Plant Asset Management Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429375 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Plant Asset Management Market Size

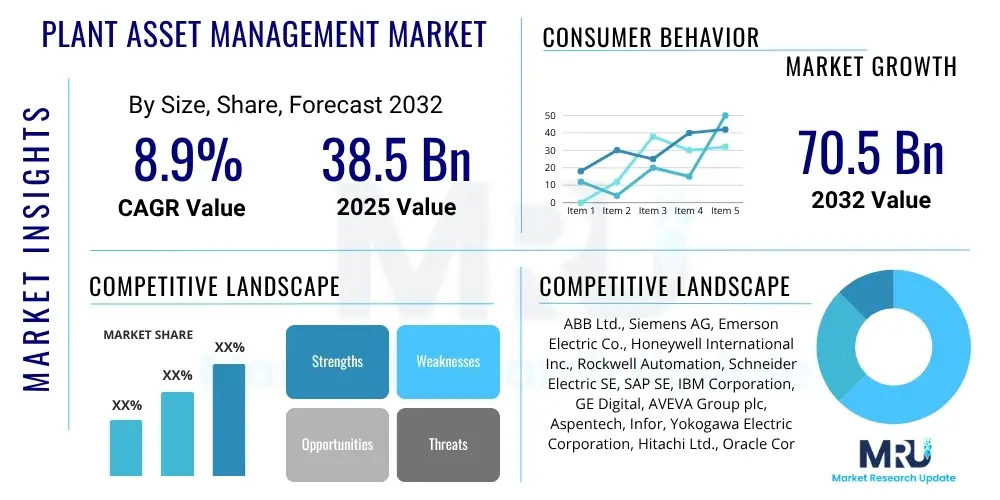

The Plant Asset Management Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2025 and 2032. The market is estimated at USD 38.5 Billion in 2025 and is projected to reach USD 70.5 Billion by the end of the forecast period in 2032.

Plant Asset Management Market introduction

The Plant Asset Management (PAM) market encompasses a suite of solutions and services designed to optimize the performance, reliability, and lifecycle of physical assets within industrial facilities. This includes hardware, software, and services aimed at monitoring, maintaining, and managing assets such as machinery, equipment, and infrastructure. These systems integrate data from various sources, including sensors, control systems, and enterprise resource planning (ERP) platforms, to provide a holistic view of asset health and operational status. The primary objective is to enhance operational efficiency, reduce downtime, minimize maintenance costs, and extend asset lifespan, thereby contributing significantly to an organization's bottom line and overall productivity.

PAM solutions typically involve a range of functionalities, including predictive maintenance, asset performance management (APM), enterprise asset management (EAM), and reliability-centered maintenance (RCM). These tools help organizations move beyond reactive maintenance strategies to proactive, data-driven approaches. By leveraging advanced analytics and real-time data, companies can anticipate potential failures, schedule maintenance tasks optimally, and allocate resources more effectively. The adoption of PAM is driven by the increasing complexity of industrial operations, stringent regulatory compliance requirements, and the continuous pressure to maximize asset utilization while ensuring safety and environmental sustainability.

Major applications of Plant Asset Management span across diverse heavy industries, including oil and gas, manufacturing, power generation, chemicals, mining, and utilities. The benefits are extensive, ranging from improved operational uptime and reduced unplanned outages to enhanced safety records and compliance with environmental standards. Key driving factors for market growth include the industrial internet of things (IIoT) integration, the rising emphasis on predictive maintenance, the aging infrastructure in many industrial sectors, and the need for cost optimization in asset-intensive operations. The imperative to digitalize industrial processes and achieve operational excellence further propels the demand for sophisticated PAM solutions.

Plant Asset Management Market Executive Summary

The Plant Asset Management (PAM) market is experiencing robust growth, primarily fueled by the accelerating adoption of digital transformation initiatives across industries and the increasing focus on operational efficiency and asset longevity. Business trends indicate a strong shift towards cloud-based PAM solutions and software-as-a-service (SaaS) models, offering scalability and reduced upfront investment. There is also a growing demand for integrated platforms that combine EAM, APM, and predictive analytics to provide comprehensive asset intelligence. Regional trends show North America and Europe as established markets due to early adoption of industrial automation and advanced technologies, while Asia Pacific is emerging as a high-growth region, driven by rapid industrialization and significant investments in smart manufacturing infrastructure. Segment trends highlight the dominance of the software component, particularly for predictive maintenance and APM functionalities, with services also forming a crucial revenue stream. The manufacturing and energy sectors continue to be the largest end-users, increasingly leveraging PAM to mitigate risks, optimize performance, and ensure regulatory compliance. Overall, the market is characterized by technological innovation, strategic partnerships, and a competitive landscape focused on delivering holistic, data-driven asset management capabilities.

AI Impact Analysis on Plant Asset Management Market

User questions regarding the impact of AI on Plant Asset Management frequently revolve around its practical applications, return on investment, data security, and the skills required for implementation and operation. Common themes include queries about how AI can genuinely improve predictive accuracy, whether it can handle the vast and varied data streams from industrial assets, and what the cybersecurity implications are. Expectations are high for AI to transform reactive maintenance into highly precise predictive maintenance, reduce human error, and enable fully autonomous decision-making processes, leading to significant cost savings and operational enhancements. Concerns often include the initial investment costs, the complexity of integrating AI with legacy systems, the need for specialized data scientists and AI engineers, and the potential for job displacement, alongside the challenges of ensuring data quality and trust in AI-driven insights.

AI's influence in the Plant Asset Management market is profound, ushering in an era of unprecedented analytical capability and operational foresight. By deploying machine learning algorithms on historical and real-time operational data, AI can detect subtle anomalies and predict equipment failures with far greater accuracy and lead time than traditional methods. This shift from calendar-based or reactive maintenance to condition-based and predictive maintenance significantly reduces unplanned downtime, extends asset life, and optimizes maintenance schedules, thereby maximizing asset availability and operational output. The integration of AI also facilitates the continuous learning and improvement of asset management strategies, adapting to changing operational conditions and asset behaviors over time.

Moreover, AI is pivotal in automating complex data analysis, processing massive datasets from IoT sensors, SCADA systems, and other industrial sources to identify patterns and correlations that human analysts might miss. This not only enhances diagnostic capabilities but also empowers operational staff with actionable insights, enabling them to make more informed decisions rapidly. AI-powered PAM systems contribute to improved safety by predicting equipment malfunctions that could lead to hazardous situations and help in optimizing energy consumption and environmental performance. The market is witnessing a surge in AI-enabled tools, from machine vision for quality control to natural language processing for maintenance log analysis, all contributing to a more intelligent, efficient, and resilient industrial landscape.

- Enhanced predictive maintenance accuracy

- Automated anomaly detection

- Optimized maintenance scheduling

- Reduced unplanned downtime

- Improved operational efficiency

- Real-time performance monitoring

- Intelligent resource allocation

- Data-driven decision making

- Automated root cause analysis

- Extended asset lifespan

- Enhanced safety and risk management

- Personalized asset health insights

- Optimized energy consumption

- Support for autonomous operations

DRO & Impact Forces Of Plant Asset Management Market

The Plant Asset Management (PAM) market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities. Key drivers include the increasing adoption of Industry 4.0 technologies and IoT, which generate vast amounts of data essential for predictive analytics and asset optimization. The growing demand for operational efficiency, cost reduction, and extended asset lifespans across asset-intensive industries further propels market growth. Moreover, stringent regulatory compliance for safety and environmental protection mandates robust asset management practices. However, several restraints challenge market expansion, notably the high initial investment costs associated with implementing advanced PAM solutions, the complexity of integrating new systems with legacy infrastructure, and a shortage of skilled personnel capable of managing and interpreting data from sophisticated PAM platforms. Cybersecurity concerns surrounding industrial IoT data also pose a significant challenge. Opportunities abound in the burgeoning demand for cloud-based PAM solutions, offering flexibility and scalability, and the continuous development of AI and machine learning technologies that enhance predictive capabilities. The increasing focus on sustainability and energy efficiency also opens new avenues for PAM solutions that can optimize resource consumption. Collectively, these forces shape the competitive landscape and strategic direction of the Plant Asset Management market.

Segmentation Analysis

The Plant Asset Management market is meticulously segmented to provide a granular view of its diverse components and applications, enabling stakeholders to understand specific market dynamics and target particular niches. This comprehensive segmentation typically covers various aspects such as components, deployment models, organization size, and end-user industries. Each segment reflects unique demands, technological preferences, and operational challenges, contributing to a varied market landscape. Analyzing these segments is critical for developing tailored strategies, identifying growth pockets, and forecasting market evolution across different business environments and industrial applications. The detailed breakdown offers insights into which technologies are gaining traction, which industries are investing heavily, and how different deployment methods are being adopted.

- By Component

- Software

- Asset Performance Management (APM)

- Enterprise Asset Management (EAM)

- Predictive Maintenance (PdM)

- Reliability Centered Maintenance (RCM)

- Computerized Maintenance Management System (CMMS)

- Services

- Consulting

- Implementation

- Support & Maintenance

- Training

- Software

- By Deployment Type

- On-Premise

- Cloud-Based

- Hybrid

- By Organization Size

- Small and Medium-sized Enterprises (SMEs)

- Large Enterprises

- By End-User Industry

- Oil and Gas

- Power Generation

- Manufacturing (Process & Discrete)

- Chemicals and Petrochemicals

- Mining and Metals

- Utilities (Water and Wastewater)

- Pharmaceuticals

- Pulp and Paper

- Food and Beverage

- Others (e.g., Transportation, Data Centers)

Value Chain Analysis For Plant Asset Management Market

The value chain for the Plant Asset Management market encompasses a series of activities that transform raw components into integrated solutions delivered to end-users. It begins with upstream activities, involving research and development, software design, and hardware manufacturing. This phase includes the creation of specialized sensors, monitoring devices, analytics platforms, and enterprise software modules. Key players in this stage are technology providers specializing in IoT, AI, cloud computing, and industrial automation, who develop the foundational technologies and components that constitute PAM solutions. These providers focus on innovation to offer robust, scalable, and secure technologies that can effectively collect, process, and analyze asset data.

Moving downstream, the value chain progresses to the integration, implementation, and service delivery phases. This involves solution integrators who combine various software and hardware components to create bespoke PAM systems tailored to specific industry needs. Service providers offer consulting, installation, configuration, training, and ongoing support and maintenance services, ensuring the optimal functioning and utilization of PAM systems. Distribution channels play a critical role, ranging from direct sales forces for large enterprise clients to indirect channels through value-added resellers (VARs), system integrators, and distributors who extend market reach and provide localized support. The effectiveness of these channels is crucial for market penetration and customer satisfaction.

The interplay between direct and indirect distribution significantly shapes market access. Direct channels are often preferred for complex, high-value projects requiring deep engagement and customization, allowing direct feedback loops between vendors and clients. Indirect channels, conversely, enable broader market coverage, particularly for SMEs, and leverage the expertise of partners in specific vertical markets or geographies. The efficiency of the entire value chain is paramount for delivering comprehensive, cost-effective, and reliable PAM solutions that effectively meet the evolving demands of industrial asset owners seeking to optimize their operational performance and maximize asset longevity.

Plant Asset Management Market Potential Customers

Potential customers for Plant Asset Management solutions are predominantly large-scale industrial enterprises and asset-intensive organizations across various sectors that operate complex machinery and critical infrastructure. These include, but are not limited to, manufacturers in process industries such as oil and gas, chemicals, and pharmaceuticals, where continuous operations and regulatory compliance are paramount. Discrete manufacturing, including automotive and electronics production, also represents a significant customer base, driven by the need for high throughput, quality control, and minimal downtime. These entities invest in PAM to gain competitive advantages by improving operational efficiency, reducing maintenance costs, and ensuring asset reliability and safety.

Another major segment of potential customers comprises the power generation and utilities sectors, including conventional power plants, renewable energy facilities, and water treatment plants. For these organizations, uninterrupted service delivery is a core mandate, making advanced asset management crucial for grid stability, energy production optimization, and infrastructure longevity. The mining and metals industry, characterized by harsh operating environments and high capital expenditure on equipment, also heavily relies on PAM to manage valuable assets, reduce operational risks, and optimize extraction processes. Across all these industries, the primary buyers are operations managers, maintenance managers, plant managers, and C-level executives (CIOs, COOs) focused on operational excellence and long-term asset value.

Furthermore, organizations facing aging infrastructure, escalating energy costs, and increasing environmental scrutiny are increasingly turning to PAM solutions. This includes public sector utilities and infrastructure operators, who are under pressure to modernize their assets while ensuring public safety and resource efficiency. The growing adoption of smart factory initiatives and digitalization across industries means that any company with significant physical assets that can benefit from predictive insights, automated maintenance scheduling, and real-time performance monitoring is a potential customer. The value proposition of PAM resonates strongly with entities aiming to transition from reactive to proactive maintenance strategies, ultimately seeking to enhance profitability and operational resilience.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 38.5 Billion |

| Market Forecast in 2032 | USD 70.5 Billion |

| Growth Rate | 8.9% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Emerson Electric Co., Honeywell International Inc., Rockwell Automation, Schneider Electric SE, SAP SE, IBM Corporation, GE Digital, AVEVA Group plc, Aspentech, Infor, Yokogawa Electric Corporation, Hitachi Ltd., Oracle Corporation, Fluke Corporation, Bentley Systems, Inc., IFS AB, Hexagon AB, PTC Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plant Asset Management Market Key Technology Landscape

The Plant Asset Management market is fundamentally shaped by a rapidly evolving technological landscape, with several key innovations driving its expansion and sophistication. The Industrial Internet of Things (IIoT) stands as a foundational technology, enabling the pervasive deployment of sensors and smart devices to collect vast quantities of real-time operational data from industrial assets. This continuous flow of data is critical for monitoring asset health, performance, and environmental conditions. Cloud computing further augments IIoT capabilities by providing scalable infrastructure for data storage, processing, and analytics, facilitating the delivery of PAM solutions as Software-as-a-Service (SaaS) and enhancing accessibility and flexibility for users.

Artificial Intelligence (AI) and Machine Learning (ML) are transformative in PAM, moving beyond simple data collection to advanced predictive analytics. AI/ML algorithms are employed to analyze historical and real-time data, identify subtle patterns indicative of impending failures, and predict maintenance needs with high accuracy. This allows for the transition from reactive or scheduled maintenance to condition-based and predictive maintenance strategies, significantly reducing downtime and optimizing maintenance costs. Furthermore, Digital Twin technology, which creates virtual replicas of physical assets, allows for real-time simulation, monitoring, and testing of assets in a virtual environment, providing critical insights into performance and potential issues without impacting actual operations.

Beyond these core technologies, Big Data analytics tools are essential for processing and deriving actionable intelligence from the immense datasets generated by industrial assets. Advanced visualization techniques, including augmented reality (AR) and virtual reality (VR), are also finding applications in PAM for maintenance training, remote assistance, and immersive operational insights. Cybersecurity measures are increasingly integrated into PAM systems to protect sensitive operational data and critical infrastructure from cyber threats. The convergence of these technologies creates a robust ecosystem that empowers industries to achieve higher levels of asset performance, reliability, and operational excellence.

Regional Highlights

The global Plant Asset Management market exhibits distinct regional dynamics, influenced by varying levels of industrialization, technological adoption, and regulatory frameworks. North America and Europe represent mature markets with high adoption rates, driven by a long history of industrial automation, stringent safety regulations, and a proactive approach to investing in advanced technologies to modernize aging infrastructure. These regions benefit from a strong presence of key market players and a robust ecosystem for research and development in industrial IoT, AI, and cloud solutions, leading to continuous innovation and widespread deployment of sophisticated PAM systems across diverse sectors like oil & gas, manufacturing, and power generation.

The Asia Pacific (APAC) region is emerging as the fastest-growing market for Plant Asset Management, propelled by rapid industrialization, massive infrastructure development, and increasing foreign direct investment in manufacturing capabilities, particularly in countries like China, India, and Southeast Asian nations. Governments in APAC are actively promoting smart factory initiatives and digital transformation, creating a fertile ground for PAM adoption. While adoption in Latin America, and the Middle East and Africa (MEA) is currently lower compared to developed regions, these markets are poised for significant growth. MEA, in particular, with its vast oil and gas reserves and ongoing investments in infrastructure, presents substantial opportunities for PAM solutions aimed at optimizing complex industrial operations and ensuring asset integrity.

- North America: Market leader, driven by early technology adoption, strong industrial base, and stringent regulatory compliance. Significant investments in smart manufacturing and Industry 4.0.

- Europe: High adoption due to focus on energy efficiency, environmental regulations, and advanced manufacturing practices. Strong presence of key solution providers and emphasis on digital transformation.

- Asia Pacific (APAC): Fastest-growing market, fueled by rapid industrialization, infrastructure development, and government initiatives for smart factories. Countries like China and India are major contributors.

- Latin America: Growing market with increasing investments in oil and gas, mining, and manufacturing sectors. Focus on improving operational efficiency and safety standards.

- Middle East and Africa (MEA): Emerging market, particularly in the oil and gas, petrochemicals, and utilities sectors. Driven by large-scale industrial projects and the need for asset integrity management.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plant Asset Management Market.- ABB Ltd.

- Siemens AG

- Emerson Electric Co.

- Honeywell International Inc.

- Rockwell Automation

- Schneider Electric SE

- SAP SE

- IBM Corporation

- GE Digital

- AVEVA Group plc

- Aspentech

- Infor

- Yokogawa Electric Corporation

- Hitachi Ltd.

- Oracle Corporation

- Fluke Corporation

- Bentley Systems, Inc.

- IFS AB

- Hexagon AB

- PTC Inc.

Frequently Asked Questions

What is Plant Asset Management (PAM)?

Plant Asset Management (PAM) is a comprehensive strategy and system for optimizing the performance, reliability, and lifecycle of physical assets within industrial facilities. It integrates hardware, software, and services to monitor, maintain, and manage assets effectively, aiming to improve operational efficiency, reduce downtime, and extend asset lifespan.

How does AI impact Plant Asset Management?

AI significantly impacts PAM by enabling advanced predictive maintenance through machine learning algorithms that analyze data to anticipate equipment failures. It enhances anomaly detection, optimizes maintenance schedules, and provides real-time insights, leading to reduced unplanned downtime, lower costs, and improved operational safety.

What are the key benefits of implementing a PAM solution?

Key benefits include increased asset uptime and reliability, reduced maintenance costs, extended asset lifespan, improved operational efficiency, enhanced safety for personnel, better compliance with environmental regulations, and data-driven decision-making for resource allocation and strategic planning.

Which industries primarily adopt Plant Asset Management?

Asset-intensive industries such as oil and gas, power generation, manufacturing (process and discrete), chemicals, mining, utilities, and pharmaceuticals are the primary adopters of Plant Asset Management solutions due to their reliance on complex machinery and critical infrastructure.

What are the main challenges in adopting Plant Asset Management?

Main challenges include high initial investment costs, complexity in integrating new PAM systems with existing legacy infrastructure, a shortage of skilled personnel to manage and interpret advanced analytics, and ensuring robust cybersecurity for industrial data.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Plant Asset Management Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Cloud (Online) Development, Offline Deployment), By Application (Aerospace & Defense, Automotive, Semiconductor & Electronics, Medical Device), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Plant Asset Management (Pam) Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Software, Services), By Application (Process Industries, Discrete Industries), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager