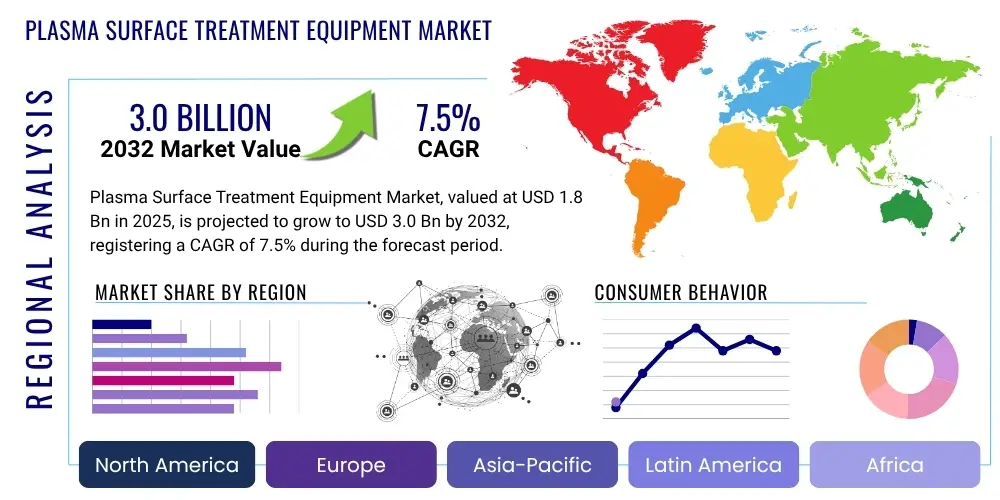

Plasma Surface Treatment Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429678 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Plasma Surface Treatment Equipment Market Size

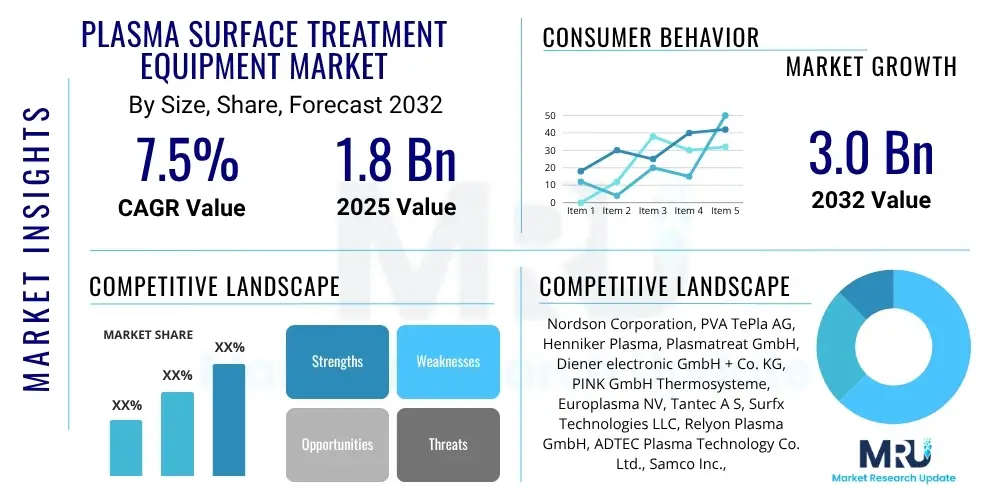

The Plasma Surface Treatment Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at USD 1.8 Billion in 2025 and is projected to reach USD 3.0 Billion by the end of the forecast period in 2032.

Plasma Surface Treatment Equipment Market introduction

The Plasma Surface Treatment Equipment Market encompasses technologies and devices utilized to modify the surface properties of materials using plasma. This advanced treatment process involves exposing material surfaces to an ionized gas, leading to chemical and physical changes that enhance properties such as adhesion, wettability, cleanliness, and resistance to wear or corrosion. The versatility of plasma surface treatment makes it indispensable across a multitude of industries, addressing critical manufacturing challenges and improving product performance.

Products within this market range from atmospheric plasma systems, which operate at ambient pressure, to vacuum plasma systems, typically used for more precise and sensitive applications. These systems are employed for various processes including surface activation, fine cleaning, etching, sterilization, and deposition of thin films or coatings. Major applications span medical devices, where sterility and biocompatibility are paramount, to automotive components requiring enhanced bonding and durability, and intricate electronic parts needing superior adhesion or insulation. The core benefits include improved material performance, extended product lifespan, reduced waste, and the ability to treat a wide array of materials without altering their bulk properties.

Driving factors for the market's expansion include the escalating demand for high-performance materials in advanced manufacturing, the increasing miniaturization of electronic components, and stringent quality and regulatory standards across industries like medical and automotive. Furthermore, the push for more sustainable and environmentally friendly manufacturing processes, as plasma treatments often replace chemical-intensive methods, contributes significantly to its adoption. The continuous innovation in plasma technology, offering greater precision and efficiency, also fuels market growth.

Plasma Surface Treatment Equipment Market Executive Summary

The Plasma Surface Treatment Equipment Market is experiencing robust growth, driven by an accelerating demand for enhanced material properties across diverse industrial sectors. Key business trends indicate a strong focus on automation and integration of plasma systems into existing production lines, along with a move towards more customizable and application-specific equipment designs. There is also a notable trend in industry consolidation, with larger players acquiring specialized technology providers to expand their product portfolios and geographical reach. Furthermore, manufacturers are investing heavily in research and development to create more energy-efficient and cost-effective plasma solutions, responding to both economic pressures and environmental considerations.

Regionally, Asia Pacific stands out as the dominant market, fueled by its burgeoning electronics, automotive, and medical device manufacturing industries, particularly in countries like China, Japan, and South Korea. North America and Europe also hold significant market shares, characterized by advanced manufacturing capabilities, stringent quality regulations, and substantial investments in R&D and innovation, especially in aerospace and medical sectors. Emerging economies in Latin America and the Middle East and Africa are showing promising growth, driven by industrialization and diversification efforts, creating new opportunities for market expansion as these regions adopt more advanced manufacturing techniques.

Segment-wise, the market is seeing significant growth in both atmospheric and vacuum plasma treatment technologies, with atmospheric plasma gaining traction due to its ease of integration and continuous processing capabilities for certain applications. In terms of application, adhesion promotion and cleaning remain critical functions, but sterilization, particularly in the medical device sector, and surface coating for enhanced durability are witnessing rapid expansion. The medical and electronics end-user segments are primary growth drivers, demanding precision, cleanliness, and advanced material modifications. The shift towards Industry 4.0 and smart manufacturing is also influencing the development of connected plasma systems capable of real-time monitoring and process optimization.

AI Impact Analysis on Plasma Surface Treatment Equipment Market

User inquiries concerning AI's influence on the Plasma Surface Treatment Equipment Market frequently center on its potential to revolutionize process control, optimize material outcomes, and enhance overall operational efficiency. There is significant interest in how AI can contribute to greater precision in plasma parameter tuning, facilitate predictive maintenance of equipment, and automate complex tasks that traditionally require expert human intervention. Users are keen to understand AI's role in improving quality assurance, reducing variability, and accelerating research and development cycles for new plasma applications, ultimately leading to more sophisticated and reliable surface treatments.

- AI-driven optimization of plasma process parameters for superior and consistent results.

- Predictive maintenance analytics for plasma equipment, reducing downtime and operational costs.

- Enhanced quality control through real-time data analysis and anomaly detection in surface treatment.

- Automated fault diagnosis and self-correction mechanisms in plasma systems.

- Accelerated development of new materials and treatment recipes through machine learning algorithms.

- Improved energy efficiency by optimizing power delivery and gas consumption.

- Integration with smart manufacturing ecosystems for seamless data flow and process synchronization.

- Advanced robotics integration for automated material handling within plasma treatment lines.

DRO & Impact Forces Of Plasma Surface Treatment Equipment Market

The Plasma Surface Treatment Equipment Market is shaped by a complex interplay of drivers, restraints, opportunities, and competitive forces that dictate its trajectory and profitability. Key drivers include the ever-increasing demand for advanced material properties across industries such as automotive, aerospace, and medical, where enhanced adhesion, wettability, and durability are crucial for product performance and longevity. The stringent quality standards and regulatory requirements, particularly in highly regulated sectors, necessitate the precise and repeatable surface modification capabilities that plasma treatment offers. Furthermore, the continuous miniaturization of electronic components and the need for reliable interconnectivity also propel the adoption of plasma etching and cleaning technologies.

Conversely, significant restraints exist, primarily the high initial investment required for sophisticated plasma treatment equipment, which can be a barrier for small and medium-sized enterprises (SMEs). The technical complexity associated with operating and maintaining these systems, coupled with the need for specialized expertise, also poses a challenge. Additionally, certain environmental concerns related to energy consumption and the handling of process gases, while less impactful than traditional chemical methods, still require careful management and can be seen as a restraint by some stakeholders. The relatively limited awareness and understanding of plasma technology benefits among potential end-users in some emerging markets also hinder broader adoption.

Opportunities for growth are abundant, particularly in emerging economies where industrialization and manufacturing capabilities are rapidly expanding. The ongoing research and development in new materials and advanced manufacturing techniques, such as additive manufacturing, continually opens new applications for plasma surface treatments. Integration with Industry 4.0 paradigms, including IoT connectivity and AI-driven process optimization, presents significant avenues for technological advancement and market penetration. The increasing focus on sustainable manufacturing practices further positions plasma treatment as an environmentally friendly alternative to traditional wet chemical processes, thereby creating additional market opportunities.

The impact forces influencing the market are multifaceted. The bargaining power of buyers is moderate to high, as the availability of various equipment providers and the customization options give buyers leverage, especially for large-scale industrial clients. The bargaining power of suppliers of raw materials and specialized components is also moderate, influenced by the criticality of certain high-purity gases and proprietary technologies. The threat of new entrants is low to moderate due to the high capital investment, extensive R&D, and technical expertise required, creating significant barriers. However, the threat of substitutes, though limited for highly specialized applications, could arise from alternative surface modification techniques or new material compositions. Competitive rivalry among existing players is intense, driven by technological innovation, product differentiation, pricing strategies, and global market share objectives.

Segmentation Analysis

The Plasma Surface Treatment Equipment Market is extensively segmented to reflect the diverse technological offerings, application areas, and end-user industries that utilize these advanced surface modification solutions. Understanding these segments is crucial for analyzing market dynamics, identifying growth opportunities, and developing targeted market strategies. The primary segmentation criteria include the type of plasma technology, the specific application of the treatment, the end-user industry employing the equipment, and the operational mode of the systems, each contributing to a comprehensive market overview.

- By Type

- Atmospheric Plasma

- Vacuum Plasma (Low-Pressure Plasma)

- By Application

- Adhesion Promotion (Bonding)

- Cleaning & Activation

- Etching & Surface Roughening

- Sterilization

- Coating Deposition (PECVD)

- Surface Functionalization

- By End-User Industry

- Medical & Healthcare (Devices, Implants)

- Electronics & Semiconductors

- Automotive

- Aerospace

- Textiles

- Packaging

- Consumer Goods

- Research & Development

- By Operation Mode

- Batch Systems

- In-line Systems (Continuous Processing)

Value Chain Analysis For Plasma Surface Treatment Equipment Market

The value chain for the Plasma Surface Treatment Equipment Market is a complex network involving various stages from raw material sourcing to end-user deployment and after-sales services. Upstream analysis focuses on the procurement of essential components and materials, including high-purity gases, power supplies, vacuum pumps, control systems, and specialized electrodes. Key suppliers in this segment provide critical technological components that dictate the performance and reliability of the final equipment. Strong relationships with these suppliers are vital for ensuring quality, managing costs, and enabling innovation in system design.

Further down the chain, the manufacturing and assembly of the plasma treatment equipment itself represent a core segment, where specialized engineering and technical expertise are paramount. This involves integrating various components, developing proprietary plasma sources, and ensuring the systems meet stringent performance and safety standards. Following manufacturing, the distribution channel plays a crucial role in bringing the equipment to the end-users. This typically involves a combination of direct sales and indirect channels, utilizing a network of distributors, agents, and system integrators who provide regional access, local support, and often customized solutions. Direct sales are common for large industrial clients or for highly specialized, bespoke systems, allowing manufacturers to maintain direct control over the sales process and customer relationships. Indirect channels leverage partners to reach a broader market, particularly SMEs and in geographically diverse regions, where local presence and support are critical.

Downstream analysis centers on the end-users and the after-sales support provided, which includes installation, training, maintenance, and technical assistance. Effective post-sales service is crucial for customer satisfaction and long-term relationships, as plasma treatment equipment often requires ongoing support and occasional troubleshooting to maintain optimal performance. The feedback loop from end-users back to manufacturers is vital for continuous product improvement and the development of new solutions that address evolving industry needs. The overall efficiency and effectiveness of this value chain are critical for market competitiveness and ensuring the widespread adoption of plasma surface treatment technologies.

Plasma Surface Treatment Equipment Market Potential Customers

Potential customers and end-users of Plasma Surface Treatment Equipment are diverse, spanning a wide array of manufacturing sectors that require precise surface modification to enhance product performance, durability, and functionality. These customers typically seek solutions for improving adhesion, cleaning surfaces at a microscopic level, enabling biocompatibility, or depositing specialized coatings. Industries with high-value products and stringent quality requirements form the primary customer base, as plasma treatment offers unparalleled precision and control over surface properties.

Key end-user segments include manufacturers in the medical device industry, such as those producing implants, catheters, and diagnostic tools, where sterility, biocompatibility, and optimal bonding for assembly are critical. The electronics and semiconductor industry relies heavily on plasma for fine cleaning, etching of circuit boards, and surface activation for advanced packaging. Automotive manufacturers utilize plasma for preparing surfaces of plastic and metal components for bonding, painting, and sealing, enhancing durability and reducing assembly defects. The aerospace sector employs plasma for lightweight composite materials and metal components to improve adhesion for coatings and structural bonding, vital for safety and performance.

Beyond these major sectors, the textile industry uses plasma for functionalizing fabrics to achieve water repellency, improved dye uptake, or enhanced breathability. The packaging industry benefits from plasma treatments for improving printability, adhesion of laminates, and barrier properties of films. Furthermore, companies involved in general industrial manufacturing, research institutions, and even consumer goods production, seeking innovative ways to enhance their product offerings or manufacturing processes, represent significant potential customers for this technology. The growing adoption of advanced materials and complex manufacturing processes across industries continues to expand the pool of potential buyers for plasma surface treatment equipment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.8 Billion |

| Market Forecast in 2032 | USD 3.0 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nordson Corporation, PVA TePla AG, Henniker Plasma, Plasmatreat GmbH, Diener electronic GmbH + Co. KG, PINK GmbH Thermosysteme, Europlasma NV, Tantec A S, Surfx Technologies LLC, Relyon Plasma GmbH, ADTEC Plasma Technology Co. Ltd., Samco Inc., AcXys Technologies, SCI Systems Inc., Softal Corona & Plasma GmbH, March Plasma Systems (Nordson Company), Kyoto Elex Co. Ltd., ULVAC Technologies Inc., Advanced Plasma Solutions, Arc Beam Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plasma Surface Treatment Equipment Market Key Technology Landscape

The technology landscape for the Plasma Surface Treatment Equipment Market is characterized by continuous innovation aimed at improving efficiency, precision, and versatility. Two primary technological categories define the market: atmospheric plasma systems and vacuum (or low-pressure) plasma systems. Atmospheric plasma treatments offer the advantage of seamless integration into existing production lines without the need for vacuum chambers, making them ideal for continuous processing and localized treatments. These often utilize cold plasma jets or dielectric barrier discharge (DBD) to activate or clean surfaces, providing cost-effective solutions for a wide range of materials from plastics to metals.

Vacuum plasma systems, conversely, operate in a controlled low-pressure environment, allowing for highly uniform and precise treatment of sensitive or complex geometries. Technologies within this segment include reactive ion etching (RIE), plasma enhanced chemical vapor deposition (PECVD) for thin film coatings, and sputtering. These systems are critical for applications demanding ultra-clean surfaces, precise etching, or the deposition of functional layers with specific electrical, optical, or mechanical properties, often found in semiconductor manufacturing, medical device coatings, and advanced material research. Advances in power supply designs, gas delivery systems, and control software are constantly pushing the boundaries of what is achievable with plasma, leading to more robust and repeatable processes.

Emerging technologies also include pulsed plasma, which offers finer control over the treatment process and minimizes thermal damage, and hybrid systems combining the benefits of both atmospheric and vacuum approaches for specialized applications. The integration of advanced diagnostics, real-time monitoring, and automation capabilities is becoming standard, ensuring consistent treatment quality and enabling predictive maintenance. Furthermore, the development of eco-friendly plasma gases and more energy-efficient plasma sources aligns with sustainability trends, reinforcing the market's technological evolution and its ability to address complex industrial challenges.

Regional Highlights

- North America: This region is a significant market for plasma surface treatment equipment, driven by robust aerospace, medical device manufacturing, and semiconductor industries. High investments in research and development, coupled with stringent quality control standards, foster innovation and adoption of advanced plasma technologies. The presence of key market players and a strong demand for high-performance materials contribute to its steady growth.

- Europe: Europe represents a mature market with strong growth, particularly in the automotive, industrial manufacturing, and medical sectors. Strict environmental regulations and a focus on sustainable manufacturing processes encourage the adoption of plasma treatments as an alternative to chemical-intensive methods. Germany, France, and the UK are leading countries, demonstrating significant R&D activities and a demand for advanced surface modification solutions.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, primarily fueled by the expansive electronics, automotive, and textile manufacturing bases in countries like China, Japan, South Korea, and India. Rapid industrialization, increasing foreign direct investment, and a burgeoning demand for consumer electronics and medical devices drive the adoption of plasma treatment equipment for mass production and quality enhancement.

- Latin America: This region is an emerging market for plasma surface treatment equipment, with increasing industrialization and a growing automotive sector. Countries like Brazil and Mexico are witnessing gradual adoption of these technologies as they modernize their manufacturing processes and seek to improve product quality and competitiveness in global markets.

- Middle East and Africa (MEA): The MEA region is experiencing nascent growth, driven by diversification efforts in industrial sectors beyond oil and gas, including automotive and medical. Investments in new manufacturing facilities and a rising awareness of advanced surface treatment benefits are expected to gradually increase the demand for plasma equipment in the coming years.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plasma Surface Treatment Equipment Market.- Nordson Corporation

- PVA TePla AG

- Henniker Plasma

- Plasmatreat GmbH

- Diener electronic GmbH + Co. KG

- PINK GmbH Thermosysteme

- Europlasma NV

- Tantec A S

- Surfx Technologies LLC

- Relyon Plasma GmbH

- ADTEC Plasma Technology Co. Ltd.

- Samco Inc.

- AcXys Technologies

- SCI Systems Inc.

- Softal Corona & Plasma GmbH

- March Plasma Systems (Nordson Company)

- Kyoto Elex Co. Ltd.

- ULVAC Technologies Inc.

- Advanced Plasma Solutions

- Arc Beam Inc.

Frequently Asked Questions

What is plasma surface treatment?

Plasma surface treatment is an advanced process that uses ionized gas to modify the surface properties of materials, enhancing adhesion, wettability, cleanliness, or resistance without altering bulk material characteristics.

What are the primary applications of plasma surface treatment equipment?

Key applications include adhesion promotion for bonding, ultra-fine cleaning, etching of surfaces, sterilization of medical devices, and deposition of functional coatings in industries like medical, electronics, and automotive.

What are the main benefits of using plasma surface treatment?

Benefits include improved material performance, extended product lifespan, enhanced adhesion for coatings and bonding, effective surface cleaning, and the ability to treat a wide range of materials in an environmentally friendly manner.

What types of plasma surface treatment equipment are available?

The market primarily offers atmospheric plasma systems, which operate at ambient pressure for continuous processing, and vacuum plasma systems, used for highly precise treatments in controlled low-pressure environments.

How is the Plasma Surface Treatment Equipment Market expected to grow?

The market is projected for significant growth, driven by increasing demand for advanced materials, miniaturization in electronics, stringent quality standards, and the adoption of sustainable manufacturing processes across key industrial sectors globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager