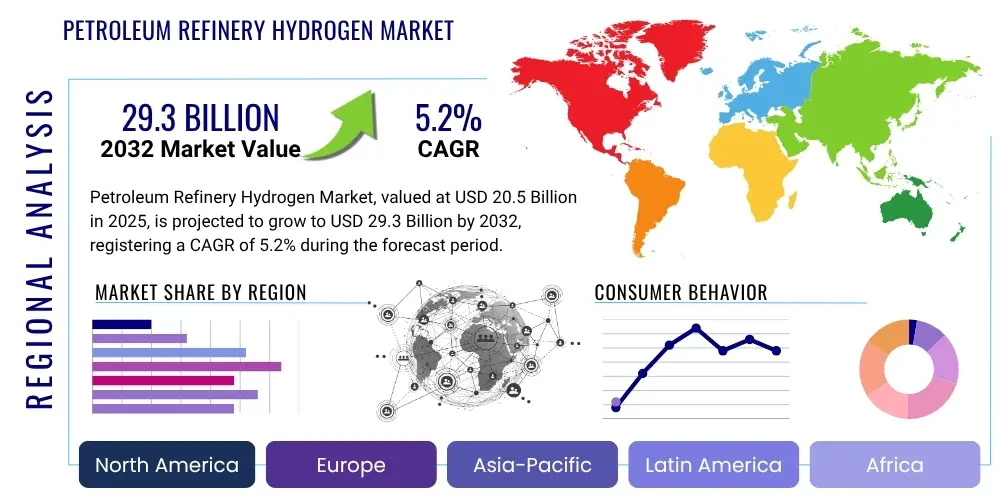

Petroleum Refinery Hydrogen Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429036 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Petroleum Refinery Hydrogen Market Size

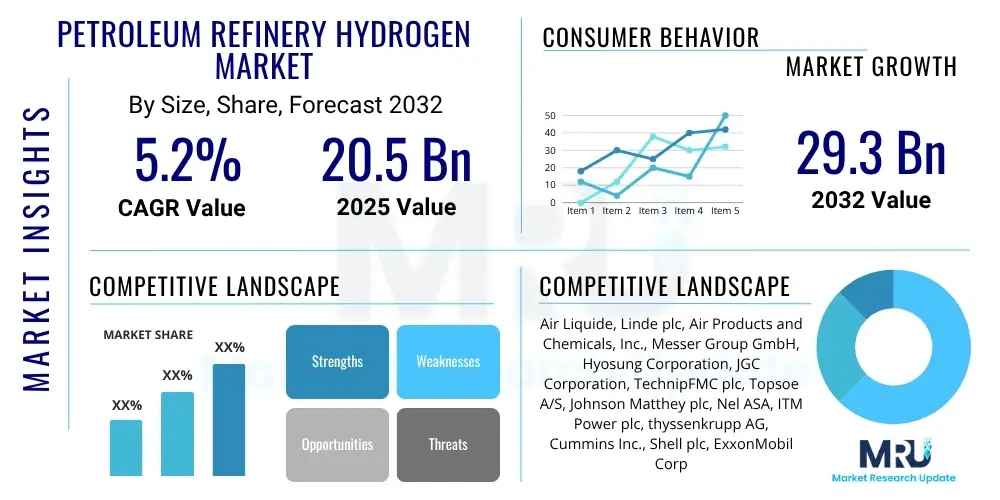

The Petroleum Refinery Hydrogen Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.2% between 2025 and 2032. The market is estimated at USD 20.5 Billion in 2025 and is projected to reach USD 29.3 Billion by the end of the forecast period in 2032.

Petroleum Refinery Hydrogen Market introduction

The Petroleum Refinery Hydrogen Market is integral to modern refining operations, providing a critical input for producing cleaner and higher-value transportation fuels. Hydrogen, often produced on-site via steam methane reforming (SMR) or other methods, is essential for various refining processes. It serves as a vital reactant in processes that remove impurities from crude oil and petroleum products, as well as in upgrading heavier crude fractions into lighter, more valuable fuels.

The primary product description involves high-purity hydrogen gas, tailored to meet the specific requirements of refinery processes. Major applications include hydrotreating, which removes sulfur, nitrogen, and metals from feedstocks to comply with stringent environmental regulations for cleaner fuels, and hydrocracking, a process that breaks down heavy petroleum molecules into lighter, more valuable products like gasoline and diesel. Additionally, hydrogen is crucial for naphtha reforming, which increases the octane number of gasoline components.

The benefits of hydrogen utilization in refineries are multifaceted, encompassing enhanced fuel quality, reduced environmental impact through lower emissions, and increased operational efficiency. Driving factors for this market include the global escalation of environmental regulations demanding ultra-low sulfur fuels, the rising demand for lighter distillates, and the increasing processing of heavier, sour crude oils which require more hydrogen for upgrading and purification. These factors collectively underscore hydrogen's indispensable role in the petroleum refining industry's sustainability and profitability.

Petroleum Refinery Hydrogen Market Executive Summary

The Petroleum Refinery Hydrogen Market is experiencing steady growth, driven by an unwavering global focus on cleaner fuels and stricter environmental mandates. Business trends indicate a shift towards optimizing hydrogen production efficiency, integrating carbon capture technologies for blue hydrogen, and exploring green hydrogen solutions to decarbonize refinery operations. Refineries are increasingly investing in technologies that enhance hydrogen recovery and utilization, thereby minimizing operational costs and environmental footprint. The market also reflects a growing emphasis on smart digital solutions for hydrogen plant management, aiming for predictive maintenance and real-time process optimization.

Regionally, Asia-Pacific remains a significant growth engine due to ongoing refinery expansions and increasing energy demand, particularly in China and India. North America and Europe, while mature, are characterized by stringent regulations and a push towards sustainable hydrogen sourcing, including blue and green hydrogen initiatives. Latin America and the Middle East and Africa are witnessing gradual market expansion, fueled by regional refinery modernization projects and efforts to meet growing domestic and international fuel quality standards. The diversity in regional market dynamics highlights varying levels of regulatory pressure and technological adoption rates.

In terms of segment trends, steam methane reforming (SMR) continues to dominate the production method segment due to its established infrastructure and cost-effectiveness, although electrolysis is gaining traction for its potential in green hydrogen production. The hydrotreating application segment holds the largest share, propelled by the need for desulfurization, while hydrocracking is growing steadily as refiners seek to upgrade heavier crude fractions. On-site hydrogen generation remains prevalent for large refineries, offering cost and logistical advantages, though the merchant hydrogen supply segment provides flexibility and specialized services, particularly for smaller facilities or fluctuating demand scenarios.

AI Impact Analysis on Petroleum Refinery Hydrogen Market

Common user inquiries regarding AI's influence on the Petroleum Refinery Hydrogen Market often revolve around optimizing production costs, enhancing operational efficiency, ensuring safety, and improving process control. Users are keen to understand how AI can lead to more sustainable hydrogen production methods within refineries, particularly concerning energy consumption and emission reduction. Key themes include the application of AI in predictive maintenance for hydrogen generation units, real-time optimization of SMR or electrolyzer performance, intelligent management of hydrogen supply and demand within complex refinery networks, and improving the overall safety of hydrogen handling and storage. Concerns also include the initial investment cost for AI integration and the expertise required to implement and manage such advanced systems.

- AI-driven predictive maintenance reduces downtime and extends the lifespan of hydrogen production assets.

- Real-time process optimization via AI algorithms enhances hydrogen yield and purity while minimizing energy consumption.

- Advanced analytics and machine learning improve feedstock management and reaction control in SMR units, boosting efficiency.

- AI-powered supply chain optimization ensures efficient distribution and storage of merchant hydrogen, reducing logistical costs.

- Intelligent fault detection and anomaly identification systems enhance safety protocols in hydrogen production and utilization areas.

- AI supports the integration of renewable energy sources for green hydrogen production by optimizing grid interactions and electrolyzer operations.

- Simulation and modeling tools predict the impact of various operating conditions on hydrogen output and quality, aiding decision-making.

DRO & Impact Forces Of Petroleum Refinery Hydrogen Market

The Petroleum Refinery Hydrogen Market is significantly shaped by a confluence of drivers, restraints, opportunities, and external impact forces. Key drivers include increasingly stringent environmental regulations, particularly those mandating lower sulfur content in fuels, which necessitate greater hydrogen consumption for hydrotreating. The global demand for lighter, cleaner transportation fuels and the increasing complexity of crude oil processing, often involving heavier and sourer crudes that require more intense upgrading, also propel market growth. Furthermore, the inherent need for process optimization and efficiency improvements within refineries contributes to the demand for advanced hydrogen production and utilization technologies.

However, the market faces several restraints that could impede its growth. The high capital expenditure required for establishing new hydrogen production facilities, especially for larger on-site plants, poses a significant barrier. Fluctuations in the price of natural gas, the primary feedstock for conventional hydrogen production methods like SMR, introduce cost volatility. Safety concerns associated with handling and storing hydrogen, a highly flammable gas, necessitate rigorous safety protocols and investments in specialized infrastructure. Additionally, in the long term, the emergence of alternative fuel sources and shifts in global energy consumption patterns could potentially reduce demand for refined petroleum products, indirectly impacting hydrogen consumption.

Despite these challenges, substantial opportunities exist. The growing global emphasis on decarbonization presents a significant opening for blue hydrogen (hydrogen with carbon capture) and green hydrogen (produced from renewable electricity via electrolysis) integration in refineries, moving towards more sustainable operations. Technological advancements in electrolysis, carbon capture utilization and storage (CCUS), and hydrogen purification membranes offer pathways for more efficient and environmentally friendly production. Moreover, the modernization and expansion of refinery capacities in developing regions, coupled with the ongoing need for upgrading existing facilities in mature markets, provide consistent demand. External impact forces, such as geopolitical stability affecting crude oil supply and prices, global economic growth patterns influencing fuel demand, and continued technological innovation, play crucial roles in shaping the market's trajectory.

Segmentation Analysis

The Petroleum Refinery Hydrogen Market is extensively segmented to provide a granular understanding of its dynamics, categorized primarily by production method, application, and source. These segmentations are critical for stakeholders to identify specific growth areas, competitive landscapes, and technological trends. Each segment reflects distinct operational characteristics, investment requirements, and market drivers, influencing supply and demand patterns across the refining industry globally. Understanding these divisions allows for tailored strategies and targeted market interventions.

- By Production Method:

- Steam Methane Reforming (SMR)

- Auto Thermal Reforming (ATR)

- Partial Oxidation (POX)

- Electrolysis

- Coal Gasification

- By Application:

- Hydrotreating

- Hydrocracking

- Naphtha Reforming

- Desulfurization

- Isomerization

- Others

- By Source:

- On-site Production

- Merchant Hydrogen Supply

Value Chain Analysis For Petroleum Refinery Hydrogen Market

The value chain for the Petroleum Refinery Hydrogen Market encompasses a series of interconnected stages, beginning with upstream activities and extending through production, distribution, and ultimately to downstream consumption within refineries. Upstream analysis involves the sourcing of primary feedstocks required for hydrogen generation. For traditional methods like Steam Methane Reforming (SMR), this primarily includes natural gas. For electrolysis, upstream activities focus on the reliable and often renewable supply of electricity and water. The efficiency and cost-effectiveness of these feedstock supplies significantly impact the overall cost of hydrogen production. Access to stable and affordable natural gas or renewable energy is a critical determinant of hydrogen competitiveness.

The core of the value chain is the hydrogen production phase, where various technologies convert feedstocks into high-purity hydrogen suitable for refinery use. This includes the operation of SMR units, auto thermal reformers, partial oxidation units, and electrolyzers, along with subsequent purification steps like Pressure Swing Adsorption (PSA) or membrane separation. Once produced, hydrogen is then delivered to refineries through various distribution channels. On-site production plants often deliver hydrogen directly via internal pipelines, ensuring a continuous and integrated supply. For merchant hydrogen, distribution involves specialized high-pressure gas trailers, cylinders, or dedicated hydrogen pipelines connecting industrial gas suppliers to multiple refineries.

Downstream analysis focuses on the utilization of hydrogen within the refinery processes, which constitute the end-users of the product. These processes include hydrotreating for sulfur removal, hydrocracking for upgrading heavy oils, and naphtha reforming for octane enhancement. The direct supply of hydrogen from an on-site plant represents a direct channel, offering tight integration and often lower unit costs due to scale and efficiency. Indirect channels involve industrial gas companies (merchant suppliers) who produce hydrogen at centralized facilities and distribute it to multiple refineries, providing flexibility and specialized expertise. The interplay between these upstream, midstream (production and distribution), and downstream (refinery application) stages defines the value dynamics and cost structure of the Petroleum Refinery Hydrogen Market.

Petroleum Refinery Hydrogen Market Potential Customers

Potential customers for the Petroleum Refinery Hydrogen Market primarily comprise entities within the petroleum refining and petrochemical industries that require hydrogen for their various processing operations. The dominant end-users are large integrated oil refineries, which consume substantial volumes of hydrogen daily for critical processes such as desulfurization, hydrocracking, and isomerization. These facilities depend on a steady and reliable supply of hydrogen to produce refined petroleum products that meet stringent environmental and quality specifications, particularly for gasoline, diesel, and jet fuel.

Beyond the major integrated refineries, independent refineries and smaller specialized processing plants also represent significant buyers of hydrogen. These facilities, while perhaps not operating on the same scale, still require hydrogen for similar upgrading and purification tasks to remain competitive and compliant. Their demand often leans towards merchant hydrogen supply due to lower capital investment requirements compared to building and operating their own on-site hydrogen production units. The diversity of crude oil feedstocks processed by these refineries, ranging from light sweet to heavy sour varieties, dictates the specific hydrogen consumption rates and the types of applications where it is utilized.

Furthermore, petrochemical complexes that are co-located or integrated with refineries can also be considered potential customers, especially when they utilize refinery by-products or produce feedstocks that require hydrogen treatment. These buyers are typically interested in the most cost-effective and reliable hydrogen supply, whether through long-term contracts with industrial gas suppliers or by leveraging integrated refinery hydrogen production streams. The evolving landscape of sustainable fuel production, including biofuels co-processing in traditional refineries, also expands the base of potential customers seeking hydrogen for hydrogenation processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 20.5 Billion |

| Market Forecast in 2032 | USD 29.3 Billion |

| Growth Rate | 5.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Air Liquide, Linde plc, Air Products and Chemicals, Inc., Messer Group GmbH, Hyosung Corporation, JGC Corporation, TechnipFMC plc, Topsoe A/S, Johnson Matthey plc, Nel ASA, ITM Power plc, thyssenkrupp AG, Cummins Inc., Shell plc, ExxonMobil Corporation, Chevron Corporation, Sinopec Corp., China National Petroleum Corporation (CNPC), Reliance Industries Limited, Engie SA |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Petroleum Refinery Hydrogen Market Key Technology Landscape

The Petroleum Refinery Hydrogen Market is underpinned by a diverse and evolving technological landscape, primarily focused on efficient, cost-effective, and increasingly sustainable hydrogen production and purification. The dominant technology currently is Steam Methane Reforming (SMR), which converts natural gas and steam into hydrogen and carbon dioxide. This process is well-established, reliable, and accounts for the majority of refinery hydrogen production globally. Variants like Auto Thermal Reforming (ATR) and Partial Oxidation (POX) are also utilized, offering flexibility for different feedstocks, including heavier hydrocarbons.

Alongside production, hydrogen purification technologies are crucial for meeting refinery specifications. Pressure Swing Adsorption (PSA) is widely used to achieve high-purity hydrogen by selectively adsorbing impurities. Membrane separation technologies are also gaining traction for their efficiency in separating hydrogen from other gases, offering a more compact and energy-efficient solution in some applications. These purification steps are vital to ensure the hydrogen's quality for sensitive catalytic processes within the refinery.

Looking ahead, significant advancements are occurring in green and blue hydrogen technologies. Electrolysis, which uses electricity to split water into hydrogen and oxygen, is a key focus for producing green hydrogen, especially when powered by renewable energy sources. Technologies such as Alkaline Electrolyzers and Proton Exchange Membrane (PEM) Electrolyzers are continuously improving in efficiency and scalability. For blue hydrogen, carbon capture utilization and storage (CCUS) technologies are becoming increasingly important, allowing for the capture of CO2 emissions from SMR or ATR plants, thereby reducing the carbon footprint of hydrogen production. These technological developments are critical for the refining industry's long-term sustainability and compliance with environmental goals.

Regional Highlights

- North America: A mature market characterized by stringent environmental regulations and significant investments in refinery upgrades. The region sees strong demand for ultra-low sulfur fuels, driving continuous hydrogen consumption for hydrotreating and hydrocracking. There is also a growing interest in carbon capture technologies for SMR units and exploration of green hydrogen opportunities.

- Europe: Driven by ambitious decarbonization targets and robust environmental policies, Europe is a frontrunner in exploring sustainable hydrogen solutions. While traditional SMR continues, there is substantial focus on developing blue and green hydrogen infrastructure for refineries, supported by government incentives and industry collaboration to meet net-zero emission goals.

- Asia Pacific (APAC): This region represents the largest and fastest-growing market, primarily due to rapid industrialization, increasing energy demand, and ongoing refinery capacity expansions, particularly in China, India, and Southeast Asia. The focus is on meeting escalating fuel consumption and upgrading existing refinery assets to produce cleaner products, often relying on cost-effective SMR solutions.

- Latin America: Characterized by a growing demand for refined products and modernization efforts in its refinery sector. Brazil, Mexico, and Argentina are key countries with increasing hydrogen consumption driven by fuel quality improvements and heavier crude processing. The market is developing with opportunities for both on-site and merchant hydrogen supply.

- Middle East and Africa (MEA): A region rich in oil and gas resources, MEA countries are significant crude oil producers and refiners. Demand for hydrogen is steady, driven by the need to upgrade sour crudes and meet international product specifications for exports. The region also presents potential for large-scale blue hydrogen production given its abundant natural gas reserves and emerging green hydrogen export ambitions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Petroleum Refinery Hydrogen Market.- Air Liquide

- Linde plc

- Air Products and Chemicals, Inc.

- Messer Group GmbH

- Hyosung Corporation

- JGC Corporation

- TechnipFMC plc

- Topsoe A/S

- Johnson Matthey plc

- Nel ASA

- ITM Power plc

- thyssenkrupp AG

- Cummins Inc.

- Shell plc

- ExxonMobil Corporation

- Chevron Corporation

- Sinopec Corp.

- China National Petroleum Corporation (CNPC)

- Reliance Industries Limited

- Engie SA

Frequently Asked Questions

Analyze common user questions about the Petroleum Refinery Hydrogen market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is petroleum refinery hydrogen primarily used for?

Petroleum refinery hydrogen is primarily used for hydrotreating to remove impurities like sulfur, nitrogen, and metals, and for hydrocracking to convert heavy crude oil fractions into lighter, more valuable products such as gasoline and diesel. It is also crucial for naphtha reforming.

What are the main methods of producing hydrogen for refineries?

The main methods include Steam Methane Reforming (SMR), Auto Thermal Reforming (ATR), and Partial Oxidation (POX), which use natural gas or other hydrocarbons as feedstocks. Electrolysis is an emerging method, particularly for green hydrogen, splitting water using electricity.

How do environmental regulations impact the petroleum refinery hydrogen market?

Environmental regulations, especially those mandating lower sulfur content in fuels, significantly drive the demand for hydrogen in refineries. These regulations compel refiners to intensify hydrotreating processes, thereby increasing hydrogen consumption to meet compliance standards and reduce emissions.

What is the role of green hydrogen in petroleum refineries?

Green hydrogen aims to decarbonize refinery operations by providing a low-carbon alternative to traditional hydrogen production. It can reduce the carbon footprint of fuels and contribute to a refinery's sustainability goals, although its widespread adoption is currently limited by cost and infrastructure.

Which regions are experiencing the most growth in this market?

The Asia Pacific region, particularly countries like China and India, is experiencing the most significant growth in the petroleum refinery hydrogen market due to ongoing refinery expansions, increasing fuel demand, and industrial development.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager