Plasma Cutting Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429355 | Date : Nov, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Plasma Cutting Machine Market Size

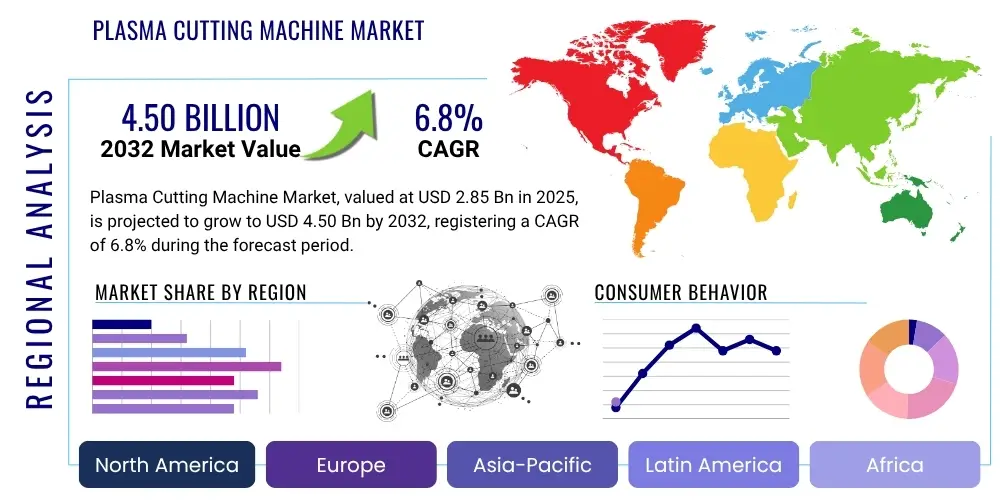

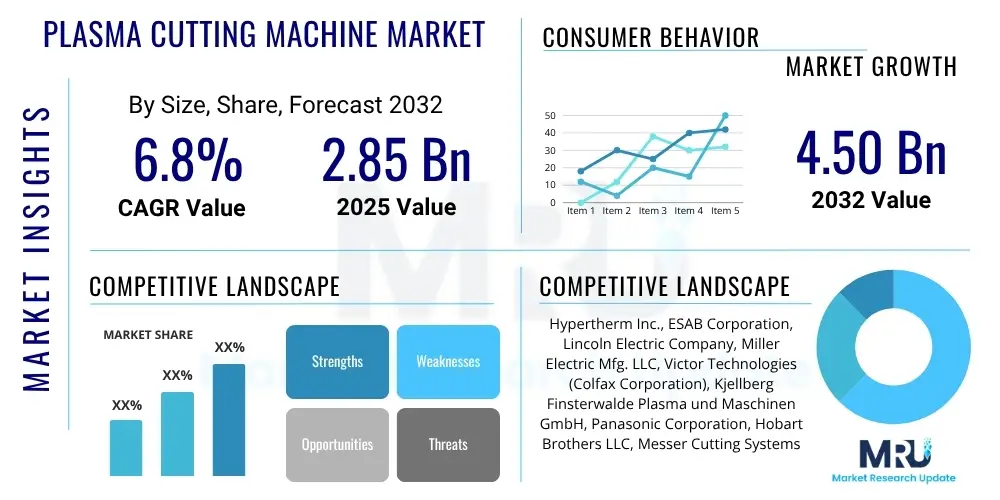

The Plasma Cutting Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $2.85 Billion in 2025 and is projected to reach $4.50 Billion by the end of the forecast period in 2032.

Plasma Cutting Machine Market introduction

The Plasma Cutting Machine Market encompasses advanced industrial equipment utilized for cutting electrically conductive materials, primarily metals, through an accelerated jet of hot plasma. These machines operate by creating an electrical channel of superheated, ionized gas which rapidly melts and expels material, offering a precise and efficient cutting solution. Plasma cutting technology is highly valued for its ability to cut a wide range of metal thicknesses and types, including steel, stainless steel, aluminum, brass, and copper, with high speed and accuracy.

Major applications for plasma cutting machines span across diverse sectors such as automotive manufacturing, general metal fabrication, shipbuilding, construction, and the energy industry. These machines are crucial for creating intricate designs, preparing edges for welding, and producing components for heavy machinery. The primary benefits of using plasma cutting technology include superior cutting speed compared to traditional methods, exceptional versatility in handling various materials and thicknesses, and the capability to produce clean, high-quality cuts with minimal slag.

Key driving factors for the growth of this market include the escalating demand for automated and high-precision metal processing in manufacturing, continuous industrial expansion in emerging economies, and increased investment in infrastructure projects globally. Technological advancements leading to improved energy efficiency, portability, and integration with Computer Numerical Control (CNC) systems further bolster market expansion. The ongoing trend towards industrial automation and the need for cost-effective manufacturing solutions also significantly contribute to the market's positive trajectory.

Plasma Cutting Machine Market Executive Summary

The Plasma Cutting Machine Market is experiencing robust growth driven by accelerating industrialization, particularly in developing nations, and the global push for enhanced manufacturing efficiency and precision. Key business trends indicate a strong shift towards advanced automation, with manufacturers integrating CNC capabilities, robotics, and smart factory solutions to improve productivity and material utilization. There is a growing demand for high-definition plasma cutting systems that offer superior cut quality and reduced post-processing, alongside an increasing emphasis on energy-efficient and environmentally friendly technologies. Strategic alliances and mergers among key players are also prevalent as companies seek to expand their product portfolios and geographical reach, catering to a diverse range of industrial applications.

From a regional perspective, Asia Pacific continues to dominate the market, fueled by massive investments in manufacturing, automotive, and construction sectors, particularly in China, India, and Southeast Asian countries. North America and Europe demonstrate mature markets characterized by a high adoption rate of advanced, automated plasma cutting solutions, with a focus on innovation and sophisticated applications in aerospace and heavy machinery. Latin America and the Middle East and Africa regions are showing promising growth, attributed to developing industrial bases, infrastructure modernization projects, and rising foreign direct investments in manufacturing capabilities. These regions present significant opportunities for market penetration and technological dissemination.

Segmentation trends highlight a strong preference for CNC plasma cutting machines due to their precision, repeatability, and ease of integration into automated production lines. The high-power segment is witnessing significant demand from heavy industries, while portable plasma cutting machines continue to be popular among small and medium-sized enterprises (SMEs) and for on-site applications. End-user industries such as general fabrication, automotive, and shipbuilding are consistently major consumers, with growing specialized demand from sectors like aerospace and energy, which require even higher levels of precision and material handling capabilities. These trends collectively underscore a market moving towards more specialized, automated, and high-performance cutting solutions.

AI Impact Analysis on Plasma Cutting Machine Market

User inquiries regarding AI's impact on the Plasma Cutting Machine Market primarily revolve around how artificial intelligence can enhance operational efficiency, precision, predictive maintenance, and overall productivity. Common questions explore the potential for AI to optimize cutting paths, reduce material waste, and improve quality control in real-time. There is significant interest in how AI can integrate with existing CNC systems to automate complex tasks, diagnose potential failures before they occur, and adapt to varying material properties or environmental conditions. Concerns often touch upon the initial investment costs, the complexity of implementation, data security, and the need for a skilled workforce capable of operating and maintaining AI-powered machinery. Users expect AI to usher in an era of smarter, more autonomous cutting operations, minimizing human intervention and maximizing output.

- AI-driven process optimization: Algorithms analyze cutting parameters to enhance speed, accuracy, and consumable life.

- Predictive maintenance: AI monitors machine health, anticipates failures, and schedules maintenance proactively, reducing downtime.

- Real-time quality control: AI vision systems detect defects and deviations during the cutting process, ensuring consistent output.

- Automated path generation: AI optimizes cutting trajectories for maximum material utilization and minimal waste.

- Robotic integration: AI enables seamless coordination between plasma cutters and robotic arms for fully automated loading, cutting, and unloading.

- Energy efficiency optimization: AI systems manage power consumption based on real-time load and material requirements.

- Operator assistance and training: AI-powered interfaces can guide operators and provide contextual support, bridging skill gaps.

DRO & Impact Forces Of Plasma Cutting Machine Market

The Plasma Cutting Machine Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities that collectively shape its trajectory and competitive landscape. Key drivers include the robust growth of the global manufacturing sector, particularly in automotive, construction, and shipbuilding industries, which consistently demand efficient and precise metal cutting solutions. The increasing adoption of automation and advanced fabrication technologies across various industrial applications further propels market expansion. Moreover, technological advancements leading to improved cutting speed, accuracy, and energy efficiency in plasma systems are making these machines more attractive to end-users, driving new investments and upgrades.

However, the market also faces notable restraints. The high initial capital investment required for advanced plasma cutting machines can be a barrier for small and medium-sized enterprises (SMEs) with limited budgets. Additionally, the availability of alternative cutting technologies, such as laser cutting and waterjet cutting, which offer different advantages in terms of precision, material compatibility, and edge quality, presents strong competition. The need for a skilled workforce to operate and maintain these sophisticated machines, along with the rising costs of consumables, can also challenge market growth in certain regions or segments.

Opportunities for growth are abundant, particularly in emerging markets where industrialization and infrastructure development are accelerating. The integration of plasma cutting machines with Industry 4.0 technologies, including IoT, AI, and advanced robotics, offers significant potential for enhancing productivity, remote monitoring, and data-driven decision-making. Developing eco-friendly plasma cutting solutions with reduced emissions and optimized energy consumption presents a critical area for innovation and market differentiation. Furthermore, the customization of plasma cutting machines for niche applications and specialized material processing can unlock new revenue streams and address unmet specific industrial demands, driving future market evolution.

Segmentation Analysis

The Plasma Cutting Machine Market is comprehensively segmented across various parameters including product type, technology, power, application, and end-user. This detailed segmentation allows for a nuanced understanding of market dynamics, revealing specific trends and growth opportunities within each category. The breakdown enables stakeholders to identify key areas of demand and tailor their product offerings and strategic initiatives to specific market needs. The segmentation reflects the diverse range of plasma cutting solutions available, from conventional manual systems to highly automated and integrated CNC platforms, addressing different industrial requirements and operational scales.

- By Product Type:

- Conventional Plasma Cutting Machines

- CNC Plasma Cutting Machines

- Robotic Plasma Cutting Machines

- Portable Plasma Cutting Machines

- By Technology:

- Air Plasma Cutting

- Dual-Gas Plasma Cutting

- Oxygen Plasma Cutting

- Nitrogen Plasma Cutting

- High-Definition Plasma Cutting

- By Power:

- Low Power Plasma Cutting Machines (less than 60 Amps)

- Medium Power Plasma Cutting Machines (60-120 Amps)

- High Power Plasma Cutting Machines (greater than 120 Amps)

- By Application:

- General Metal Fabrication

- Automotive Industry

- Shipbuilding Industry

- Construction Industry

- Aerospace and Defense

- Energy and Power Generation

- Heavy Machinery Manufacturing

- Others (Artistic Fabrication, Agriculture)

- By End-User:

- Heavy Industry

- Light Industry

- Fabrication Shops (Small & Medium Enterprises)

- Maintenance & Repair Operations (MRO)

Value Chain Analysis For Plasma Cutting Machine Market

The value chain for the Plasma Cutting Machine Market begins with upstream activities involving the sourcing and manufacturing of raw materials and key components. This includes suppliers of gases (argon, oxygen, nitrogen), power electronics (inverters, transformers), and critical consumables like electrodes, nozzles, and shields made from copper, tungsten, and hafnium. Additionally, manufacturers of motion control systems, robotics, and CAD/CAM software for CNC integration also form a crucial part of the upstream segment. The quality and availability of these components directly impact the performance and cost-effectiveness of the final plasma cutting machines.

Midstream activities involve the design, assembly, and testing of the plasma cutting machines by original equipment manufacturers (OEMs). This stage focuses on research and development to innovate new technologies, improve cutting precision, enhance energy efficiency, and ensure robust machine construction. Production processes include precision engineering, quality control, and integration of various subsystems to build a complete and functional plasma cutting solution. Marketing and branding efforts are also crucial at this stage to differentiate products in a competitive market.

Downstream activities encompass the distribution, sales, installation, and after-sales support of plasma cutting machines. Distribution channels are varied, involving direct sales from manufacturers to large industrial clients, a network of authorized distributors and dealers catering to a broader customer base, and increasingly, online sales platforms. Post-sales services, including technical support, maintenance, spare parts supply, and training for operators, are critical for customer satisfaction and long-term relationships. These services ensure optimal machine performance and longevity, contributing significantly to the overall value proposition for the end-user.

Plasma Cutting Machine Market Potential Customers

The Plasma Cutting Machine Market serves a wide array of industries and businesses, making its potential customer base highly diverse and extensive. End-users span across various scales of operation, from large multinational corporations engaged in heavy industrial manufacturing to small and medium-sized fabrication shops requiring versatile and portable cutting solutions. These customers are primarily entities involved in processes that require the precise and efficient cutting of electrically conductive metals.

Key segments of potential customers include metal fabrication shops, which form the backbone of demand due to their continuous need for cutting various metal components for diverse projects. Automotive manufacturers utilize plasma cutting for chassis components, body panels, and exhaust systems, while the shipbuilding industry relies on these machines for cutting large steel plates for ship hulls and superstructures. The construction sector employs plasma cutting for structural steel components, architectural elements, and HVAC ductwork, while aerospace and defense industries require high-precision plasma cutting for specialized alloys and critical components.

Furthermore, industries such as energy and power generation use plasma cutters for fabricating components for turbines, pipelines, and offshore platforms. Heavy machinery manufacturers and general engineering workshops are also significant buyers, requiring robust machines for producing industrial equipment. Maintenance and repair operations (MRO) across various sectors also represent a steady demand for portable and versatile plasma cutting machines for on-site repairs and modifications. This broad applicability across diverse industrial landscapes ensures a continuous and expanding customer base for plasma cutting machine manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $2.85 Billion |

| Market Forecast in 2032 | $4.50 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hypertherm Inc., ESAB Corporation, Lincoln Electric Company, Miller Electric Mfg. LLC, Victor Technologies (Colfax Corporation), Kjellberg Finsterwalde Plasma und Maschinen GmbH, Panasonic Corporation, Hobart Brothers LLC, Messer Cutting Systems, Kerf Developments Ltd, Bug-O Systems Inc., Technicut, Ltd., Swift-Cut Automation Ltd, SteelTailor, Inc., MultiCam, Inc., Torchmate CNC Cutting Systems, Arclight Dynamics, Thermal Dynamics, AJAN Elektronik, GoTorch |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plasma Cutting Machine Market Key Technology Landscape

The Plasma Cutting Machine Market is characterized by a continuously evolving technology landscape focused on enhancing cutting precision, speed, efficiency, and ease of use. At the core, advancements in inverter technology have significantly improved power source efficiency and reduced the size and weight of plasma cutters, making them more portable and energy-efficient. High-definition plasma technology is a critical development, offering significantly finer cuts, improved edge quality, and reduced bevel angles, which minimizes the need for secondary finishing operations, especially for thicker materials.

The integration of Computer Numerical Control (CNC) systems remains a foundational technology, enabling automated and highly precise cutting of complex shapes and designs directly from CAD/CAM software. Further innovation in this area includes advanced torch height control (THC) systems, which dynamically adjust torch distance from the workpiece to maintain optimal arc voltage, ensuring consistent cut quality even on warped materials. Robotic plasma cutting systems are gaining traction, combining the speed and power of plasma with the flexibility and automation of robotics for complex 3D cutting and mass production environments.

Emerging trends include the incorporation of smart features and connectivity, aligning with the broader Industry 4.0 paradigm. This involves IoT sensors for real-time performance monitoring, predictive maintenance capabilities through data analytics, and remote diagnostics. Enhanced software capabilities for nesting optimization, material utilization, and process simulation are also becoming standard. Manufacturers are additionally focusing on developing environmentally friendlier plasma gases and consumable designs that offer extended life, further reducing operational costs and environmental impact, thereby shaping the future direction of plasma cutting technology.

Regional Highlights

- North America: A mature market characterized by high adoption of advanced, automated plasma cutting solutions. The region benefits from strong industrial infrastructure and a focus on high-precision applications in aerospace, automotive, and heavy machinery. The United States and Canada are key contributors, driven by manufacturing revival initiatives and investments in smart factory technologies.

- Europe: Europe showcases a robust market with a strong emphasis on technological innovation, quality, and environmental regulations. Countries like Germany, Italy, and France are leaders in manufacturing and metal fabrication, driving demand for sophisticated CNC plasma cutting systems. The region is also at the forefront of adopting Industry 4.0 technologies and developing energy-efficient solutions.

- Asia Pacific (APAC): The largest and fastest-growing market globally, fueled by rapid industrialization, urbanization, and massive infrastructure development projects, especially in China, India, Japan, and South Korea. This region's growth is propelled by high demand from automotive, shipbuilding, construction, and electronics manufacturing sectors, coupled with increasing investments in advanced manufacturing capabilities.

- Latin America: An emerging market experiencing consistent growth due to ongoing industrialization, foreign investments in manufacturing, and infrastructure modernization initiatives. Countries such as Brazil, Mexico, and Argentina are expanding their fabrication capacities, leading to increased adoption of plasma cutting machines for various industrial applications.

- Middle East and Africa (MEA): This region is witnessing steady market expansion, primarily driven by economic diversification efforts, significant investments in infrastructure, oil and gas, and construction projects. Countries like Saudi Arabia, UAE, and South Africa are key markets, with a growing demand for metal processing equipment to support their industrial growth and development plans.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plasma Cutting Machine Market.- Hypertherm Inc.

- ESAB Corporation

- Lincoln Electric Company

- Miller Electric Mfg. LLC

- Victor Technologies (Colfax Corporation)

- Kjellberg Finsterwalde Plasma und Maschinen GmbH

- Panasonic Corporation

- Hobart Brothers LLC

- Messer Cutting Systems

- Kerf Developments Ltd

- Bug-O Systems Inc.

- Technicut, Ltd.

- Swift-Cut Automation Ltd

- SteelTailor, Inc.

- MultiCam, Inc.

- Torchmate CNC Cutting Systems

- Arclight Dynamics

- Thermal Dynamics

- AJAN Elektronik

- GoTorch

Frequently Asked Questions

What is a plasma cutting machine?

A plasma cutting machine is an industrial tool that uses an accelerated jet of superheated, ionized gas (plasma) to cut through electrically conductive materials, primarily metals like steel, aluminum, and copper, with high speed and precision.

How does AI impact the plasma cutting machine market?

AI significantly impacts the market by enabling predictive maintenance, optimizing cutting paths for material efficiency, enhancing real-time quality control, and facilitating greater automation and robotic integration, leading to increased productivity and reduced operational costs.

What are the primary drivers for the growth of this market?

The key drivers include the robust growth of the global manufacturing sector, increasing adoption of industrial automation, rising demand for high-precision metal fabrication, and extensive investments in infrastructure development worldwide.

Which industries are the major end-users of plasma cutting machines?

Major end-users include general metal fabrication shops, the automotive industry, shipbuilding, construction, aerospace and defense, and the energy sector, all requiring efficient and precise metal cutting capabilities.

Which regions are expected to show the most significant growth?

The Asia Pacific region is anticipated to exhibit the most significant growth due to rapid industrialization, large-scale infrastructure projects, and expanding manufacturing bases in countries like China, India, and Southeast Asia.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Inverter Plasma Cutting Machine Market Statistics 2025 Analysis By Application (Automobile Industry, Metal Processing, Equipment Manufacturing), By Type (220V, 380V), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Fine Plasma Cutting Machine Market Statistics 2025 Analysis By Application (Automobile Industry, Metal Processing, Equipment Manufacturing), By Type (Manual Plasma Cutting Machine, Automatic Plasma Cutting Machine), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Portable Plasma Cutting Machine Market Statistics 2025 Analysis By Application (Automobile Industry, Metal Processing, Equipment Manufacturing), By Type (Manual Plasma Cutting Machine, Automatic Plasma Cutting Machine), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager