Pile Driving Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429497 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Pile Driving Machine Market Size

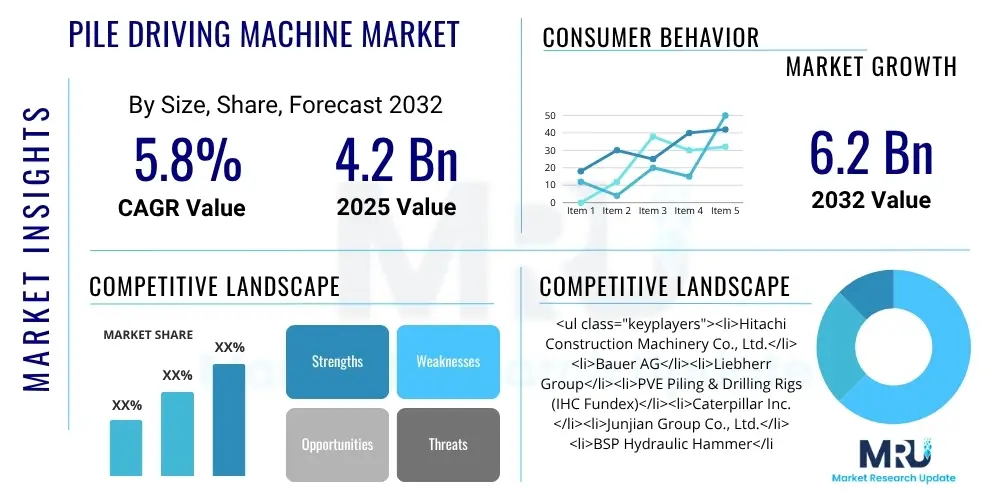

The Pile Driving Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 4.2 billion in 2025 and is projected to reach USD 6.2 billion by the end of the forecast period in 2032.

Pile Driving Machine Market introduction

The Pile Driving Machine Market encompasses a specialized segment within the heavy construction equipment industry, focusing on machinery designed for driving piles into the ground to establish robust and stable foundations. These machines are critical for distributing the structural load of buildings, bridges, and other large constructions onto deeper, more stable soil layers, especially in challenging geological conditions or areas prone to seismic activity. The continuous global demand for resilient infrastructure and advanced construction methodologies underscores the indispensable role of these machines in modern engineering and urban development, driving significant innovation and market expansion across diverse applications.

Pile driving machines are engineered to apply significant force, either through impact, vibration, or static pressure, to install various types of foundation piles, including timber, concrete, and steel piles. The product portfolio includes several distinct categories: hydraulic hammer pile drivers, known for their precision and power; vibratory hammer pile drivers, valued for their speed and suitability in granular soils; diesel hammer pile drivers, recognized for their robust performance in heavy-duty applications; and drop hammer pile drivers, which are among the simplest yet effective solutions. Major applications span a broad spectrum, from high-rise commercial and residential construction to critical infrastructure projects such as highways, railways, port expansions, and offshore platforms for oil and gas extraction, as well as renewable energy installations like wind farms. The core benefits derived from employing these machines include greatly enhanced foundational stability, significant acceleration of construction project timelines due to efficient pile installation processes, and the proven capability to execute projects effectively even in the most demanding and varied geological terrains. These technological advantages ensure structures are built on secure footings, minimizing risks associated with ground settlement and structural integrity over time.

The market's sustained growth is predominantly fueled by several potent driving factors. Firstly, there is an unrelenting global push for extensive infrastructure development, particularly evident in rapidly urbanizing regions and emerging economies that require new transportation networks, utility systems, and public amenities. Secondly, the accelerating pace of urbanization worldwide necessitates the construction of taller and larger structures on often constrained or less-than-ideal ground conditions, thereby increasing the reliance on deep foundation solutions. Thirdly, the burgeoning renewable energy sector, especially the expansion of offshore wind power, demands specialized pile driving equipment for erecting turbine foundations in marine environments. Furthermore, continuous technological advancements, including improved energy efficiency, reduced noise and vibration, and enhanced automation capabilities, contribute significantly to the appeal and adoption of new pile driving machinery, ensuring their continued relevance and critical function in the evolving global construction landscape. These collective forces underscore the strategic importance of the Pile Driving Machine Market as a foundational pillar for global economic and urban expansion.

Pile Driving Machine Market Executive Summary

The Pile Driving Machine Market is currently experiencing a dynamic phase, characterized by several key business trends that are reshaping its competitive landscape and operational methodologies. A primary trend involves the increasing integration of advanced automation and smart technologies, which are profoundly enhancing operational efficiency, elevating safety standards, and improving the precision of pile installation. There is a discernible shift towards more eco-friendly and energy-efficient machinery, driven by escalating environmental regulations and a global imperative for sustainable construction practices. Furthermore, the growth of the equipment rental market is becoming a significant factor, offering flexible and cost-effective solutions for contractors, particularly smaller and medium-sized enterprises, to access cutting-edge technology without the burden of substantial upfront capital investment. Manufacturers are increasingly focused on research and development initiatives aimed at producing equipment that not only meets rigorous performance demands but also adheres to stricter emission controls and noise reduction mandates, thereby aligning with broader sustainability objectives and enhancing their market appeal.

From a regional perspective, the Asia Pacific region continues to exert a dominant influence on the global market, propelled by ambitious mega-infrastructure projects, unprecedented rates of urbanization, and widespread industrialization across economic powerhouses such as China, India, and various Southeast Asian nations. This region's insatiable demand for new construction acts as a powerful catalyst for market expansion. In contrast, North America and Europe are witnessing robust demand for highly advanced and digitally integrated pile driving machines, driven primarily by extensive infrastructure modernization programs, the replacement of aging facilities, and the strict adherence to elevated safety and environmental performance standards. Emerging markets in Latin America and the Middle East & Africa are rapidly gaining prominence, drawing substantial investments into new construction, civil engineering, and energy sector projects, which are generating considerable opportunities for market growth. Each geographic region presents its own unique set of market dynamics, specific regulatory environments, and diverse project requirements, necessitating meticulously tailored market penetration strategies for sustained success.

Segment-wise, the hydraulic hammer segment is projected to secure and maintain a substantial market share, primarily attributed to its exceptional versatility, formidable power output, and inherent precision across a diverse range of soil conditions and project scales. This adaptability makes hydraulic systems a preferred choice for complex foundational tasks. Concurrently, the vibratory hammer segment is experiencing remarkable growth, especially for applications situated in granular soils and in urban environments where stringent noise reduction is an absolute critical requirement. The increasing emphasis on minimizing environmental impact, including noise and vibration, fuels the adoption of these specialized machines. Moreover, key end-user segments, including large-scale building and commercial construction, extensive infrastructure development projects, and the dynamic oil and gas sector, continue to serve as the principal generators of demand for pile driving machinery. A notable trend observed across the market is the development and adoption of highly specialized machines, custom-engineered for niche applications, which are designed to enhance specific operational efficiencies and optimize performance for particular project types, thus contributing to a diversified and robust growth trajectory across the entire market spectrum.

AI Impact Analysis on Pile Driving Machine Market

Common user questions regarding the pervasive impact of Artificial Intelligence (AI) on the Pile Driving Machine Market frequently revolve around a core set of concerns: how AI technologies can fundamentally enhance operational efficiency, significantly improve safety protocols on construction sites, and meticulously optimize complex maintenance schedules for these critical heavy equipment assets. Users are intensely curious about the tangible potential for achieving fully autonomous or highly automated pile driving operations, the implementation of sophisticated predictive analytics to foresee and prevent equipment failures, and the application of real-time monitoring systems to ensure unparalleled precision during pile driving processes, thereby markedly reducing instances of human error. There is a strong, collective expectation within the industry that the integration of AI will invariably lead to the development of more intelligent, self-optimizing machines that possess the inherent capability to dynamically adapt to highly variable ground conditions, ultimately delivering superior productivity rates and generating substantial cost savings across a wide array of construction projects. Furthermore, users frequently inquire about the practical challenges associated with integrating AI-powered solutions into existing operational frameworks and the critical new skill sets that will be indispensable for effectively operating and maintaining these advanced AI-enabled pile driving systems, highlighting a forward-looking perspective on industry transformation.

- Enhanced operational efficiency through sophisticated autonomous control systems, allowing for precise and repetitive tasks with minimal human intervention.

- Implementation of advanced predictive maintenance analytics, drastically reducing unplanned downtime and optimizing equipment lifespan by anticipating potential failures.

- Real-time monitoring and adaptive control capabilities, enabling dynamic adjustments to pile driving depth, force, and frequency based on immediate ground conditions and project specifications.

- Significantly improved safety protocols on construction sites by minimizing human exposure to hazardous environments and automating high-risk operational sequences.

- Facilitation of data-driven decision-making for site-specific adjustments, resource allocation, and overall project management through comprehensive performance insights.

- Optimization of energy consumption patterns and reduction of the environmental impact through intelligent operational algorithms that conserve fuel and minimize emissions.

- Integration of automated fault detection and diagnostic capabilities, leading to quicker identification of issues and substantially faster repair times, enhancing overall uptime.

- Advanced capabilities for optimizing pile placement accuracy and ensuring structural integrity through continuous feedback loops and machine learning models.

DRO & Impact Forces Of Pile Driving Machine Market

The Pile Driving Machine Market is fundamentally propelled by a confluence of powerful drivers that underscore its critical role in global development. Foremost among these is the robust and ongoing global infrastructure development, characterized by massive investments in new roads, expansive bridge networks, modern port facilities, and a surge in both commercial and residential construction worldwide. These extensive projects necessitate efficient and highly reliable foundation solutions, directly fueling the demand for advanced pile driving equipment. Furthermore, accelerated urbanization trends globally mandate the construction of increasingly complex and taller structures, often in challenging geological conditions, which intensifies the reliance on deep foundation techniques. The burgeoning renewable energy sector, particularly the rapid expansion of offshore wind farms, creates a specialized and significant demand for marine pile driving solutions. Coupled with continuous technological advancements leading to more efficient, precise, and environmentally friendly machines, these factors collectively serve as powerful engines for sustained market growth and innovation. The perpetual need for foundational stability in an expanding built environment ensures a consistent and evolving demand for these specialized machines, reinforcing their indispensable position in the construction value chain.

Despite these strong growth drivers, the market faces several significant restraints that challenge its expansion and operational efficiency. A primary barrier is the substantial initial capital investment required for acquiring advanced pile driving machines, which can be particularly prohibitive for smaller and medium-sized contractors, limiting their access to cutting-edge technology. Stringent and evolving environmental regulations, especially in developed regions, concerning noise pollution, ground vibrations, and exhaust emissions from heavy machinery, impose considerable operational and design constraints on manufacturers and users alike. Adherence to these regulations often necessitates costly design modifications or the adoption of more expensive, quieter, and cleaner technologies. Moreover, a persistent shortage of highly skilled operators and specialized maintenance personnel capable of effectively managing and servicing increasingly complex and technologically sophisticated modern machinery represents a critical bottleneck. This scarcity impacts operational efficiency, increases labor costs, and can lead to extended downtime. These multifaceted restraints demand strategic adaptation from market participants, including innovations in financing models, investment in advanced training programs, and a concerted focus on developing machines that inherently mitigate environmental and skill-related challenges.

However, alongside these challenges, the market is rife with significant opportunities that promise substantial growth. The increasing demand for equipment rental services provides a viable pathway for smaller enterprises to access advanced pile driving technology without the burden of large upfront capital expenditures, thereby broadening market participation. The rapid integration of smart and automated pile driving technologies, encompassing IoT, AI, and advanced telematics, offers transformative potential for enhancing productivity, improving safety, and enabling predictive maintenance, thus creating new value propositions. Furthermore, emerging markets across the Asia Pacific, Latin America, and the Middle East continue to present lucrative prospects, driven by ongoing urbanization, ambitious infrastructure projects, and economic diversification efforts. These regions represent untapped potential for market penetration and expansion as their construction sectors mature. The market's competitive dynamics are further shaped by a range of impact forces: the bargaining power of buyers remains moderate to high, largely influenced by the availability of diverse product offerings, competitive pricing strategies among manufacturers, and the specific scale and complexity of construction projects. The bargaining power of suppliers is moderate, dictated by the specialized nature of components, fluctuations in raw material costs, and the proprietary technologies held by key component providers. The threat of new entrants is typically low to moderate due to the substantial capital investment required, extensive research and development costs, and the strong brand loyalty often commanded by established industry players. The threat of substitute foundation methods, such as drilled shafts, caissons, and other shallow foundation techniques, remains a moderate but constant pressure, compelling manufacturers to continuously innovate and demonstrate the superior value, efficiency, and cost-effectiveness of pile driving solutions. Consequently, competitive rivalry within the market is intensely high, fostering continuous advancements in machine performance, technological features, and comprehensive service offerings, which ultimately benefits end-users through improved product quality and operational support across the entire industry value chain.

- Drivers:

- Extensive global infrastructure development and significant governmental and private sector investments.

- Accelerated urbanization trends and increasing demand for robust, deep foundation solutions in dense urban areas.

- Rapid expansion of the renewable energy sector, particularly large-scale offshore wind farm installations.

- Continuous technological advancements leading to more efficient, precise, and environmentally compliant machinery.

- Growing preference for deep foundation techniques for large-scale, complex structures and challenging geological conditions.

- Restraints:

- Substantial initial capital investment required for purchasing high-performance pile driving equipment.

- Strict and evolving environmental regulations concerning noise pollution, ground vibrations, and exhaust emissions.

- Persistent shortage of highly skilled operators and specialized maintenance technicians for complex modern machinery.

- Logistical complexities and high costs associated with the transportation and mobilization of heavy machinery to diverse project sites.

- Vulnerability to global economic fluctuations and project delays in major construction and infrastructure sectors.

- Opportunities:

- Increasing adoption of equipment rental services, providing accessibility to advanced machinery for diverse contractors.

- Significant growth potential in emerging markets across Asia Pacific, Latin America, and the Middle East and Africa.

- Accelerated integration of advanced digital technologies such as IoT, AI, telematics, and automation for enhanced operational efficiency.

- Development and commercialization of eco-friendly and energy-efficient pile drivers, including electric and hybrid models.

- Expansion into specialized niche applications requiring tailored pile driving solutions, fostering product differentiation.

- Impact Forces:

- Bargaining Power of Buyers: Moderate to High, influenced by project scale, market competition, and product differentiation, demanding performance and cost-effectiveness.

- Bargaining Power of Suppliers: Moderate, determined by the specialized nature of components, proprietary technology, and fluctuations in raw material prices.

- Threat of New Entrants: Low to Moderate, primarily due to the considerable capital investment, extensive R&D requirements, and established brand loyalty within the market.

- Threat of Substitutes: Moderate, as alternative foundation methods like drilled shafts, caissons, and shallow foundations offer viable, though often less suitable, alternatives.

- Competitive Rivalry: High, characterized by numerous global and regional players intensely competing on technological innovation, pricing strategies, product features, and comprehensive after-sales service.

Segmentation Analysis

The Pile Driving Machine Market is meticulously segmented across various critical dimensions, providing a granular and comprehensive understanding of its intricate structure and diverse operational landscape. This detailed segmentation is instrumental for market participants to accurately identify specific market demands, strategically tailor their product and service offerings, and formulate highly effective marketing and sales initiatives. The market's multifaceted nature reflects the wide array of technical specifications and performance requirements demanded by global construction and infrastructure projects, necessitating a highly adaptable and innovative approach to both product development and strategic market penetration. By disaggregating the market into distinct segments, stakeholders can better analyze competitive dynamics, evaluate growth opportunities, and mitigate potential risks associated with varying regional and application-specific demands, thereby optimizing their investment and operational decisions for maximum impact.

The primary axes of segmentation include the distinct machine types available, such as hydraulic hammer pile drivers, diesel hammer pile drivers, vibratory hammer pile drivers, and traditional drop hammer pile drivers, along with specialized boring pile drivers (rotary drills). Each type is engineered to deliver optimal performance under particular soil conditions and for specific project scales, addressing diverse foundational requirements. Further segmentation occurs by operation type, categorizing machines into conventional manual systems and increasingly prevalent automated or semi-automated pile driving solutions, which mirrors the industry's significant shift towards enhancing efficiency, precision, and safety through technological integration. The market is also segmented by end-user industries, which include the extensive building and commercial construction sector, vast infrastructure projects encompassing roads, bridges, and railways, the dynamic oil and gas industry, critical marine and port construction, the rapidly expanding energy sector (especially wind power), and the mining industry. Each of these end-user segments exhibits unique technical demands, regulatory compliance needs, and distinct purchasing behaviors. Furthermore, the market is geographically analyzed across major global regions, highlighting varying levels of infrastructure maturity, technological adoption rates, and regional investment patterns.

A deep understanding of these intricate segmentations is absolutely vital for market players to effectively allocate their resources, refine their product portfolios, and strategically position themselves for sustainable future growth. The dynamic interplay between emerging technologies, specialized application requirements, and fluctuating regional demand perpetually drives the evolution and differentiation within each market segment. For instance, the demand for high-frequency vibratory hammers might be significantly higher in urban areas with granular soils due to their efficiency and lower noise footprint, whereas hydraulic hammers are often preferred for their unparalleled versatility and power across a broader spectrum of soil types and challenging geological formations. This illustrates how highly specific product attributes and technological capabilities cater to distinct segment needs and regulatory environments. This granular and detailed segmentation analysis forms the bedrock for informed strategic decision-making processes for manufacturers, distributors, rental companies, and service providers alike, empowering them to skillfully navigate the inherent complexities of the global Pile Driving Machine Market with precision and foresight, ensuring long-term competitiveness and market relevance in an ever-evolving industrial landscape.

- By Machine Type:

- Hydraulic Hammer Pile Drivers: Characterized by high precision, variable energy control, and suitability for a wide range of soil conditions, often used in large-scale and sensitive projects.

- Diesel Hammer Pile Drivers: Known for their robustness, high impact energy, and cost-effectiveness for heavy-duty applications, particularly in remote areas.

- Vibratory Hammer Pile Drivers: Favored for their speed, quiet operation, and effectiveness in granular or cohesive soils, often used for sheet piling and timber piles.

- Drop Hammer Pile Drivers: Simple, reliable, and cost-effective, utilizing gravity for impact, suitable for various pile types but generally slower.

- Boring Pile Drivers (Rotary Drills): Specialized for creating bored piles, often used in urban areas to minimize noise and vibration, or for deep, complex foundations.

- By Operation Type:

- Conventional Pile Driving Machines: Manually operated systems requiring skilled human input for each stage of the pile driving process.

- Automated/Semi-Automated Pile Driving Machines: Incorporate advanced control systems, sensors, and sometimes robotics to automate parts or the entirety of the pile driving sequence, enhancing precision and safety.

- By End-User:

- Building and Construction: Includes residential, commercial, and industrial building foundations, requiring various pile types and machine capabilities.

- Infrastructure (Roads, Bridges, Railways, Airports): Large-scale public works projects demanding powerful and efficient machines for foundational stability.

- Oil and Gas: Offshore and onshore platform foundations, requiring robust and often specialized marine pile driving equipment.

- Marine and Port Construction: Jetties, docks, breakwaters, and port expansions, necessitating machines suitable for aquatic environments and heavy loads.

- Energy (Wind Power, Power Plants): Foundations for wind turbines (onshore and offshore), power transmission towers, and conventional power plants.

- Mining: Support structures for mining operations, processing plants, and heavy equipment foundations in challenging geological settings.

- By Application:

- Sheet Piling: Installation of interlocking steel sheets to create retaining walls or cofferdams for excavation support or water exclusion.

- Bearing Piles: Piles designed to transfer the structural load through weak soil layers to a stronger bearing stratum.

- Foundation Piles: General category of piles used to support structures, encompassing both bearing and friction piles.

- Micro Piling: Small-diameter, high-capacity piles used in restricted access areas, for structural underpinning, or to resist uplift forces.

- By Sales Channel:

- Direct Sales: Manufacturers selling directly to large contractors or government entities, often for bespoke or large-volume orders.

- Distributor/Dealer Sales: Sales through a network of independent distributors and dealers who provide local sales, service, and support.

- Rental Services: Providing machines for short-term or project-specific use, popular among smaller contractors and for specialized tasks.

Value Chain Analysis For Pile Driving Machine Market

The value chain for the Pile Driving Machine Market commences with comprehensive upstream activities, primarily centered around the sourcing and meticulous manufacturing of essential raw materials and highly specialized components. This foundational stage involves key suppliers providing high-grade steel, intricate hydraulic systems, robust engines, advanced control units, and various other critical parts that collectively form the complex architecture of these heavy machinery assets. The intrinsic quality, consistent availability, and cost-effectiveness of these foundational components directly and significantly influence the overall performance, long-term durability, and ultimate market competitiveness of the final pile driving product. Establishing and maintaining strong, collaborative relationships with a network of reliable and high-quality suppliers is absolutely paramount for manufacturers to ensure a steady supply of top-tier components, manage intricate production schedules effectively, and meticulously control overall manufacturing costs, thereby laying a solid groundwork for the entire value creation process within the industry. This initial stage requires significant foresight and strategic procurement to minimize supply chain risks and optimize input quality.

The midstream segment of the value chain is characterized by the complex and multi-stage processes of manufacturing and precision assembly of the pile driving machines themselves. This stage demands sophisticated engineering expertise, highly precise machining operations, and rigorous, multi-tiered quality control protocols to produce equipment that not only meets but often exceeds stringent international performance, safety, and environmental standards. Leading manufacturers actively invest substantial resources into continuous research and development efforts, focusing on innovating new designs, seamlessly integrating cutting-edge technologies such as advanced automation, telematics, and Internet of Things (IoT) capabilities, and constantly striving to improve energy efficiency and operational sustainability. Following the meticulous production phase, the finished products transition through various distribution channels. These typically include direct sales models, where manufacturers sell directly to major construction firms or government bodies, often for large-scale, customized projects. Additionally, a robust network of indirect sales channels, comprising independent distributors and authorized dealers, plays a crucial role. These intermediaries are vital for extending market reach, providing localized sales and after-sales support, and often facilitating flexible financing options for end-users. The overall efficiency and strategic reach of this intricate distribution network are absolutely critical for ensuring broad market penetration, enhancing customer accessibility, and facilitating timely delivery of equipment to diverse project sites globally.

Downstream activities within the value chain are intensely focused on the end-user market and the comprehensive support services provided post-sale. The primary end-users include a broad spectrum of entities such as large-scale construction companies, specialized civil engineering contractors, government agencies responsible for public infrastructure, and a growing segment of equipment rental service providers, all of whom critically rely on these machines for their diverse project requirements. A pivotal aspect of this downstream phase is the provision of robust after-sales services, which encompass routine maintenance, the prompt supply of genuine spare parts, extensive technical support, and comprehensive operator training. These services are absolutely indispensable for maximizing equipment uptime, ensuring optimal operational performance throughout the machine's lifecycle, and cultivating strong, long-term customer satisfaction and loyalty. The market effectively operates through both direct and indirect distribution mechanisms. Direct channels offer manufacturers the advantage of closer client relationships, enabling the provision of highly customized solutions and direct feedback loops from major clients. Conversely, indirect channels, facilitated by independent distributors and specialized rental companies, are instrumental in significantly expanding market reach, particularly to smaller contractors and across geographically dispersed and diverse regions. These indirect partners offer invaluable local market knowledge, immediate product availability, and specialized support, thereby enhancing the overall operational fluidity and comprehensive customer service capabilities of the entire Pile Driving Machine Market, ensuring that the right equipment reaches the right project at the right time.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.2 Billion |

| Market Forecast in 2032 | USD 6.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered |

|

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Pile Driving Machine Market Key Technology Landscape

The Pile Driving Machine Market is currently undergoing a transformative phase driven by significant advancements in technology, all aimed at enhancing operational efficiency, elevating precision, ensuring superior safety standards, and fostering greater environmental sustainability. Among the most pivotal technological integrations is the widespread adoption of advanced Global Positioning System (GPS) and Global Navigation Satellite System (GNSS) technologies. These systems enable exceptionally accurate positioning and alignment of piles, coupled with real-time monitoring of the entire pile driving operation. This unprecedented level of precision drastically minimizes errors, significantly reduces the need for costly rework, and optimally utilizes resources on increasingly complex and challenging construction sites. Furthermore, the pervasive integration of telematics and Internet of Things (IoT) devices has become an industry standard. These technologies furnish operators, project managers, and maintenance teams with invaluable, granular data on machine performance metrics, detailed fuel consumption patterns, crucial operational parameters, and predictive maintenance alerts. Such data-driven insights are instrumental in facilitating proactive maintenance strategies, enabling remote diagnostics, and ultimately maximizing equipment uptime and operational longevity. This confluence of navigation and data acquisition technologies is fundamentally redefining how pile driving operations are planned, executed, and managed in the modern construction era.

Automation and semi-automation are profoundly revolutionizing operational efficiency across the pile driving sector, with cutting-edge machines now capable of executing complex pile driving sequences with minimal human intervention. This significant leap towards autonomous operation not only dramatically boosts overall site productivity but also substantially enhances worker safety by systematically removing human personnel from inherently hazardous operational zones. Innovations in sophisticated hydraulic systems, coupled with advanced, adaptive control algorithms, allow for unprecedentedly precise control over hammer energy, stroke frequency, and impact force. This enables machines to dynamically adapt to highly variable and unpredictable soil conditions in real-time, optimizing performance and preventing damage. Concurrently, there is an intensifying global focus on mitigating the environmental impact of pile driving activities. This critical area of development includes the engineering of quieter vibratory hammers, the introduction of machines powered by cleaner alternative fuels or entirely electric motors to drastically reduce greenhouse gas emissions, and the implementation of state-of-the-art noise and vibration dampening technologies. These innovations are crucial for complying with increasingly stringent urban environmental regulations and promoting more sustainable construction practices, showcasing the industry's commitment to ecological responsibility alongside operational excellence.

The seamless convergence of these diverse technological advancements is giving rise to a new generation of intelligent pile driving solutions that are inherently more adaptive, significantly more efficient, and demonstrably more environmentally responsible. Advanced sensor arrays provide continuous and crucial feedback loops on critical parameters such as ground resistance, pile integrity, and structural load distribution during installation, thereby ensuring optimal performance, preventing structural damage, and guaranteeing the long-term soundness of foundations. Manufacturers are consistently making substantial investments in extensive research and development initiatives to further integrate advanced artificial intelligence (AI) for self-optimization capabilities, machine learning models for sophisticated predictive modeling of soil behavior and equipment performance, and augmented reality (AR) for greatly enhanced operator training simulations and highly efficient, guided maintenance procedures. These pioneering technological shifts are comprehensively reshaping the Pile Driving Machine Market, driving an escalating demand for high-tech equipment that consistently delivers superior performance, effectively minimizes operational risks, and robustly contributes to global sustainable construction practices. This innovative landscape provides a significant competitive advantage to companies that successfully embrace and implement these cutting-edge solutions, setting new benchmarks for efficiency and ecological footprint in the heavy machinery sector.

Regional Highlights

- Asia Pacific (APAC): This region undeniably dominates the global Pile Driving Machine Market, propelled by an unparalleled scale of infrastructure development, exceptionally rapid urbanization, and extensive industrialization across economic powerhouses such as China, India, and various countries within Southeast Asia. Enormous governmental and private sector investments in ambitious smart city initiatives, expansive transportation networks, and crucial renewable energy projects (including massive solar and hydroelectric installations) serve as powerful catalysts, driving sustained and robust demand for advanced pile driving machinery. The sheer volume of ongoing construction, coupled with an increasing emphasis on modern deep foundation techniques for large-scale urban and industrial complexes, positions APAC as the primary growth engine for the global market, accounting for a significant portion of both sales and innovation in the sector.

- North America: Characterized by a highly mature yet dynamic construction industry, North America's market for pile driving machines is predominantly focused on the comprehensive modernization and strategic replacement of existing, often aging, infrastructure. This includes extensive rehabilitation projects for bridges, highways, and commercial structures. The region also demonstrates a strong and growing adoption of highly advanced, automated, and digitally integrated pile driving technologies, all geared towards significantly enhancing operational efficiency, precision, and worker safety on construction sites. Furthermore, the presence of increasingly stringent environmental regulations rigorously drives the demand for low-emission, quieter, and more energy-efficient equipment, pushing manufacturers towards innovative, sustainable solutions that meet both performance and ecological mandates.

- Europe: The European market for pile driving machines is robust and strategically driven by substantial investments in critical renewable energy infrastructure, most notably the continuous expansion of large-scale offshore wind farms across the North Sea and other coastal areas. Simultaneously, ongoing renovation, refurbishment, and strategic expansion projects within dense urban infrastructure networks contribute significantly to market demand. A deeply entrenched emphasis on sustainable construction practices, coupled with stringent adherence to exceptionally high environmental standards, profoundly influences the selection and adoption of cutting-edge pile driving technologies. This fosters a strong demand for innovative, environmentally compliant machines that minimize noise, vibration, and carbon footprint, aligning with the continent's ambitious green agenda and circular economy principles in construction.

- Latin America: This region emerges as a rapidly growing and promising market for pile driving machines, experiencing escalating demand fueled by accelerating urbanization rates, substantial public and private sector investments in vital infrastructure projects (such as new road networks, port upgrades, and urban development), and significant natural resource extraction initiatives. Key contributing countries to this market growth include Brazil, Mexico, and Argentina, which are undertaking major construction endeavors. However, the market dynamics in Latin America can be periodically influenced by economic fluctuations, political instabilities, and varying levels of foreign investment, which can sometimes introduce unpredictability into project timelines and overall market trajectory, necessitating careful strategic planning by market entrants.

- Middle East and Africa (MEA): The MEA region is currently experiencing a period of exceptionally significant growth, largely attributed to the proliferation of ambitious, large-scale construction mega-projects. These include iconic commercial buildings, luxurious hospitality developments, and extensive oil & gas infrastructure projects designed to diversify national economies. Major economic powerhouses like Saudi Arabia, the UAE, and Qatar are at the forefront of this construction boom, channeling substantial investments into their Vision 2030 and similar national development plans. This aggressive push for economic diversification and rapid modernization is generating immense demand for advanced, high-capacity construction machinery, including state-of-the-art pile driving equipment, ensuring a vibrant and expanding market across the region for specialized foundational solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pile Driving Machine Market, encompassing a blend of global leaders and specialized manufacturers known for their innovation, market presence, and technological contributions.- Hitachi Construction Machinery Co., Ltd.

- Bauer AG

- Liebherr Group

- PVE Piling & Drilling Rigs (IHC Fundex)

- Caterpillar Inc.

- Junjian Group Co., Ltd.

- BSP Hydraulic Hammer

- ICE - International Construction Equipment

- JUNTTAN OY

- Komatsu Ltd.

- Kobelco Construction Machinery Co., Ltd.

- Sany Heavy Industry Co., Ltd.

- Xuzhou Construction Machinery Group Co., Ltd. (XCMG)

- Zoomlion Heavy Industry Science and Technology Co., Ltd.

- Casagrande S.p.A.

- SOILMEC S.p.A.

- ABI GmbH (SENNEBOGEN)

- WOLTMAN Piling & Drilling Rigs

- MAIT S.p.A.

- FURUKAWA CO., LTD.

- PTC Fayat Group

- Daedong Industrial Co., Ltd.

Frequently Asked Questions

What is the projected growth rate of the Pile Driving Machine Market?

The Pile Driving Machine Market is projected to exhibit a robust Compound Annual Growth Rate (CAGR) of 5.8% between the years 2025 and 2032. This growth trajectory is anticipated to elevate the market's valuation from an estimated USD 4.2 billion in 2025 to a substantial USD 6.2 billion by the conclusion of the forecast period in 2032, underscoring significant expansion.

Which key factors are primarily driving the growth of the Pile Driving Machine Market?

The market's growth is predominantly driven by extensive global infrastructure development projects, rapid urbanization necessitating complex foundational solutions, and the accelerating expansion of the renewable energy sector, particularly in offshore wind farm installations. Continuous technological advancements in machine efficiency and automation also significantly contribute to this market expansion, making equipment more appealing.

What are the main types of pile driving machines available in the market?

The primary types of pile driving machines include hydraulic hammer pile drivers, known for precision; diesel hammer pile drivers, valued for power in heavy-duty applications; vibratory hammer pile drivers, favored for speed and lower noise; and traditional drop hammer pile drivers. Additionally, specialized boring pile drivers (rotary drills) are used for specific geotechnical conditions.

How does Artificial Intelligence (AI) impact the Pile Driving Machine Market?

Artificial Intelligence significantly impacts the Pile Driving Machine Market by enabling advanced autonomous operation, facilitating highly accurate predictive maintenance to minimize downtime, and offering real-time monitoring and adaptive control systems. These AI applications collectively lead to enhanced operational efficiency, drastically improved safety standards, and optimized resource utilization across all pile driving operations, fostering smarter construction practices.

Which geographical region currently holds the largest share in the Pile Driving Machine Market?

The Asia Pacific (APAC) region currently holds the most substantial market share in the Pile Driving Machine Market. This dominance is primarily attributed to the region's unprecedented scale of infrastructure development, rapid urbanization rates, and robust industrial growth, especially in countries such as China, India, and various emerging Southeast Asian economies, driving immense demand for foundational equipment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager