Pharmaceutical Storage and Material Handling Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428315 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Pharmaceutical Storage and Material Handling Equipment Market Size

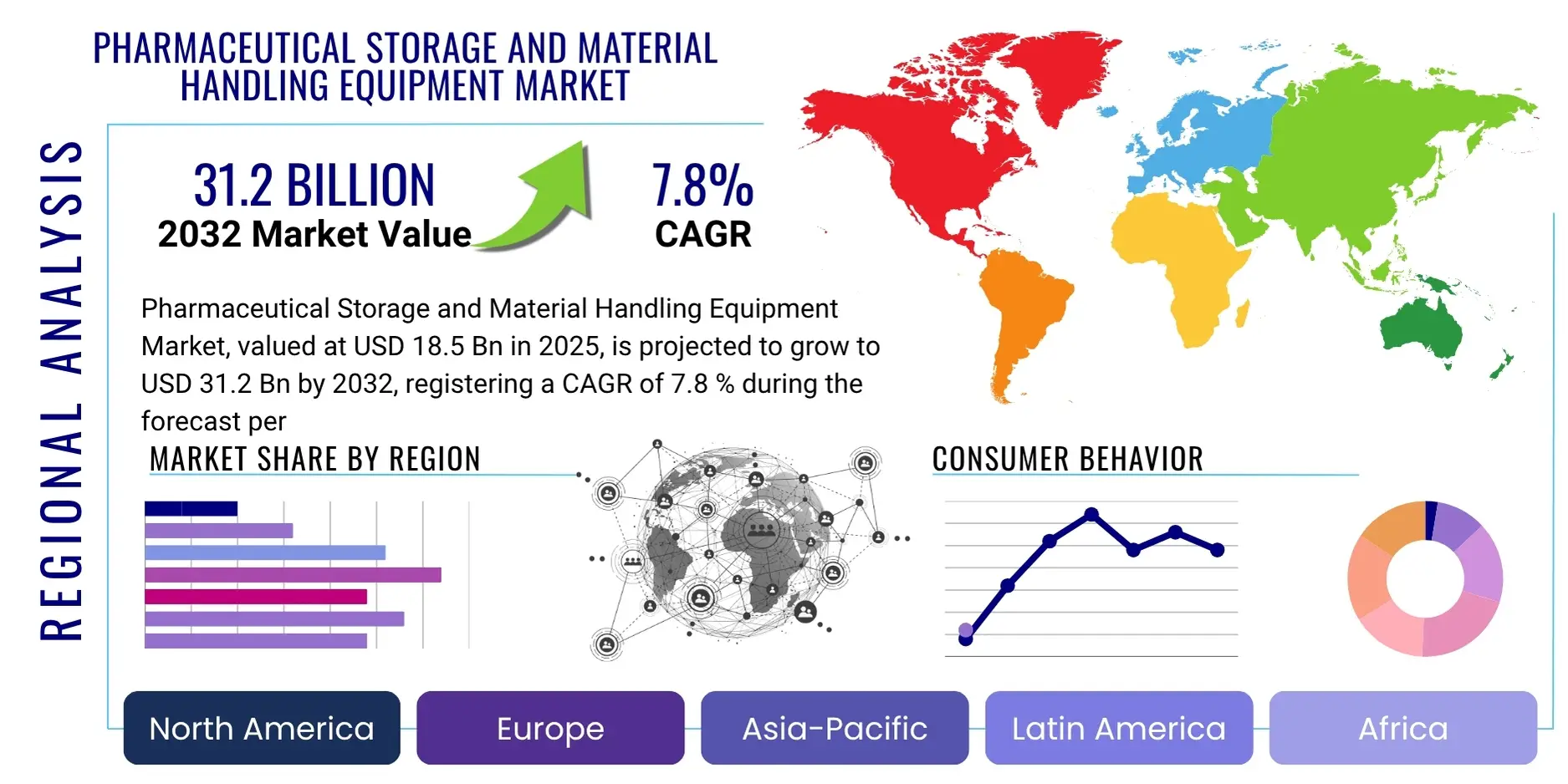

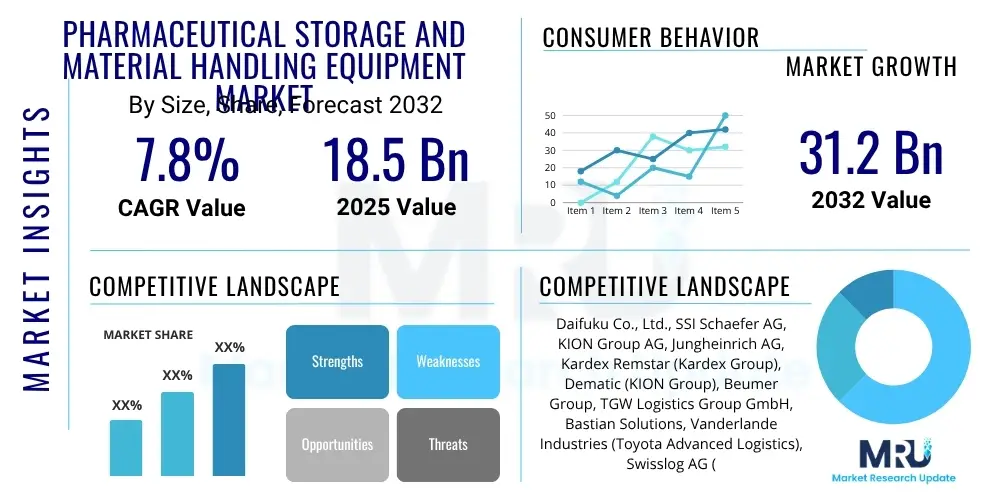

The Pharmaceutical Storage and Material Handling Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 18.5 billion in 2025 and is projected to reach USD 31.2 billion by the end of the forecast period in 2032.

Pharmaceutical Storage and Material Handling Equipment Market introduction

The Pharmaceutical Storage and Material Handling Equipment Market is a cornerstone of the global pharmaceutical and biotechnology industries, critical for ensuring product integrity, operational efficiency, and stringent regulatory compliance throughout the entire drug lifecycle, from research and development to manufacturing, packaging, and distribution. This market encompasses a wide array of specialized products, including temperature-controlled storage solutions (cold chain), automated storage and retrieval systems (AS/RS), robotics, conveyors, racking, shelving, and specialized forklifts, all designed to meet the unique demands of handling sensitive and valuable pharmaceutical products. Major applications span pharmaceutical manufacturing facilities, research laboratories, distribution centers, hospitals, and pharmacies, where these solutions are vital for maintaining sterile environments, preventing cross-contamination, and managing diverse product types ranging from bulk active pharmaceutical ingredients (APIs) to finished biologics and vaccines. The primary benefits include enhanced product safety, minimized human error, significant improvements in inventory management, accelerated supply chain velocity, and substantial cost savings through optimized space utilization and reduced labor requirements. Key driving factors propelling this market forward include the increasing global demand for pharmaceuticals, particularly biologics and temperature-sensitive drugs, the escalating complexity of pharmaceutical supply chains, an intensifying focus on automation and digitalization within the healthcare sector, and the continuous evolution of strict regulatory standards, such as those mandated by the FDA and EMA, which necessitate sophisticated and reliable handling and storage solutions.

Pharmaceutical Storage and Material Handling Equipment Market Executive Summary

The Pharmaceutical Storage and Material Handling Equipment Market is currently undergoing transformative shifts driven by several overarching business trends, including a pronounced pivot towards greater automation, the integration of smart warehousing technologies, and the adoption of modular and flexible system designs to accommodate rapidly changing production demands and product portfolios. Companies are increasingly investing in Internet of Things (IoT) solutions for real-time monitoring and predictive maintenance, alongside artificial intelligence and machine learning for advanced inventory optimization and demand forecasting, aiming for seamless integration across their supply chains. Regionally, North America and Europe continue to lead in technological adoption and advanced infrastructure, propelled by high R&D spending and robust regulatory frameworks, while the Asia Pacific region is emerging as a significant growth engine due to expanding pharmaceutical manufacturing capabilities, rising healthcare expenditures, and increasing investments in modern logistics infrastructure. Latin America and the Middle East & Africa are also witnessing growth, albeit at an earlier stage of development, as they modernize their healthcare and pharmaceutical supply chains. In terms of market segments, the cold chain segment remains paramount, experiencing consistent growth fueled by the proliferation of biologics, vaccines, and other temperature-sensitive pharmaceuticals. There is also a surging demand for highly sterile and contamination-free handling equipment, particularly for aseptic processing and packaging. The adoption of robotic systems, including Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), is a rapidly growing segment, revolutionizing picking, sorting, and transport operations within pharmaceutical warehouses, thereby enhancing efficiency, accuracy, and worker safety while reducing reliance on manual labor.

AI Impact Analysis on Pharmaceutical Storage and Material Handling Equipment Market

The integration of Artificial Intelligence (AI) is fundamentally transforming the Pharmaceutical Storage and Material Handling Equipment Market, addressing critical user questions and expectations regarding efficiency, accuracy, and compliance. Users are keenly interested in how AI can enhance supply chain visibility, minimize human error in critical processes, ensure unwavering regulatory adherence, and optimize storage conditions for sensitive pharmaceuticals. Common concerns revolve around the initial investment costs, the complexity of integrating AI solutions with existing legacy systems, and robust data security protocols essential for handling sensitive pharmaceutical data. However, there is a strong expectation that AI will drive significant operational efficiencies by enabling more precise demand forecasting, optimizing warehouse layouts for maximum throughput, and facilitating proactive, predictive maintenance to minimize downtime. AI's capacity for real-time data analysis and intelligent decision-making is anticipated to offer transformative solutions for managing complex logistics challenges, particularly within the cold chain and sterile environments, thereby ensuring product integrity from manufacturing to patient delivery.

- Predictive analytics for optimized inventory management and demand forecasting, significantly reducing waste and stockouts.

- Automated quality control through computer vision and machine learning algorithms, identifying defects or deviations in real-time.

- Enhanced warehouse management systems (WMS) utilizing AI for dynamic slotting, route optimization for picking robots, and workload balancing.

- Real-time monitoring and control of environmental conditions (temperature, humidity) within cold chain storage, preventing excursions and ensuring compliance.

- Implementation of robotic process automation (RPA) for repetitive tasks such as documentation, order processing, and data entry, freeing human resources for complex problem-solving.

- Proactive maintenance scheduling for material handling equipment, leveraging AI to predict potential failures based on operational data, thus minimizing unplanned downtime.

- Improved supply chain transparency and traceability, utilizing AI to track products from source to destination, crucial for counterfeit prevention and recall management.

DRO & Impact Forces Of Pharmaceutical Storage and Material Handling Equipment Market

The Pharmaceutical Storage and Material Handling Equipment Market is profoundly shaped by a dynamic interplay of Drivers, Restraints, Opportunities, and broader Impact Forces. Key drivers include the escalating global demand for pharmaceutical products, particularly complex biologics, vaccines, and personalized medicines that require precise temperature control and sterile handling throughout their lifecycle. The continuous expansion of pharmaceutical research and development activities, coupled with increasingly stringent regulatory mandates from bodies like the FDA, EMA, and WHO regarding drug safety, quality, and traceability, compel pharmaceutical companies to adopt advanced and compliant storage and handling solutions. Furthermore, the growing adoption of automation and digitalization across the pharmaceutical industry, aimed at enhancing efficiency, reducing labor costs, and mitigating human error, acts as a significant market accelerant. However, the market faces notable restraints, primarily the substantial initial capital investment required for implementing advanced automated systems and specialized storage infrastructure, which can be prohibitive for smaller companies or those in developing regions. The inherent complexity of integrating new material handling technologies with existing legacy systems presents another challenge, often requiring extensive customization and operational adjustments. Additionally, a persistent shortage of skilled personnel capable of operating and maintaining sophisticated automated equipment and managing complex software solutions poses a significant hurdle to widespread adoption. Opportunities abound in emerging markets, where healthcare infrastructure is rapidly developing, alongside the growing prevalence of personalized medicine and cell and gene therapies, which necessitate highly specialized and flexible handling equipment. The continuous advancements in robotics, artificial intelligence, and the Internet of Things offer avenues for innovative solutions that improve efficiency and compliance. Broader impact forces, such as rapid technological innovation in automation and data analytics, the globalization of pharmaceutical supply chains demanding seamless international logistics, evolving regulatory landscapes pushing for higher standards, fluctuating global economic conditions influencing investment decisions, and the persistent threat of public health crises like pandemics, which stress supply chains and underscore the need for robust storage and distribution capabilities, collectively influence the market's trajectory, compelling constant adaptation and strategic investment.

Segmentation Analysis

The Pharmaceutical Storage and Material Handling Equipment Market is extensively segmented to reflect the diverse needs and specialized requirements of the pharmaceutical industry. This segmentation helps in understanding the intricate dynamics of demand across different product categories, applications, end-users, and operational characteristics, thereby enabling market players to tailor their offerings effectively. The market can be broadly analyzed based on the types of equipment utilized, the specific applications where these systems are deployed, the various end-user industries that leverage these solutions, the level of automation integrated into the systems, and the crucial temperature ranges required for different pharmaceutical products. This multi-faceted approach provides a comprehensive view of market penetration and growth opportunities within each distinct segment.

- Product Type:

- Racking & Shelving Systems: Static racking, mobile racking, pallet racking, cantilever racking, wire shelving, modular shelving units.

- Conveyor Systems: Belt conveyors, roller conveyors, chain conveyors, powered & non-powered conveyors, overhead conveyors.

- Automated Storage & Retrieval Systems (AS/RS): Unit-load AS/RS, mini-load AS/RS, shuttle AS/RS, vertical lift modules (VLMs), carousel systems.

- Robotics & Automated Guided Vehicles (AGVs) / Autonomous Mobile Robots (AMRs): Collaborative robots (cobots), palletizing robots, picking robots, AGVs for material transport, AMRs for flexible navigation.

- Cold Storage Equipment: Refrigerators, freezers (ultra-low freezers, cryogenic freezers), walk-in cold rooms, cold storage containers, insulated shippers.

- Palletizers & Depalletizers: Robotic palletizers, conventional layer palletizers, automatic depalletizers.

- Forklifts & Pallet Jacks: Electric forklifts, reach trucks, order pickers, pallet trucks, stackers.

- Packaging & Labeling Equipment: Automated packaging lines, blister packaging machines, labeling machines, serialization systems.

- Other Equipment: Ergonomic workstations, lifting equipment, laboratory material handling devices, weighing and dosing systems.

- Application:

- Pharmaceutical Manufacturing: Bulk drug production, formulation, filling & finishing, secondary packaging.

- Research & Development (R&D): Laboratory material handling, sample storage, biorepository management.

- Pharmaceutical Distribution & Logistics: Warehouse operations, order fulfillment, cross-docking, transportation logistics.

- Hospitals & Pharmacies: Pharmacy automation, drug storage, inventory management, dispensing systems.

- Contract Research & Manufacturing Organizations (CRMOs): Support for diverse client needs in research, development, and manufacturing.

- End-User:

- Pharmaceutical Companies (Branded, Generics, OTC Manufacturers)

- Biotechnology Companies (Biologics, Vaccines, Gene Therapy Developers)

- Research Institutions & Academic Centers

- Hospitals & Clinics

- Wholesalers & Distributors of Pharmaceutical Products

- Contract Manufacturing & Packaging Organizations (CMOs/CPOs)

- Automation Level:

- Manual Systems: Basic racking, manual pallet jacks, hand carts.

- Semi-Automated Systems: Conveyors with manual loading/unloading, semi-automatic palletizers, basic WMS.

- Fully Automated Systems: Integrated AS/RS, robotics, AGVs/AMRs, sophisticated WCS/WMS, smart warehouses.

- Temperature Range:

- Ambient Storage: Controlled room temperature (CRT) for stable drugs.

- Refrigerated Storage: 2°C to 8°C for sensitive biologicals, vaccines.

- Frozen Storage: -20°C to -80°C for certain biologics, reagents.

- Ultra-Low & Cryogenic Storage: Below -80°C down to -196°C for cell therapies, advanced biologics.

Value Chain Analysis For Pharmaceutical Storage and Material Handling Equipment Market

The value chain for the Pharmaceutical Storage and Material Handling Equipment Market is a complex ecosystem involving various stages from raw material procurement to end-user deployment and ongoing service. Upstream activities primarily involve the sourcing and processing of raw materials such as steel, aluminum, plastics, rubber, and various electronic components including sensors, motors, and control units, which form the foundational elements of storage and handling equipment. Key component manufacturers supply specialized parts like motors, gears, programmable logic controllers (PLCs), robotic arms, and advanced sensor technologies to equipment fabricators. Midstream, the equipment manufacturers design, engineer, and assemble the diverse range of products, including racking systems, conveyors, AS/RS, and robotic solutions, often incorporating custom features to meet specific pharmaceutical industry requirements for sterile environments, temperature control, and regulatory compliance. Downstream activities involve the distribution, installation, integration, and ongoing maintenance and support of these sophisticated systems. Distribution channels are varied, encompassing direct sales from manufacturers to large pharmaceutical companies, partnerships with third-party distributors and specialized logistics providers for broader market reach, and collaboration with system integrators who offer complete turnkey solutions, integrating hardware, software (like Warehouse Management Systems - WMS and Warehouse Control Systems - WCS), and automation technologies. Both direct and indirect distribution play crucial roles; direct channels allow for tailored solutions and strong customer relationships, particularly for complex projects, while indirect channels provide wider market access and localized support, essential for maintenance and quick response services. The provision of after-sales services, including spare parts, technical support, software updates, and training, represents a significant segment of the downstream value chain, ensuring the longevity and optimal performance of installed equipment and systems within the highly regulated pharmaceutical environment.

Pharmaceutical Storage and Material Handling Equipment Market Potential Customers

The Pharmaceutical Storage and Material Handling Equipment Market serves a diverse yet highly specialized clientele across the entire pharmaceutical ecosystem, all united by the critical need for precise, compliant, and efficient handling of sensitive products. The primary end-users and buyers of these advanced solutions include large multinational pharmaceutical corporations that require sophisticated, integrated systems for their extensive manufacturing, R&D, and global distribution networks. Biotechnology companies, particularly those developing biologics, vaccines, and cell and gene therapies, represent a rapidly growing customer segment, as their products often necessitate ultra-low temperature storage and highly specialized aseptic handling capabilities. Contract Manufacturing Organizations (CMOs) and Contract Research Organizations (CROs) are also significant customers, as they must provide flexible, high-capacity solutions to meet the varied demands of their numerous clients, often handling diverse product portfolios with different storage and handling requirements. Hospitals and large pharmacy chains invest in automation for their internal drug storage, inventory management, and dispensing systems to enhance patient safety, reduce medication errors, and improve operational efficiency. Additionally, pharmaceutical wholesalers and third-party logistics (3PL) providers specializing in healthcare logistics are crucial buyers, as they manage vast inventories and complex distribution networks, requiring robust cold chain infrastructure and efficient material flow systems to ensure timely and compliant delivery of medicines to various points of care globally. The common denominator among all these potential customers is the imperative for solutions that guarantee product integrity, adhere to stringent regulatory guidelines, and contribute to overall operational excellence within the highly scrutinized pharmaceutical supply chain.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 18.5 Billion |

| Market Forecast in 2032 | USD 31.2 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Daifuku Co., Ltd., SSI Schaefer AG, KION Group AG, Jungheinrich AG, Kardex Remstar (Kardex Group), Dematic (KION Group), Beumer Group, TGW Logistics Group GmbH, Bastian Solutions, Vanderlande Industries (Toyota Advanced Logistics), Swisslog AG (KUKA Group), Honeywell Intelligrated, Murata Machinery, Ltd., Toyota Material Handling, The Raymond Corporation, Interroll Holding AG, Fives Group, PSS Store Equipment GmbH, Westfalia Technologies, Inc., Mecalux S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pharmaceutical Storage and Material Handling Equipment Market Key Technology Landscape

The Pharmaceutical Storage and Material Handling Equipment Market is at the forefront of technological innovation, constantly integrating advanced solutions to meet the evolving demands for precision, speed, and regulatory compliance. Central to this landscape are Automated Storage and Retrieval Systems (AS/RS), which, through their ability to quickly store and retrieve items without human intervention, significantly enhance efficiency, accuracy, and space utilization in pharmaceutical warehouses. Robotics, including collaborative robots (cobots), Automated Guided Vehicles (AGVs), and Autonomous Mobile Robots (AMRs), are increasingly deployed for tasks such as picking, packing, sorting, and internal transport, reducing manual labor, improving throughput, and ensuring consistent operations in controlled environments. The Internet of Things (IoT) plays a crucial role in enabling real-time monitoring of critical parameters like temperature, humidity, and equipment performance, which is vital for maintaining cold chain integrity and ensuring proactive maintenance. AI and Machine Learning algorithms are being leveraged for predictive analytics, optimizing inventory levels, forecasting demand more accurately, and enhancing overall supply chain visibility and responsiveness. Advanced identification technologies such as Radio Frequency Identification (RFID) and sophisticated barcode systems provide robust tracking and tracing capabilities, essential for serialization and anti-counterfeiting efforts in the pharmaceutical supply chain. Furthermore, cloud-based Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) are becoming standard, offering scalable, flexible, and integrated platforms for managing complex logistics, inventory, and order fulfillment processes. Innovations in cold chain technologies, including advanced refrigeration units, passive thermal packaging, and real-time temperature mapping sensors, continue to be paramount for the safe handling and storage of temperature-sensitive drugs, reflecting a continuous drive towards fully integrated, intelligent, and highly compliant material handling solutions for the pharmaceutical sector.

Regional Highlights

- North America: This region stands as a dominant force in the market, characterized by high pharmaceutical R&D spending, extensive adoption of advanced automation technologies, and the presence of numerous major pharmaceutical and biotechnology companies. Stringent regulatory frameworks from bodies like the FDA drive demand for compliant and sophisticated storage and handling solutions, particularly for biologics and specialty drugs.

- Europe: A mature market that emphasizes sustainable and energy-efficient solutions, coupled with a strong focus on automation and digitalization. Countries like Germany, Switzerland, and France are hubs for pharmaceutical innovation and advanced logistics, pushing for integrated cold chain management and robust supply chain security in line with EMA regulations.

- Asia Pacific (APAC): Positioned as the fastest-growing market, driven by expanding pharmaceutical manufacturing bases in countries like China and India, increasing healthcare expenditure, and a rising prevalence of chronic diseases. Investments in modern warehousing and logistics infrastructure are escalating, with a growing demand for cost-effective yet high-tech solutions.

- Latin America: This region is experiencing steady growth, propelled by the development of its pharmaceutical industry, increasing access to healthcare, and the need to modernize existing supply chain infrastructure. Brazil and Mexico are key markets, focusing on improving cold chain capabilities and adopting semi-automated solutions to enhance efficiency.

- Middle East & Africa (MEA): An emerging market with significant potential, fueled by government initiatives to diversify economies, invest in healthcare infrastructure, and improve regional pharmaceutical production capabilities. The focus is on developing robust cold chain logistics and implementing foundational material handling systems to support growing pharmaceutical demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pharmaceutical Storage and Material Handling Equipment Market.- Daifuku Co., Ltd.

- SSI Schaefer AG

- KION Group AG

- Jungheinrich AG

- Kardex Remstar (Kardex Group)

- Dematic (KION Group)

- Beumer Group

- TGW Logistics Group GmbH

- Bastian Solutions

- Vanderlande Industries (Toyota Advanced Logistics)

- Swisslog AG (KUKA Group)

- Honeywell Intelligrated

- Murata Machinery, Ltd.

- Toyota Material Handling

- The Raymond Corporation

- Interroll Holding AG

- Fives Group

- PSS Store Equipment GmbH

- Westfalia Technologies, Inc.

- Mecalux S.A.

Frequently Asked Questions

What is the projected growth rate for the Pharmaceutical Storage and Material Handling Equipment Market?

The Pharmaceutical Storage and Material Handling Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032, reaching USD 31.2 billion by the end of the forecast period.

What are the primary drivers for the growth of this market?

Key drivers include the increasing global demand for pharmaceuticals, particularly temperature-sensitive biologics, stringent regulatory compliance, and the growing adoption of automation and digitalization to enhance efficiency and reduce errors in pharmaceutical supply chains.

How is AI impacting pharmaceutical storage and material handling?

AI is significantly impacting the market by enabling predictive analytics for inventory, optimizing warehouse operations, enhancing real-time monitoring of cold chain conditions, and supporting robotic process automation to improve accuracy and efficiency.

Which regions are leading in the adoption of advanced pharmaceutical storage solutions?

North America and Europe currently lead in the adoption of advanced solutions due to high R&D investments and stringent regulatory requirements, while the Asia Pacific region is rapidly growing due to expanding manufacturing and healthcare infrastructure.

What types of equipment are crucial for cold chain management in pharmaceuticals?

Crucial equipment for cold chain management includes ultra-low freezers, cryogenic storage, walk-in cold rooms, refrigerated storage units, and specialized insulated containers, all integrated with real-time temperature monitoring systems to maintain product integrity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager