Plug-In Industrial Surge Protection Devices Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428175 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Plug-In Industrial Surge Protection Devices Market Size

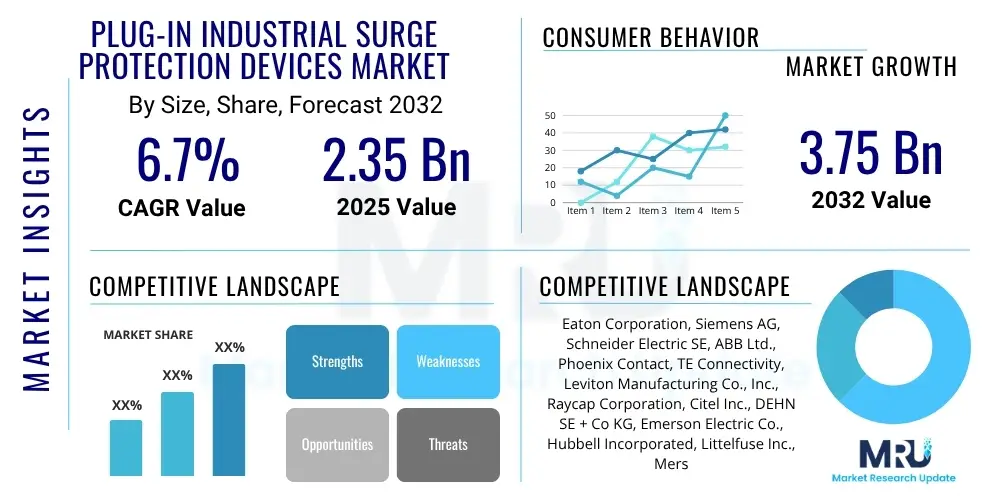

The Plug-In Industrial Surge Protection Devices Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at USD 2.35 Billion in 2025 and is projected to reach USD 3.75 Billion by the end of the forecast period in 2032.

Plug-In Industrial Surge Protection Devices Market introduction

The Plug-In Industrial Surge Protection Devices (SPDs) Market encompasses solutions designed to safeguard sensitive industrial equipment and systems from transient overvoltages, commonly known as surges or spikes. These devices are crucial in protecting critical infrastructure, machinery, and control systems from damage caused by lightning strikes, utility switching, and other power disturbances. Their plug-in nature offers significant advantages in terms of ease of installation, maintenance, and scalability, making them highly attractive for diverse industrial environments seeking robust and adaptable electrical protection.

These specialized SPDs are engineered to meet stringent industrial standards, ensuring high performance and reliability in harsh operating conditions. They operate by diverting excess voltage to the ground, thereby limiting the voltage supplied to an electrical device by clamping or blocking the unwanted surge. The primary applications span across manufacturing, oil and gas, energy, telecommunications, and process industries, where uninterrupted operation and protection of expensive assets are paramount. The devices protect everything from programmable logic controllers (PLCs) and industrial control panels to communication lines and data networks within these sectors.

The core benefits of deploying plug-in industrial SPDs include enhanced operational uptime, reduced maintenance costs, extended lifespan of equipment, and improved safety for personnel and assets. These benefits are significant drivers of market growth, as industries increasingly recognize the financial and operational implications of unprotected electrical systems. The escalating reliance on automation, digital control systems, and interconnected IoT devices within industrial settings further amplifies the need for comprehensive surge protection, as these sophisticated systems are particularly vulnerable to voltage transients. Regulatory compliance and insurance requirements also play a role in driving adoption.

Plug-In Industrial Surge Protection Devices Market Executive Summary

The Plug-In Industrial Surge Protection Devices Market is experiencing robust growth, primarily fueled by the accelerating pace of industrial automation, the proliferation of sensitive electronic equipment in manufacturing and process control, and the critical need to mitigate operational downtime and equipment damage. Key business trends indicate a shift towards modular and intelligent SPD solutions that offer advanced diagnostics, remote monitoring capabilities, and enhanced integration with broader industrial control systems. Manufacturers are focusing on developing products that not only provide superior protection but also offer simplified installation, reduced total cost of ownership, and compliance with evolving international safety standards. Strategic partnerships and acquisitions are common as companies seek to expand their product portfolios and geographical reach, addressing niche industrial demands and leveraging technological advancements.

Regionally, Asia Pacific is emerging as a dominant market, driven by rapid industrialization, significant investments in infrastructure development, and the expansion of manufacturing bases in countries such as China, India, and Southeast Asian nations. North America and Europe, while mature, continue to show steady growth, spurred by the modernization of existing industrial facilities, stringent regulatory frameworks for electrical safety, and the adoption of Industry 4.0 technologies. Latin America and the Middle East & Africa are demonstrating promising growth trajectories, supported by increasing foreign direct investments in industrial sectors, particularly in oil and gas, mining, and renewable energy, where robust surge protection is essential for operational continuity in often remote and challenging environments.

Segment-wise, the market is primarily categorized by type (e.g., DIN Rail Mount, Panel Mount), application (e.g., power distribution, data lines, control systems), and end-use industry. The DIN Rail Mount segment is particularly prominent due to its versatility and ease of integration into existing industrial cabinets. Within applications, the protection of power distribution systems remains critical, alongside growing demand for safeguarding data and signal lines essential for modern industrial communication networks. End-use industries such as manufacturing, energy & utilities, and oil & gas represent significant revenue generators, each requiring tailored SPD solutions to address specific voltage levels, environmental conditions, and operational requirements. The trend is towards comprehensive, multi-layered protection schemes across all these segments.

AI Impact Analysis on Plug-In Industrial Surge Protection Devices Market

Common user questions regarding AI's impact on the Plug-In Industrial Surge Protection Devices Market often revolve around how artificial intelligence can enhance the functionality, predictive capabilities, and overall efficiency of surge protection. Users are keen to understand if AI can lead to "smarter" SPDs that anticipate potential surges, optimize response times, or even contribute to the self-healing of electrical grids. Concerns also include the potential for AI-driven systems to identify root causes of transients more accurately and provide actionable insights for preventative maintenance, moving beyond simple reactive protection to proactive risk management. Expectations are high for AI to transform surge protection from a standalone device to an integrated component within intelligent energy management and industrial automation platforms.

The integration of AI into industrial surge protection devices heralds a new era of proactive and intelligent power management. AI algorithms can analyze vast amounts of real-time data from grid conditions, weather patterns, and equipment performance to predict the likelihood and severity of transient events. This predictive capability allows for more sophisticated and adaptive surge protection strategies, enabling devices to anticipate and prepare for potential surges rather than merely reacting to them. Such intelligent systems can differentiate between normal operational fluctuations and genuine surge threats, minimizing false alarms and optimizing device lifespan. This shift from reactive to predictive maintenance enhances the reliability and resilience of industrial electrical systems, reducing unexpected downtime and prolonging the life of sensitive equipment.

Furthermore, AI-powered SPDs can offer advanced diagnostic capabilities, providing detailed insights into the nature and frequency of surge events. By analyzing surge waveforms and historical data, AI can help pinpoint weaknesses in electrical infrastructure, suggest optimal placement of protection devices, and recommend maintenance schedules. This data-driven approach facilitates continuous improvement in power quality management and system robustness. The ability of AI to learn from past events and adapt its response mechanisms means that surge protection systems can become more effective over time, offering a dynamic layer of defense against evolving electrical threats. This ultimately translates into significant operational savings and improved safety within industrial environments.

- Predictive Maintenance: AI analyzes grid data and historical surge events to anticipate and prevent potential overvoltages, enabling proactive intervention.

- Enhanced Diagnostics: AI-driven systems provide granular insights into surge characteristics, aiding in root cause analysis and optimized system design.

- Adaptive Protection: AI allows SPDs to dynamically adjust protection levels based on real-time environmental conditions and equipment vulnerability.

- Remote Monitoring & Control: AI facilitates intelligent remote management of SPDs, offering real-time status updates and automated response mechanisms.

- Integration with Smart Grids: AI enables seamless communication and coordination of SPDs within broader smart grid and industrial IoT ecosystems for holistic power quality management.

DRO & Impact Forces Of Plug-In Industrial Surge Protection Devices Market

The Plug-In Industrial Surge Protection Devices Market is shaped by a complex interplay of drivers, restraints, and opportunities, all contributing to its evolving impact forces. Key drivers include the exponential growth in industrial automation and digitalization, where sensitive electronic equipment, PLCs, and SCADA systems are increasingly susceptible to voltage transients. The rising financial implications of equipment damage and operational downtime due to surges compel industries to invest in robust protection. Furthermore, increasingly stringent regulatory standards and safety requirements across various industries, coupled with the expansion of renewable energy infrastructure that often introduces grid instabilities, significantly boost the demand for reliable SPDs. The convenience and flexibility offered by plug-in designs, simplifying installation and maintenance, also act as a strong market driver.

However, the market faces several restraints. A significant challenge is the lack of universal awareness and understanding among some end-users regarding the critical importance and benefits of comprehensive surge protection, particularly in developing regions. Initial capital investment costs, though offset by long-term savings, can be a deterrent for smaller industrial players. Additionally, the presence of counterfeit or sub-standard products in the market poses a risk to equipment safety and erodes consumer trust, making it difficult for legitimate manufacturers to compete solely on quality. The complexity of selecting the right SPD for diverse industrial applications, requiring specific technical expertise, also acts as a barrier to wider adoption for less informed buyers.

Opportunities for market growth are abundant, particularly in the emerging economies experiencing rapid industrialization and infrastructure development. The increasing adoption of Industry 4.0 and IoT technologies across manufacturing, smart cities, and critical infrastructure offers new avenues for integrated, intelligent surge protection solutions. Innovations in materials, module design, and smart features (like predictive diagnostics and remote monitoring) create significant opportunities for product differentiation and market expansion. Furthermore, the growing focus on energy efficiency and grid stability, especially with the integration of distributed generation sources, positions SPDs as crucial components for maintaining power quality and system resilience. Developing customized solutions for niche applications and offering comprehensive lifecycle support can unlock substantial market potential.

Segmentation Analysis

The Plug-In Industrial Surge Protection Devices Market is comprehensively segmented to provide a detailed understanding of its diverse landscape and to cater to the specific needs of various industrial applications. These segmentations typically involve categorizing products by type, application, and end-use industry, allowing for targeted market analysis and strategic planning. Each segment reflects unique operational requirements, technical specifications, and market dynamics, offering insights into growth areas and potential challenges. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for end-users to make informed purchasing decisions based on their particular industrial demands for robust electrical protection.

The segmentation by type focuses on the form factor and installation method of the SPDs, which significantly impacts their suitability for different industrial setups. This includes devices designed for DIN Rail mounting, which are popular for their ease of integration into standard industrial control cabinets, as well as panel mount and module-based solutions that offer flexibility in high-density installations. Each type caters to different space constraints, wiring complexities, and environmental considerations within industrial facilities, impacting ease of maintenance and scalability. The choice of type often depends on the existing infrastructure and the specific protection points within a system, such as power supply inputs, data lines, or specific machinery interfaces.

Further segmentation by application highlights the diverse functions that plug-in industrial SPDs fulfill, ranging from safeguarding main power distribution systems to protecting sensitive data and communication lines. End-use industry segmentation, on the other hand, categorizes the market based on the primary sector where these devices are deployed, such as manufacturing, energy and utilities, oil and gas, telecommunications, and transportation. Each industry presents unique challenges related to voltage levels, environmental conditions, and regulatory compliance, necessitating specialized SPD solutions. This granular segmentation aids in identifying high-growth sectors and tailoring marketing and product development efforts to meet the precise demands of each industrial vertical, ensuring optimal protection and operational continuity across critical infrastructure.

- By Type:

- DIN Rail Mount SPDs

- Panel Mount SPDs

- Plug-in Module SPDs

- Hardwired SPDs (with plug-in replaceable modules)

- By Application:

- Power Distribution Systems Protection

- Data Line & Signal Protection

- Control & Instrumentation Protection

- Telecommunication Systems Protection

- LED Lighting Systems Protection

- HVAC Systems Protection

- By End-Use Industry:

- Manufacturing (Automotive, Food & Beverage, Chemicals, etc.)

- Energy & Utilities (Power Generation, Transmission, Distribution, Renewable Energy)

- Oil & Gas (Upstream, Midstream, Downstream)

- Telecommunications

- Transportation (Railways, Airports, Marine)

- Water & Wastewater Treatment

- Mining & Metals

- Building & Construction (Commercial & Industrial Facilities)

- Healthcare & Pharmaceuticals

- By Technology:

- Metal Oxide Varistor (MOV)

- Silicon Avalanche Diode (SAD) / Transient Voltage Suppressor (TVS)

- Gas Discharge Tube (GDT)

- Hybrid Technologies

- By Class/Type (IEC Standard):

- Type 1 SPDs (Main Service Entrance)

- Type 2 SPDs (Sub-Distribution Boards)

- Type 3 SPDs (Point of Use)

Value Chain Analysis For Plug-In Industrial Surge Protection Devices Market

The value chain for the Plug-In Industrial Surge Protection Devices Market begins with upstream activities focused on the procurement and processing of raw materials and components. This stage involves suppliers of critical materials such as Metal Oxide Varistors (MOVs), Silicon Avalanche Diodes (SADs), Gas Discharge Tubes (GDTs), and various conductive metals, plastics, and electronic components. Manufacturers rely heavily on a stable supply chain for these specialized parts, ensuring quality and cost-effectiveness. Research and development also plays a crucial upstream role, as innovation in surge protection technology, material science, and miniaturization directly impacts product performance and market competitiveness. Key activities include design, prototyping, and testing of new SPD modules and enclosures.

Midstream activities primarily encompass the manufacturing and assembly of the plug-in industrial SPDs. This involves highly specialized processes, including automated assembly lines for component integration, intricate wiring, enclosure fabrication, and rigorous quality control testing to meet international safety and performance standards such as IEC and UL. Manufacturers invest significantly in advanced production facilities and skilled labor to ensure the reliability and durability of their products, which are critical for industrial applications. Packaging and branding are also part of this stage, preparing the products for market distribution while adhering to industry-specific labeling and certification requirements, signifying compliance and quality to end-users.

Downstream activities involve the distribution, sales, installation, and after-sales support of plug-in industrial SPDs. Products reach end-users through a combination of direct and indirect distribution channels. Direct channels might include sales teams targeting large industrial clients, original equipment manufacturers (OEMs), or large-scale infrastructure projects. Indirect channels typically involve a network of authorized distributors, electrical wholesalers, system integrators, and value-added resellers who provide localized sales, technical support, and sometimes installation services. After-sales support, including warranties, maintenance, and technical assistance, is critical for maintaining customer satisfaction and fostering long-term relationships, especially for complex industrial installations. The effectiveness of these downstream channels directly influences market penetration and customer retention, completing the value delivery cycle.

Plug-In Industrial Surge Protection Devices Market Potential Customers

The primary potential customers for Plug-In Industrial Surge Protection Devices are diverse industrial entities that operate critical electrical and electronic systems, where uninterrupted operation and protection of valuable assets are paramount. These end-users span across various sectors, from heavy manufacturing to sophisticated data centers, all sharing the common vulnerability to transient overvoltages and the need for robust defensive measures. Organizations with substantial investments in automation, control systems, communication networks, and sensitive instrumentation are particularly strong candidates for these devices. The rising cost of downtime and equipment replacement drives their purchasing decisions, making them actively seek reliable and scalable surge protection solutions to ensure operational continuity and protect their bottom line.

Manufacturers across industries like automotive, food and beverage, chemicals, and pharmaceuticals represent a significant customer base. Their reliance on PLCs, robotic systems, and automated production lines means that even minor voltage surges can lead to costly production halts, product spoilage, or equipment damage. Similarly, the energy and utilities sector, including power generation plants, transmission and distribution networks, and renewable energy facilities (solar farms, wind turbines), are critical adopters. These environments are often exposed to severe weather conditions and grid instabilities, necessitating advanced surge protection for substations, control panels, and communication infrastructure to maintain grid stability and reliable power supply.

Other key end-users include the oil and gas industry, where remote and harsh environments demand highly resilient protection for drilling equipment, pipelines, and control systems. Telecommunications companies require SPDs to protect their vast networks, base stations, and data centers. The transportation sector, encompassing railway signaling, airport lighting, and traffic control systems, also relies heavily on these devices to ensure public safety and operational efficiency. Furthermore, water and wastewater treatment plants, mining operations, and large commercial facilities with extensive building management systems are increasingly recognizing the necessity of plug-in industrial SPDs. These diverse applications underscore the widespread need for effective surge protection across the industrial landscape, making a broad range of industrial enterprises potential customers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.35 Billion |

| Market Forecast in 2032 | USD 3.75 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eaton Corporation, Siemens AG, Schneider Electric SE, ABB Ltd., Phoenix Contact, TE Connectivity, Leviton Manufacturing Co., Inc., Raycap Corporation, Citel Inc., DEHN SE + Co KG, Emerson Electric Co., Hubbell Incorporated, Littelfuse Inc., Mersen Corporate, Weidmüller Interface GmbH & Co. KG, Tripp Lite (Eaton), Belden Inc., OBO Bettermann Holding GmbH & Co. KG, Legrand SA, Bourns Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plug-In Industrial Surge Protection Devices Market Key Technology Landscape

The technology landscape for Plug-In Industrial Surge Protection Devices is characterized by continuous innovation aimed at enhancing protection capabilities, increasing reliability, and integrating smarter functionalities. At the core of these devices are various surge-diverting components, primarily Metal Oxide Varistors (MOVs), Silicon Avalanche Diodes (SADs) or Transient Voltage Suppressors (TVS), and Gas Discharge Tubes (GDTs). MOVs are widely used for their high energy absorption capabilities and fast response times, particularly in AC power applications. SADs/TVS diodes offer extremely fast clamping and precise voltage regulation, making them ideal for protecting sensitive data and signal lines. GDTs provide robust protection against very high surge currents, often used in conjunction with other components in a multi-stage protection scheme.

Beyond these primary components, modern plug-in industrial SPDs incorporate advanced circuitry and modular designs. Many devices feature a plug-in module architecture, allowing for easy replacement of exhausted protection modules without interrupting power to the system, thereby minimizing downtime. This modularity also facilitates upgrades and maintenance. Thermal disconnect mechanisms are crucial for safety, designed to disconnect the SPD from the line if it overheats due to an excessive surge or end-of-life, preventing potential fire hazards. Indicator lights and remote signaling contacts are integrated to provide visual and remote status indications, alerting operators to the device's operational health and indicating when a module needs replacement.

The emerging technology landscape is increasingly focused on smart SPDs that integrate with industrial IoT (IIoT) and Industry 4.0 ecosystems. This includes features like predictive diagnostics, remote monitoring via network connectivity (Ethernet, Modbus, etc.), and data logging capabilities. These smart functionalities allow for real-time monitoring of power quality, detection of incipient surge conditions, and proactive maintenance, moving beyond traditional reactive protection. Miniaturization, enhanced surge current ratings, and compliance with increasingly stringent international standards (e.g., IEC 61643 series, UL 1449) are also key areas of technological development, ensuring that new devices offer superior performance and adhere to global safety benchmarks for critical industrial applications.

Regional Highlights

- North America: A mature market driven by modernization of industrial infrastructure, stringent safety regulations, and significant adoption of automation in manufacturing. The presence of key market players and a strong focus on smart grid technologies contribute to stable growth.

- Europe: Characterized by robust industrial sectors, high environmental standards, and a strong emphasis on renewable energy integration. Germany, the UK, and France are leading countries, investing heavily in industrial digitalization and requiring comprehensive surge protection for critical assets.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, infrastructure development, and expanding manufacturing capabilities in countries like China, India, Japan, and South Korea. Increased foreign investments and the proliferation of sensitive electronics drive high demand.

- Latin America: Experiencing steady growth due to investments in energy infrastructure, mining, and manufacturing sectors. Brazil and Mexico are key markets, focusing on improving industrial reliability and complying with international operational standards.

- Middle East & Africa (MEA): An emerging market with significant potential, driven by substantial investments in oil & gas, petrochemicals, utilities, and infrastructure projects. The region's exposure to harsh environmental conditions and remote operations underscores the need for durable surge protection solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plug-In Industrial Surge Protection Devices Market.- Eaton Corporation

- Siemens AG

- Schneider Electric SE

- ABB Ltd.

- Phoenix Contact

- TE Connectivity

- Leviton Manufacturing Co., Inc.

- Raycap Corporation

- Citel Inc.

- DEHN SE + Co KG

- Emerson Electric Co.

- Hubbell Incorporated

- Littelfuse Inc.

- Mersen Corporate

- Weidmüller Interface GmbH & Co. KG

- Tripp Lite (Eaton)

- Belden Inc.

- OBO Bettermann Holding GmbH & Co. KG

- Legrand SA

- Bourns Inc.

Frequently Asked Questions

Analyze common user questions about the Plug-In Industrial Surge Protection Devices market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are Plug-In Industrial Surge Protection Devices (SPDs)?

Plug-In Industrial SPDs are electrical safety components designed to protect industrial equipment, control systems, and communication networks from transient overvoltages, such as those caused by lightning or utility switching. Their plug-in design allows for easy installation and module replacement.

Why are industrial SPDs crucial for manufacturing facilities?

Industrial SPDs are crucial for manufacturing facilities to prevent costly downtime, protect sensitive automation equipment (PLCs, robotics), extend the lifespan of machinery, and ensure operational continuity, safeguarding against revenue losses from production interruptions caused by power surges.

How does a plug-in design benefit industrial applications?

The plug-in design offers significant benefits including simplified installation, quick and easy replacement of protection modules without needing to disconnect wiring, reduced maintenance time, and enhanced scalability, making them highly adaptable for diverse industrial environments.

What types of industrial equipment do these devices protect?

These devices protect a wide range of industrial equipment, including power distribution systems, data lines, control systems, instrumentation, programmable logic controllers (PLCs), SCADA systems, communication infrastructure, and LED lighting systems.

What is the expected growth trajectory of the Plug-In Industrial Surge Protection Devices Market?

The market is projected for robust growth with a CAGR of 6.7% between 2025 and 2032, driven by increasing industrial automation, digitalization, the need for enhanced equipment protection, and growing regulatory compliance demands across various industrial sectors globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager