Pavers Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430544 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Pavers Equipment Market Size

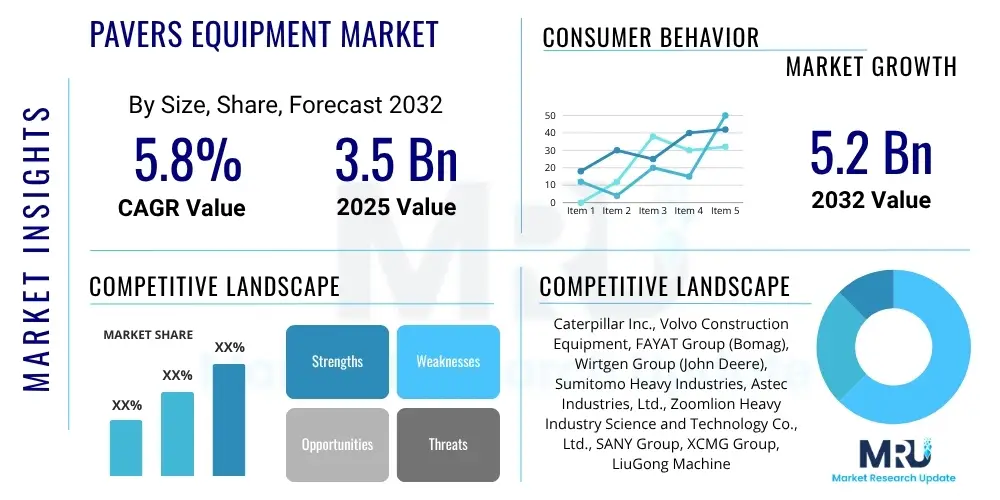

The Pavers Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at $3.5 Billion in 2025 and is projected to reach $5.2 Billion by the end of the forecast period in 2032.

Pavers Equipment Market introduction

The Pavers Equipment Market encompasses specialized machinery utilized for laying various construction materials, primarily asphalt, concrete, and other aggregates, to create smooth and durable surfaces for roads, highways, airports, and urban infrastructure. This essential equipment is pivotal in infrastructure development and maintenance projects worldwide, facilitating the efficient construction of transportation networks and paved areas. Products range from asphalt pavers, which are fundamental for road construction, to concrete pavers used in more rigid applications like highways and airport runways, as well as compact pavers for smaller-scale commercial and residential projects.

The core function of pavers equipment involves receiving material, spreading it evenly, and pre-compacting it to a desired thickness and width, ensuring structural integrity and longevity of the paved surface. Major applications span across vast road construction initiatives, urban development projects, commercial parking lots, residential driveways, and specialized industrial flooring. The significant benefits derived from utilizing modern pavers equipment include enhanced operational efficiency, superior paving quality, reduced labor costs, and improved project timelines, all contributing to safer and more durable infrastructure.

The market's growth is predominantly driven by increasing government investments in infrastructure development, particularly in emerging economies undergoing rapid urbanization and industrialization. A rising focus on road maintenance and repair, coupled with the need to upgrade aging infrastructure in developed regions, further propels demand. Technological advancements aimed at improving fuel efficiency, precision, and automation are also key driving factors, making operations more cost-effective and environmentally sustainable.

Pavers Equipment Market Executive Summary

The Pavers Equipment Market is currently experiencing robust growth, propelled by significant global investments in infrastructure development and an escalating demand for efficient road construction and maintenance solutions. Key business trends indicate a strong move towards automation, digitalization, and the integration of advanced telematics to enhance operational efficiency and predictive maintenance capabilities. Furthermore, there is a growing preference for eco-friendly and energy-efficient equipment, driven by stringent environmental regulations and a corporate emphasis on sustainability. The rental market for pavers equipment is also expanding, offering greater flexibility and cost-effectiveness for various project scales, thereby stimulating broader market access and utilization.

Regionally, the Asia Pacific region continues to dominate the market, primarily due to large-scale infrastructure projects in countries like China, India, and Southeast Asian nations. This rapid urbanization and industrial expansion necessitate extensive road networks and commercial paving. North America and Europe, while mature markets, show consistent demand driven by ongoing infrastructure repair, replacement projects, and the adoption of technologically advanced, high-efficiency machinery. Latin America, the Middle East, and Africa are also emerging as significant markets, fueled by economic growth, urban development, and investment in transportation infrastructure.

Segment-wise, asphalt pavers hold a substantial share, reflecting their widespread use in road construction. However, the concrete paver segment is witnessing increasing adoption for high-durability applications such as highways, airports, and specialized industrial sites. The market is also seeing a shift towards compact and medium-sized pavers for urban and residential projects, highlighting versatility in equipment demand. Technological advancements across all segments are focusing on improving paving precision, reducing material waste, and integrating smart features to streamline operations and enhance safety.

AI Impact Analysis on Pavers Equipment Market

Common user questions regarding AI's impact on the Pavers Equipment Market frequently revolve around how artificial intelligence can revolutionize operational efficiency, precision, and safety. Users often inquire about the potential for fully autonomous paving machines, the role of AI in predictive maintenance to minimize downtime, and how AI-driven analytics can optimize material usage and project management. There is also significant interest in the financial implications of AI integration, including the initial investment costs versus long-term returns, as well as concerns about job displacement and the need for new skill sets among operators. Expectations center on AI's ability to create more consistent and higher-quality paved surfaces, reduce manual errors, and provide real-time data for better decision-making.

- Enhanced Paving Precision: AI algorithms can analyze real-time data from sensors to control paving parameters like thickness and slope, leading to superior surface quality and adherence to specifications.

- Predictive Maintenance: AI-powered systems monitor equipment performance, predict potential failures, and schedule maintenance proactively, significantly reducing unplanned downtime and operational costs.

- Optimized Material Usage: AI can analyze project requirements and environmental conditions to recommend optimal material mixtures and paving speeds, minimizing waste and improving cost-efficiency.

- Autonomous and Semi-Autonomous Operation: AI facilitates the development of self-driving pavers, reducing the need for extensive manual labor and enhancing safety on construction sites.

- Improved Project Management: AI provides data analytics for project progress, resource allocation, and risk assessment, enabling more informed decision-making and efficient project execution.

- Enhanced Safety: AI-powered collision avoidance systems and intelligent monitoring can detect hazards and alert operators, significantly improving safety for personnel on site.

- Data-Driven Performance Insights: AI collects and analyzes vast amounts of operational data, offering valuable insights into equipment performance, fuel consumption, and overall efficiency for continuous improvement.

DRO & Impact Forces Of Pavers Equipment Market

The Pavers Equipment Market is influenced by a complex interplay of various forces, including robust drivers, critical restraints, and promising opportunities, all shaped by broader impact forces. Drivers primarily encompass the accelerating pace of global urbanization and industrialization, leading to substantial governmental and private sector investments in extensive infrastructure projects worldwide. The continuous need for maintenance, repair, and upgrade of existing road networks and public infrastructure in developed economies further stimulates demand. Additionally, stringent safety regulations and an increasing focus on the quality and durability of paved surfaces necessitate advanced and reliable paving equipment, pushing market growth.

Conversely, significant restraints pose challenges to market expansion. High initial capital investment required for modern pavers equipment can be a barrier for smaller construction firms or those in developing regions. A persistent shortage of skilled labor capable of operating and maintaining advanced paving machinery impacts operational efficiency and project timelines. Furthermore, volatile raw material prices and currency fluctuations can affect manufacturing costs and equipment pricing, introducing market instability. Environmental regulations concerning emissions and noise pollution also necessitate costly technological upgrades, which can slow adoption for some players.

Opportunities within the market are abundant, particularly in emerging economies where infrastructure development is still in its nascent stages. The increasing adoption of rental equipment models provides a cost-effective solution for contractors, expanding market reach and utility. Technological advancements, including the integration of telematics, GPS, and automation, offer avenues for enhanced productivity, precision, and fuel efficiency, creating new product differentiation and market niches. The development of hybrid and electric pavers equipment also presents a substantial opportunity for sustainable growth, addressing environmental concerns and catering to evolving regulatory landscapes. The cumulative effect of these drivers, restraints, and opportunities, underpinned by global economic conditions, technological innovation cycles, and environmental policies, collectively shapes the dynamic landscape of the Pavers Equipment Market.

Segmentation Analysis

The Pavers Equipment Market is meticulously segmented to provide a granular understanding of its diverse landscape, enabling stakeholders to identify specific growth areas and strategic opportunities. This comprehensive segmentation typically categorizes the market based on critical attributes such as product type, operating weight, application, and end-user, reflecting the varied requirements across different construction scenarios and operational scales. Analyzing these segments helps in understanding market dynamics, competitive intensity, and consumer preferences, which are crucial for product development, marketing strategies, and investment decisions.

Each segment offers unique insights into demand patterns and technological adoption trends. For instance, the product type segmentation highlights the prevalence of asphalt pavers versus concrete pavers, dictated by material preference and project specifications. Operating weight segmentation distinguishes between compact machines suitable for urban projects and heavy-duty equipment for major highway construction. Application-based segmentation reveals demand from distinct sectors like road construction, commercial, and residential projects. Finally, end-user segmentation clarifies who the primary buyers are, ranging from large construction enterprises to governmental bodies and rental agencies, each with specific purchasing behaviors and operational needs.

- Product Type

- Asphalt Pavers

- Concrete Pavers

- Other Pavers (e.g., Curb and Gutter Pavers, Slipform Pavers)

- Operating Weight

- Compact Pavers (less than 10 metric tons)

- Medium Pavers (10-20 metric tons)

- Heavy Pavers (above 20 metric tons)

- Application

- Road Construction and Repair

- Highways and Bridges

- Airport and Port Infrastructure

- Commercial and Residential Paving

- Urban Infrastructure

- Specialized Industrial Paving

- End-User

- Construction Companies

- Rental Agencies

- Government and Municipalities

- Paving Contractors

Value Chain Analysis For Pavers Equipment Market

The value chain for the Pavers Equipment Market is intricate, encompassing various stages from raw material procurement to end-user utilization, highlighting the flow of goods and services. The upstream segment involves the sourcing of critical components and raw materials, such as specialized steel alloys for chassis, hydraulic systems, engines, electronic control units, and other sophisticated parts. Key suppliers in this phase include manufacturers of heavy-duty engines, transmission systems, advanced sensors, and specialized tires. Strong relationships with reliable component suppliers are crucial for maintaining production quality, managing costs, and ensuring timely delivery, impacting the final product's performance and market competitiveness. Innovation in this upstream segment, particularly concerning engine efficiency and control systems, directly influences the technological capabilities of the final paving equipment.

Moving downstream, the primary activities include the design, manufacturing, assembly, and testing of the pavers equipment. This stage often involves significant research and development investments to incorporate the latest technologies, such as telematics, automation, and fuel-efficient powertrains, meeting evolving customer demands and regulatory standards. After manufacturing, equipment moves through various distribution channels to reach end-users. Direct distribution involves original equipment manufacturers (OEMs) selling directly to large construction companies or government entities, offering customized solutions and direct support. Indirect distribution, a more prevalent model, relies on extensive networks of authorized dealers, distributors, and rental companies that provide sales, after-sales service, parts, and equipment rentals to a broader customer base, including small to medium-sized contractors.

The distribution channel strategy is critical for market penetration and customer reach. While direct sales can foster strong client relationships and allow for tailored product offerings, indirect channels leveraging dealer networks provide wider geographical coverage, localized support, and access to a diverse range of customers. Rental fleets form a significant part of the downstream market, offering flexibility to contractors who may not wish to commit to outright purchases, especially for project-specific or seasonal needs. Effective after-sales service, including maintenance, repairs, and spare parts supply, plays a pivotal role in customer satisfaction and loyalty, extending the operational life of the equipment and contributing significantly to the overall value proposition. This comprehensive value chain ensures that high-quality paving equipment is efficiently produced, distributed, and supported throughout its lifecycle, meeting the demanding requirements of the construction industry.

Pavers Equipment Market Potential Customers

The Pavers Equipment Market caters to a diverse range of end-users and buyers, each with specific needs and procurement patterns, forming the core customer base. These potential customers are primarily entities involved in infrastructure development, maintenance, and various paving projects. Large-scale construction companies represent a significant segment, undertaking major national and international projects such as highways, airports, and industrial complexes. Their demand typically leans towards heavy-duty, high-capacity pavers that offer advanced features, precision, and durability to handle extensive and complex assignments efficiently.

Government and municipal bodies are also crucial end-users, responsible for public road networks, urban development, and local infrastructure maintenance. Their purchasing decisions are often influenced by public tenders, budgetary constraints, and a focus on long-term equipment reliability and environmental compliance. Furthermore, the burgeoning rental industry serves as a key intermediary, purchasing equipment from manufacturers to lease to smaller contractors or for projects with temporary or specific equipment needs. This segment provides flexibility and cost-efficiency for a broad spectrum of contractors who may not justify direct ownership.

In addition to these major players, the market also targets private developers for commercial and residential paving, including parking lots, private roads, and housing developments. These customers may opt for compact or medium-sized pavers that offer versatility and efficiency for smaller to medium-scale projects. The varied demands across these customer segments necessitate a broad product portfolio from manufacturers, encompassing different sizes, capacities, and technological capabilities, alongside robust sales, service, and support networks to meet the distinct operational and financial requirements of each buyer type.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $3.5 Billion |

| Market Forecast in 2032 | $5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Caterpillar Inc., Volvo Construction Equipment, FAYAT Group (Bomag), Wirtgen Group (John Deere), Sumitomo Heavy Industries, Astec Industries, Ltd., Zoomlion Heavy Industry Science and Technology Co., Ltd., SANY Group, XCMG Group, LiuGong Machinery Co. Ltd., Shandong Lingong Construction Machinery Co., Ltd. (SDLG), Hyundai Doosan Infracore, CNH Industrial (CASE Construction Equipment), Hyundai Construction Equipment, Komatsu Ltd., Ammann Group, Dynapac (Fayat Group), Joseph Vogele AG (Wirtgen Group) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pavers Equipment Market Key Technology Landscape

The Pavers Equipment Market is undergoing a significant technological transformation, driven by the demand for increased efficiency, precision, and sustainability in construction. One of the most prominent advancements is the integration of advanced navigation and control systems, such as GPS/GNSS and total stations, which enable millimeter-level paving accuracy. These systems ensure that materials are laid precisely according to design specifications, minimizing waste and rework, and resulting in superior surface quality and longevity. Furthermore, telematics and IoT (Internet of Things) technologies are becoming standard, allowing for real-time monitoring of equipment performance, fuel consumption, and location, facilitating proactive maintenance and optimized fleet management.

Automation and semi-automation features are rapidly being adopted to reduce operator fatigue, enhance safety, and maintain consistent paving parameters. This includes automated steering, slope control, and material flow management systems that can self-adjust based on sensor data, leading to more uniform and higher-quality finishes. The industry is also witnessing a shift towards more environmentally friendly powertrains, with the development of hybrid and electric pavers. These machines offer reduced emissions, lower noise levels, and improved fuel efficiency, aligning with increasingly stringent environmental regulations and the growing global emphasis on sustainable construction practices. The integration of data analytics and artificial intelligence is further optimizing operational workflows, predictive maintenance schedules, and overall project management.

Innovations extend to intelligent compaction systems, which use sensors to measure material stiffness and provide real-time feedback to the operator, ensuring optimal compaction and avoiding over or under-compaction. Advanced sensor technology, including infrared temperature sensors and ultrasonic sensors, monitors material temperature and screed position, ensuring consistent application and preventing material segregation. Additionally, modular design principles are being applied to paver equipment, allowing for easier customization, maintenance, and quicker adaptation to different project requirements. These technological advancements collectively contribute to increased productivity, enhanced safety, reduced operational costs, and the production of more durable and high-quality paved infrastructure.

Regional Highlights

- North America: This region exhibits a mature market characterized by significant investments in maintaining and upgrading existing infrastructure, particularly aging road networks and bridges. The demand for pavers equipment is driven by a focus on quality, efficiency, and the adoption of advanced technologies such as telematics and automation to optimize operations and reduce emissions. Canada and the United States are key players, with a strong emphasis on smart city initiatives and sustainable construction practices that necessitate high-performance and environmentally compliant machinery. The region also benefits from a robust rental market, providing flexible solutions for contractors.

- Europe: Europe represents a technologically advanced market with stringent environmental regulations and a strong emphasis on fuel efficiency and low emissions. Countries like Germany, France, and the UK are major contributors, characterized by a demand for high-precision, automated pavers equipment for both new construction and extensive road repair projects. The region's focus on urban infrastructure development and a push towards electrification and alternative fuel sources for construction machinery heavily influences market trends. Government initiatives supporting green construction further bolster the market for modern, efficient paving solutions.

- Asia Pacific (APAC): APAC is the leading and fastest-growing market for pavers equipment, fueled by rapid urbanization, industrialization, and massive government-led infrastructure development projects. Countries such as China, India, and the ASEAN nations are experiencing unprecedented growth in road construction, highway expansion, and development of new cities, driving substantial demand for all types of paving machinery. The region benefits from a large population, increasing disposable income, and government focus on improving connectivity and logistics, making it a lucrative market for both established global players and regional manufacturers.

- Latin America: This region is characterized by developing infrastructure and increasing investments in transportation networks to support economic growth and trade. Countries like Brazil, Mexico, and Argentina are witnessing significant projects in road construction, urban paving, and mining infrastructure. The demand here is often for cost-effective, durable, and versatile equipment. While adoption of advanced technologies is slower compared to developed regions, there is a growing trend towards mechanization and efficiency improvements, driving market expansion.

- Middle East and Africa (MEA): The MEA region presents considerable growth potential, driven by oil revenue-fueled infrastructure mega-projects, especially in the Gulf Cooperation Council (GCC) countries. Expanding road networks, new city developments, and the need to modernize existing infrastructure contribute to the demand for pavers equipment. African nations, particularly those with stable economies, are also investing in infrastructure to support urbanization and resource extraction, creating new opportunities. The focus is on robust equipment capable of operating in challenging climatic conditions, alongside an increasing interest in advanced paving technologies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pavers Equipment Market.- Caterpillar Inc.

- Volvo Construction Equipment

- FAYAT Group (Bomag)

- Wirtgen Group (John Deere)

- Sumitomo Heavy Industries

- Astec Industries, Ltd.

- Zoomlion Heavy Industry Science and Technology Co., Ltd.

- SANY Group

- XCMG Group

- LiuGong Machinery Co. Ltd.

- Shandong Lingong Construction Machinery Co., Ltd. (SDLG)

- Hyundai Doosan Infracore

- CNH Industrial (CASE Construction Equipment)

- Hyundai Construction Equipment

- Komatsu Ltd.

- Ammann Group

- Dynapac (Fayat Group)

- Joseph Vogele AG (Wirtgen Group)

- Gomaco Corporation

- Power Curbers Inc.

Frequently Asked Questions

What is the primary function of pavers equipment in construction?

Pavers equipment is primarily used to lay various construction materials, such as asphalt, concrete, and aggregates, to create smooth, level, and durable surfaces for roads, highways, bridges, and other infrastructure projects, ensuring consistent quality and thickness.

Which region currently dominates the global pavers equipment market?

The Asia Pacific region currently dominates the global pavers equipment market, driven by extensive infrastructure development, rapid urbanization, and significant government investments in road construction projects across countries like China, India, and Southeast Asia.

What are the key technological advancements transforming the pavers equipment industry?

Key technological advancements include GPS/GNSS for precision paving, telematics for remote monitoring, automation and semi-automation features for consistent quality, hybrid and electric powertrains for sustainability, and intelligent compaction systems for optimal material density.

How does artificial intelligence (AI) impact the pavers equipment market?

AI impacts the pavers equipment market by enabling enhanced paving precision, predictive maintenance to reduce downtime, optimized material usage through data analytics, development of autonomous operations, and improved project management, leading to greater efficiency and cost savings.

What are the main challenges faced by the Pavers Equipment Market?

The main challenges include the high initial capital investment required for advanced machinery, a persistent shortage of skilled labor to operate and maintain complex equipment, stringent environmental regulations necessitating eco-friendly solutions, and fluctuations in raw material costs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager