Plastic Injection Molding Machine for MedTech Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428944 | Date : Oct, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Plastic Injection Molding Machine for MedTech Market Size

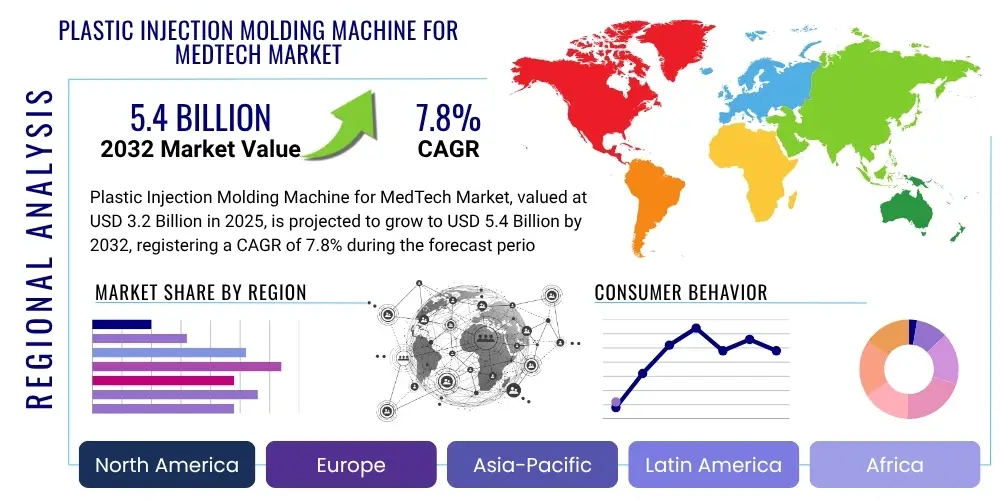

The Plastic Injection Molding Machine for MedTech Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at $3.2 Billion in 2025 and is projected to reach $5.4 Billion by the end of the forecast period in 2032.

Plastic Injection Molding Machine for MedTech Market introduction

The Plastic Injection Molding Machine for MedTech Market encompasses specialized machinery designed for the precision manufacturing of plastic components used across the medical and healthcare sectors. These machines are crucial for producing a wide array of medical devices, from intricate surgical instruments and diagnostic equipment to disposable consumables and implantable components. The core product description involves advanced injection molding systems that can handle medical-grade plastics with extremely tight tolerances, high repeatability, and often, under stringent cleanroom conditions to ensure product safety and regulatory compliance.

Major applications of these machines include the production of syringes, catheters, IV components, diagnostic test strips, device housings, orthopedic implants, dental prosthetics, and various other critical medical parts. The benefits derived from utilizing these specialized machines are paramount for the MedTech industry, enabling manufacturers to achieve exceptional part accuracy, consistency in mass production, and cost-efficiency through automation. Furthermore, the ability to produce sterile and biocompatible components directly contributes to improved patient outcomes and reduced contamination risks.

Driving factors for this market's growth are multifaceted, primarily fueled by a globally aging population requiring more sophisticated healthcare interventions and diagnostics. This demographic shift, coupled with increasing healthcare expenditure in both developed and emerging economies, stimulates demand for advanced medical devices. Technological advancements in medical plastics, automation, and manufacturing processes also play a significant role, allowing for the creation of new, highly functional, and miniaturized medical products that require precision molding capabilities.

Plastic Injection Molding Machine for MedTech Market Executive Summary

The Plastic Injection Molding Machine for MedTech Market is experiencing robust growth driven by continuous innovation in medical device manufacturing and an expanding global healthcare landscape. Current business trends highlight a strong emphasis on automation, digitalization, and the integration of smart manufacturing principles to enhance operational efficiency, reduce human error, and ensure strict quality control in the production of critical medical components. Manufacturers are increasingly seeking solutions that offer greater flexibility for short runs of specialized products, alongside high-volume production capabilities for consumables, all while meeting rigorous regulatory standards.

Regional trends indicate North America and Europe as established markets characterized by high healthcare spending, advanced manufacturing infrastructure, and stringent regulatory environments, which drive demand for sophisticated, high-precision molding solutions. The Asia Pacific region, however, is emerging as a significant growth engine, fueled by expanding healthcare access, rising medical tourism, and increasing investment in domestic medical device manufacturing capabilities, particularly in countries like China, India, and Japan. Latin America and the Middle East & Africa are also demonstrating growth potential, albeit at a slower pace, as their healthcare infrastructures mature and local manufacturing initiatives gain traction.

Segment trends within the market reveal a notable shift towards electric and hybrid injection molding machines due to their energy efficiency, lower noise levels, and superior precision and repeatability compared to traditional hydraulic systems. There is also a growing demand for machines capable of multi-component molding, micro-molding, and those equipped with integrated robotics and vision systems for automated assembly and inspection, crucial for complex medical devices. Furthermore, the increasing necessity for production within certified cleanroom environments is driving demand for specialized machine designs and ancillary equipment that support aseptic manufacturing processes, ensuring compliance with medical device regulations and patient safety standards.

AI Impact Analysis on Plastic Injection Molding Machine for MedTech Market

User inquiries concerning AI's influence on the Plastic Injection Molding Machine for MedTech Market frequently revolve around improvements in operational efficiency, quality control, predictive maintenance, and product design optimization. Users express interest in how AI can automate complex decision-making processes, minimize waste, and accelerate time-to-market for new medical devices. Common concerns include the initial investment costs associated with AI integration, the need for specialized data scientists and engineers, and challenges related to data security and compliance within the highly regulated MedTech sector. Expectations are high for AI to revolutionize the precision, speed, and reliability of medical component manufacturing, while also addressing traceability and regulatory adherence.

- AI enhances real-time process monitoring and control, optimizing parameters for precision and consistency.

- Predictive analytics powered by AI forecasts machine maintenance needs, reducing downtime and improving equipment longevity.

- AI-driven vision systems facilitate automated quality inspection, identifying microscopic defects beyond human capability.

- Generative design and simulation tools leverage AI to optimize mold designs for better material flow and part performance.

- AI supports supply chain optimization and inventory management for medical-grade raw materials.

- Automated defect detection and classification using AI algorithms minimize scrap rates and material waste.

- AI facilitates traceability and data logging, essential for regulatory compliance in medical device manufacturing.

DRO & Impact Forces Of Plastic Injection Molding Machine for MedTech Market

The Plastic Injection Molding Machine for MedTech Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and inherent impact forces. Key drivers propelling market expansion include the escalating global demand for advanced medical devices due to an aging population and increasing prevalence of chronic diseases, necessitating sophisticated manufacturing solutions. Furthermore, continuous advancements in medical plastic materials, offering enhanced biocompatibility and performance, along spur innovation in device design that requires precision molding. The increasing adoption of automation and digitalization within manufacturing facilities also serves as a significant driver, aimed at improving efficiency, reducing labor costs, and ensuring high product quality and consistency.

However, several restraints temper this growth. The high initial capital investment required for advanced plastic injection molding machines and associated cleanroom infrastructure presents a significant barrier for smaller manufacturers and new entrants. Stringent regulatory frameworks, such as FDA and EU MDR, impose complex and costly compliance requirements on medical device manufacturers, influencing machine specifications and operational protocols. Moreover, a persistent shortage of skilled labor capable of operating and maintaining these sophisticated machines, coupled with rising energy costs, adds to operational challenges and can hinder market expansion.

Opportunities for growth are abundant, particularly in emerging markets where healthcare infrastructure is rapidly developing, leading to increased demand for locally produced medical devices. The trend towards personalized medicine and customized implants creates niches for specialized, highly flexible molding solutions. Furthermore, a growing emphasis on sustainable manufacturing practices, including the use of recycled or bio-based plastics and energy-efficient machines, presents new avenues for innovation and market differentiation. The long-term impact forces are characterized by ongoing technological advancements, particularly in robotics, AI, and material science, which continually reshape production capabilities and product offerings. Regulatory evolution, economic fluctuations, and global health crises also exert significant influence, shaping investment decisions and market dynamics.

Segmentation Analysis

The Plastic Injection Molding Machine for MedTech Market is intricately segmented across various dimensions to reflect the diverse needs and applications within the medical technology sector. This segmentation allows for a granular understanding of market dynamics, identifying key areas of growth, technological preferences, and end-user requirements. Analyzing these segments provides strategic insights into market penetration, product development, and competitive positioning for manufacturers and suppliers.

- Machine Type

- Hydraulic

- Electric

- Hybrid

- Tonnage

- Less than 100 Ton

- 100-300 Ton

- More than 300 Ton

- Application

- Consumables (e.g., Syringes, Catheters, IV Components)

- Implants (e.g., Orthopedic, Dental)

- Diagnostic Devices (e.g., Test Strips, Housings)

- Surgical Instruments (e.g., Handles, Casings)

- Others (e.g., Pharmaceutical Packaging)

- End-Use

- Hospitals

- Clinics

- Ambulatory Surgical Centers

- Diagnostic Laboratories

- Medical Device Manufacturers (OEMs & CMOs)

Value Chain Analysis For Plastic Injection Molding Machine for MedTech Market

The value chain for the Plastic Injection Molding Machine for MedTech Market is characterized by a series of interconnected stages, beginning with upstream raw material suppliers and extending through to the end-users of medical devices. Upstream analysis involves suppliers of specialized medical-grade polymers, such as polycarbonate, PEEK, silicone, and various thermoplastics, which meet stringent biocompatibility and regulatory standards. Additionally, component manufacturers for machine parts, robotics, control systems, and automation software play a crucial role in the development and assembly of the injection molding machines themselves. These upstream providers are critical for ensuring the quality, performance, and technological sophistication of the final molding equipment.

Further down the value chain, the core stage involves the design, manufacturing, and assembly of the plastic injection molding machines by original equipment manufacturers (OEMs). These OEMs often collaborate with technology providers for advanced features like cleanroom compatibility, precision control, and data integration. Downstream activities primarily encompass the distribution, installation, and after-sales support of these machines to medical device manufacturers. The ultimate downstream segment comprises the medical device manufacturers themselves, including large multinational corporations and specialized contract manufacturing organizations (CMOs), who utilize these machines to produce a vast array of medical products. These manufacturers then distribute their finished medical devices to hospitals, clinics, and other healthcare providers, forming the final link in the chain.

Distribution channels for plastic injection molding machines in the MedTech market typically involve both direct and indirect approaches. Direct sales are common for larger, more complex installations where OEMs engage directly with major medical device manufacturers, offering customized solutions, technical support, and comprehensive training. Indirect channels involve a network of authorized distributors, agents, and value-added resellers who cater to smaller and medium-sized enterprises (SMEs), providing local sales, service, and spare parts. These indirect partners are vital for market penetration in geographically diverse regions and for reaching a broader customer base, offering specialized knowledge of local market requirements and regulatory landscapes. The efficiency of these distribution networks is crucial for timely delivery and sustained operational support, which are paramount in the high-stakes medical device industry.

Plastic Injection Molding Machine for MedTech Market Potential Customers

The potential customers for Plastic Injection Molding Machines in the MedTech market are diverse, primarily comprising entities involved in the design, development, and manufacturing of medical and healthcare products. The most significant end-users and buyers are medical device manufacturers, ranging from large, multinational Original Equipment Manufacturers (OEMs) that produce a wide array of devices to specialized smaller companies focusing on niche products such as advanced surgical instruments or implantable devices. These manufacturers require highly precise and reliable molding solutions to meet strict industry standards and regulatory compliance.

Another crucial segment of potential customers includes contract manufacturing organizations (CMOs) that specialize in producing medical components and devices for other companies. CMOs often invest heavily in advanced injection molding technology to offer comprehensive services, including prototyping, tooling, and high-volume production, adhering to rigorous quality and regulatory specifications on behalf of their clients. Their business model thrives on flexibility and the ability to handle diverse project requirements, making them significant buyers of versatile molding machinery.

Furthermore, pharmaceutical companies, particularly those involved in drug delivery systems or medical packaging components, also represent a segment of potential customers. Research and development institutions, academic laboratories, and specialized healthcare startups exploring innovative medical technologies may also acquire these machines for prototyping, small-batch production, and experimental purposes. The common thread among all these potential customers is the critical need for manufacturing precision, material integrity, and regulatory compliance, which advanced plastic injection molding machines are designed to deliver.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $3.2 Billion |

| Market Forecast in 2032 | $5.4 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Arburg GmbH + Co KG, Engel Austria GmbH, Sumitomo (SHI) Demag Plastics Machinery GmbH, KraussMaffei AG, Wittmann Battenfeld GmbH, Milacron Holdings Corp., Husky Injection Molding Systems Ltd., Nissei Plastic Industrial Co., Ltd., JSW Plastic Machinery Co., Ltd., Fanuc Corporation, Shibaura Machine Co., Ltd., Haitian International Holdings Limited, Yizumi Group, Netstal Maschinen AG, Bole Machinery, Borche North America Inc., Chen Hsong Holdings Limited, Absolute Haitian, FCS (Fu Chun Shin), Woojin Plaimm |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Injection Molding Machine for MedTech Market Key Technology Landscape

The Plastic Injection Molding Machine for MedTech Market is characterized by a dynamic and evolving technology landscape, driven by the critical need for extreme precision, repeatability, and regulatory compliance. Key technological advancements include the widespread adoption of electric and hybrid injection molding machines, which offer superior energy efficiency, quieter operation, and significantly enhanced process control compared to traditional hydraulic systems. These machines enable tighter tolerance control and reduced part variation, which are essential for manufacturing delicate medical components. Furthermore, multi-component molding technologies, allowing for the injection of different materials or colors in a single cycle, are gaining traction for producing complex medical devices with integrated functionalities.

Micro-molding techniques represent another crucial area, enabling the production of extremely small and intricate medical parts, such as micro-catheters, surgical device components, and tiny connectors, often with features in the micron range. This demands specialized machine designs, highly precise tooling, and advanced material handling systems. Integrated automation solutions, including robotic arms for part removal, assembly, and packaging, are becoming standard to minimize human intervention and maintain sterile production environments, particularly within cleanroom settings. Cleanroom-compatible machine designs and integrated monitoring systems are pivotal for preventing contamination and adhering to ISO 13485 and FDA regulations, ensuring product safety and efficacy.

The integration of Industry 4.0 concepts, such as the Industrial Internet of Things (IIoT) and advanced data analytics, is transforming machine operations. These technologies enable real-time monitoring of molding parameters, predictive maintenance, and comprehensive data collection for process optimization and traceability. Smart sensors and AI-powered algorithms are used to detect anomalies, optimize cycle times, and ensure consistent quality, reducing scrap rates and improving overall equipment effectiveness. These technological advancements collectively enhance the capabilities of plastic injection molding machines, allowing medical device manufacturers to meet increasingly stringent quality standards, accelerate product innovation, and achieve greater manufacturing efficiency.

Regional Highlights

- North America: Dominates the market due to a highly developed healthcare infrastructure, substantial R&D investments, and the presence of numerous leading medical device manufacturers. Strict regulatory standards drive demand for advanced, high-precision molding solutions.

- Europe: A mature market characterized by stringent quality controls, strong focus on innovation, and significant investments in medical technology, particularly in Germany, Switzerland, and France. Increasing demand for sophisticated medical devices and sustainable manufacturing practices fuels growth.

- Asia Pacific (APAC): Expected to exhibit the highest growth rate, driven by expanding healthcare access, rising disposable incomes, medical tourism, and a burgeoning domestic medical device manufacturing industry in countries like China, India, and Japan. Increased government support and foreign direct investment further bolster market expansion.

- Latin America: Shows promising growth potential with improving healthcare infrastructure and increasing healthcare expenditure. Countries like Brazil and Mexico are emerging as key markets, attracting investment in local medical device production capabilities.

- Middle East and Africa (MEA): A developing market with growth driven by efforts to diversify economies, enhance healthcare services, and reduce reliance on imported medical devices. Investments in new hospitals and medical facilities are creating opportunities for advanced manufacturing equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Injection Molding Machine for MedTech Market.- Arburg GmbH + Co KG

- Engel Austria GmbH

- Sumitomo (SHI) Demag Plastics Machinery GmbH

- KraussMaffei AG

- Wittmann Battenfeld GmbH

- Milacron Holdings Corp.

- Husky Injection Molding Systems Ltd.

- Nissei Plastic Industrial Co., Ltd.

- JSW Plastic Machinery Co., Ltd.

- Fanuc Corporation

- Shibaura Machine Co., Ltd.

- Haitian International Holdings Limited

- Yizumi Group

- Netstal Maschinen AG

- Bole Machinery

- Borche North America Inc.

- Chen Hsong Holdings Limited

- Absolute Haitian

- FCS (Fu Chun Shin)

- Woojin Plaimm

Frequently Asked Questions

What is the projected growth rate for the Plastic Injection Molding Machine for MedTech Market?

The market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032, driven by increasing demand for precision medical devices.

Which machine types are most prevalent in MedTech plastic injection molding?

Electric and hybrid injection molding machines are gaining significant prevalence due to their superior precision, energy efficiency, and suitability for cleanroom environments in MedTech manufacturing.

What are the key drivers for market growth?

Key drivers include an aging global population, rising healthcare expenditure, continuous advancements in medical plastics, and increasing adoption of automation and digitalization in medical device production.

How does AI impact the Plastic Injection Molding Machine for MedTech Market?

AI impacts include enhanced real-time process monitoring, predictive maintenance, automated quality inspection, and optimized mold design, leading to improved efficiency and reduced waste in medical manufacturing.

Which region is expected to show the highest growth in this market?

The Asia Pacific (APAC) region is anticipated to exhibit the highest growth, fueled by expanding healthcare access, increased medical tourism, and burgeoning domestic medical device manufacturing capabilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager