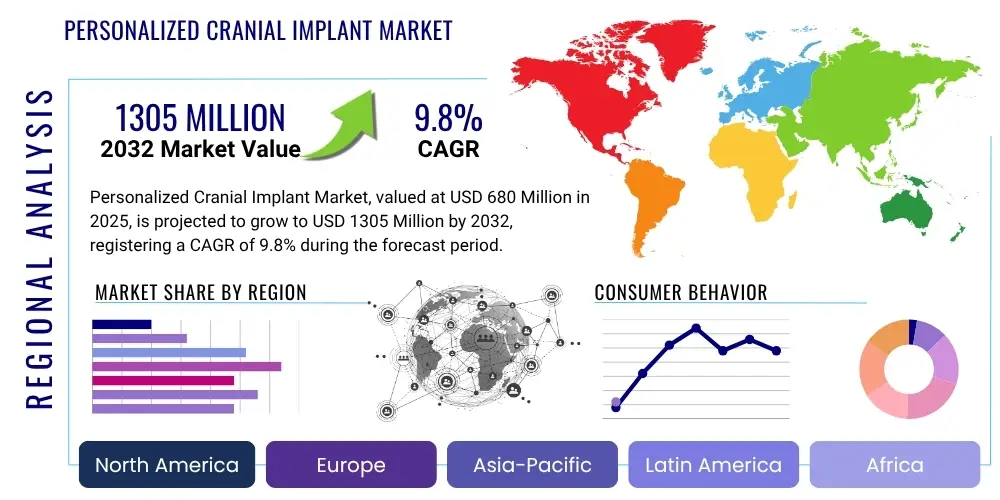

Personalized Cranial Implant Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429105 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Personalized Cranial Implant Market Size

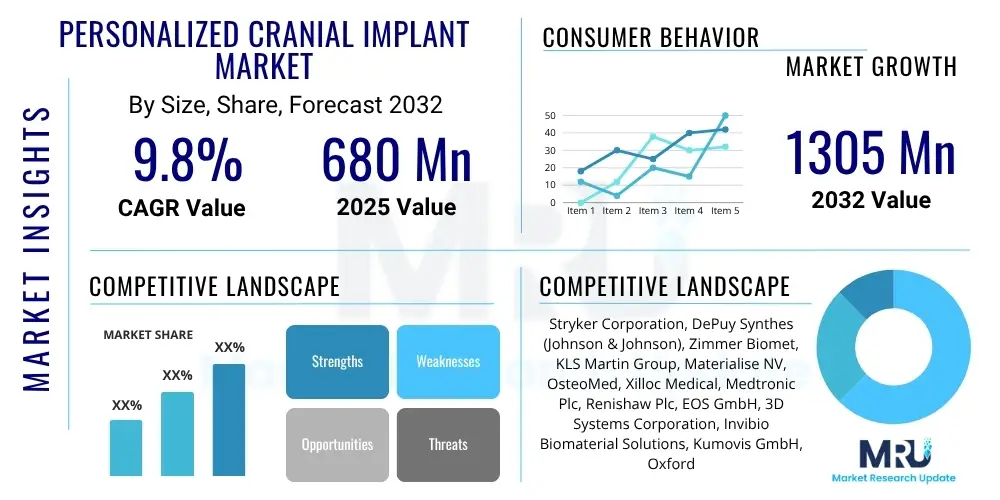

The Personalized Cranial Implant Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2025 and 2032. The market is estimated at USD 680 Million in 2025 and is projected to reach USD 1305 Million by the end of the forecast period in 2032.

Personalized Cranial Implant Market introduction

The Personalized Cranial Implant Market encompasses the design, manufacturing, and application of patient-specific implants used in neurosurgical and craniofacial reconstructive procedures. These implants, tailored precisely to an individual's unique anatomical requirements, address a range of conditions including trauma, congenital defects, tumor resections, and craniosynostosis, offering superior fit and aesthetic outcomes compared to standard, off-the-shelf alternatives. Leveraging advanced imaging technologies and additive manufacturing, these implants significantly enhance surgical precision and patient recovery.

The core product in this market involves custom-designed plates, meshes, or prostheses fabricated from biocompatible materials such as titanium, PEEK, or PMMA, meticulously engineered from high-resolution patient scan data. Key applications span reconstructive surgery following severe head trauma, correction of craniofacial anomalies, repair of skull defects after tumor removal, and revision surgeries where conventional implants have failed. The inherent benefits include reduced operating room time, minimized risk of infection or rejection due to precise fit, improved cosmetic results, and often accelerated post-operative healing due to better integration with surrounding tissues.

Driving factors for market expansion are multifaceted, primarily stemming from technological advancements in 3D printing and medical imaging that enable intricate custom designs and rapid prototyping. The increasing global incidence of neurological disorders, head injuries, and craniofacial defects also fuels demand. Furthermore, a growing emphasis on personalized medicine, coupled with rising patient expectations for optimal functional and aesthetic outcomes, significantly propels the adoption of these specialized cranial implants, fostering continuous innovation in materials and manufacturing processes.

Personalized Cranial Implant Market Executive Summary

The Personalized Cranial Implant Market is experiencing robust growth, driven by an accelerating shift towards patient-specific healthcare solutions and significant technological advancements in medical manufacturing. Business trends indicate a strong focus on research and development by key players, leading to novel material formulations and more efficient production workflows, particularly through the widespread adoption of 3D printing and advanced CAD/CAM software. Strategic collaborations between implant manufacturers, software providers, and healthcare institutions are becoming crucial for expanding market reach and clinical integration, ensuring seamless transitions from patient imaging to surgical implantation. The market also observes an increasing number of regulatory approvals for new materials and custom implant designs, which instills greater confidence among surgeons and patients, thereby supporting broader market acceptance and commercialization efforts globally.

Regionally, North America continues to dominate the market due to its advanced healthcare infrastructure, high prevalence of neurological conditions, substantial healthcare expenditure, and favorable reimbursement policies that support high-value medical procedures. Europe follows closely, driven by similar factors, alongside a strong emphasis on medical innovation and personalized medicine initiatives. The Asia Pacific region is projected to exhibit the highest growth rate during the forecast period, attributed to improving healthcare access, rising medical tourism, a burgeoning aging population susceptible to head trauma and neurological disorders, and increasing investment in healthcare infrastructure and technology adoption in emerging economies like China and India. Latin America, the Middle East, and Africa are also showing nascent but promising growth, fueled by increasing awareness and improving healthcare capabilities.

Segmentation trends highlight the increasing preference for titanium and PEEK materials due to their biocompatibility, strength, and favorable mechanical properties. While traditional CAD/CAM remains vital, 3D printing technologies are rapidly gaining traction for their ability to create highly complex and precise geometries efficiently. Hospitals represent the largest end-user segment, given their capacity for complex surgical procedures and advanced diagnostic imaging, though specialized clinics are also contributing significantly. Applications related to trauma and tumor reconstruction continue to be primary drivers, reflecting the critical need for effective reconstructive solutions in these challenging clinical scenarios. The market is also witnessing a gradual shift towards less invasive surgical techniques enabled by these personalized implants, contributing to better patient outcomes and reduced recovery times.

AI Impact Analysis on Personalized Cranial Implant Market

User inquiries about AI's impact on the Personalized Cranial Implant Market predominantly center on its capacity to revolutionize design precision, enhance surgical planning, and potentially reduce costs and manufacturing timelines. Key themes include the role of AI in analyzing complex anatomical data for optimal implant fit, predicting surgical outcomes, and automating elements of the design process to improve efficiency. Concerns often arise regarding data privacy, the validation of AI-generated designs, and the ethical implications of autonomous decision-making in medical device manufacturing. Users anticipate that AI will lead to more functional and aesthetically superior implants, streamlining the entire workflow from diagnosis to post-operative care, while also questioning the practical implementation challenges and the necessary regulatory oversight for such advanced technologies.

- Enhanced precision in 3D modeling and reconstruction from imaging data.

- Optimized implant design through generative AI algorithms, considering biomechanical properties and patient anatomy.

- AI-assisted surgical planning and navigation systems for more accurate placement and reduced intraoperative errors.

- Predictive analytics for patient-specific outcomes, improving pre-surgical assessment and implant longevity.

- Automation of manufacturing processes, potentially leading to faster production cycles and cost efficiencies.

- Development of smart implants with integrated sensors for real-time monitoring, enabled by AI data processing.

- Improved quality control and defect detection during implant fabrication, ensuring higher safety standards.

- Personalized material selection recommendations based on patient data and biological response simulations.

DRO & Impact Forces Of Personalized Cranial Implant Market

The Personalized Cranial Implant Market is significantly shaped by a confluence of driving forces, inherent restraints, and emerging opportunities, all interacting to define its growth trajectory and competitive landscape. Key drivers include the remarkable advancements in 3D printing and medical imaging technologies, which enable the creation of highly precise and customized implants previously unattainable. Furthermore, the global increase in traumatic head injuries, neurological disorders requiring cranial reconstruction, and the rising prevalence of congenital craniofacial defects significantly bolster the demand for these specialized medical devices. The growing emphasis on patient-specific treatment approaches and the resultant push for improved aesthetic and functional outcomes also act as powerful market accelerators. Favorable reimbursement policies in developed economies further incentivize the adoption of these higher-value, personalized solutions, making them more accessible to patients requiring complex care.

Despite the strong growth drivers, several restraints pose challenges to market expansion. The high initial cost associated with personalized cranial implants, primarily due to custom design, advanced materials, and specialized manufacturing processes, can be a significant barrier for some healthcare systems and patients. Stringent regulatory approval processes for novel materials and custom devices, particularly concerning biocompatibility and long-term efficacy, can delay market entry and increase development costs. Moreover, a shortage of highly skilled neurosurgeons, craniofacial specialists, and medical engineers proficient in utilizing advanced design software and surgical planning tools can limit adoption rates in various regions. Limited awareness among both medical professionals and the general public regarding the benefits and availability of personalized solutions in some developing countries also contributes to slower market penetration. The complex logistics involved in producing and delivering custom implants on a case-by-case basis adds another layer of operational complexity.

Opportunities for market growth are abundant and varied, stemming from the continuous evolution of material science, particularly the development of novel biocompatible and bioresorbable materials that can offer improved integration and long-term performance. The expansion into emerging economies with rapidly developing healthcare infrastructures and increasing disposable incomes presents substantial untapped market potential. The further integration of artificial intelligence and machine learning into the design and manufacturing workflow promises to enhance precision, reduce lead times, and optimize costs, thereby making personalized implants more scalable and affordable. Exploration of new application areas beyond traditional trauma and tumor reconstruction, such as advanced aesthetic corrections or complex revision surgeries, also offers avenues for market diversification. Strategic partnerships and collaborations between medical device manufacturers, academic institutions, and technology companies are crucial for fostering innovation and accelerating the clinical translation of advanced research into practical patient care solutions. Ultimately, the market is poised for sustained expansion as personalized medicine becomes increasingly mainstream, driven by technological ingenuity and a commitment to superior patient outcomes.

Segmentation Analysis

The Personalized Cranial Implant Market is broadly segmented based on material type, design technology, end-user, and application, each playing a crucial role in defining market dynamics and identifying specific areas of growth and innovation. This comprehensive segmentation allows for a detailed analysis of market trends, consumer preferences, and technological advancements across various product offerings and their clinical uses, providing a granular understanding of the market landscape and facilitating strategic decision-making for stakeholders.

- By Material:

- Titanium

- PEEK (Polyether Ether Ketone)

- PMMA (Polymethyl Methacrylate)

- Hydroxyapatite

- Others (e.g., bioresorbable polymers, ceramics)

- By Design Technology:

- CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing)

- 3D Printing (Additive Manufacturing)

- Bioprinting (Emerging)

- By End-User:

- Hospitals

- Specialty Clinics

- Ambulatory Surgical Centers

- By Application:

- Trauma (e.g., severe skull fractures)

- Tumor Resection (e.g., craniotomies for brain tumors)

- Congenital Deformities (e.g., craniosynostosis)

- Craniosynostosis

- Others (e.g., aesthetic reconstruction, revision surgery)

Value Chain Analysis For Personalized Cranial Implant Market

The value chain for the Personalized Cranial Implant Market is intricate, beginning with specialized raw material suppliers and extending through advanced manufacturing to direct healthcare providers, each stage adding critical value. Upstream activities involve the procurement of high-grade biocompatible materials like titanium alloys, PEEK polymers, and PMMA from specialized chemical and metallurgical companies. This phase also includes the development and licensing of sophisticated software for medical imaging processing, computer-aided design (CAD), and computer-aided manufacturing (CAM), which form the digital backbone for personalized implant creation. These suppliers and technology providers ensure the foundational quality and precision required for patient-specific devices.

Midstream in the value chain, highly specialized manufacturers utilize these raw materials and software tools to design and produce the cranial implants. This involves processing patient-specific imaging data (CT/MRI), creating a digital 3D model of the defect and the desired implant, and then employing advanced manufacturing techniques, predominantly 3D printing (additive manufacturing) or CNC machining, to fabricate the physical implant. Rigorous quality control and regulatory compliance are paramount at this stage to ensure product safety, efficacy, and precise anatomical fit. Companies may also engage in post-processing, sterilization, and packaging activities to prepare the implant for surgical use, often working under strict medical device regulations.

Downstream activities focus on distribution and direct delivery to end-users. Manufacturers often employ a hybrid distribution channel, utilizing direct sales forces for large hospital networks and key opinion leaders, ensuring direct communication and technical support. Indirect channels involve partnerships with specialized medical device distributors who have established networks within specific regional healthcare systems, especially in fragmented markets. The final recipients are hospitals, specialty neurosurgical and craniofacial clinics, and increasingly, ambulatory surgical centers, where surgeons perform the implantation procedures. Post-sale support, including surgeon training, technical assistance, and patient follow-up, is also a critical component of the downstream value chain, ensuring successful clinical outcomes and fostering long-term relationships with healthcare providers. Effective communication and collaboration throughout this entire chain are essential for the efficient and safe delivery of personalized cranial implants to patients.

Personalized Cranial Implant Market Potential Customers

The primary potential customers for personalized cranial implants are healthcare institutions and individual medical practitioners specializing in neurosurgery and craniomaxillofacial reconstruction. These include large university hospitals, regional trauma centers, and specialized surgical clinics that regularly handle complex cases involving cranial defects resulting from trauma, tumor resections, or congenital anomalies. These entities serve as direct purchasers and users of the implants, driven by the need for superior patient outcomes, reduced surgical complications, and enhanced aesthetic results, which personalized solutions uniquely provide. Their purchasing decisions are often influenced by clinical evidence, product efficacy, economic considerations like reimbursement, and the overall reputation of the implant manufacturers. The institutions also value comprehensive support, including surgical planning assistance and technical training, offered by the implant providers.

Beyond institutional buyers, the end-users or direct beneficiaries of these products are patients requiring cranial reconstruction, referred by their treating physicians. These patients often face significant functional or cosmetic challenges due to their cranial defects, seeking solutions that can restore normalcy and improve their quality of life. While patients do not directly purchase the implants, their needs and the clinical judgment of their surgeons ultimately drive demand for personalized solutions over standard alternatives. Furthermore, academic and research institutions engaged in craniofacial and neurological studies also represent a niche customer segment, procuring implants for research and development purposes to advance surgical techniques and material science, contributing to the future evolution of the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 680 Million |

| Market Forecast in 2032 | USD 1305 Million |

| Growth Rate | CAGR 9.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stryker Corporation, DePuy Synthes (Johnson & Johnson), Zimmer Biomet, KLS Martin Group, Materialise NV, OsteoMed, Xilloc Medical, Medtronic Plc, Renishaw Plc, EOS GmbH, 3D Systems Corporation, Invibio Biomaterial Solutions, Kumovis GmbH, Oxford Performance Materials (OPM), OssDsign AB, Anatomics Pty Ltd, Facure Inc., Formlabs, Inc., Nexxt Spine LLC, Sygnis AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Personalized Cranial Implant Market Key Technology Landscape

The Personalized Cranial Implant Market is fundamentally shaped by a dynamic and evolving technological landscape, where innovation in medical imaging, design software, and advanced manufacturing processes converges to create patient-specific solutions. At its core are sophisticated imaging modalities such as Computed Tomography (CT) and Magnetic Resonance Imaging (MRI), which provide high-resolution anatomical data essential for accurate defect assessment and subsequent implant design. These imaging techniques form the critical initial step, generating the precise digital blueprint required for personalization, ensuring that every contour and detail of the patient's cranial anatomy is captured accurately for surgical planning and implant fabrication. Continuous advancements in these imaging systems, including faster scan times and reduced radiation exposure, further enhance their utility and adoption in clinical settings, making the personalized approach more feasible.

Following image acquisition, Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software suites are indispensable. CAD software allows engineers and surgeons to meticulously design the implant digitally, customizing its shape, size, and features to perfectly match the patient’s defect and reconstructive needs. This digital design phase often involves advanced simulation tools to predict biomechanical performance and ensure optimal fit and function. Subsequently, CAM software translates these digital designs into instructions for manufacturing equipment, predominantly 3D printers. The advent of medical-grade 3D printing (additive manufacturing) technologies, including Selective Laser Sintering (SLS), Electron Beam Melting (EBM), and Fused Deposition Modeling (FDM) specifically adapted for biocompatible materials like titanium and PEEK, has revolutionized implant production, enabling the creation of complex geometries with unparalleled precision and efficiency, significantly reducing lead times compared to traditional manufacturing methods.

Beyond design and manufacturing, the market also benefits from advancements in materials science, focusing on developing highly biocompatible, bioinert, and increasingly bioresorbable materials that offer improved integration with biological tissues and reduced risk of complications. Furthermore, the integration of Artificial Intelligence (AI) and Machine Learning (ML) is an emerging technology trend, promising to enhance the entire workflow from automated image segmentation and defect identification to generative design optimization and predictive analytics for patient outcomes. Surgical navigation systems, which utilize real-time imaging and tracking technologies, further complement personalized implants by guiding surgeons during implantation, ensuring precise placement and alignment, thereby improving surgical accuracy and reducing operative risks. These interconnected technologies collectively drive the efficacy, safety, and widespread adoption of personalized cranial implants, pushing the boundaries of reconstructive medicine.

Regional Highlights

- North America: This region consistently dominates the Personalized Cranial Implant Market, primarily driven by its highly advanced healthcare infrastructure, robust research and development activities, and a high prevalence of traumatic head injuries and neurological disorders. The presence of leading medical device manufacturers, coupled with favorable reimbursement policies and a strong emphasis on personalized medicine, ensures sustained market leadership. The United States, in particular, contributes significantly to this dominance due benefiting from substantial healthcare expenditure and rapid adoption of innovative surgical technologies, making it a pivotal market for custom implants.

- Europe: Europe represents the second-largest market for personalized cranial implants, characterized by its mature healthcare systems, strong focus on medical innovation, and high patient awareness regarding advanced treatment options. Countries like Germany, France, and the UK are key contributors, investing heavily in 3D printing technologies and promoting collaborations between academic institutions and industry players. The region's stringent regulatory frameworks also contribute to the high quality and safety standards of available personalized implants.

- Asia Pacific (APAC): Expected to be the fastest-growing region, APAC offers immense market potential due to its large and aging population, increasing healthcare expenditure, and improving healthcare infrastructure in emerging economies such as China and India. Rising awareness about advanced medical treatments, coupled with growing medical tourism, is driving the adoption of personalized cranial implants. Government initiatives to enhance healthcare access and the expansion of medical device manufacturing capabilities within the region are also significant growth factors.

- Latin America: This region is an emerging market for personalized cranial implants, driven by increasing healthcare investments and a growing demand for advanced medical technologies. Countries like Brazil and Mexico are witnessing a gradual rise in the adoption of these implants, primarily due to improving economic conditions and enhanced access to specialized medical care. However, challenges related to healthcare affordability and limited awareness persist, indicating significant growth potential as these factors are addressed.

- Middle East and Africa (MEA): The MEA region is experiencing steady growth in the personalized cranial implant market, fueled by rising healthcare spending, development of modern medical facilities, and an increasing incidence of road accidents and related head injuries in certain areas. Countries in the Gulf Cooperation Council (GCC) are leading this growth, investing in state-of-the-art healthcare technologies and attracting skilled medical professionals. However, disparities in healthcare access and infrastructure across the broader region present both challenges and opportunities for future expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Personalized Cranial Implant Market.- Stryker Corporation

- DePuy Synthes (Johnson & Johnson)

- Zimmer Biomet

- KLS Martin Group

- Materialise NV

- OsteoMed

- Xilloc Medical

- Medtronic Plc

- Renishaw Plc

- EOS GmbH

- 3D Systems Corporation

- Invibio Biomaterial Solutions

- Kumovis GmbH

- Oxford Performance Materials (OPM)

- OssDsign AB

- Anatomics Pty Ltd

- Facure Inc.

- Formlabs, Inc.

- Nexxt Spine LLC

- Sygnis AG

Frequently Asked Questions

Analyze common user questions about the Personalized Cranial Implant market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are personalized cranial implants?

Personalized cranial implants are custom-made medical devices designed to precisely fit an individual patient's skull defect, often resulting from trauma, tumor removal, or congenital conditions. They are crafted using advanced imaging and 3D printing technologies to ensure an exact anatomical match.

How are personalized cranial implants manufactured?

The process typically involves obtaining high-resolution CT or MRI scans of the patient, using CAD software to design a perfectly matched implant, and then fabricating it using medical-grade 3D printing (additive manufacturing) techniques with biocompatible materials like titanium or PEEK.

What are the primary benefits of using personalized cranial implants?

Key benefits include superior anatomical fit, improved aesthetic outcomes, reduced surgical time, lower risk of complications such as infection or rejection, and potentially faster patient recovery compared to standard, off-the-shelf implants due to their exact customization.

What materials are commonly used for personalized cranial implants?

Common materials include titanium alloys (known for strength and biocompatibility), PEEK (Polyether Ether Ketone) for its radiolucency and bone-like properties, and PMMA (Polymethyl Methacrylate) for its versatility. Hydroxyapatite and other advanced biocompatible polymers are also gaining traction.

What is the future outlook for the Personalized Cranial Implant Market?

The market is projected for significant growth, driven by continued advancements in 3D printing, AI integration for design optimization, development of novel biocompatible materials, and increasing demand for patient-specific solutions in emerging economies. The trend towards personalized medicine will further fuel its expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager