PET Bottles Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429540 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

PET Bottles Market Size

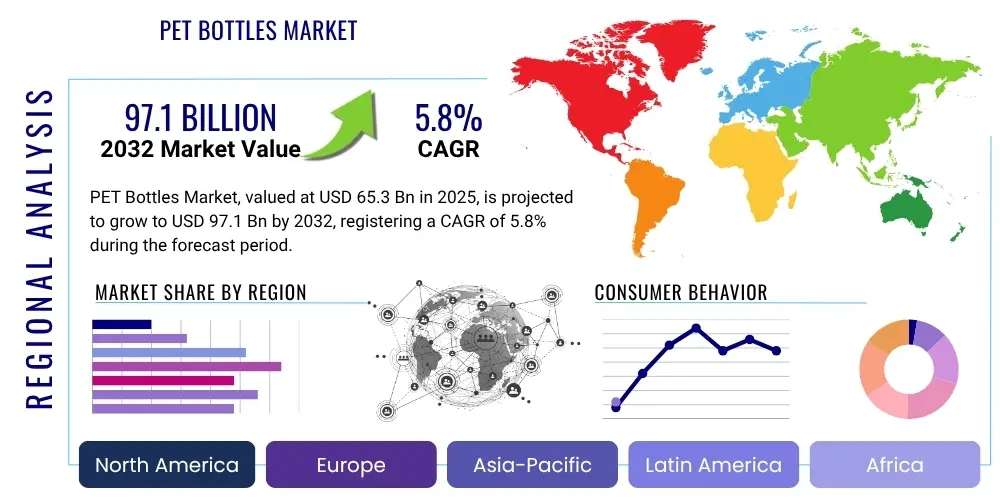

The PET Bottles Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 65.3 billion in 2025 and is projected to reach USD 97.1 billion by the end of the forecast period in 2032.

PET Bottles Market introduction

The PET Bottles Market encompasses the global production, distribution, and consumption of containers made from polyethylene terephthalate (PET) plastic. These bottles are widely recognized for their lightweight nature, exceptional strength-to-weight ratio, clarity, and excellent barrier properties against gases and moisture, making them ideal for packaging a diverse range of products. The manufacturing process typically involves injection molding for preforms followed by stretch blow molding to create the final bottle shape, allowing for high design versatility and cost-effective production at scale.

PET bottles serve as a cornerstone in modern packaging across numerous industries, primarily due to their performance characteristics and the material's recyclability. Major applications span from beverages like carbonated soft drinks, water, juices, and edible oils, to non-food items such as household cleaning products, personal care items, and pharmaceuticals. The inherent benefits of PET, including its shatter resistance, chemical inertness, and ability to protect product integrity, contribute significantly to its widespread adoption. These attributes ensure product safety and extend shelf life, which are critical considerations for both manufacturers and consumers.

Key driving factors propelling the growth of the PET bottles market include rapid urbanization, increasing disposable incomes, and the consequent surge in demand for packaged food and beverages, particularly in emerging economies. Moreover, the pharmaceutical and personal care sectors are expanding, necessitating reliable, safe, and convenient packaging solutions. Continuous innovations in PET bottle design, lightweighting technologies, and enhanced recycling infrastructure further bolster market expansion by addressing environmental concerns and improving economic viability.

PET Bottles Market Executive Summary

The PET Bottles Market is currently experiencing robust growth, primarily driven by the escalating demand for packaged consumer goods, particularly in the food and beverage sectors globally. Business trends indicate a significant push towards sustainability, with manufacturers increasingly investing in recycled PET (rPET) production capabilities and lightweighting technologies to reduce material usage and environmental footprint. Strategic partnerships across the value chain, from resin suppliers to brand owners, are becoming more prevalent, aimed at optimizing supply chains and enhancing recycling efforts. Furthermore, innovations in barrier technologies are expanding the application scope of PET bottles, allowing them to house more sensitive products with extended shelf lives.

Regional trends highlight Asia Pacific as the fastest-growing market, propelled by its large population base, rapid economic development, and increasing consumer spending on packaged products. North America and Europe, while mature markets, are leading in terms of sustainable practices and regulatory frameworks that favor circular economy principles, driving the adoption of rPET and advanced recycling solutions. Latin America and the Middle East and Africa regions are also exhibiting substantial growth, fueled by industrialization, improving infrastructure, and a growing consumer preference for convenient, hygienic packaging formats. The diverse regulatory landscapes across these regions significantly influence market strategies and product development.

Segmentation trends reveal that the beverage segment, encompassing water, carbonated soft drinks, and juices, remains the dominant application area for PET bottles. However, the food, personal care, and pharmaceutical sectors are also demonstrating healthy expansion, driven by specific packaging requirements for safety, hygiene, and shelf stability. From a material perspective, while virgin PET still holds a substantial share, the demand for rPET is witnessing an unprecedented surge due to corporate sustainability commitments and consumer preferences for eco-friendly products. This shift is expected to reshape sourcing and manufacturing strategies across the industry, fostering a more circular approach to PET packaging.

AI Impact Analysis on PET Bottles Market

Common user inquiries regarding the impact of AI on the PET Bottles Market frequently center on its potential to revolutionize manufacturing efficiency, enhance product quality, and significantly improve sustainability efforts, particularly in recycling and waste management. Users are keenly interested in how AI can optimize production lines for reduced waste and energy consumption, predict equipment failures to minimize downtime, and contribute to the development of smarter, more efficient sorting and recycling processes for post-consumer PET. There are also expectations about AI's role in personalized packaging designs, demand forecasting, and overall supply chain resilience, addressing concerns about cost, environmental impact, and market responsiveness.

- Predictive maintenance for blow molding machines, reducing downtime and operational costs.

- Enhanced quality control through real-time defect detection using AI-powered vision systems.

- Optimized production scheduling and resource allocation, improving manufacturing efficiency.

- Advanced sorting technologies in recycling facilities, increasing PET recovery rates and purity.

- Supply chain optimization and demand forecasting for raw materials and finished products.

- Development of smart packaging features for consumer engagement and traceability.

- AI-driven material innovation for lightweighting and barrier property improvements.

- Energy consumption monitoring and optimization across the production lifecycle.

DRO & Impact Forces Of PET Bottles Market

The PET Bottles Market is shaped by a complex interplay of drivers, restraints, opportunities, and inherent impact forces. Key drivers include the ever-growing global population and the associated increase in demand for packaged food and beverages, especially convenience-oriented products. Urbanization trends and rising disposable incomes, particularly in developing economies, further stimulate consumption of goods that rely heavily on PET packaging. The inherent benefits of PET, such as its lightweight nature, cost-effectiveness in production and transportation, transparency, and superior barrier properties, continue to make it a preferred material across diverse end-use industries, from pharmaceuticals to personal care.

However, the market also faces significant restraints. Environmental concerns pertaining to plastic waste and pollution remain paramount, leading to stringent governmental regulations on single-use plastics and increasing consumer backlash. This pressure often results in higher operational costs associated with compliance and the need for investment in sustainable alternatives. Additionally, competition from other packaging materials like glass, aluminum cans, and cartons, which are often perceived as more sustainable, poses a continuous challenge to market share, requiring PET manufacturers to innovate constantly to maintain relevance and competitive advantage.

Despite these challenges, substantial opportunities exist for growth and innovation. The increasing focus on circular economy principles is driving significant investment in recycled PET (rPET) production and advanced recycling technologies, creating new value streams and improving the sustainability profile of PET. Lightweighting innovations continue to reduce material usage, while the development of bio-based PET offers a pathway towards reduced reliance on fossil fuels. Emerging markets present untapped potential for market penetration as infrastructure develops and consumer preferences evolve. The push for greater convenience and product safety also fuels demand for advanced PET solutions, including those with enhanced barrier properties for extended shelf life.

Segmentation Analysis

The PET Bottles market is comprehensively segmented based on various factors, including the type of product contained, the end-use application, the material composition (virgin vs. recycled), and bottle capacity. This granular segmentation provides a detailed understanding of market dynamics, consumer preferences, and industry-specific requirements, allowing for targeted product development and marketing strategies. Each segment exhibits unique growth trajectories and market characteristics influenced by technological advancements, regulatory environments, and evolving consumer trends.

- By Type:

- Still/Carbonated Water Bottles

- Carbonated Soft Drink (CSD) Bottles

- Food Oil Bottles

- Juice Bottles

- Beer Bottles

- Milk Bottles

- Edible Oil Bottles

- Others (Sauces, Syrups, etc.)

- By Application:

- Beverage Industry

- Food Industry

- Household Products (Cleaners, Detergents)

- Pharmaceutical Industry

- Personal Care Industry (Cosmetics, Shampoos)

- Others (Automotive fluids, Industrial chemicals)

- By Material:

- Virgin PET

- Recycled PET (rPET)

- By Capacity:

- Up to 500ml

- 501ml to 1000ml

- 1001ml to 2000ml

- Above 2000ml

Value Chain Analysis For PET Bottles Market

The value chain for the PET Bottles Market is a multi-layered ecosystem, starting from the procurement of raw materials and extending through various manufacturing stages, distribution channels, and ultimately to the end-consumer and recycling. Upstream analysis involves the sourcing of key petrochemical derivatives, primarily purified terephthalic acid (PTA) and monoethylene glycol (MEG), which are the foundational components for PET resin production. Major chemical companies are responsible for supplying these raw materials to PET resin manufacturers. The quality and cost of these raw materials significantly impact the overall production cost of PET bottles, making robust supplier relationships critical for stability and competitive pricing in the market.

Midstream activities in the value chain involve the conversion of PET resin into preforms and then into final PET bottles. This stage includes injection molding companies that produce PET preforms, and subsequently, blow molding companies that transform these preforms into a diverse range of bottle shapes and sizes. These manufacturers often specialize in specific bottle types or cater to particular industries, employing advanced technologies such as stretch blow molding, aseptic filling, and barrier coating to meet stringent quality and functional requirements. Efficiency in manufacturing processes, technological innovation, and adherence to quality standards are paramount at this stage to ensure product performance and cost-effectiveness.

Downstream analysis focuses on the distribution and end-use of PET bottles. Once manufactured, the bottles are supplied to various filling and bottling companies across the beverage, food, pharmaceutical, personal care, and household product industries. These companies integrate the bottles into their automated filling lines. Distribution channels are diverse, including direct sales from manufacturers to large brand owners, as well as indirect channels involving wholesalers, distributors, and retailers. The efficient logistics and supply chain management are crucial for timely delivery and market responsiveness. Ultimately, consumers purchase products packaged in PET bottles, leading to the final stage of the value chain which increasingly emphasizes collection, sorting, and recycling, closing the loop to foster a circular economy for PET materials.

PET Bottles Market Potential Customers

The PET Bottles Market serves a vast and diverse customer base, primarily comprising businesses that require reliable, cost-effective, and safe packaging solutions for their products. These potential customers are predominantly found across various fast-moving consumer goods (FMCG) sectors and specialized industries. The extensive adoption of PET bottles stems from their advantageous properties, making them suitable for a wide array of products that need protection, aesthetic appeal, and convenience for the end-user.

The beverage industry stands as the largest end-user segment for PET bottles. This includes major global and regional players in carbonated soft drinks, bottled water, fruit juices, sports drinks, ready-to-drink teas, and even alcoholic beverages like beer and spirits, particularly in smaller formats. These companies demand high-volume production, consistent quality, and often require bottles with specific barrier properties to maintain product freshness and carbonation levels. The convenience and portability offered by PET bottles are key drivers for their preference among beverage manufacturers.

Beyond beverages, the food industry represents another significant customer segment, utilizing PET bottles for packaging edible oils, sauces, dressings, condiments, and certain dairy products like milk. Pharmaceutical companies leverage PET for medicine bottles, vitamin containers, and other health-related liquids due to its inertness, shatter resistance, and ability to protect contents from contamination. Furthermore, the personal care sector (shampoos, conditioners, lotions, soaps) and the household products industry (cleaners, detergents, fabric softeners) are substantial buyers, valuing PET for its design flexibility, durability, and cost-effectiveness in high-volume applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 65.3 Billion |

| Market Forecast in 2032 | USD 97.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amcor, Berry Global, Graham Packaging, Plastipak Holdings, RESILUX NV, ALPLA, RETAL, Esterform Packaging, CKS Packaging, RPC Group, SIPA, Nampak, Consolidated Container Company, Færch Plast, Gerresheimer, Indorama Ventures Public Company Limited, DS Smith Plc, Kian Joo Can Factory Berhad, Westfall Technik Inc., The Coca-Cola Company (bottle manufacturing through subsidiaries) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

PET Bottles Market Key Technology Landscape

The PET Bottles Market is consistently evolving with advancements in manufacturing processes and material science, driven by demands for increased efficiency, enhanced product performance, and greater sustainability. The core of PET bottle production relies on sophisticated molding technologies, predominantly injection stretch blow molding (ISBM). This process involves first injection molding PET resin into a preform, which is then reheated and stretch blow molded into the final bottle shape. Innovations in ISBM focus on reducing cycle times, minimizing energy consumption, and producing lightweight bottles without compromising structural integrity or barrier properties.

Furthermore, aseptic filling technology has become critical for extending the shelf life of sensitive beverages like juices, dairy, and sports drinks without the need for preservatives or refrigeration. This technology ensures that both the bottle and the product are sterilized before filling in a controlled, contamination-free environment. Barrier technologies represent another crucial area of innovation, particularly for products sensitive to oxygen ingress or CO2 loss. Manufacturers employ multi-layer PET bottles, plasma coatings, or oxygen scavengers embedded within the PET structure to enhance barrier performance, thereby protecting product freshness and extending shelf life for a wider range of applications.

The increasing emphasis on environmental sustainability is driving significant technological advancements in the realm of recycled PET (rPET). Technologies for chemical recycling (depolymerization) are gaining traction, allowing for the breakdown of post-consumer PET into its base monomers, which can then be repolymerized into virgin-quality PET, effectively closing the loop. Mechanical recycling processes are also continually being refined, with improvements in sorting, washing, and flake processing leading to higher quality rPET suitable for food-grade applications. Lightweighting techniques, which involve optimizing bottle design to reduce material usage while maintaining performance, and the exploration of bio-based PET alternatives are also pivotal technological trends shaping the future of the PET bottle market.

Regional Highlights

- North America: This region is a mature market characterized by high consumption of packaged beverages and a strong focus on sustainability. Innovations in rPET usage, advanced recycling infrastructure development, and stringent regulations on plastic waste are key market drivers. The presence of major beverage and food companies also contributes to stable demand.

- Europe: Europe is at the forefront of the circular economy transition, with ambitious recycling targets and robust legislative frameworks like the EU Single-Use Plastics Directive. This drives significant investment in rPET production and chemical recycling technologies. Consumer demand for sustainable packaging heavily influences market trends and product development.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for PET bottles, fueled by rapid urbanization, rising disposable incomes, and an expanding middle class. Countries like China, India, and Southeast Asian nations are experiencing surging demand for packaged food and beverages. While sustainability efforts are growing, the sheer volume of consumption often outpaces recycling infrastructure development.

- Latin America: This region demonstrates steady growth, driven by increasing industrialization and changing consumer lifestyles that favor convenience foods and beverages. Economic development and improving retail infrastructure are expanding market access. Focus on cost-effective packaging solutions is a significant factor.

- Middle East and Africa (MEA): The MEA region is witnessing considerable growth, spurred by population expansion, infrastructure development, and increased foreign investment. Demand for bottled water and soft drinks is particularly strong due to climatic conditions and evolving consumer habits. Investment in local manufacturing capabilities is on the rise to cater to this growing demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the PET Bottles Market.- Amcor Plc

- Berry Global Group Inc.

- Graham Packaging Company

- Plastipak Holdings Inc.

- RESILUX NV

- ALPLA Group

- RETAL Industries Ltd.

- Esterform Packaging Limited

- CKS Packaging Inc.

- RPC Group (a part of Berry Global Group Inc.)

- SIPA S.p.A.

- Nampak Ltd.

- Consolidated Container Company LLC (a part of Loews Corporation)

- Færch Plast A/S

- Gerresheimer AG

- Indorama Ventures Public Company Limited

- DS Smith Plc

- Kian Joo Can Factory Berhad

- Westfall Technik Inc.

- COFCO Packaging Holdings Limited

Frequently Asked Questions

What are PET bottles made of?

PET bottles are primarily made from polyethylene terephthalate, a strong, lightweight, and recyclable thermoplastic polymer derived from petrochemicals, specifically purified terephthalic acid (PTA) and monoethylene glycol (MEG).

Are PET bottles recyclable?

Yes, PET bottles are widely recyclable and are one of the most commonly recycled plastic types globally. Recycled PET (rPET) can be processed into new bottles, fibers, and other products, contributing to a circular economy.

What are the main applications of PET bottles?

The primary applications of PET bottles include packaging for carbonated soft drinks, bottled water, juices, edible oils, milk, beer, pharmaceuticals, personal care products, and household cleaning solutions.

How is the PET bottle market evolving?

The PET bottle market is evolving towards greater sustainability, with increased focus on lightweighting, the use of recycled PET (rPET), advanced recycling technologies, and the development of bio-based PET to reduce environmental impact and meet regulatory demands.

What are the benefits of using PET bottles for packaging?

Benefits of using PET bottles include their lightweight nature, excellent clarity, shatter resistance, strong barrier properties against gases and moisture, cost-effectiveness, design versatility, and widespread recyclability, ensuring product safety and extended shelf life.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Recycled PET Bottles Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- PET Bottles Market Size Report By Type (High, Medium, Low, By Colour, Transparent, Coloured, By Distribution Channel Type, Business to Business, Retail), By Application (Beverages, Packaged Water, Carbonated Soft Drinks, Food Bottles and Jars, Non-Food Bottles and Jars, Fruit Juice, Beer, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager