering prowess allows robots to adapt efficiently to a broad spectrum of industrial requirements, ranging from the delicate handling of lightweight consumer goods to the rigorous manipulation of heavy automotive parts or bulky building materials, ensuring both speed and precision in operations.

Furthermore, the deep integration of Artificial Intelligence (AI) and advanced machine vision systems has become an indispensable element, fundamentally transforming how robots perceive and interact with their environment. AI-powered vision systems, often leveraging deep learning algorithms, empower robots to "see" with unprecedented accuracy, enabling real-time object detection, precise identification of irregularly shaped products, and dynamic adjustment of gripping strategies to optimize handling. This advanced visual intelligence is further augmented by a suite of sophisticated sensors, including highly sensitive force-torque sensors for delicate manipulation and collision detection, and proximity sensors for precise positioning and enhanced safety protocols. These sensory inputs are crucial for providing real-time feedback to the robot's controller, significantly contributing to both the precision of placement and the safety of human-robot interaction, particularly in collaborative robotic applications where shared workspaces are common.

The technological arsenal also extends to robust control systems that frequently incorporate machine learning for adaptive control and advanced algorithms for predictive maintenance. These capabilities enhance overall operational efficiency by allowing robots to learn from experience, optimize their movements over time, and proactively identify potential mechanical failures, thereby significantly reducing unplanned downtime and extending the equipment's operational lifespan. Seamless connectivity solutions, powered by the Internet of Things (IoT), are critical for enabling remote monitoring, comprehensive data analytics, and seamless integration with broader factory automation systems, aligning closely with the principles of Industry 4.0 and smart manufacturing. Moreover, the development of intuitive simulation software and user-friendly human-robot interfaces (HRI) is drastically streamlining the programming, teaching, and deployment processes, making advanced palletizing solutions more accessible, versatile, and easier to reconfigure across an ever-expanding array of end-user applications and dynamic production demands, fostering widespread adoption and innovation.

Regional Highlights

- Asia Pacific: This region holds the largest and fastest-growing market share, primarily driven by its extensive and rapidly expanding manufacturing hubs, particularly in economic giants like China, Japan, South Korea, and India. The robust demand for automation is fueled by surging domestic and export markets, significant government investments in industrial modernization, and the thriving e-commerce sector, leading to widespread adoption of palletizing robots across various industries.

- Europe: As a mature market, Europe demonstrates high adoption rates of palletizing robots, with countries such as Germany, Italy, France, and the UK at the forefront. The region's growth is propelled by stringent quality standards, a strong emphasis on Industry 4.0 initiatives, and the critical need to counteract persistent skilled labor shortages. European manufacturers prioritize advanced, flexible, and collaborative robotic solutions to maintain global competitiveness and optimize highly automated production lines.

- North America: Exhibiting significant growth, the North American market is predominantly driven by the exponential expansion of the e-commerce industry, steadily increasing labor costs, and a strategic imperative to enhance productivity and bolster supply chain resilience. The United States, Canada, and Mexico are making substantial investments in advanced manufacturing technologies and logistics automation to meet consumer demands and address workforce challenges effectively.

- Latin America: This region represents an emerging market with considerable untapped potential. Industrialization efforts in key countries like Brazil and Mexico, coupled with increasing foreign direct investment in manufacturing sectors, are spurring demand for efficient and modern logistical solutions. While growth is promising, the initial high capital investment costs for advanced robotic systems remain a significant factor influencing the pace of adoption in this developing region.

- Middle East and Africa (MEA): A nascent but progressively developing market, the MEA region is characterized by ongoing infrastructure development and strategic economic diversification away from traditional oil-dependent economies. Automation adoption is steadily gaining traction in crucial sectors such as food processing, logistics, and construction, with countries like the UAE, Saudi Arabia, and South Africa leading the charge in implementing robotic palletizing solutions to modernize their industrial capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Palletizing Robot Market.- ABB

- FANUC Corporation

- KUKA AG

- Yaskawa Electric Corporation

- Kawasaki Heavy Industries Ltd.

- Universal Robots A/S

- Schmalz GmbH

- Columbia Okura LLC

- Fuji Robotics America Corporation

- Intelligrated (Honeywell Intelligrated)

- Premier Tech Ltd.

- BEUMER Group GmbH & Co. KG

- Rethink Robotics

- Mitsubishi Electric Corporation

- Nachi-Fujikoshi Corp.

- Comau S.p.A.

- Estun Automation

- Seiko Epson Corporation

- Stäubli International AG

- Omron Adept Technologies, Inc.

Frequently Asked Questions

What are the primary benefits of implementing palletizing robots in industrial operations?

Implementing palletizing robots offers a multitude of significant benefits for industrial operations, including drastically enhanced operational efficiency by automating repetitive tasks, substantial reductions in labor costs and associated overheads, and marked improvements in workplace safety through the elimination of strenuous manual lifting. Furthermore, these robots ensure consistent, high-quality pallet configurations that minimize product damage during transit, leading to increased throughput and optimized supply chain logistics, ultimately boosting overall productivity and competitiveness.

Which key industries are currently the largest adopters of palletizing robots and why?

The largest adopters of palletizing robots predominantly include the food and beverage industry for hygienic and high-speed handling, pharmaceutical manufacturers requiring extreme precision and regulatory compliance, the automotive sector for heavy component handling, and the vast logistics and warehousing operations, especially those serving the e-commerce boom, for managing high volumes of goods. These industries leverage robots to overcome labor shortages, improve throughput, ensure product integrity, and enhance operational safety in their demanding end-of-line processes.

What are the main types of palletizing robots available in the market and their primary uses?

The market primarily features several robot types, each suited for specific applications: Articulated robots offer high flexibility for complex patterns; SCARA robots excel in high-speed, light-load pick-and-place tasks; Gantry and Cartesian robots provide high payload capacity and large work envelopes for heavy-duty applications; and Collaborative Robots (cobots) are increasingly popular for their safety in shared human workspaces, ease of programming, and adaptability in diverse, smaller-scale operations.

How does Artificial Intelligence (AI) significantly influence the capabilities and future development of modern palletizing robots?

Artificial Intelligence profoundly influences modern palletizing robots by empowering them with enhanced vision systems for precise object recognition and anomaly detection, adaptive learning algorithms for dynamic pallet pattern optimization, and predictive maintenance capabilities to minimize downtime. AI also facilitates more intuitive human-robot collaboration, improves path planning for greater efficiency, and enables automated decision-making for handling diverse and unpredictable product loads, making robots smarter, more flexible, and easier to integrate and manage.

What are the key driving factors propelling the substantial growth of the Palletizing Robot Market globally?

The substantial growth of the Palletizing Robot Market is primarily driven by several critical factors: the escalating global demand for industrial automation to enhance efficiency and productivity; persistent labor shortages and rising labor costs across manufacturing and logistics sectors; the exponential expansion of the e-commerce industry necessitating rapid and efficient material handling; an increased focus on improving workplace safety by reducing manual heavy lifting; and continuous, rapid technological advancements in robotics, AI, and sensor technologies that make these systems more capable and accessible to a wider range of industries.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager