Petrochemical Pumps Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427401 | Date : Oct, 2025 | Pages : 239 | Region : Global | Publisher : MRU

Petrochemical Pumps Market Size

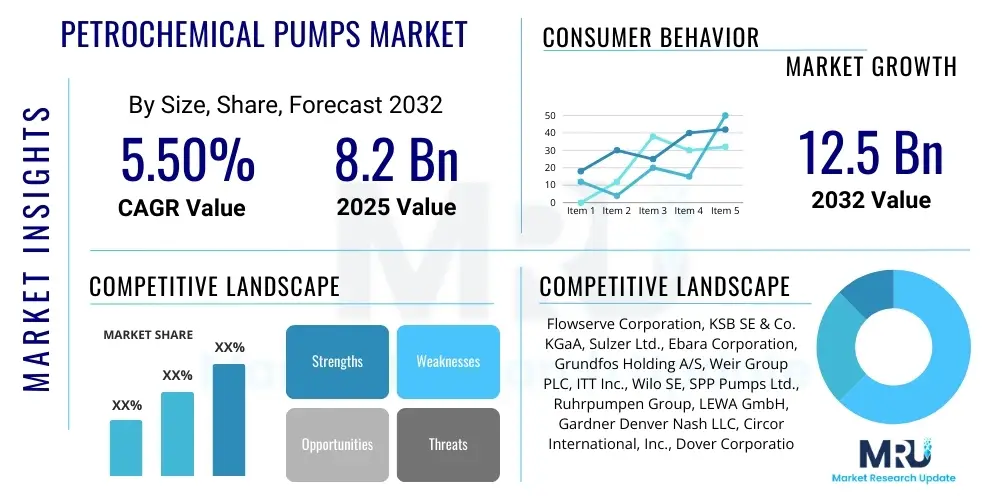

The Petrochemical Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2025 and 2032. The market is estimated at USD 8.2 billion in 2025 and is projected to reach USD 12.5 billion by the end of the forecast period in 2032.

Petrochemical Pumps Market introduction

Petrochemical pumps are indispensable components within the global petrochemical industry, designed to facilitate the safe and efficient transfer of various fluids, including crude oil, refined products, chemical intermediates, and finished chemicals. These pumps operate under stringent conditions, handling highly corrosive, abrasive, volatile, and often hazardous substances at extreme temperatures and pressures. Their robust construction and adherence to international standards are paramount for ensuring operational integrity and preventing environmental contamination in critical processing environments.

The product portfolio encompasses a wide range of pump types, such as centrifugal, positive displacement, and specialty pumps, each engineered for specific applications and fluid characteristics. Major applications span across oil and gas exploration and production, refining, chemical processing, and petrochemical manufacturing facilities, where they are integral to distillation, cracking, blending, and purification processes. These pumps are crucial for maintaining continuous production cycles and ensuring the uninterrupted flow of materials through complex industrial infrastructure.

The primary benefits of advanced petrochemical pumps include enhanced operational reliability, reduced downtime, improved energy efficiency, and compliance with stringent safety and environmental regulations. Key driving factors propelling market growth include the escalating global demand for energy and petrochemical derivatives, significant investments in new refinery and chemical plant capacities, and the modernization of existing infrastructure to improve efficiency and reduce emissions. The ongoing expansion of industrialization, particularly in emerging economies, further contributes to the sustained demand for these critical industrial assets.

Petrochemical Pumps Market Executive Summary

The Petrochemical Pumps Market is currently experiencing dynamic shifts driven by evolving industrial landscapes and technological advancements. Key business trends indicate a strong focus on automation, digitalization, and the integration of smart technologies for enhanced operational efficiency and predictive maintenance capabilities. Market players are increasingly investing in research and development to offer high-performance, energy-efficient, and custom-engineered solutions that address the specific challenges of handling diverse and often hazardous fluids in petrochemical environments. Strategic partnerships and mergers and acquisitions are also prevalent, aimed at expanding market reach and bolstering technological portfolios.

Regionally, the market exhibits varied growth trajectories, with the Asia-Pacific region emerging as a dominant force due to rapid industrialization, increasing energy consumption, and significant investments in new refinery and chemical production capacities, particularly in countries like China and India. North America and Europe continue to be critical markets, driven by modernization projects, stringent environmental regulations necessitating advanced pumping solutions, and a focus on operational excellence. The Middle East and Africa also represent substantial growth opportunities, fueled by extensive oil and gas reserves and ongoing infrastructure development projects.

Segmentation trends reveal a sustained demand for centrifugal pumps due to their versatility and suitability for high-volume applications, while positive displacement pumps are preferred for precise flow control and handling viscous fluids. The market is witnessing a growing emphasis on aftermarket services, including maintenance, repairs, and spare parts, which contribute significantly to overall revenue streams and customer loyalty. The increasing adoption of advanced materials for pump construction, designed to withstand extreme corrosive and abrasive conditions, further defines market dynamics, alongside a rising demand for pumps compliant with international safety and environmental standards.

AI Impact Analysis on Petrochemical Pumps Market

The integration of Artificial Intelligence (AI) is fundamentally transforming the petrochemical pumps market by addressing critical industry challenges related to operational efficiency, maintenance, and safety. Common user inquiries revolve around how AI can enhance predictive maintenance capabilities, reduce unplanned downtime, optimize energy consumption, and improve the overall reliability of complex pumping systems. Users are keen to understand the practical applications of AI in real-time monitoring, anomaly detection, and the automation of operational adjustments, aiming to minimize human intervention in hazardous environments and maximize asset lifespan. There is also a significant interest in the potential of AI to drive data-driven decision-making, leading to more efficient resource allocation and cost savings across the entire value chain.

- Enhanced Predictive Maintenance: AI algorithms analyze sensor data from pumps (vibration, temperature, pressure) to predict potential failures, enabling proactive maintenance and significantly reducing unplanned downtime.

- Optimized Operational Efficiency: AI-driven systems monitor and adjust pump parameters in real-time, optimizing flow rates, pressure, and energy consumption, leading to substantial energy savings and improved throughput.

- Automated Anomaly Detection: Machine learning models can quickly identify subtle deviations from normal operating conditions, signaling potential issues before they escalate, thereby preventing costly damage and ensuring operational safety.

- Improved Asset Management: AI tools support digital twins of pumping systems, allowing for simulation of various scenarios, performance optimization, and informed decision-making regarding upgrades and replacements.

- Enhanced Safety Protocols: By minimizing the need for manual inspections and interventions in hazardous areas, AI-powered remote monitoring and control systems contribute to a safer working environment.

- Supply Chain Optimization: AI can forecast demand for spare parts, optimize inventory levels, and streamline logistics, ensuring timely availability of critical components and reducing lead times for maintenance.

- Design and Engineering Acceleration: AI and generative design tools are being explored to optimize pump designs for specific applications, improving hydraulic performance, material selection, and manufacturability.

DRO & Impact Forces Of Petrochemical Pumps Market

The Petrochemical Pumps Market is shaped by a complex interplay of driving forces, inherent restraints, and emerging opportunities, all influenced by broader economic and technological impacts. Key drivers include the ever-increasing global demand for petrochemical products, such as plastics, fertilizers, and fuels, which necessitates continuous expansion and modernization of refining and chemical processing capacities. Significant investments in oil and gas exploration, production, and midstream infrastructure, particularly in regions rich in hydrocarbon resources, further stimulate demand for robust and reliable pumping solutions. Urbanization and industrial growth in developing economies also play a pivotal role, driving the construction of new industrial facilities that require extensive pumping systems.

Despite robust growth drivers, the market faces several notable restraints. The volatility of crude oil prices directly impacts investment decisions in the upstream and downstream sectors, leading to periods of reduced capital expenditure on new equipment. Stringent environmental regulations and evolving emission standards compel manufacturers to invest heavily in research and development for more eco-friendly and energy-efficient pump designs, adding to production costs. Furthermore, the high capital expenditure associated with purchasing and installing advanced petrochemical pumps, coupled with the specialized maintenance required for such complex machinery, can deter smaller operators. The inherent risks associated with handling hazardous materials also demand exceptionally high safety standards, which can increase operational complexities.

Opportunities in the market primarily stem from the ongoing digitalization and automation trends. The integration of Internet of Things (IoT), AI, and advanced analytics for predictive maintenance and operational optimization offers significant avenues for market expansion and value creation. The growing emphasis on sustainable and green chemical processes, along with the adoption of renewable energy sources in industrial applications, presents new market niches for pumps designed to handle alternative feedstocks and processes. Broader impact forces, such as global economic growth, geopolitical stability influencing energy policies, and rapid technological advancements in materials science and manufacturing, significantly shape the markets trajectory by influencing investment climates, regulatory landscapes, and competitive dynamics.

Segmentation Analysis

The Petrochemical Pumps Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation typically involves categorizing the market based on pump type, application, material of construction, and end-use industry. Analyzing these segments helps stakeholders identify specific growth areas, understand competitive landscapes, and tailor product offerings to meet the precise requirements of various industrial processes within the petrochemical sector. The varying operational demands, fluid properties, and environmental conditions across different applications necessitate a broad range of specialized pumping solutions, making a granular segmentation crucial for strategic planning.

- By Type:

- Centrifugal Pumps (e.g., Axial Flow, Radial Flow, Mixed Flow, Multistage)

- Positive Displacement Pumps (e.g., Reciprocating - Piston, Plunger, Diaphragm; Rotary - Gear, Lobe, Screw, Vane)

- Specialty Pumps (e.g., Magnetic Drive, Canned Motor, Submersible, Metering Pumps)

- By Application:

- Upstream Oil & Gas (e.g., Drilling, Production, Water Injection)

- Midstream Oil & Gas (e.g., Pipeline Transfer, Storage)

- Downstream Oil & Gas (e.g., Refining, Petrochemical Processing)

- Chemical Processing (e.g., Bulk Chemicals, Specialty Chemicals, Polymers)

- Power Generation (e.g., Fuel Transfer, Cooling Water)

- Water & Wastewater Treatment (Industrial)

- By Material:

- Cast Iron

- Stainless Steel

- Alloy Steel (e.g., Duplex, Super Duplex)

- Non-metallic (e.g., Plastics, Composites)

- Exotic Alloys (e.g., Hastelloy, Titanium)

- By End-Use Industry:

- Oil & Gas Industry

- Chemical Industry

- Pharmaceutical Industry

- Power Industry

- Water & Wastewater Industry

- Food & Beverage Industry (Industrial scale)

Petrochemical Pumps Market Value Chain Analysis

The value chain for the Petrochemical Pumps Market is a complex network involving multiple stages, from raw material sourcing to post-sales services, each contributing to the final products value and market delivery. The upstream segment begins with the procurement of specialized raw materials such as various grades of steel, alloys, ceramics, and composites, which are crucial for manufacturing pump components capable of withstanding corrosive, abrasive, and high-temperature environments. This also includes the production of auxiliary components like motors, seals, bearings, and control systems, often sourced from specialized suppliers, emphasizing precision and durability in their specifications to ensure optimal pump performance and longevity.

The midstream phase primarily encompasses the design, engineering, manufacturing, and assembly of the pumps. Manufacturers leverage advanced design software, material science expertise, and precision machining to produce pumps that meet stringent industry standards, such as API (American Petroleum Institute) specifications. Following manufacturing, the distribution channel plays a critical role. This involves both direct sales, where major pump manufacturers deal directly with large-scale petrochemical operators and EPC (Engineering, Procurement, and Construction) firms, and indirect channels, which include a network of authorized distributors, agents, and local representatives who manage sales, inventory, and local support for a broader customer base, especially in diverse geographical markets.

The downstream segment of the value chain focuses on the installation, commissioning, operation, and, crucially, the extensive aftermarket services. End-users in refineries, chemical plants, and oil and gas facilities integrate these pumps into their complex processes. Aftermarket activities, including preventative maintenance, repairs, spare parts supply, upgrades, and technical support, form a significant portion of the total value and revenue for pump manufacturers. These services ensure the continuous and reliable operation of the pumps throughout their lifecycle, minimizing downtime and optimizing performance, thereby contributing significantly to the overall profitability and sustainability of the petrochemical industrys operations.

Petrochemical Pumps Market Potential Customers

The primary potential customers for petrochemical pumps are large-scale operators and facilities within the expansive oil and gas industry. This segment includes companies involved in upstream exploration and production, where pumps are essential for drilling operations, crude oil extraction, and water injection for enhanced oil recovery. Midstream players, responsible for the transportation and storage of crude oil and natural gas through pipelines and terminals, also represent a significant customer base, requiring robust pumps for efficient fluid transfer. Furthermore, downstream refining facilities are heavy users, deploying a multitude of pumps for various processes, including distillation, cracking, and product blending, ensuring continuous operation and high throughput.

Another substantial customer segment comprises the diverse chemical processing industry, encompassing manufacturers of bulk chemicals, specialty chemicals, fertilizers, and polymers. These industries require pumps capable of handling an extensive array of corrosive, volatile, and viscous chemical compounds under precise conditions of temperature and pressure. The demand here is driven by the continuous need for process intensification, product quality control, and adherence to strict safety and environmental regulations, pushing for pumps with advanced material compatibility and superior sealing technologies.

Beyond the core oil, gas, and chemical sectors, other significant potential customers include engineering, procurement, and construction (EPC) firms that undertake large-scale industrial projects, designing and building new petrochemical plants and upgrading existing facilities. Additionally, industrial power generation plants that rely on hydrocarbon fuels for energy production also utilize petrochemical pumps for fuel transfer and other auxiliary systems. Companies involved in industrial water and wastewater treatment, particularly within large industrial complexes, also form a segment of the customer base, requiring pumps for handling process water, effluents, and chemicals. The long operational life and critical nature of these pumps make aftermarket service providers and MRO (Maintenance, Repair, and Operations) companies key stakeholders as well.

Petrochemical Pumps Market Key Technology Landscape

The technology landscape for the petrochemical pumps market is continuously evolving, driven by the imperative for enhanced efficiency, reliability, safety, and environmental compliance. Foundational technologies include advanced material science, focusing on the development of corrosion-resistant alloys such as duplex stainless steel, Hastelloy, and titanium, along with high-performance polymers and composites. These materials are crucial for pump components exposed to aggressive chemicals and extreme temperatures. Precision engineering in hydraulic design is another cornerstone, aimed at optimizing impeller geometry and casing design to maximize efficiency, reduce energy consumption, and minimize cavitation, thereby extending pump life and reducing operational costs.

The integration of smart technologies, particularly the Internet of Things (IoT) and advanced sensor networks, represents a significant technological leap. IoT-enabled pumps feature integrated sensors that monitor critical operational parameters such as vibration, temperature, pressure, flow rate, and power consumption in real-time. This data is transmitted to centralized control systems or cloud platforms for analysis, enabling condition-based monitoring and predictive maintenance. This proactive approach helps in identifying potential failures before they occur, scheduling maintenance efficiently, reducing unplanned downtime, and optimizing spare parts inventory management, significantly improving asset utilization and operational reliability.

Further technological advancements include the development of variable speed drives (VSDs) for precise flow control and energy optimization, magnetic drive and canned motor pumps for leak-free operation in highly hazardous applications, and modular pump designs that offer greater flexibility and ease of maintenance. The adoption of digital twin technology allows for virtual replication and simulation of pump performance, aiding in design optimization and operational troubleshooting. Furthermore, research into additive manufacturing (3D printing) for complex pump components and the use of artificial intelligence for advanced diagnostics and autonomous operation are emerging trends, promising further innovation in the market by enhancing customization, performance, and safety standards.

Regional Highlights

- Asia-Pacific: Dominant market due to rapid industrialization, burgeoning energy demand, and substantial investments in new refinery and chemical plant capacities, particularly in China, India, and Southeast Asian nations.

- North America: Mature market driven by a robust oil and gas sector, ongoing modernization of existing infrastructure, and a strong focus on advanced technologies, energy efficiency, and stringent environmental regulations.

- Europe: Characterized by high technological adoption, stringent safety and environmental standards, and a focus on upgrading existing facilities with more efficient and sustainable pumping solutions. Germany, UK, and France are key contributors.

- Middle East & Africa: Significant growth potential due to vast oil and gas reserves, extensive infrastructure development projects, and increasing investments in downstream processing capabilities. Saudi Arabia and UAE are pivotal markets.

- Latin America: Emerging market with growth spurred by increasing exploration and production activities, particularly in Brazil and Mexico, coupled with investments in petrochemical facilities to meet domestic demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Petrochemical Pumps Market.- Flowserve Corporation

- KSB SE & Co. KGaA

- Sulzer Ltd.

- Ebara Corporation

- Grundfos Holding A/S

- Weir Group PLC

- ITT Inc.

- Wilo SE

- SPP Pumps Ltd.

- Ruhrpumpen Group

- LEWA GmbH

- Gardner Denver Nash LLC

- Circor International, Inc.

- Dover Corporation (OPW Engineered Systems)

- Pentair plc

Frequently Asked Questions

What is the current market size and growth forecast for petrochemical pumps?

The Petrochemical Pumps Market is estimated at USD 8.2 billion in 2025, projected to grow at a CAGR of 5.5% to reach USD 12.5 billion by 2032. This growth is driven by increasing global demand for petrochemical products and infrastructure investments.

What are the primary applications of petrochemical pumps?

Petrochemical pumps are primarily used in upstream, midstream, and downstream oil and gas operations, including drilling, refining, and pipeline transfer. They are also critical in chemical processing, power generation, and industrial water treatment facilities for handling various fluids under demanding conditions.

How is AI impacting the petrochemical pumps market?

AI is significantly impacting the market by enabling advanced predictive maintenance, optimizing operational efficiency, automating anomaly detection, and enhancing safety protocols. AI-driven analytics leverage sensor data for real-time monitoring, reducing downtime and improving asset longevity.

What are the key drivers and restraints for market growth?

Key drivers include rising global demand for petrochemical products, significant investments in new industrial capacities, and modernization of existing infrastructure. Restraints involve volatile crude oil prices, high capital expenditure for advanced systems, and stringent environmental regulations.

Which regions are leading in the petrochemical pumps market?

Asia-Pacific is the leading region due to rapid industrialization and extensive investments in new chemical and refining plants. North America and Europe also hold substantial market shares, driven by technological advancements and infrastructure upgrades, while the Middle East shows strong growth.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager