Planar Solid Oxide Fuel Cell Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429928 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Planar Solid Oxide Fuel Cell Market Size

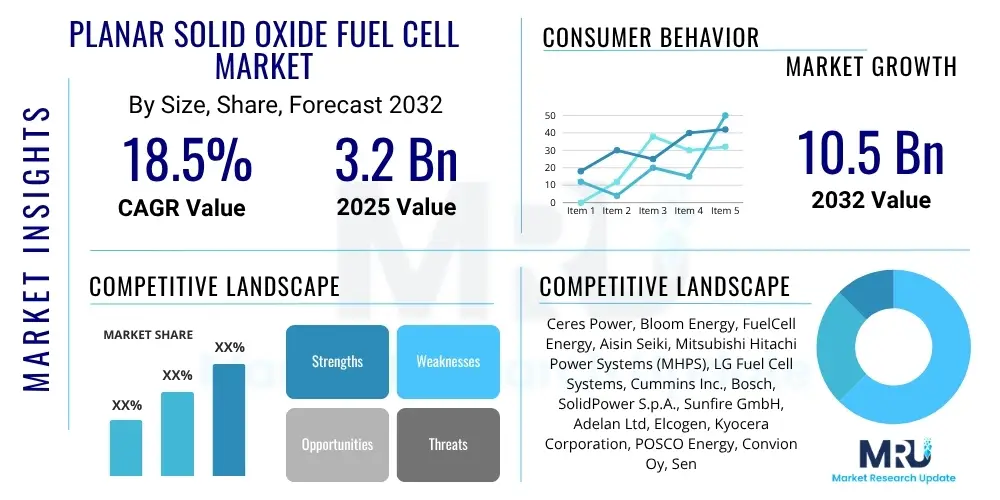

The Planar Solid Oxide Fuel Cell Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at $3.2 Billion in 2025 and is projected to reach $10.5 Billion by the end of the forecast period in 2032.

Planar Solid Oxide Fuel Cell Market introduction

The Planar Solid Oxide Fuel Cell (SOFC) market is rapidly evolving, driven by the global imperative for clean, efficient, and reliable energy solutions. Planar SOFCs are electrochemical devices that convert chemical energy from a fuel source, such as natural gas, hydrogen, biogas, or syngas, directly into electricity with high efficiency and significantly lower emissions compared to conventional combustion engines. These devices operate at high temperatures, typically between 600°C and 1000°C, which allows for internal reforming of various fuels, increasing their versatility and operational flexibility. The planar design, characterized by its flat ceramic layers, facilitates mass production and offers advantages in terms of power density and modularity, making them suitable for a wide array of applications.

The primary applications for planar SOFC technology span across distributed power generation, where they provide resilient and localized energy supply, and combined heat and power (CHP) systems, maximizing overall energy utilization by capturing waste heat for various purposes. They are also increasingly adopted in auxiliary power units (APUs) for transportation, especially in heavy-duty vehicles and marine vessels, and as reliable power sources for data centers and industrial processes requiring continuous, stable electricity. The inherent benefits of planar SOFCs include their remarkable electrical efficiency, which can exceed 60% and even higher when configured in CHP systems, along with their fuel flexibility, enabling them to adapt to diverse energy infrastructures. Furthermore, their modular nature allows for scalable deployments, from kilowatt-scale residential units to megawatt-scale industrial installations.

Driving factors for the market's growth include the escalating global demand for sustainable energy sources, the urgent need to mitigate carbon emissions to combat climate change, and the increasing focus on energy security and independence. Governments worldwide are implementing stringent environmental regulations and offering incentives for the adoption of clean energy technologies, further accelerating market expansion. The ongoing advancements in materials science and manufacturing processes are continuously improving the durability, performance, and cost-effectiveness of planar SOFCs, making them an increasingly attractive alternative to traditional power generation methods. The synergistic development of the hydrogen economy also positions SOFCs as a pivotal technology for utilizing green hydrogen for power generation.

Planar Solid Oxide Fuel Cell Market Executive Summary

The Planar Solid Oxide Fuel Cell (SOFC) market is poised for substantial growth, driven by an accelerating transition towards sustainable energy solutions and robust technological advancements. Business trends indicate a strong push for strategic collaborations between SOFC manufacturers, utilities, and research institutions to accelerate commercialization and reduce costs. There is a noticeable shift towards integrating SOFCs with renewable energy sources and deploying them in microgrid applications, enhancing grid resilience and energy independence. Investment in research and development remains high, focusing on improving cell durability, reducing operating temperatures, and exploring novel materials to enhance performance and lower manufacturing expenses, paving the way for broader market acceptance and competitive pricing strategies. Furthermore, service models for SOFC systems, including maintenance and operational support, are becoming critical offerings to ensure long-term customer satisfaction and system uptime, establishing new revenue streams for market players.

Regionally, the market exhibits dynamic growth patterns with Asia Pacific emerging as a dominant force due to rapid industrialization, increasing energy demand, and proactive government initiatives promoting clean energy and hydrogen-related technologies, particularly in countries like Japan, South Korea, and China. Europe is also a significant market, propelled by stringent decarbonization targets and substantial investments in green hydrogen infrastructure and distributed power solutions, especially in Germany and the UK. North America, primarily driven by the United States, demonstrates steady growth, bolstered by state-level mandates for renewable energy and federal support for fuel cell research and deployment in industrial and commercial sectors. Emerging economies in Latin America, the Middle East, and Africa are gradually adopting SOFC technology for remote power generation and energy access, although at a slower pace due to higher initial costs and limited infrastructure.

Segment-wise, the market is experiencing strong demand across various applications. Distributed generation and combined heat and power (CHP) systems are leading segments, capitalizing on SOFCs' high efficiency and environmental benefits for on-site power production. The auxiliary power unit (APU) segment is gaining traction, particularly in heavy-duty transportation and marine sectors, offering fuel-efficient and low-emission alternatives to traditional generators. In terms of fuel type, natural gas remains a primary fuel source due to its established infrastructure, but there is a clear trend towards increased utilization of hydrogen and biogas as their production scales up and infrastructure develops. Technologically, anode-supported cells continue to dominate due to their superior performance, though advancements in metal-supported SOFCs are promising for enhanced durability and cost reduction. The market is also seeing increased demand from commercial and industrial end-users seeking reliable, efficient, and low-emission power solutions.

AI Impact Analysis on Planar Solid Oxide Fuel Cell Market

Common user questions regarding AI's impact on the Planar Solid Oxide Fuel Cell market frequently revolve around how artificial intelligence can enhance efficiency, reduce operational costs, and accelerate technological development. Users are keen to understand AI's role in optimizing SOFC performance, predicting maintenance needs, and improving system integration with complex energy grids. There is also significant interest in AI's potential to streamline manufacturing processes, develop new materials, and manage fuel supply chains more effectively. The overarching themes include leveraging AI for smarter, more reliable, and cost-efficient SOFC deployments, addressing concerns about system complexity and long-term viability.

- AI can optimize SOFC operational parameters, such as temperature, fuel flow, and current density, to maximize electrical efficiency and prolong stack lifespan.

- Predictive maintenance driven by AI algorithms analyzes real-time sensor data to forecast component failures, enabling proactive servicing and reducing downtime.

- Advanced control systems integrated with AI can manage complex SOFC power plants, improving stability and responsiveness to fluctuating energy demands.

- AI accelerates material discovery and design by simulating and predicting the properties of novel ceramic electrolytes, electrodes, and interconnects, leading to more efficient and durable SOFC components.

- AI facilitates better integration of SOFC systems into smart grids, optimizing power dispatch, balancing loads, and enhancing overall grid stability and resilience.

- Demand forecasting for energy and fuel, powered by AI, helps optimize SOFC system sizing and fuel procurement, leading to more cost-effective operations.

- Automated quality control and anomaly detection in SOFC manufacturing processes, utilizing AI-driven vision systems, can improve production consistency and reduce defect rates.

- AI can enhance the cybersecurity of interconnected SOFC systems and smart grid infrastructure, protecting against potential cyber threats.

DRO & Impact Forces Of Planar Solid Oxide Fuel Cell Market

The Planar Solid Oxide Fuel Cell (SOFC) market is significantly shaped by a combination of key drivers, inherent restraints, emerging opportunities, and a range of impact forces. A primary driver is the escalating global demand for clean and efficient energy generation, propelled by stringent environmental regulations aimed at reducing carbon emissions and air pollution. The high electrical efficiency and fuel flexibility of SOFCs, enabling them to operate on various fuels like natural gas, biogas, and hydrogen, position them as a compelling solution for sustainable power. Furthermore, the increasing need for reliable distributed power generation and energy independence, especially in regions prone to grid instability or seeking off-grid solutions, greatly contributes to market expansion. The growing interest in hydrogen as a future energy carrier also acts as a strong catalyst, as SOFCs are highly efficient in converting hydrogen into electricity. Continuous technological advancements in materials science, manufacturing techniques, and system integration are steadily improving the performance, durability, and cost-effectiveness of SOFCs, making them more attractive for diverse applications.

Despite these strong drivers, the market faces several restraints. The high initial capital cost associated with SOFC systems, particularly for smaller-scale deployments, remains a significant barrier to widespread adoption, though costs are decreasing with scaling production. Issues related to long-term stack degradation, thermal cycling stability, and susceptibility to certain fuel contaminants (e.g., sulfur) also pose technical challenges that require ongoing research and development. The operational complexity, including the need for high operating temperatures and sophisticated balance-of-plant (BOP) components, can add to installation and maintenance costs. Furthermore, competition from established energy technologies, such as gas turbines and reciprocating engines, as well as other emerging clean energy solutions like proton exchange membrane (PEM) fuel cells and battery storage systems, creates a competitive landscape that demands continuous innovation and cost reduction from SOFC manufacturers. A lack of standardized infrastructure for alternative fuels in some regions also hinders rapid market penetration.

Opportunities for growth are abundant, particularly in niche and high-value applications where SOFCs' unique benefits are highly valued. These include remote power generation, data centers requiring uninterruptible power supplies, and marine auxiliary power, where their high efficiency and quiet operation are critical. The integration of SOFCs with renewable energy sources, such as solar and wind power, offers a synergistic approach to hybrid energy systems, providing stable baseload power. Government incentives, subsidies, and supportive regulatory frameworks for clean energy technologies are creating a favorable environment for investment and deployment. Moreover, the development of advanced materials, such as ceria-based electrolytes and metal-supported cells, promises to enhance cell performance, reduce operating temperatures, and lower manufacturing costs, thereby expanding market accessibility. The expansion of hydrogen production and distribution infrastructure globally will unlock significant new opportunities for hydrogen-fueled SOFCs, especially for utility-scale applications.

The impact forces influencing the SOFC market are multifaceted. Technological advancements, particularly in materials engineering and system design, directly dictate the efficiency, durability, and cost-competitiveness of SOFCs. Regulatory support and government policies, including carbon pricing, emission standards, and renewable energy mandates, play a crucial role in shaping market demand and investment. Economic factors, such as fluctuating energy prices and the overall cost of electricity, influence the economic viability of SOFC installations compared to conventional power sources. Geopolitical stability and energy security concerns drive investments in diversified and localized energy generation technologies. Lastly, market competition, both from other fuel cell technologies and traditional power generation methods, continuously pushes for innovation and cost optimization within the planar SOFC sector. Consumer and industrial preferences for reliable, environmentally friendly, and decentralized power solutions also exert a strong demand-side impact on market growth.

Segmentation Analysis

The Planar Solid Oxide Fuel Cell market is comprehensively segmented across various dimensions to provide a detailed understanding of its dynamics and growth trajectories. These segmentations allow for a granular analysis of market trends, identifying key areas of demand, technological preferences, and regional uptake. The market can be dissected based on factors such as the type of cell support, the fuel consumed, the specific application areas, and the end-use industries. This multi-faceted approach helps stakeholders, from manufacturers to investors, pinpoint opportunities and tailor strategies effectively within the evolving energy landscape. Understanding these segments is crucial for predicting future growth and adapting to technological shifts and regulatory changes.

- By Type:

- Anode-Supported SOFC

- Electrolyte-Supported SOFC

- Metal-Supported SOFC

- By Fuel Type:

- Natural Gas

- Hydrogen

- Biogas

- Syngas

- Others (e.g., Methanol, Ammonia)

- By Application:

- Distributed Generation (Grid-connected and Off-grid)

- Combined Heat and Power (CHP)

- Auxiliary Power Units (APUs)

- Data Centers

- Industrial

- Marine

- Residential

- By End-Use Industry:

- Commercial

- Industrial

- Residential

- Transportation

- Defense

Value Chain Analysis For Planar Solid Oxide Fuel Cell Market

The value chain for the Planar Solid Oxide Fuel Cell market encompasses a series of interconnected activities, starting from raw material sourcing to the final deployment and maintenance of SOFC systems, highlighting both upstream and downstream dynamics. Upstream activities involve the extraction and processing of critical raw materials, primarily specialized ceramics such as Yttria-stabilized zirconia (YSZ) for electrolytes, various oxides for electrodes, and high-temperature alloys for interconnects and balance of plant (BOP) components. This segment also includes the manufacturing of individual cell components like anodes, cathodes, and electrolytes, often through highly specialized fabrication techniques such as tape casting, screen printing, and sintering. Research and development in advanced materials and cell designs form a crucial part of this upstream stage, driving innovation and cost reduction.

Midstream activities focus on the assembly of individual cells into stacks, which are the core power-generating units, and then integrating these stacks with the balance of plant (BOP) components such as fuel reformers, heat exchangers, compressors, and power electronics to form complete SOFC systems. This stage also involves rigorous testing and quality control to ensure system performance, reliability, and safety. Downstream activities are centered around the distribution, installation, and post-sales support of these SOFC systems. Distribution channels are varied, including direct sales to large industrial and commercial customers, partnerships with energy service companies (ESCOs), and collaborations with original equipment manufacturers (OEMs) who integrate SOFCs into their products.

The distribution channels for Planar Solid Oxide Fuel Cells can be broadly categorized into direct and indirect. Direct channels involve manufacturers selling and installing SOFC systems directly to end-users, which is common for large-scale industrial projects or specialized applications that require extensive customization and technical support. This approach allows for closer customer relationships and direct feedback. Indirect channels involve a network of distributors, system integrators, and value-added resellers who bundle SOFC technology with other components or services to offer complete energy solutions to a broader market, including residential, small commercial, and specific niche applications. The after-sales service, including maintenance contracts, performance monitoring, and spare parts supply, forms a crucial part of the downstream value chain, ensuring the long-term operational integrity and customer satisfaction. The efficient flow of information and products across this entire value chain is essential for market growth and the successful commercialization of SOFC technology.

Planar Solid Oxide Fuel Cell Market Potential Customers

Potential customers for Planar Solid Oxide Fuel Cell (SOFC) technology span a diverse range of industries and sectors, primarily driven by their need for highly efficient, low-emission, and reliable power generation. Industrial facilities, particularly those with consistent thermal and electrical demands such as chemical plants, food processing facilities, and manufacturing sites, represent a significant customer base. These industries can leverage SOFCs in Combined Heat and Power (CHP) configurations to maximize energy utilization and reduce operational costs. Commercial establishments, including large office buildings, hotels, retail complexes, and data centers, are also prime candidates, seeking resilient power solutions that offer energy security, lower carbon footprints, and reduced reliance on grid power, especially for critical infrastructure.

The transportation sector, specifically heavy-duty trucking, marine vessels, and potentially rail, represents another growing segment of potential customers for Auxiliary Power Units (APUs) that replace inefficient diesel generators. Military and defense applications also present a strong opportunity due to the need for silent, efficient, and robust power sources for remote bases, field operations, and specialized vehicles. Residential customers, while currently a smaller segment due to the higher initial costs, are emerging as a long-term potential market for micro-CHP systems as SOFC technology becomes more compact and affordable, driven by a desire for energy independence and lower utility bills. Furthermore, utilities and energy service providers are increasingly looking at SOFCs for distributed generation projects and grid stabilization, integrating them into microgrids or virtual power plants to enhance resilience and manage peak loads. The expanding hydrogen economy also positions hydrogen producers and large-scale consumers as potential customers for SOFCs converting green hydrogen into electricity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $3.2 Billion |

| Market Forecast in 2032 | $10.5 Billion |

| Growth Rate | CAGR of 18.5% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ceres Power, Bloom Energy, FuelCell Energy, Aisin Seiki, Mitsubishi Hitachi Power Systems (MHPS), LG Fuel Cell Systems, Cummins Inc., Bosch, SolidPower S.p.A., Sunfire GmbH, Adelan Ltd, Elcogen, Kyocera Corporation, POSCO Energy, Convion Oy, SenerTec Kraft-Warme-Energietechnik GmbH, Fiaxell S.A., Ceramic Fuel Cells Limited, Proton Motor Fuel Cell GmbH, Doosan Fuel Cell |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Planar Solid Oxide Fuel Cell Market Key Technology Landscape

The technological landscape of the Planar Solid Oxide Fuel Cell (SOFC) market is characterized by continuous innovation aimed at enhancing efficiency, durability, and cost-effectiveness. Central to this are advancements in materials science, particularly the development of robust ceramic electrolytes like Yttria-stabilized zirconia (YSZ) and Scandia-stabilized zirconia (ScSZ), which exhibit high ionic conductivity at elevated temperatures. Efforts are also focused on developing novel electrode materials that offer improved catalytic activity and stability against fuel impurities. For interconnects, metallic alloys with tailored thermal expansion coefficients and corrosion resistance are crucial for maintaining mechanical integrity and electrical contact within the high-temperature operating environment. The shift towards metal-supported SOFCs is a notable trend, promising greater mechanical robustness, faster thermal cycling capabilities, and potentially lower manufacturing costs compared to traditional ceramic-supported designs, opening avenues for more compact and flexible system integrations.

Fabrication techniques play a pivotal role in the performance and manufacturability of planar SOFCs. Advanced methods such as tape casting, screen printing, and atmospheric plasma spraying are employed for precise layering of thin ceramic films, crucial for minimizing ohmic losses and maximizing power density. Research is increasingly exploring additive manufacturing (3D printing) to create complex geometric structures for cells and stacks, potentially leading to customized designs with enhanced performance and reduced material waste. Furthermore, the development of sophisticated balance-of-plant (BOP) components, including fuel reformers that convert various hydrocarbons into hydrogen-rich gas, heat exchangers for thermal management, and power electronics for efficient AC/DC conversion and grid integration, are vital for complete system functionality. These components must be designed for high-temperature operation and long-term reliability to match the lifespan of the fuel cell stack itself.

Another significant aspect of the technology landscape involves system integration and control strategies. Optimizing the overall SOFC system requires advanced thermal management to maintain uniform operating temperatures and minimize thermal stresses during startup and shutdown. Intelligent control algorithms, increasingly incorporating AI and machine learning, are being developed to monitor cell performance, manage fuel and air flows, predict maintenance needs, and optimize power output under varying load conditions. This allows for greater operational flexibility and extends the system’s lifespan. Furthermore, the ability to integrate SOFCs with other energy technologies, such as gas turbines in hybrid cycles for even higher efficiencies or with renewable energy sources for resilient microgrid solutions, represents a key technological frontier. The ongoing pursuit of intermediate-temperature SOFCs (IT-SOFCs) aims to reduce operating temperatures, simplifying BOP requirements and improving start-up times, thereby broadening the range of applications and reducing overall system costs.

Regional Highlights

- North America: This region, particularly the United States and Canada, demonstrates robust growth driven by increasing demand for distributed power generation, data center reliability, and the burgeoning hydrogen economy. Government incentives, such as tax credits for clean energy technologies, and a growing emphasis on energy resilience contribute significantly. Key markets include California, New York, and Texas, where progressive environmental policies and industrial demand foster adoption.

- Europe: A leading market propelled by stringent decarbonization targets, high energy costs, and substantial investments in green hydrogen infrastructure. Countries like Germany, the UK, Denmark, and the Netherlands are at the forefront, implementing supportive policies for fuel cell development and deployment in residential, commercial, and industrial sectors. The focus on energy security and efficiency also plays a crucial role.

- Asia Pacific (APAC): The fastest-growing market globally, characterized by rapid industrialization, urbanization, and escalating energy demand. China, Japan, and South Korea are key players, with significant government funding for SOFC research, manufacturing, and commercialization. The region's commitment to reducing air pollution and diversifying energy sources fuels the adoption of high-efficiency SOFCs in diverse applications, from large-scale power plants to residential CHP.

- Latin America: An emerging market with growing interest in SOFC technology, primarily for off-grid power solutions, remote communities, and industrial applications in countries like Brazil and Chile. The region's abundant natural resources and increasing focus on sustainable development present long-term growth opportunities, although economic stability and infrastructure development remain challenges.

- Middle East and Africa (MEA): This region is experiencing nascent adoption, driven by the need for energy diversification, remote power generation in challenging environments, and the potential for hydrogen production. Countries in the GCC are exploring SOFCs as part of their broader clean energy transition strategies, particularly in industrial and utility-scale projects, leveraging their fossil fuel resources for hydrogen production.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Planar Solid Oxide Fuel Cell Market.- Ceres Power

- Bloom Energy

- FuelCell Energy

- Aisin Seiki

- Mitsubishi Hitachi Power Systems (MHPS)

- LG Fuel Cell Systems

- Cummins Inc.

- Bosch

- SolidPower S.p.A.

- Sunfire GmbH

- Adelan Ltd

- Elcogen

- Kyocera Corporation

- POSCO Energy

- Convion Oy

- SenerTec Kraft-Warme-Energietechnik GmbH

- Fiaxell S.A.

- Ceramic Fuel Cells Limited

- Proton Motor Fuel Cell GmbH

- Doosan Fuel Cell

Frequently Asked Questions

What is a Planar Solid Oxide Fuel Cell?

A Planar Solid Oxide Fuel Cell (SOFC) is an electrochemical device that converts the chemical energy from a fuel, such as natural gas or hydrogen, directly into electricity and heat through an electrochemical reaction, utilizing a solid ceramic electrolyte. The planar design refers to its flat, layered construction, which optimizes power density and manufacturability.

What are the main advantages of Planar SOFCs?

The primary advantages of Planar SOFCs include high electrical efficiency, fuel flexibility (can use various hydrocarbon fuels, biogas, or hydrogen), low emissions compared to combustion engines, modular design for scalability, and quiet operation. They also produce high-quality waste heat suitable for combined heat and power (CHP) applications.

What are the key applications for Planar SOFC technology?

Key applications for Planar SOFC technology include distributed power generation for commercial and industrial facilities, combined heat and power (CHP) systems, auxiliary power units (APUs) for transportation (e.g., heavy-duty vehicles, marine), and reliable power sources for data centers and critical infrastructure. They are also being explored for residential micro-CHP systems and grid stabilization.

What challenges does the Planar SOFC market face?

The Planar SOFC market faces challenges such as high initial capital costs compared to conventional energy systems, issues related to long-term stack degradation, thermal cycling durability, and the complexity of high-temperature operation. Competition from other clean energy technologies and the need for further infrastructure development for alternative fuels also pose hurdles.

How is AI impacting the development and deployment of Planar SOFCs?

AI is significantly impacting Planar SOFCs by enabling advanced performance optimization, predictive maintenance to reduce downtime, and sophisticated control systems for efficient operation and grid integration. AI also accelerates the discovery and development of new, more durable materials and streamlines manufacturing processes, ultimately making SOFC technology more cost-effective and reliable.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager