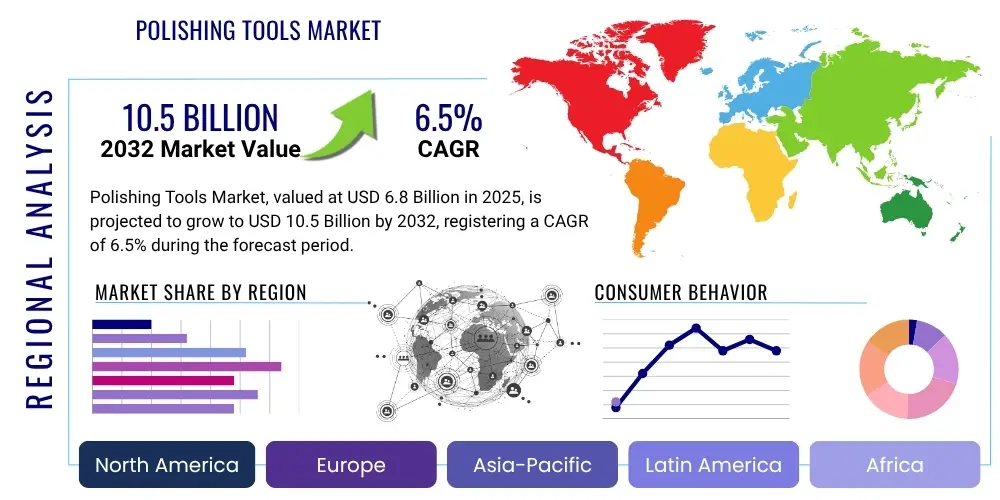

Polishing Tools Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428804 | Date : Oct, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Polishing Tools Market Size

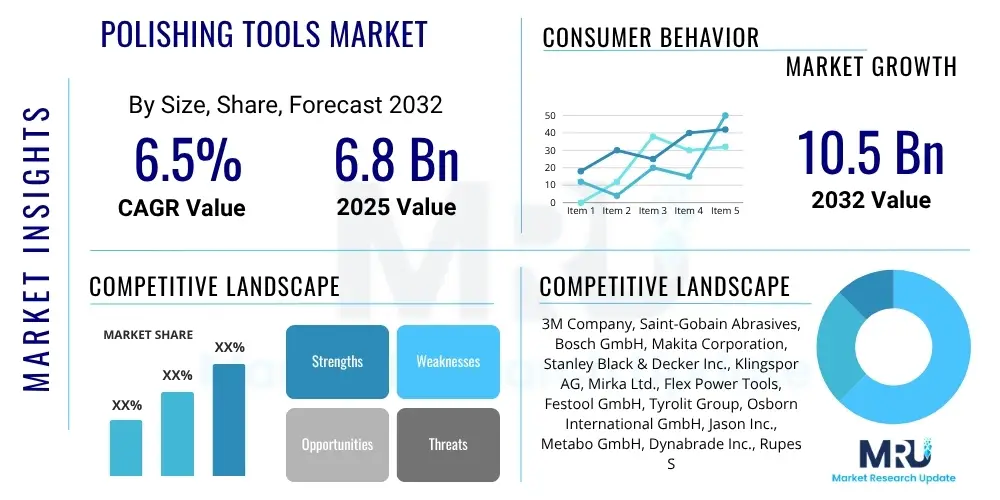

The Polishing Tools Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 6.8 Billion in 2025 and is projected to reach USD 10.5 Billion by the end of the forecast period in 2032.

Polishing Tools Market introduction

The Polishing Tools Market encompasses a diverse range of equipment and accessories designed to enhance surface finishes, remove imperfections, and achieve desired aesthetic or functional properties on various materials. These tools are crucial across numerous industries for applications ranging from coarse material removal to achieving mirror-like finishes. Products include abrasive discs, buffing pads, polishing compounds, grinders, sanders, and specialized robotic polishing systems, catering to both manual and automated processes. The market's evolution is driven by continuous innovation in abrasive technologies and machine precision, alongside increasing demand for high-quality surface treatments in manufacturing and consumer goods.

Major applications for polishing tools span critical sectors such as automotive, aerospace, metal fabrication, electronics, construction, and woodworking, as well as the rapidly growing DIY segment. In the automotive industry, polishing tools are indispensable for vehicle body finishing and paint correction, while in aerospace, they ensure critical component surface integrity. The benefits of using high-quality polishing tools are significant, including improved product aesthetics, enhanced functional performance (e.g., reduced friction, increased durability), precision material removal, and overall quality assurance. The demand for flawless surfaces in high-value products and precision components acts as a primary driving factor for market expansion, pushing manufacturers to innovate and deliver more efficient and effective solutions.

Polishing Tools Market Executive Summary

The Polishing Tools Market is experiencing robust growth, primarily fueled by global industrial expansion, particularly in automotive, aerospace, and electronics manufacturing. Key business trends include the increasing adoption of automated and robotic polishing systems to improve efficiency and consistency, alongside a strong focus on developing more sustainable and environmentally friendly abrasive materials and processes. The rise of e-commerce platforms has also democratized access to specialized polishing tools for smaller businesses and DIY enthusiasts, driving market penetration. Companies are investing in R&D to introduce innovative products that offer higher precision, durability, and user-friendliness, catering to evolving industry demands for superior surface finishes.

Regionally, Asia Pacific is poised to remain the dominant market due to rapid industrialization, burgeoning manufacturing sectors, and increasing infrastructure development in countries like China, India, and Japan. North America and Europe demonstrate mature markets characterized by high technological adoption, demand for advanced polishing solutions in precision engineering, and a strong emphasis on automation and smart manufacturing. Segment-wise, the market is seeing a shift towards powered polishing tools, especially electric and pneumatic variants, due to their efficiency and reduced manual effort. The abrasive materials segment is diversifying with the introduction of advanced composites and ceramics, offering superior performance and longevity, while end-use industries such as automotive and metalworking continue to be the largest consumers, driven by stringent quality standards and consumer expectations for high-grade finishes.

AI Impact Analysis on Polishing Tools Market

User inquiries concerning AI's impact on the Polishing Tools Market frequently revolve around the potential for increased automation, precision, and efficiency, as well as concerns regarding job displacement and the complexity of integration. Common questions include how AI can enhance the accuracy of polishing processes, if autonomous polishing systems will become standard, the role of AI in predictive maintenance for polishing equipment, and its contribution to quality control. Users express expectations for AI to minimize human error, reduce cycle times, and optimize material usage, leading to significant cost savings and improved product consistency. There is also interest in AI's capability to analyze complex surface data and adapt polishing strategies in real-time, addressing the challenges of varied material properties and intricate geometries.

The integration of artificial intelligence is fundamentally transforming the polishing tools sector by enabling unprecedented levels of control and optimization. AI algorithms can analyze vast datasets from sensors on polishing machines, including force, vibration, and visual feedback, to precisely control toolpaths, pressure, and speed. This capability allows for highly accurate and consistent finishes, especially for complex or delicate components where manual polishing is prone to inconsistencies. Furthermore, AI-driven systems can learn from previous polishing operations, continuously improving their performance and adapting to new materials or geometries with minimal human intervention, thereby reducing waste and rework.

- Enhanced Precision and Consistency: AI-powered vision systems and feedback loops ensure ultra-fine control over polishing parameters, leading to superior and uniform surface finishes.

- Predictive Maintenance: AI algorithms analyze machine operational data to predict potential failures, optimizing maintenance schedules and reducing downtime for polishing equipment.

- Autonomous Polishing Robotics: AI enables robots to independently plan and execute complex polishing tasks, adapting to part variations and minimizing human oversight.

- Optimized Material Removal: Machine learning models can determine the optimal abrasive types and process parameters for specific materials and desired finishes, reducing material waste.

- Real-time Quality Control: AI-driven inspection systems can detect surface defects during or immediately after polishing, ensuring high-quality output without manual inspection bottlenecks.

- Process Optimization: AI helps in developing intelligent polishing strategies, learning from each operation to refine techniques and improve overall efficiency and effectiveness.

- Reduced Human Error and Fatigue: Automation guided by AI minimizes the need for manual, repetitive tasks, leading to fewer errors and a safer working environment.

- Customization and Flexibility: AI-driven systems can quickly reconfigure for different part geometries and finish requirements, boosting manufacturing flexibility and mass customization capabilities.

DRO & Impact Forces Of Polishing Tools Market

The Polishing Tools Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all shaped by various impact forces. Key drivers include the ever-increasing demand for high-quality surface finishes across a multitude of industries, such as automotive, aerospace, and electronics, where aesthetic appeal and functional performance are paramount. The continuous growth of industrial manufacturing worldwide, coupled with the adoption of automation and robotic solutions, further fuels the demand for advanced polishing tools capable of precise and consistent results. Furthermore, the development of new, high-performance materials often necessitates specialized polishing techniques, driving innovation in tool technology. The rising consumer expectations for durable and visually appealing products also indirectly contribute to market growth, as manufacturers strive to meet these standards.

Despite the strong drivers, the market faces several restraints. The high initial capital investment required for advanced polishing machinery, especially robotic systems, can be a barrier for smaller enterprises. The need for skilled labor to operate and maintain sophisticated polishing tools and processes also presents a challenge, as there is often a shortage of adequately trained personnel. Environmental concerns related to dust generation, waste disposal from abrasive materials, and the use of certain chemicals in polishing compounds are prompting stricter regulations and pushing manufacturers towards more sustainable but potentially costlier solutions. Additionally, the fluctuating prices of raw materials, such as abrasives and metals used in tool construction, can impact manufacturing costs and product pricing, leading to market instability.

Opportunities within the polishing tools market are abundant, particularly in emerging economies where industrialization and infrastructure development are accelerating, creating new demand centers. The growing trend towards customization and personalization across various consumer and industrial products opens avenues for specialized and versatile polishing solutions. Manufacturers are also exploring opportunities in developing more eco-friendly polishing techniques and biodegradable compounds to address environmental concerns and meet evolving regulatory standards. Furthermore, the integration of smart technologies, such as IoT and AI, into polishing tools for enhanced monitoring, control, and predictive maintenance presents a significant growth avenue. Strategic collaborations between tool manufacturers and end-use industries to develop tailor-made solutions also represent a substantial opportunity for market expansion and innovation, particularly as industries seek greater efficiency and precision in their finishing processes.

Segmentation Analysis

The Polishing Tools Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation allows for targeted analysis of different product types, materials, end-use applications, power sources, and distribution channels, reflecting the varied needs of industrial and consumer markets. By dissecting the market along these lines, stakeholders can identify specific growth areas, competitive landscapes, and evolving consumer preferences, enabling more informed strategic decisions. The intricate nature of polishing processes demands a granular view, differentiating between general-purpose tools and highly specialized equipment for niche applications.

- By Product Type:

- Abrasive Discs

- Buffing Pads

- Polishing Compounds/Pastes

- Grinding Wheels

- Sanding Belts

- Brushes

- Specialized Polishing Systems (e.g., robotic arms, vibratory polishers)

- By Material:

- Aluminum Oxide

- Silicon Carbide

- Diamond

- Ceramic

- Zirconia Alumina

- Non-woven (Nylon, Polyester)

- Cotton/Wool

- By Power Source:

- Electric

- Pneumatic

- Cordless (Battery-Powered)

- Manual

- By End-Use Industry:

- Automotive

- Aerospace and Defense

- Metal Fabrication

- Electronics and Semiconductors

- Medical Devices

- Construction

- Woodworking and Furniture

- Jewelry and Watchmaking

- Marine

- DIY and Consumer

- By Distribution Channel:

- Online Retail

- Offline Retail (Specialty Stores, Hardware Stores)

- Direct Sales

- Distributors/Wholesalers

Value Chain Analysis For Polishing Tools Market

The value chain for the Polishing Tools Market begins with upstream activities focused on the procurement and processing of raw materials. This includes suppliers of abrasive grains such as aluminum oxide, silicon carbide, and industrial diamonds, as well as manufacturers of backing materials like paper, cloth, and non-woven fabrics. Key components such as electric motors, pneumatic mechanisms, battery cells, and housing materials (plastics, metals) are also sourced at this stage. These raw material and component suppliers play a crucial role in determining the quality, performance, and cost-effectiveness of the final polishing tools. Innovation in material science, particularly in developing more durable and efficient abrasives, directly impacts the competitive edge of tool manufacturers. Rigorous quality control at this initial stage is essential to ensure the reliability and longevity of the polishing tools.

Midstream activities involve the manufacturing and assembly of the polishing tools. This encompasses the bonding of abrasive grains to backings to create discs, belts, and wheels, as well as the fabrication and assembly of powered polishing machines (grinders, sanders, buffers). Manufacturers invest heavily in R&D to enhance tool ergonomics, power efficiency, durability, and safety features. The production process also includes the formulation of polishing compounds and pastes, requiring expertise in chemical engineering. Post-manufacturing, the downstream segment of the value chain focuses on bringing these products to market. This involves a network of distribution channels, including direct sales to large industrial clients, partnerships with wholesalers and distributors who cater to a broader range of businesses, and increasingly, online retail platforms that serve both professional and DIY customers. Effective logistics and supply chain management are critical to ensure timely delivery and market reach.

The distribution channel landscape for polishing tools is bifurcated into direct and indirect methods. Direct sales typically involve manufacturers selling high-value, specialized polishing systems directly to large industrial end-users like automotive plants or aerospace manufacturers, often accompanied by installation, training, and after-sales support. This channel allows for direct feedback and customized solutions. Indirect channels are more pervasive, utilizing a network of distributors, wholesalers, and retailers (both brick-and-mortar hardware stores and e-commerce platforms). Distributors act as intermediaries, stocking a wide range of products from various manufacturers and supplying them to smaller businesses, workshops, and individual consumers. The growth of e-commerce has significantly expanded the reach of polishing tools, allowing manufacturers to access a global customer base with reduced overheads, while also increasing competition among brands and offering customers greater choice and price transparency. The choice of distribution strategy often depends on the product's complexity, target market, and volume of sales.

Polishing Tools Market Potential Customers

The Polishing Tools Market serves a vast and diverse customer base, primarily segmented by end-use industry and application. Industrial sectors represent the largest segment of potential customers, with manufacturers requiring high-precision tools for finishing their products. The automotive industry stands as a major buyer, utilizing polishing tools for vehicle body paint correction, engine component finishing, and restoration work, demanding robust and efficient solutions. Similarly, the aerospace and defense sectors rely on highly specialized polishing tools to ensure the integrity and performance of critical aircraft and spacecraft components, where surface finish directly impacts safety and operational efficiency. Metal fabrication shops, from small workshops to large-scale operations, are constant users of polishing tools for deburring, grinding, and achieving specific surface textures on metal parts before further processing or final assembly. These industries prioritize durability, precision, and consistent performance from their tools.

Beyond heavy industry, the electronics and semiconductor sectors represent a rapidly growing segment of potential customers, requiring ultra-fine polishing capabilities for silicon wafers, circuit boards, and other sensitive components to meet stringent quality and performance standards. The medical device industry also relies heavily on polishing tools for finishing surgical instruments, implants, and other medical equipment, where biocompatibility and smooth surfaces are critical for patient safety. Construction and woodworking industries use polishing tools for preparing surfaces, finishing wood, stone, and concrete, and restoration projects. The jewelry and watchmaking sectors require very fine and precise polishing tools to achieve high aesthetic finishes on precious metals and gemstones. Additionally, the DIY (Do-It-Yourself) and consumer markets form a significant and expanding customer segment, driven by homeowners and hobbyists seeking tools for home improvement, automotive detailing, and various craft projects. This segment often seeks user-friendly, versatile, and affordable polishing solutions, fueling demand for portable and cordless options. Each of these customer groups has distinct needs regarding tool power, abrasive type, ergonomics, and application specificity, making the market highly segmented and competitive.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.8 Billion |

| Market Forecast in 2032 | USD 10.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Saint-Gobain Abrasives, Bosch GmbH, Makita Corporation, Stanley Black & Decker Inc., Klingspor AG, Mirka Ltd., Flex Power Tools, Festool GmbH, Tyrolit Group, Osborn International GmbH, Jason Inc., Metabo GmbH, Dynabrade Inc., Rupes S.p.A., Ingersoll Rand, Atlas Copco, Chicago Pneumatic, Tormek AB, Dremel (Robert Bosch Tool Corporation) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polishing Tools Market Key Technology Landscape

The Polishing Tools Market is undergoing significant technological transformation, driven by the relentless pursuit of higher precision, efficiency, and automation in surface finishing processes. Traditional manual polishing methods are increasingly being augmented or replaced by advanced mechanical and digital solutions. Robotic polishing systems, integrated with Computer Numerical Control (CNC) technology, are becoming paramount, offering unparalleled consistency and repeatability, especially for complex geometries and large-volume production. These systems often feature multi-axis arms capable of intricate movements, reducing human error and improving throughput. The development of advanced abrasive materials, such as micro-abrasives and specialized ceramic grains, is also a critical technological area, enabling superior surface finishes with reduced material removal and longer tool life. Nanotechnology is beginning to play a role, with nano-abrasives offering ultra-fine polishing capabilities for sensitive surfaces like semiconductors and optical components.

Further technological advancements include the integration of smart sensors and the Internet of Things (IoT) into polishing tools and machinery. These sensors collect real-time data on parameters such as pressure, temperature, vibration, and material removal rates, providing operators and automated systems with critical feedback for process optimization. This data can be analyzed by AI and machine learning algorithms to predict tool wear, identify potential defects, and recommend adjustments, thereby enhancing operational efficiency and predictive maintenance. Laser polishing and ultrasonic polishing represent cutting-edge, non-contact methods that offer precise and heat-affected zone-free finishing for delicate or hard-to-reach surfaces, expanding the range of materials and applications for polishing. Moreover, the focus on ergonomics and user safety in powered hand tools continues, with innovations in vibration dampening, dust extraction systems, and lightweight designs improving the user experience and reducing occupational hazards. The interplay of material science, robotics, and digital technologies is collectively reshaping the landscape of the polishing tools market, pushing the boundaries of what is achievable in surface finishing.

Regional Highlights

The global Polishing Tools Market exhibits distinct regional dynamics, influenced by industrialization levels, technological adoption rates, and economic development. North America, encompassing the United States and Canada, is a mature market characterized by high industrial automation and a strong emphasis on precision manufacturing, particularly in the automotive, aerospace, and medical device sectors. The region benefits from significant R&D investments, leading to the adoption of advanced robotic polishing systems and smart tools. Demand is driven by stringent quality standards and the need for efficient production processes, fostering innovation in both abrasive materials and polishing machinery. The presence of major automotive manufacturers and an established industrial base ensures a consistent demand for high-performance polishing solutions, making it a key region for premium products and technological advancements.

Europe, with economic powerhouses like Germany, the UK, France, and Italy, represents another significant market. The region’s strong manufacturing base, especially in automotive, metalworking, and luxury goods, drives the demand for high-quality surface finishes. European countries are at the forefront of adopting sustainable manufacturing practices, leading to a focus on environmentally friendly polishing compounds and energy-efficient tools. Precision engineering and craftsmanship are highly valued, pushing manufacturers to offer tools that deliver superior aesthetic and functional results. Regulatory frameworks promoting workplace safety also influence product design, favoring tools with advanced dust extraction and ergonomic features. The market here is characterized by a blend of established players and specialized manufacturers catering to niche industrial applications.

Asia Pacific (APAC) stands as the largest and fastest-growing market for polishing tools, primarily due to rapid industrialization, burgeoning manufacturing sectors, and infrastructure development in countries such as China, India, Japan, and South Korea. This region serves as a global manufacturing hub for electronics, automotive components, and consumer goods, necessitating a vast array of polishing solutions. The increasing disposable income and urbanization also contribute to a growing DIY market. Latin America and the Middle East and Africa (MEA) are emerging markets, showing steady growth driven by expanding industrial bases, construction activities, and increasing investment in manufacturing capabilities. While still developing, these regions present significant future opportunities for polishing tool manufacturers as their economies mature and industrial output rises.

- North America: High adoption of automated and robotic polishing systems; strong demand from automotive, aerospace, and medical device industries; focus on precision manufacturing and advanced abrasive technologies.

- Europe: Significant market driven by automotive, metalworking, and luxury goods sectors; strong emphasis on precision engineering, sustainability, and adherence to safety regulations.

- Asia Pacific (APAC): Largest and fastest-growing market fueled by extensive manufacturing base (electronics, automotive), rapid industrialization, and increasing DIY market in countries like China, India, and Japan.

- Latin America: Growing industrial and construction sectors; increasing demand for industrial and consumer-grade polishing tools as manufacturing capabilities expand.

- Middle East and Africa (MEA): Emerging market with rising infrastructure development, growing automotive assembly, and manufacturing investments, driving demand for basic to intermediate polishing solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polishing Tools Market.- 3M Company

- Saint-Gobain Abrasives

- Bosch GmbH

- Makita Corporation

- Stanley Black & Decker Inc.

- Klingspor AG

- Mirka Ltd.

- Flex Power Tools

- Festool GmbH

- Tyrolit Group

- Osborn International GmbH

- Jason Inc.

- Metabo GmbH

- Dynabrade Inc.

- Rupes S.p.A.

- Ingersoll Rand

- Atlas Copco

- Chicago Pneumatic

- Tormek AB

- Dremel (Robert Bosch Tool Corporation)

Frequently Asked Questions

What is the projected growth rate of the Polishing Tools Market?

The Polishing Tools Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032.

Which industries are the primary consumers of polishing tools?

Key industries include automotive, aerospace, metal fabrication, electronics, medical devices, construction, and woodworking, driven by the need for high-quality surface finishes.

How is AI impacting the Polishing Tools Market?

AI is significantly impacting the market by enabling enhanced precision, automation through robotics, predictive maintenance, real-time quality control, and optimized material removal processes.

What are the main drivers for market growth?

Primary drivers include increasing demand for superior surface finishes, global industrial expansion, growing adoption of automation, and advancements in material processing technologies.

Which region holds the largest share in the Polishing Tools Market?

Asia Pacific (APAC) currently holds the largest market share and is expected to exhibit the fastest growth, owing to its rapid industrialization and extensive manufacturing base.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager