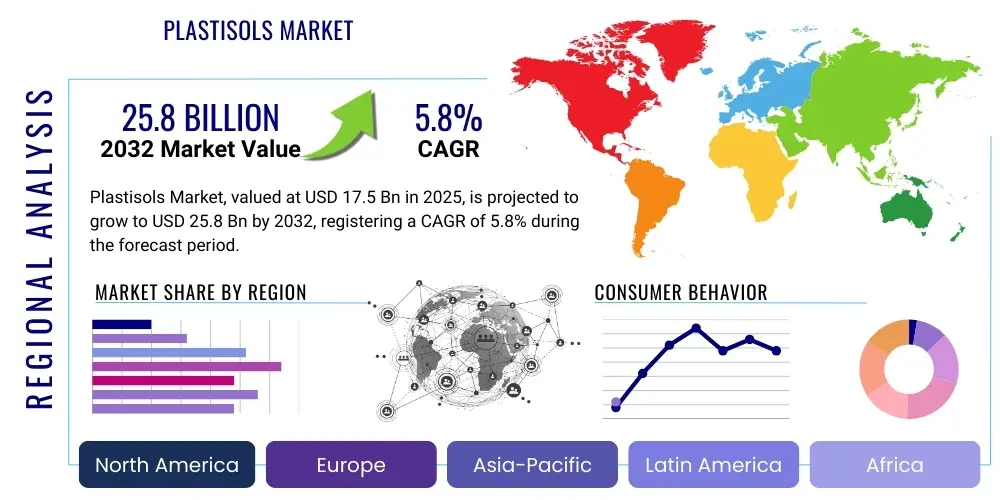

Plastisols Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427544 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Plastisols Market Size

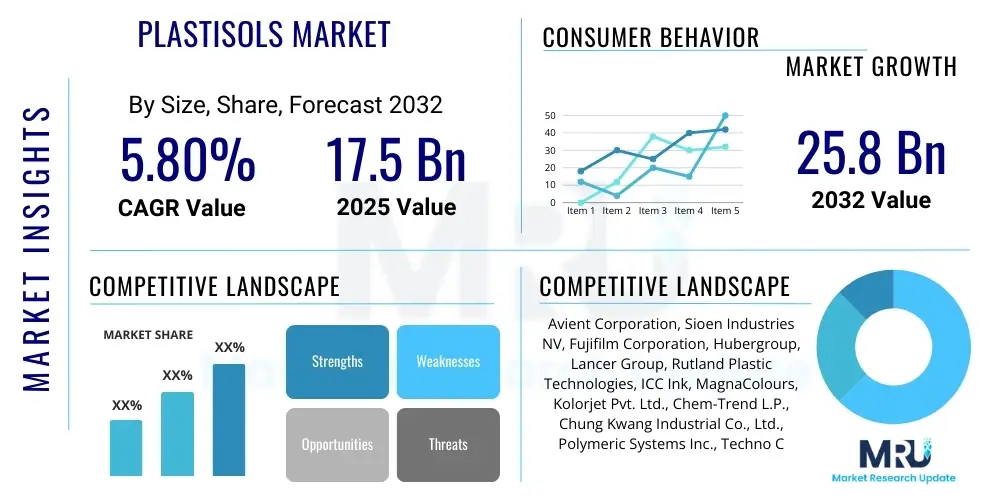

The Plastisols Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 17.5 billion in 2025 and is projected to reach USD 25.8 billion by the end of the forecast period in 2032.

Plastisols Market introduction

Plastisols represent a distinctive class of plastic materials, essentially a suspension of fine polyvinyl chloride (PVC) resin particles dispersed in a liquid plasticizer. This unique formulation allows plastisols to remain a liquid at room temperature, transforming into a solid, durable, and flexible plastic material upon heating. The key to their versatility lies in their ability to be easily processed into various forms, making them highly desirable across numerous industrial and consumer applications. This inherent flexibility and ease of manufacturing position plastisols as a cornerstone material in modern production processes, catering to demands for both robust performance and cost-effectiveness in diverse end-use sectors.

The primary applications for plastisols span a broad spectrum, including textile printing, where they impart vibrant colors and excellent durability to fabrics, and in the automotive sector for underbody coatings, sealants, and various interior components, offering corrosion resistance and sound dampening properties. Additionally, they are extensively used in dipped goods like gloves and tool handles, coatings for metal and fabric, and in the creation of molded products such as toys and consumer goods. The benefits of using plastisols are manifold, encompassing superior adhesion to diverse substrates, excellent chemical and abrasion resistance, electrical insulation properties, and the ability to be formulated for specific hardness, texture, and color requirements. These attributes, coupled with their cost-effectiveness and relatively simple processing requirements, serve as significant driving factors for their sustained demand and market growth across industrial and manufacturing landscapes globally.

Plastisols Market Executive Summary

The global Plastisols Market is currently experiencing dynamic shifts driven by evolving industrial demands, regulatory landscapes, and technological advancements. Business trends indicate a strong push towards sustainable formulations, with manufacturers increasingly investing in non-phthalate plasticizers and lower Volatile Organic Compound (VOC) alternatives to address environmental and health concerns. This pivot is not only a response to regulatory pressures but also a proactive measure to meet the growing consumer and industrial demand for eco-friendlier products. Furthermore, the market is witnessing a surge in innovative applications, particularly in niche segments requiring specialized properties like enhanced heat resistance, improved UV stability, or tailored tactile finishes, indicating a trend towards high-performance and customized plastisol solutions that transcend traditional uses. The competitive landscape is characterized by both established players and emerging innovators, all striving to differentiate through product efficacy, processing efficiency, and compliance with stringent quality and environmental standards.

Regional trends highlight Asia-Pacific as the dominant and fastest-growing market, primarily fueled by rapid industrialization, expanding manufacturing bases, and significant growth in automotive, construction, and textile industries in countries like China and India. North America and Europe, while mature markets, are focusing on advanced specialty plastisols and adherence to stricter environmental regulations, driving innovation in safer and more sustainable formulations. Segment-wise, textile printing continues to be a major application, benefiting from the durability and vibrancy plastisols offer. However, the automotive industry is emerging as a significant growth driver, utilizing plastisols for underbody coatings, sealants, and interior trim due to their superior protective and sound-dampening qualities. The dipped goods segment, including medical gloves and various industrial coatings, also exhibits robust growth, propelled by increasing hygiene standards and industrial safety requirements. The overall market trajectory indicates a balanced growth, spurred by application diversification, technological innovation, and a strategic response to global sustainability mandates.

AI Impact Analysis on Plastisols Market

Common user inquiries regarding AIs impact on the Plastisols Market frequently center on how artificial intelligence can enhance manufacturing efficiency, optimize product formulations, improve quality control, and contribute to sustainable practices within the industry. Users are particularly interested in AIs role in predictive analytics for raw material sourcing, process automation, and the development of novel plastisol compounds with superior properties or reduced environmental footprints. Theres a strong expectation that AI will streamline operational complexities, minimize waste, and accelerate innovation cycles, ultimately leading to more cost-effective production and environmentally responsible products. The key themes revolve around leveraging AI for precision, predictive capabilities, and strategic decision-making throughout the plastisol value chain, transforming traditional manufacturing into a more intelligent and responsive ecosystem.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) technologies is poised to significantly revolutionize various aspects of the Plastisols Market, transitioning from traditional empirical methods to data-driven precision. AI can be instrumental in optimizing complex manufacturing processes, enabling real-time adjustments to parameters like temperature, pressure, and mixing speeds to ensure consistent product quality and maximize yield. This predictive capability extends to maintenance, where AI algorithms can analyze equipment data to anticipate failures, thus reducing downtime and operational costs. Furthermore, AI-powered material informatics can accelerate research and development efforts by simulating different plasticizer and resin combinations, identifying optimal formulations for specific applications, and even predicting the performance of new compounds, thereby drastically cutting down on physical experimentation and accelerating time-to-market for innovative plastisol products. This advanced analytical capability is crucial for developing sustainable, high-performance plastisols that meet evolving industry standards and consumer expectations.

- Process Optimization: AI algorithms analyze real-time production data to fine-tune manufacturing parameters, ensuring consistent quality, reducing energy consumption, and optimizing throughput for plastisol manufacturing lines.

- Quality Control and Assurance: Machine Vision systems powered by AI can detect microscopic defects, color variations, or inconsistencies in plastisol products with greater accuracy and speed than human inspection, significantly enhancing product reliability.

- Research and Development Acceleration: AI-driven material informatics platforms can predict the properties of novel plastisol formulations, including non-phthalate plasticizers and bio-based alternatives, thereby reducing experimental cycles and accelerating innovation.

- Supply Chain Management: AI can predict raw material price fluctuations, optimize inventory levels, and manage logistics more efficiently, mitigating risks associated with supply chain disruptions for PVC resins, plasticizers, and additives.

- Predictive Maintenance: AI-powered sensors and analytics monitor machinery health, anticipating potential breakdowns in processing equipment used for plastisols, thus minimizing costly unplanned downtime and extending equipment lifespan.

- Sustainability and Environmental Monitoring: AI tools can monitor and optimize resource utilization, identify areas for waste reduction, and track the environmental impact of plastisol production, facilitating the development of greener manufacturing processes and products.

DRO & Impact Forces Of Plastisols Market

The Plastisols Market is influenced by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces that shape its competitive landscape and future trajectory. Key drivers include the robust expansion of end-use industries such as automotive, construction, and textiles, where plastisols offer superior performance characteristics like durability, flexibility, and chemical resistance. The ease of processing, coupled with the cost-effectiveness of plastisol formulations, further propels their adoption across various manufacturing sectors. Technological advancements leading to improved formulations, particularly those enhancing environmental sustainability and performance in specialized applications, also serve as strong market accelerators. The ability of plastisols to be tailored for specific mechanical, thermal, and aesthetic properties ensures their continued relevance and demand in a wide array of industrial applications, supporting persistent market growth.

Conversely, the market faces notable restraints, primarily stemming from stringent environmental regulations concerning the use of certain plasticizers, especially phthalates, due to health concerns. This has necessitated significant investment in research and development for non-phthalate alternatives, which can sometimes impact cost and performance. Volatility in raw material prices, particularly for PVC resin and plasticizers, poses another challenge, affecting profit margins for manufacturers. Competition from alternative materials, such as solvent-based coatings or other polymer systems, also limits market expansion in certain applications. Opportunities for market growth primarily lie in the development of sustainable and bio-based plastisol formulations, the increasing demand for specialized coatings in emerging applications, and the expansion into developing economies with rapidly industrializing sectors. The impact forces, including the bargaining power of buyers and suppliers, the threat of new entrants and substitutes, and the intensity of competitive rivalry, collectively dictate the markets dynamics, compelling companies to innovate continuously and differentiate their offerings to maintain a competitive edge and capture new growth avenues.

Segmentation Analysis

The Plastisols Market is meticulously segmented based on various factors, including the type of plasticizer used, the specific application, and the end-use industry, to provide a granular understanding of market dynamics and opportunities. This detailed segmentation allows stakeholders to identify key growth areas, understand market preferences, and tailor product development and marketing strategies effectively. The differentiation by plasticizer type reflects the industrys response to regulatory pressures and sustainability trends, moving towards more environmentally friendly options. Application-based segmentation highlights the diverse utility of plastisols, from high-volume industrial uses to specialized niche markets, while end-use industry segmentation provides insights into the primary sectors driving demand and innovation.

- By Type:

- Phthalate Plastisols: Traditionally used due to cost-effectiveness and good performance, but facing increasing regulatory scrutiny.

- Non-Phthalate Plastisols: Gaining significant traction due to environmental and health concerns, driven by demand for safer alternatives.

- By Application:

- Textile Printing: For screen printing on fabrics, offering vibrant colors and durable finishes.

- Coatings: Protective and decorative coatings for various substrates, including metal, fabric, and paper.

- Dipped Goods: Manufacturing of gloves, tool handles, medical devices, and other items by dipping molds into liquid plastisol.

- Molding: Creation of molded parts for toys, automotive components, and consumer goods.

- Adhesives and Sealants: Used for bonding and sealing applications in construction and automotive industries.

- Automotive: Underbody coatings, sealants, interior components, and wiring harnesses for protection and sound dampening.

- Construction: Roofing membranes, flooring, protective coatings, and sealants.

- Consumer Goods: Toys, sporting equipment, and various household items requiring flexible and durable materials.

- Others: Including medical devices, electrical components, and industrial protective wear.

- By End-Use Industry:

- Automotive Industry: Significant consumer for coatings, sealants, and interior parts.

- Textile Industry: Primarily for screen printing applications.

- Construction Industry: For roofing, flooring, and protective coatings.

- Medical Industry: For dipped goods like medical gloves and specialized tubing.

- Consumer Goods Industry: For toys, sporting goods, and household items.

- General Industrial: Diverse applications across various manufacturing processes.

Plastisols Market Value Chain Analysis

The Plastisols Market value chain is a complex network involving several stages, beginning with the upstream sourcing of raw materials, progressing through manufacturing and formulation, and culminating in distribution to diverse end-use industries. At the upstream end, the market is highly dependent on the availability and pricing of key raw materials, primarily PVC resin, which is a polymer derived from crude oil and natural gas, and various plasticizers that provide flexibility and processability. Other crucial additives include stabilizers, pigments, fillers, and rheology modifiers, each supplied by specialized chemical manufacturers. The quality and consistent supply of these raw materials are paramount, as they directly impact the final properties and cost-effectiveness of the plastisol product. Manufacturers of these raw materials play a critical role, influencing the cost structure and innovation potential within the plastisols industry through their research and development efforts in sustainable and high-performance components.

Moving downstream, the value chain encompasses the actual production and formulation of plastisols by specialized manufacturers who combine the raw materials into customized compounds tailored for specific applications. These formulators possess expertise in blending, compounding, and quality control, ensuring that the plastisols meet the rigorous specifications required by various industries. The finished plastisols are then distributed through a combination of direct sales channels, where manufacturers engage directly with large industrial clients, and indirect channels, involving a network of distributors, agents, and wholesalers. These intermediaries play a crucial role in reaching smaller customers, managing inventory, and providing localized technical support. The distribution strategy is often optimized based on regional market demands, product complexity, and customer relationship requirements. Ultimately, the end-users, ranging from textile printers and automotive manufacturers to construction companies and medical device producers, integrate these plastisols into their final products, creating a robust and interconnected value chain that drives demand and innovation throughout the entire market ecosystem.

Plastisols Market Potential Customers

The Plastisols Market caters to a remarkably diverse range of end-users and buyers, spanning across multiple industrial and commercial sectors due to the materials versatile properties and customizable nature. These potential customers are primarily businesses involved in manufacturing processes where durable, flexible, and protective coatings, molded parts, or specialized adhesives are required. One of the largest customer segments includes textile printers who utilize plastisols for screen printing applications on garments, providing vibrant, long-lasting designs with excellent wash fastness and flexibility. Another significant customer base comprises automotive component manufacturers, who employ plastisols for underbody coatings to protect against corrosion, for sealants to enhance vehicle integrity, and for various interior parts requiring aesthetic appeal and sound dampening properties. The materials ability to offer both functional and decorative solutions makes it invaluable in vehicle production.

Beyond these major segments, the construction industry represents a substantial cohort of potential customers, leveraging plastisols for roofing membranes, flooring materials, protective coatings for structural elements, and specialized sealants for building envelopes, benefiting from their weather resistance and durability. Manufacturers of dipped goods, such as medical gloves, industrial work gloves, and tool handles, are also key buyers, relying on the easy processing and excellent physical properties of plastisols. Furthermore, producers of consumer goods, including toys, sporting equipment, and various household items, utilize plastisols for their flexibility, vibrant color options, and non-toxic formulations (especially non-phthalate variants). The electrical and electronics sector also finds applications for plastisols in wire and cable insulation, and in protective coatings for components, due to their excellent dielectric properties. This expansive and varied customer landscape underscores the widespread utility and indispensability of plastisols across global manufacturing industries, continually driving demand for innovative and application-specific formulations.

Plastisols Market Key Technology Landscape

The technology landscape for the Plastisols Market is continually evolving, driven by the dual imperatives of enhancing product performance and addressing environmental and health concerns. At its core, the production of plastisols relies on advanced polymerization techniques for manufacturing high-quality polyvinyl chloride (PVC) resins with specific particle sizes and molecular weights, which are critical for achieving desired rheological properties in the liquid plastisol. Significant technological advancements are also concentrated in plasticizer development, particularly the shift towards non-phthalate plasticizers. Innovations in this area include the development of bio-based plasticizers derived from renewable resources, such as epoxidized soybean oil or citrates, which offer comparable performance to traditional plasticizers while significantly reducing environmental impact and addressing regulatory restrictions. These advancements require sophisticated chemical engineering to ensure compatibility, processing efficiency, and long-term stability within the plastisol formulation.

Beyond raw material innovation, the processing and application technologies for plastisols are also experiencing continuous improvement. This includes advancements in additive technologies, such as improved heat stabilizers, UV absorbers, flame retardants, and rheology modifiers, which enhance the durability, appearance, and functional performance of the final plastisol product across diverse applications. For instance, new dispersion technologies ensure better pigment distribution and color consistency in textile printing. Equipment manufacturers are also developing more precise and efficient processing machinery for screen printing, dipping, rotocasting, and coating applications, allowing for finer control over thickness, texture, and curing. Automation and digitalization are increasingly integrated into production lines, enabling better process control and quality assurance. This continuous technological evolution across raw materials, additives, and processing methods is vital for the Plastisols Market to meet ever-increasing demands for performance, cost-efficiency, and environmental responsibility, ensuring its sustained relevance in future industrial applications.

Regional Highlights

- Asia Pacific: This region stands as the largest and fastest-growing market for plastisols, driven by rapid industrialization, burgeoning manufacturing sectors, and increasing disposable incomes in countries like China, India, and Southeast Asian nations. Significant growth is observed in automotive production, construction activities, and the thriving textile and apparel industry. The expanding middle class and urbanization further fuel demand for consumer goods utilizing plastisols, positioning Asia Pacific as a critical hub for market expansion and innovation.

- North America: A mature yet highly innovative market, North America demonstrates a strong demand for high-performance and specialty plastisols, particularly in the automotive, construction, and medical industries. The region is characterized by stringent environmental regulations, which are driving a significant shift towards non-phthalate and low-VOC formulations. Investment in research and development for sustainable solutions and advanced processing technologies is a key trend in this market.

- Europe: Similar to North America, Europe is a mature market marked by stringent regulatory frameworks, particularly concerning REACH regulations and the use of certain chemicals. This has spurred considerable innovation in green plastisol formulations, including bio-based plasticizers and alternatives with reduced environmental footprints. Key applications include automotive, construction, and high-end textile printing, with a strong focus on quality, durability, and sustainability.

- Latin America: The market in Latin America is experiencing steady growth, influenced by industrial development and urbanization, particularly in countries like Brazil, Mexico, and Argentina. Expanding automotive manufacturing, construction projects, and a growing consumer goods sector contribute to the demand for plastisols. While cost-effectiveness remains a key factor, there is a gradual shift towards adopting more modern and sustainable formulations.

- Middle East & Africa (MEA): This region is an emerging market for plastisols, driven by significant investments in infrastructure development, construction projects, and the expansion of the manufacturing sector. The demand for coatings, sealants, and various industrial applications is on the rise. While the market is currently smaller compared to other regions, its growth potential is substantial due to ongoing economic diversification efforts and industrial expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastisols Market.- Avient Corporation (formerly PolyOne)

- Sioen Industries NV

- Fujifilm Corporation

- Hubergroup

- Lancer Group

- Rutland Plastic Technologies

- ICC Ink (International Coatings)

- MagnaColours

- Kolorjet (India) Pvt. Ltd.

- Chem-Trend L.P.

- Chung Kwang Industrial Co., Ltd.

- Polymeric Systems Inc.

- Techno Coatings Co. Ltd.

- Vipul Dye-Chem Ltd.

- Dongguan Jianmei Rubber and Plastic Products Co., Ltd.

Frequently Asked Questions

What are plastisols and what are their primary uses?

Plastisols are unique liquid suspensions of fine polyvinyl chloride (PVC) resin particles in a plasticizer, which solidify into a flexible plastic upon heating. Their primary uses include screen printing on textiles, protective coatings for various materials, dipped goods like gloves, automotive components for corrosion protection and sealing, and molded products such as toys.

Are plastisols safe to use, especially concerning environmental and health impacts?

The safety of plastisols depends largely on their formulation. Traditionally, some plastisols contained phthalate plasticizers, which raised health concerns. However, the industry has increasingly shifted towards non-phthalate and bio-based plasticizers, developing safer, more environmentally friendly formulations that meet stringent global health and environmental regulations, making them safe for a wide range of applications.

What are the main types of plastisols available in the market?

The main types of plastisols are categorized primarily by their plasticizer content: Phthalate Plastisols, which are traditional and cost-effective, and Non-Phthalate Plastisols, which are gaining dominance due to regulatory pressures and consumer demand for safer, greener alternatives. These types offer varying levels of flexibility, durability, and environmental impact.

How is the Plastisols Market projected to grow in the coming years?

The Plastisols Market is projected for steady growth, driven by expanding applications in the automotive, construction, and textile sectors. Innovations in sustainable and high-performance formulations, coupled with increasing industrialization in emerging economies, are key factors contributing to its anticipated Compound Annual Growth Rate (CAGR) and market value increase through 2032.

What role does technology, including AI, play in the advancement of the Plastisols Market?

Technology plays a crucial role in advancing the Plastisols Market through improved raw material development (e.g., bio-based plasticizers), enhanced processing techniques, and additive innovations. Artificial Intelligence (AI) is increasingly vital for optimizing manufacturing processes, accelerating R&D for new formulations, improving quality control, and managing supply chain efficiencies, leading to more precise and sustainable plastisol production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager