Polybutadiene Elastomers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427865 | Date : Oct, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Polybutadiene Elastomers Market Size

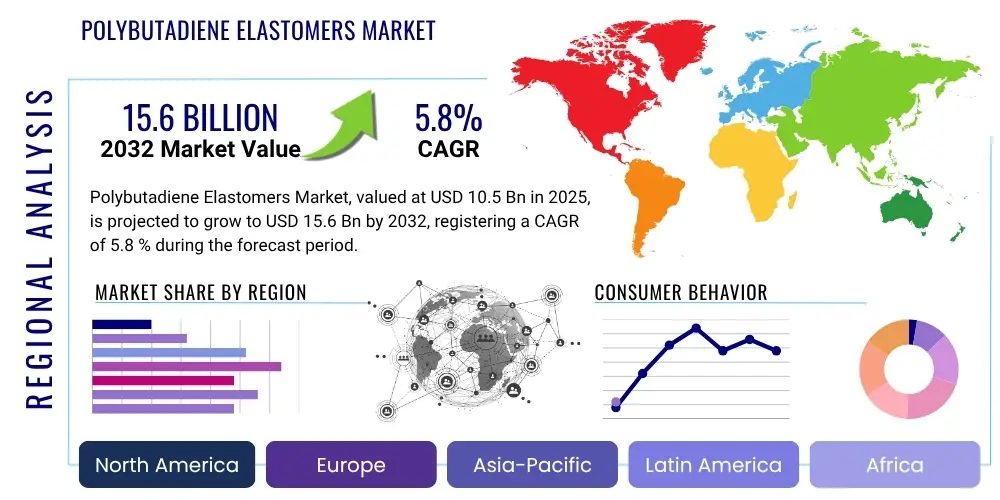

The Polybutadiene Elastomers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 10.5 Billion in 2025 and is projected to reach USD 15.6 Billion by the end of the forecast period in 2032.

Polybutadiene Elastomers Market introduction

Polybutadiene Elastomers (PBR) constitute a critical segment within the synthetic rubber industry, primarily derived from the polymerization of 1,3-butadiene monomer. This versatile synthetic rubber is highly valued for its exceptional properties, including high elasticity, superior abrasion resistance, low heat buildup, and excellent low-temperature flexibility. These attributes make PBR an indispensable material across numerous industrial applications, contributing significantly to product longevity and performance. Its unique microstructure, predominantly cis-1,4 configuration, imparts specific performance characteristics that are difficult to replicate with other materials.

The major applications of Polybutadiene Elastomers span a broad spectrum of industries, with the automotive sector being the foremost consumer. In tire manufacturing, PBR is extensively utilized in tire treads, sidewalls, and inner liners to enhance wear resistance, reduce rolling resistance, and improve overall vehicle fuel efficiency. Beyond tires, it finds significant application as an impact modifier for plastics, particularly in High Impact Polystyrene (HIPS) and Acrylonitrile Butadiene Styrene (ABS), where it dramatically improves the toughness and durability of these polymers. Other notable applications include conveyor belts, golf ball cores, shoe soles, and various industrial rubber goods requiring high resilience and abrasion resistance.

The market for Polybutadiene Elastomers is primarily driven by the robust growth of the global automotive industry, particularly in emerging economies, which fuels the demand for high-performance and fuel-efficient tires. Furthermore, the increasing consumption of plastics in construction, packaging, and consumer goods sectors, coupled with the rising need for impact-resistant materials, provides a substantial impetus for PBR market expansion. The inherent benefits of PBR, such as extended product life and enhanced functional performance in end-use applications, continue to underpin its sustained demand and market growth.

Polybutadiene Elastomers Market Executive Summary

The Polybutadiene Elastomers market is characterized by dynamic business trends driven by technological advancements and shifting industry demands. Key business trends include a sustained focus on research and development to produce specialized PBR grades with enhanced performance attributes, such as improved wet grip or lower rolling resistance, often through advanced catalyst systems. Furthermore, strategic collaborations, mergers, and acquisitions are common as companies seek to expand their geographic footprint, diversify product portfolios, and gain competitive advantages. There is also an increasing emphasis on sustainable manufacturing practices and the development of bio-based PBR to address environmental concerns and regulatory pressures.

From a regional perspective, the Asia-Pacific region continues to dominate the Polybutadiene Elastomers market, primarily due to the expansive automotive manufacturing bases in countries like China, India, and Japan, coupled with rapid industrialization and infrastructural development. North America and Europe, while mature markets, exhibit a strong demand for high-performance and specialty PBR grades, driven by stringent regulatory standards and a focus on premium applications. Latin America and the Middle East & Africa are emerging as significant growth regions, propelled by industrial expansion and increasing vehicle production.

Segmentation trends reveal that cis-polybutadiene rubber (CBR) remains the largest segment by product type, owing to its superior properties for tire applications. However, high-vinyl PBR and trans-PBR are gaining traction for niche applications requiring specific performance characteristics. In terms of application, the tire segment maintains its preeminent position, but plastic modification is experiencing robust growth due to the increasing adoption of engineering plastics. The market is also witnessing a gradual shift towards more specialized PBR types and customized solutions to meet the evolving demands of various end-use industries, highlighting a trend towards product differentiation and value addition across the supply chain.

AI Impact Analysis on Polybutadiene Elastomers Market

Users are keenly interested in understanding how Artificial Intelligence (AI) can revolutionize the Polybutadiene Elastomers market. The prevalent questions revolve around AI's capacity to enhance operational efficiency, optimize complex manufacturing processes, improve supply chain resilience, and accelerate innovation in new material development. There is a strong expectation that AI will play a transformative role in predictive maintenance, quality control, demand forecasting, and resource management, ultimately leading to cost reductions, increased productivity, and the creation of more advanced and sustainable PBR products. Users anticipate that AI integration will provide data-driven insights to address market volatility and drive strategic decision-making throughout the PBR value chain.

- AI-driven predictive maintenance optimizes machinery uptime and reduces operational costs in PBR manufacturing plants.

- Enhanced supply chain optimization through AI algorithms for raw material sourcing, inventory management, and logistics, minimizing disruptions and waste.

- Accelerated research and development of novel PBR formulations by leveraging AI for materials discovery, property prediction, and simulation.

- Improved accuracy in demand forecasting using AI and machine learning models, leading to better production planning and reduced overstocking.

- Automated quality control systems employing computer vision and AI for real-time defect detection and consistency monitoring during PBR production.

- Energy consumption optimization in polymerization processes through AI-powered process control, contributing to sustainability efforts.

- Personalized customer solutions and technical support facilitated by AI analytics, tailoring PBR products to specific application requirements.

- Risk assessment and mitigation strategies developed with AI to manage volatile raw material prices and market fluctuations more effectively.

- Enhanced worker safety through AI-monitored environments and predictive analytics for potential hazards in manufacturing facilities.

- Development of smart manufacturing facilities for PBR with interconnected systems and real-time data analysis, driving Industry 4.0 adoption.

DRO & Impact Forces Of Polybutadiene Elastomers Market

The Polybutadiene Elastomers market is predominantly driven by the robust expansion of the automotive industry, particularly the increasing global demand for high-performance tires that offer improved fuel efficiency, extended tread life, and enhanced safety features. Additionally, the growing utilization of PBR as an impact modifier in various plastic applications, such as high-impact polystyrene (HIPS) and acrylonitrile butadiene styrene (ABS) for consumer goods, packaging, and construction, further propels market growth. The intrinsic properties of PBR, including its excellent abrasion resistance and low hysteresis, make it a preferred choice in these critical end-use sectors.

Despite the strong demand, the market faces significant restraints, primarily stemming from the volatile prices of its key raw material, butadiene, which is a petrochemical derivative. Fluctuations in crude oil prices directly impact butadiene costs, leading to instability in PBR production expenses and pricing strategies for manufacturers. Furthermore, growing environmental concerns regarding synthetic rubber production and disposal, coupled with stringent regulatory frameworks concerning volatile organic compound (VOC) emissions, present challenges for market players, necessitating investments in cleaner production technologies.

Opportunities for market growth lie in the continuous innovation and development of specialty PBR grades with tailored properties for specific applications, such as bio-based PBR, which addresses sustainability concerns and opens new market avenues. Expansion into emerging economies with rapidly growing industrial and automotive sectors also offers significant potential. The market is further influenced by impact forces such as technological advancements in polymerization processes, the evolving landscape of sustainable chemistry, and the dynamic interplay of global economic conditions and trade policies that shape supply chain dynamics and market demand.

Segmentation Analysis

The Polybutadiene Elastomers market is comprehensively segmented to reflect the diverse applications and end-use requirements, allowing for a granular understanding of market dynamics. This segmentation helps in analyzing consumption patterns, identifying key growth areas, and understanding competitive landscapes across different product types, application areas, and end-use industries. Each segment is characterized by unique performance demands and market drivers, influencing product development and strategic investments by manufacturers.

- By Type:

- Cis-Polybutadiene Rubber (CBR)

- High-Vinyl Polybutadiene Rubber (HVBR)

- Trans-Polybutadiene Rubber (TPR)

- Low-Cis Polybutadiene Rubber (LCBR)

- Solution Polybutadiene Rubber (S-PBR)

- Emulsion Polybutadiene Rubber (E-PBR)

- By Application:

- Tires

- Passenger Car Tires

- Commercial Vehicle Tires (Truck & Bus Tires)

- Two-Wheeler Tires

- Off-the-Road (OTR) Tires

- Plastic Modification

- High Impact Polystyrene (HIPS)

- Acrylonitrile Butadiene Styrene (ABS)

- Styrene-Butadiene-Styrene (SBS) Block Copolymers

- Industrial Rubber Goods

- Conveyor Belts

- Hoses

- Gaskets and Seals

- Rollers

- Mountings

- Footwear (Shoe Soles)

- Golf Balls

- Adhesives and Sealants

- Other Applications (e.g., Wire and Cable, Battery Separators)

- Tires

- By End-Use Industry:

- Automotive

- Construction

- Consumer Goods

- Industrial

- Sports and Leisure

- Packaging

- Electrical and Electronics

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Polybutadiene Elastomers Market

The value chain for the Polybutadiene Elastomers market commences with the upstream extraction and processing of crude oil, from which the primary feedstock, butadiene monomer, is derived through steam cracking processes. Several major chemical companies specialize in the production and purification of butadiene, which then serves as a crucial raw material for PBR manufacturers. This initial stage is highly capital-intensive and susceptible to global energy price fluctuations, directly impacting the cost structure of the entire value chain.

The core manufacturing stage involves the polymerization of butadiene into various grades of PBR, utilizing sophisticated catalytic processes such as Ziegler-Natta, Neodymium, or Lithium-based systems, depending on the desired microstructural properties and end-use performance. PBR producers often invest heavily in research and development to optimize these processes, enhance product quality, and develop specialty grades. These manufacturers then supply PBR in bales or pellets to downstream processors.

Further downstream, the PBR is processed by various industries. Tire manufacturers are the largest consumers, compounding PBR with other rubbers, carbon black, and chemicals to create tire treads, sidewalls, and other components. Plastic compounders incorporate PBR as an impact modifier into polymers like HIPS and ABS. Other end-users include manufacturers of industrial rubber goods, footwear components, and golf balls. Distribution channels typically involve direct sales to large original equipment manufacturers (OEMs) and major industrial clients, while smaller enterprises and specialized applications are often served through a network of chemical distributors and traders, encompassing both direct and indirect routes to market.

Polybutadiene Elastomers Market Potential Customers

The Polybutadiene Elastomers market serves a diverse range of potential customers across various industries, primarily those requiring materials with high elasticity, excellent abrasion resistance, and robust impact strength. The largest segment of end-users comprises tire manufacturers, including global automotive tire brands for passenger cars, commercial vehicles, and specialty vehicles, as PBR is essential for enhancing tire longevity and performance. These customers continually seek PBR grades that contribute to fuel efficiency and improved wet grip, driven by stringent automotive regulations and consumer demands.

Beyond the tire industry, a substantial customer base exists within the plastics sector, particularly among manufacturers of high-impact polystyrene (HIPS) and acrylonitrile butadiene styrene (ABS). These companies utilize PBR as a crucial impact modifier to impart toughness and durability to their polymer products, which are then used in applications ranging from consumer electronics and packaging to construction materials. The demand from this segment is growing due to the increasing adoption of engineering plastics in various high-performance applications.

Additionally, the market includes manufacturers of industrial rubber goods such as conveyor belts, hoses, gaskets, and seals, where the resilience and wear resistance of PBR are highly valued. Producers of sports equipment, specifically golf balls, also constitute a significant customer group, leveraging PBR's rebound properties. Footwear manufacturers, particularly for shoe soles and heels, also represent a consistent demand source for PBR due to its durability and comfort-enhancing characteristics. This broad customer base underscores the material's versatility and indispensable role in modern industrial and consumer products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 10.5 Billion |

| Market Forecast in 2032 | USD 15.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Lanxess AG, Sinopec Group, Reliance Industries Limited, Trinseo S.A., Kumho Petrochemical Co. Ltd., UBE Corporation, LG Chem, Versalis S.p.A., Braskem S.A., JSR Corporation, Sibur Holding, Goodyear Tire & Rubber Company, Sumitomo Chemical Co. Ltd., Asahi Kasei Corporation, ZEON Corporation, Synthos S.A., TSRC Corporation, PetroChina Company Limited, Kuraray Co. Ltd., Michelin |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polybutadiene Elastomers Market Key Technology Landscape

The Polybutadiene Elastomers market is heavily reliant on sophisticated polymerization technologies that dictate the microstructure and, consequently, the performance characteristics of the final rubber product. The most prevalent technology involves solution polymerization, utilizing various catalyst systems to achieve specific PBR grades. Ziegler-Natta catalysts, particularly those based on cobalt or nickel, are widely employed for producing high-cis PBR, which is valued for its high resilience and low heat buildup, making it ideal for tire applications. These catalyst systems enable precise control over the stereoregularity of the polymer chain, significantly impacting tire rolling resistance and wear.

Further technological advancements include the use of neodymium-based catalysts, which allow for even higher cis-1,4 content and narrow molecular weight distribution, resulting in PBR with superior dynamic properties and better processing characteristics. Lithium-based catalysts are crucial for producing high-vinyl PBR, which enhances wet grip and provides a balance of properties important for specific tire and plastic modification applications. Emulsion polymerization, while less common for general-purpose PBR, is utilized for specific grades where different molecular architectures or grafting capabilities are required.

Current technological trends are focused on developing new generations of catalyst systems that offer greater versatility, enabling the synthesis of tailor-made PBR with a broader range of microstructures and functionalities. This includes efforts to improve polymerization efficiency, reduce energy consumption, and minimize environmental impact. Additionally, there is significant research into incorporating bio-based butadiene monomers to create more sustainable PBR, aligning with global efforts towards green chemistry and circular economy principles. Innovations in process control and automation, often leveraging AI and machine learning, are also key to enhancing manufacturing consistency, optimizing yields, and reducing production costs across the PBR industry.

Regional Highlights

- Asia Pacific (APAC): Dominates the Polybutadiene Elastomers market, driven by the significant growth of the automotive industry, particularly in countries like China, India, Japan, and South Korea. Rapid industrialization, increasing infrastructure development, and a large manufacturing base for tires and plastics contribute to its leading position. The region is a major hub for both PBR production and consumption.

- Europe: A mature market characterized by stringent environmental regulations and a strong emphasis on high-performance and specialty PBR grades. Countries such as Germany, France, and Italy are key consumers, with demand primarily from the automotive sector for premium and ultra-high-performance tires, as well as sophisticated industrial applications.

- North America: Represents a substantial market for Polybutadiene Elastomers, primarily fueled by a robust automotive industry and increasing demand for advanced materials in plastic modification and industrial applications in the USA and Canada. The region focuses on technological innovation and sustainable product development.

- Latin America: An emerging market experiencing steady growth, largely due to expanding automotive production and industrialization in countries like Brazil and Mexico. Increased foreign investments and infrastructure projects are boosting the demand for PBR in various applications, including tires and construction-related products.

- Middle East & Africa (MEA): A growing market with increasing investment in infrastructure, manufacturing, and automotive industries. While smaller in market share compared to other regions, MEA presents significant future growth opportunities as industrial bases expand and regional consumption of tires and plastics rises.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polybutadiene Elastomers Market.- Lanxess AG

- Sinopec Group

- Reliance Industries Limited

- Trinseo S.A.

- Kumho Petrochemical Co. Ltd.

- UBE Corporation

- LG Chem

- Versalis S.p.A.

- Braskem S.A.

- JSR Corporation

- Sibur Holding

- Goodyear Tire & Rubber Company

- Sumitomo Chemical Co. Ltd.

- Asahi Kasei Corporation

- ZEON Corporation

- Synthos S.A.

- TSRC Corporation

- PetroChina Company Limited

- Kuraray Co. Ltd.

- Michelin

Frequently Asked Questions

Analyze common user questions about the Polybutadiene Elastomers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of Polybutadiene Elastomers?

Polybutadiene Elastomers (PBR) are primarily used in tire manufacturing (treads, sidewalls), as impact modifiers for plastics like HIPS and ABS, and in various industrial rubber goods such as conveyor belts and shoe soles.

What factors are driving the growth of the PBR market?

The PBR market's growth is largely driven by the expanding global automotive industry, increasing demand for high-performance and fuel-efficient tires, and the rising utilization of PBR in plastic modification across various end-use sectors.

What are the main restraints impacting the Polybutadiene Elastomers market?

Key restraints include the volatility of raw material prices (butadiene), which is linked to crude oil costs, and growing environmental concerns alongside stringent regulations regarding synthetic rubber production and emissions.

How is Artificial Intelligence (AI) influencing the Polybutadiene Elastomers market?

AI is impacting the PBR market by enhancing production efficiency through predictive maintenance, optimizing supply chains, accelerating R&D for new formulations, improving demand forecasting accuracy, and automating quality control processes.

Which geographical region holds the largest share in the Polybutadiene Elastomers market?

The Asia Pacific region currently holds the largest market share for Polybutadiene Elastomers, primarily due to its robust automotive manufacturing base and rapid industrialization in key countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager