Polyolefin Shrink Film Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427333 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Polyolefin Shrink Film Market Size

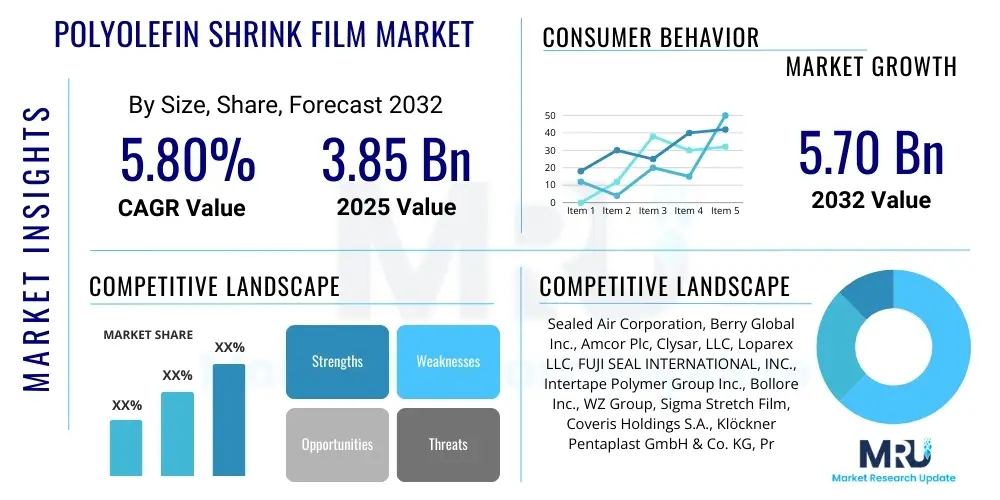

The Polyolefin Shrink Film Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 3.85 billion in 2025 and is projected to reach USD 5.70 billion by the end of the forecast period in 2032. This substantial growth is primarily driven by the escalating demand for secure, aesthetically pleasing, and cost-effective packaging solutions across various industrial sectors, alongside the burgeoning e-commerce landscape which necessitates robust protective packaging.

Polyolefin Shrink Film Market introduction

Polyolefin shrink film is a versatile packaging material known for its strength, clarity, and exceptional shrink performance. It is produced from synthetic polymers, primarily polypropylene and polyethylene, offering a superior alternative to traditional PVC shrink films due to its enhanced durability, resistance to temperature fluctuations, and absence of chlorine, making it a more environmentally conscious choice in certain applications. This film is widely utilized across a diverse range of industries for bundling, protective wrapping, and tamper-evident sealing, providing both product integrity and visual appeal.

The primary applications of polyolefin shrink film span numerous consumer and industrial sectors. In the food and beverage industry, it is extensively used for packaging fresh produce, baked goods, frozen foods, and multipacks of beverages, ensuring freshness, hygiene, and extended shelf life. Beyond consumables, it serves the industrial sector for protecting electronic components, hardware, and automotive parts from dust, moisture, and damage during transit and storage. Its application in consumer goods is equally significant, covering everything from toys, stationery, and cosmetics to textiles and pharmaceutical products, offering tamper protection and enhancing product presentation on retail shelves.

Key benefits driving the adoption of polyolefin shrink film include its high clarity, which allows for excellent product visibility, and its robust tear and puncture resistance, which offers superior protection. Furthermore, its ability to conform tightly to product shapes provides a sleek, professional finish, reducing package volume and weight. The films versatility in heat sealing, coupled with its excellent memory retention, ensures a consistent and durable wrap. These attributes, combined with its cost-effectiveness in high-speed packaging operations, position polyolefin shrink film as a preferred solution for modern packaging requirements, catering to both aesthetic and functional demands.

Polyolefin Shrink Film Market Executive Summary

The Polyolefin Shrink Film Market is experiencing robust expansion, propelled by significant business trends such as the relentless growth of the e-commerce sector and the increasing demand for sustainable packaging solutions. E-commerce platforms require durable and secure packaging to withstand complex logistics chains, a need perfectly met by the strength and protective qualities of polyolefin films. Simultaneously, a global shift towards eco-friendlier practices is driving innovations in polyolefin formulations, with a focus on recyclable, bio-based, and lighter-gauge options. Furthermore, advancements in film extrusion technologies are enabling the production of thinner, yet stronger films, reducing material usage and enhancing cost-efficiency for manufacturers.

Regional trends indicate a pronounced growth in Asia-Pacific, driven by rapid industrialization, burgeoning manufacturing sectors, and increasing disposable incomes that fuel consumer goods consumption. Countries like China and India are at the forefront of this expansion, witnessing significant investments in packaging infrastructure and an escalating demand for packaged food and non-food items. North America and Europe, while mature markets, are characterized by a strong emphasis on technological innovation and sustainability, leading to the adoption of advanced polyolefin films with enhanced barrier properties and improved recyclability. Latin America and the Middle East & Africa are also emerging as significant growth frontiers, influenced by developing retail landscapes and rising consumer awareness regarding packaged products.

Segment-wise, the market is primarily driven by the food and beverage industry, which remains the largest end-user due to stringent food safety regulations and the need for extended shelf life. Within this segment, cross-linked polyolefin films are gaining traction for applications requiring superior strength and clarity, particularly for irregularly shaped or heavy items. The industrial and consumer goods segments are also contributing substantially, propelled by the need for tamper-evident and protective packaging for a diverse array of products. Innovations in film thickness and specialized formulations catering to specific product requirements, such as anti-fog properties for fresh produce or UV protection for outdoor goods, are continually shaping segment dynamics and fostering new growth avenues within the polyolefin shrink film market.

AI Impact Analysis on Polyolefin Shrink Film Market

The integration of Artificial Intelligence (AI) and machine learning within the polyolefin shrink film market is poised to revolutionize various aspects, from raw material procurement and film production to quality control and supply chain management. Common user questions regarding AIs influence highlight a strong interest in how these technologies can optimize operational efficiency, enhance product quality, and contribute to sustainability efforts. Users are keen to understand AIs potential in predicting demand fluctuations, automating production lines for reduced waste, and even accelerating the development of novel film formulations. The expectation is for AI to usher in an era of smarter manufacturing, predictive maintenance, and highly responsive supply chains, ultimately leading to significant cost savings and improved environmental footprints for market players.

- AI-driven predictive maintenance optimizes machinery uptime by forecasting equipment failures, reducing unplanned downtime in film extrusion and packaging lines.

- Machine learning algorithms enhance quality control through real-time defect detection during film production, ensuring consistent film thickness, clarity, and strength.

- AI-powered demand forecasting and inventory management systems minimize material waste and optimize raw material procurement, leading to cost efficiencies and reduced environmental impact.

- Robotics and AI-vision systems automate packaging processes, improving speed, accuracy, and labor efficiency in applying polyolefin shrink films.

- AI assists in developing sustainable film formulations by simulating material properties and optimizing polymer blends for enhanced recyclability or bio-based content.

- Advanced analytics identify patterns in energy consumption during manufacturing, enabling optimization for reduced power usage and lower operational costs.

- AI-enhanced supply chain visibility and logistics optimization improve delivery efficiency and reduce carbon emissions associated with transportation.

DRO & Impact Forces Of Polyolefin Shrink Film Market

The Polyolefin Shrink Film Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, shaped by various impactful forces. A primary driver is the continuous expansion of the global packaging industry, fueled by population growth, urbanization, and rising disposable incomes, all contributing to increased consumption of packaged goods. The rapid proliferation of e-commerce, demanding robust and secure packaging for diverse products, further amplifies the need for high-performance shrink films. Additionally, the food and beverage sector’s stringent requirements for hygiene, freshness, and extended shelf life necessitate reliable packaging solutions, where polyolefin films excel due to their protective properties and barrier capabilities. The aesthetic appeal and tamper-evident features of these films also serve as strong selling points for consumer goods.

Despite these growth drivers, the market faces notable restraints. Volatility in the prices of raw materials, primarily crude oil derivatives such as polyethylene and polypropylene resins, directly impacts production costs and profit margins for film manufacturers. Furthermore, increasing environmental concerns regarding plastic waste and the growing regulatory pressure to reduce single-use plastics pose a significant challenge. This scrutiny often leads to public perception issues and a push towards alternative packaging materials or stricter recycling mandates, which can affect market adoption. The availability and fluctuating costs of alternative packaging solutions, such as paperboard, flexible pouches, or biodegradable wraps, also present competitive pressures for polyolefin shrink films.

Opportunities within the market largely stem from advancements in material science and sustainable practices. The development of thinner-gauge films that maintain strength and performance, along with the innovation of recyclable, compostable, or bio-based polyolefin alternatives, presents avenues for market expansion and improved environmental profiles. Emerging markets in Asia-Pacific, Latin America, and Africa offer substantial untapped potential due to their developing retail infrastructure and growing middle-class populations. Technological advancements in film co-extrusion and printing allow for specialized films with enhanced barrier properties, anti-fog features, or unique branding capabilities, opening doors to niche applications and premium markets. The emphasis on smart packaging, incorporating elements like RFID tags or QR codes, also creates future growth prospects for integrated solutions within the polyolefin shrink film ecosystem.

Segmentation Analysis

The Polyolefin Shrink Film market is meticulously segmented to provide a granular understanding of its diverse components, allowing for targeted strategies and accurate market assessments. These segments are primarily defined by film type, application area, end-use industry, and thickness, each reflecting specific characteristics and demand drivers. Analyzing these segments helps in identifying key growth pockets, understanding competitive dynamics, and forecasting future trends, providing invaluable insights for stakeholders seeking to optimize their product portfolios and market penetration strategies across different consumer and industrial landscapes.

- By Type:

- Cross-Linked Polyolefin (CLPOF): Known for superior strength, puncture resistance, and clarity; ideal for irregular shapes and heavy items.

- Non-Cross-Linked Polyolefin (NCLPOF): Offers good clarity and strength; generally more cost-effective for standard packaging needs.

- By Application:

- Food & Beverage Packaging: Meat, poultry, seafood, baked goods, frozen foods, dairy, beverages.

- Industrial Packaging: Electronics, hardware, automotive parts, machinery.

- Consumer Goods Packaging: Toys, sporting goods, stationery, cosmetics, textiles.

- Pharmaceutical & Healthcare Packaging: Medical devices, over-the-counter drugs, sterile packaging.

- Other Applications: Agricultural products, graphic arts, logistics and e-commerce bundling.

- By End-Use Industry:

- Food Processing Industry: For direct food contact and primary packaging.

- Beverage Industry: For multipacking bottles and cans.

- Personal Care & Cosmetics Industry: For tamper evidence and presentation.

- Pharmaceutical Industry: For sterile and secure packaging of medical products.

- E-commerce & Logistics: For bundling and protective shipping.

- Other Manufacturing Industries: Including electronics, automotive, and general consumer goods.

- By Thickness:

- Up to 15 Micron: Lightweight films for delicate items and cost-efficient wrapping.

- 15-25 Micron: Standard thickness for a wide range of products, balancing protection and material usage.

- Above 25 Micron: Heavy-duty films for robust protection of industrial goods and challenging applications.

Polyolefin Shrink Film Market Value Chain Analysis

The value chain of the Polyolefin Shrink Film Market is a complex network involving multiple stages, from raw material sourcing to the final end-user application. It begins with the upstream segment, dominated by petrochemical companies that produce the foundational polymers—polyethylene and polypropylene resins, along with various additives like UV stabilizers, anti-fog agents, and slip additives. These raw material suppliers are crucial as they determine the initial cost structure and the base properties of the film. Their pricing strategies, production capacities, and innovation in polymer science directly impact the overall markets competitiveness and the performance characteristics of the ultimate shrink film products. Efficiency in this segment is critical for maintaining supply stability and managing cost fluctuations, which are often tied to global oil prices.

The midstream of the value chain involves film manufacturers and converters who transform these resins into polyolefin shrink films through advanced extrusion processes, such as blown film or cast film extrusion, followed by stretching and sometimes cross-linking. These companies invest heavily in R&D to develop films with enhanced properties like improved clarity, puncture resistance, reduced thickness, and better shrink characteristics. They also perform printing, slitting, and other converting operations to customize films according to specific customer requirements. The technological sophistication and operational efficiency of these film producers are pivotal in delivering high-quality, cost-effective shrink films that meet diverse market demands, from intricate food packaging to robust industrial applications.

The downstream segment encompasses the distribution channels and end-users. Polyolefin shrink films reach their target markets through a mix of direct sales, involving direct engagement between film manufacturers and large-scale industrial customers, and indirect channels, primarily through a network of distributors, wholesalers, and packaging solution providers. These intermediaries play a vital role in reaching smaller businesses, providing specialized packaging advice, and offering inventory management services. The ultimate end-users include manufacturers in the food and beverage, consumer goods, industrial, pharmaceutical, and e-commerce sectors, who integrate these films into their automatic and semi-automatic packaging lines. The effectiveness of the distribution network significantly influences market penetration and ensures that the diverse needs of the end-user base are efficiently met, making logistics and customer service critical components of the value chain.

Polyolefin Shrink Film Market Potential Customers

Potential customers for polyolefin shrink film are diverse, encompassing a wide array of industries that prioritize product protection, aesthetic presentation, and efficient packaging solutions. At the forefront are companies within the food and beverage sector, ranging from large-scale food processors, bakeries, and dairies to beverage bottling plants. These customers rely on polyolefin films for packaging fresh produce, frozen foods, multi-packs of drinks, and baked goods, primarily for hygiene, tamper evidence, and extending shelf life. Their purchasing decisions are heavily influenced by film clarity, barrier properties, and compliance with food safety regulations, as well as the films performance on high-speed packaging lines to maintain operational efficiency and cost-effectiveness.

Beyond consumables, a significant customer base exists within the consumer goods and industrial manufacturing sectors. Manufacturers of electronics, hardware, automotive parts, and machinery utilize polyolefin shrink films to protect their products from dust, moisture, and physical damage during storage and transit, ensuring products reach consumers in pristine condition. Similarly, brands in cosmetics, personal care, toys, sporting goods, and stationery industries adopt these films for their attractive finish, tamper-evident features, and branding opportunities. The e-commerce and logistics sectors are also rapidly emerging as major customers, utilizing shrink films for bundling products, protecting individual items during shipping, and providing a final layer of security and presentation before delivery to the end consumer. These customers seek films that offer excellent puncture resistance, good memory, and consistent performance across varied environmental conditions to safeguard packages throughout the supply chain.

Furthermore, the pharmaceutical and healthcare industries represent a specialized yet critical segment of potential customers. Here, polyolefin shrink films are employed for packaging medical devices, over-the-counter medicines, and sterile products, where tamper evidence, hygiene, and product integrity are paramount. The film’s ability to provide a clean, secure wrap that meets regulatory standards is a key driver for adoption in this sector. These diverse customer groups, each with unique operational requirements and product characteristics, collectively drive the demand for a broad spectrum of polyolefin shrink film types and specifications, continuously pushing manufacturers to innovate and customize their offerings to cater to evolving market needs.

Polyolefin Shrink Film Market Key Technology Landscape

The Polyolefin Shrink Film markets technological landscape is characterized by continuous innovation in film extrusion, material science, and processing techniques, aimed at enhancing film performance, sustainability, and production efficiency. At the core are advanced extrusion technologies, including blown film extrusion and cast film extrusion, which are continuously refined to produce thinner, stronger, and more consistent films. Co-extrusion, a key process, allows for the creation of multi-layer films with tailored properties, combining different polyolefin resins or incorporating barrier materials to achieve specific functionalities such as enhanced moisture or oxygen barrier, anti-fog, or UV protection. These advancements enable manufacturers to precisely control film thickness, shrink characteristics, and mechanical properties, catering to diverse application demands from delicate food items to robust industrial goods.

Further technological developments revolve around film modification and post-processing. Cross-linking technology, whether by electron beam or chemical methods, is crucial for producing high-strength, high-clarity polyolefin films that offer superior tear and puncture resistance, making them ideal for challenging packaging applications and irregular product shapes. Surface treatments, such as corona or plasma treatment, improve printability and adhesion for lamination, allowing for vibrant branding and enhanced visual appeal. In terms of sustainability, innovations in resin formulations are leading to the development of bio-based polyolefins derived from renewable resources and advanced recycling technologies that facilitate the reprocessing of post-consumer polyolefin shrink films into new products, addressing the growing demand for circular economy solutions within the packaging sector.

The integration of smart manufacturing principles, often leveraging Industry 4.0 technologies, is also becoming a prominent feature in the polyolefin shrink film production landscape. This includes automated control systems for extrusion lines, real-time quality monitoring using sensors and vision systems to detect defects and ensure consistent film properties, and data analytics for process optimization and predictive maintenance. These technologies not only improve production efficiency and reduce waste but also enable greater customization and responsiveness to market demands. Moreover, research into advanced additives, such as anti-block agents, slip agents, and anti-static compounds, continues to refine film processability and end-use performance, ensuring that polyolefin shrink films remain a leading choice for modern packaging needs.

Regional Highlights

- Asia-Pacific: This region dominates the polyolefin shrink film market, driven by rapid industrialization, burgeoning manufacturing sectors in countries like China, India, and Southeast Asian nations, and a massive consumer base. The proliferation of e-commerce, expanding food and beverage industries, and increasing disposable incomes contribute significantly to market growth. Investment in packaging infrastructure and a growing awareness of modern packaging solutions are key drivers.

- North America: A mature market characterized by high demand for sophisticated and high-performance packaging. The region exhibits strong growth in e-commerce, food processing, and consumer goods sectors. There is a significant emphasis on sustainable packaging solutions, driving innovation in recyclable and reduced-gauge polyolefin films, particularly in the United States and Canada.

- Europe: This region is a major market, distinguished by stringent environmental regulations and a strong focus on sustainability. Countries like Germany, the UK, France, and Italy are investing in advanced polyolefin film technologies that offer enhanced recyclability and reduced environmental footprint. The food industry, pharmaceuticals, and industrial packaging segments are key demand generators.

- Latin America: An emerging market experiencing steady growth due to urbanization, increasing retail penetration, and rising consumer spending. Brazil, Mexico, and Argentina are leading the regional market, driven by expanding food and beverage industries and a developing manufacturing sector. Economic stability and foreign investments are fostering market expansion.

- Middle East & Africa: This region is characterized by nascent but rapidly growing markets, particularly in the GCC countries and South Africa. Investments in infrastructure, diversification of economies, and growth in the food, beverage, and personal care sectors are stimulating demand for polyolefin shrink films. The region presents significant untapped potential for future growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polyolefin Shrink Film Market.- Sealed Air Corporation

- Berry Global Inc.

- Amcor Plc (formerly Bemis Company Inc.)

- Clysar, LLC

- Loparex LLC

- FUJI SEAL INTERNATIONAL, INC.

- Intertape Polymer Group Inc.

- Bollore Inc.

- WZ Group (Shanghai Wenzhou Co., Ltd.)

- Sigma Stretch Film (a division of Sigma Plastics Group)

- Coveris Holdings S.A.

- Klöckner Pentaplast GmbH & Co. KG

- Profol Group

- Taghleef Industries LLC

- Bonset America Corporation

Frequently Asked Questions

What is Polyolefin Shrink Film?

Polyolefin shrink film is a highly versatile and durable plastic film made from synthetic polymers, typically polypropylene and polyethylene. It is known for its excellent clarity, high strength, and resistance to tearing and punctures. When heated, the film shrinks tightly around products, providing a secure, tamper-evident, and aesthetically pleasing package that protects against dust, moisture, and damage during handling and transportation. Unlike PVC, it does not contain chlorine, making it a preferred choice for various applications.

What are the primary advantages of using Polyolefin Shrink Film?

The key advantages of polyolefin shrink film include its superior strength and tear resistance, offering robust product protection. It provides high clarity for excellent product visibility and a professional, glossy finish, enhancing shelf appeal. The film is food-safe, suitable for direct food contact, and exhibits good shrink characteristics at lower temperatures, leading to energy savings in packaging processes. Furthermore, it is more environmentally friendly than PVC, being recyclable in certain streams, and offers excellent tamper evidence and versatility across various packaging machinery.

In which industries is Polyolefin Shrink Film most commonly used?

Polyolefin shrink film finds extensive application across numerous industries. It is predominantly used in the food and beverage sector for packaging fresh produce, baked goods, frozen foods, and multipacks of beverages due to its protective and hygienic properties. Other major applications include consumer goods packaging (toys, cosmetics, stationery, textiles), industrial packaging (electronics, hardware, automotive parts), pharmaceutical and healthcare packaging (medical devices, medicines), and increasingly, in the e-commerce and logistics sectors for bundling and protective shipping of diverse products.

Is Polyolefin Shrink Film recyclable?

Yes, polyolefin shrink film is generally considered recyclable, particularly in areas with established infrastructure for collecting and processing #2 (HDPE) or #4 (LDPE) plastics, depending on its specific composition. Efforts are ongoing in the industry to enhance its recyclability, including the development of mono-material films and improved collection schemes. Consumers are encouraged to check local recycling guidelines and labels on packaging to ensure proper disposal. The trend towards sustainable packaging solutions is driving innovation in creating more easily recyclable and bio-based polyolefin formulations.

What factors are driving the growth of the Polyolefin Shrink Film Market?

Several key factors are propelling the growth of the Polyolefin Shrink Film Market. The rapid expansion of the global e-commerce industry, which demands secure and protective packaging, is a primary driver. Continuous growth in the food and beverage sector, coupled with increasing demand for packaged goods due to urbanization and changing consumer lifestyles, further boosts market expansion. Additionally, the films versatility, cost-effectiveness, superior product protection, and aesthetic appeal, along with ongoing innovations in sustainable and high-performance film technologies, are significant contributors to its market growth.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager