Polyvinyl Alcohol Films Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428233 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Polyvinyl Alcohol Films Market Size

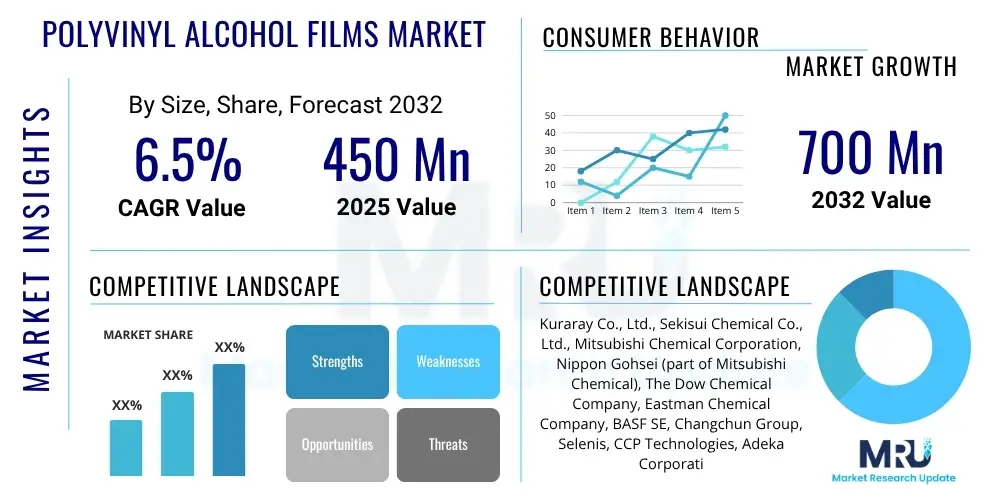

The Polyvinyl Alcohol Films Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 450 Million in 2025 and is projected to reach USD 700 Million by the end of the forecast period in 2032.

Polyvinyl Alcohol Films Market introduction

Polyvinyl Alcohol (PVA) films represent a cutting-edge category of synthetic polymer films, meticulously engineered for a myriad of applications due to their exceptional physical and chemical properties. Derived primarily from the hydrolysis of polyvinyl acetate, PVA films are distinguished by their notable water solubility, impressive gas barrier capabilities, and inherent biodegradability, positioning them as a critical material in the global drive towards sustainable solutions. These films offer a unique combination of strength, flexibility, and chemical resistance, making them indispensable across various industrial and consumer sectors where conventional plastics may fall short of environmental or functional requirements. The versatility of PVA allows for its formulation into films with varying dissolution rates, thicknesses, and mechanical strengths, catering to highly specific end-user demands, from rapid-dissolving consumer product packaging to long-lasting agricultural applications.

Major applications for PVA films span across several pivotal industries. In the consumer goods sector, their water solubility makes them ideal for individual dose packaging of detergents, dishwashing tablets, and other household chemicals, providing convenience and precise dosing while eliminating plastic waste. The agricultural industry leverages PVA films for seed tapes, pesticide encapsulation, and controlled release of fertilizers, enhancing efficiency and minimizing environmental impact. The medical field utilizes these films for disposable laundry bags in hospitals to reduce contamination risks and in advanced drug delivery systems. Furthermore, PVA films find utility in the textile industry as sizing agents and embroidery backings, and in specialized electronic applications due to their optical clarity and barrier properties. The breadth of these applications underscores the material's adaptability and growing importance in modern manufacturing and product design.

The market for Polyvinyl Alcohol films is propelled by several robust driving factors. A paramount influence is the escalating global imperative for environmentally sustainable packaging and materials, which positions biodegradable PVA films as a compelling alternative to non-degradable plastics. The increasing consumer preference for convenience-oriented products, such as unit-dose laundry pods, directly correlates with the demand for water-soluble packaging solutions. Ongoing advancements in polymer science and film manufacturing technologies continue to improve the performance characteristics of PVA films, including enhanced barrier properties and tunable dissolution rates, thereby expanding their applicability and addressing previous limitations. Moreover, supportive regulatory frameworks promoting the use of eco-friendly materials in many regions further stimulate market adoption, solidifying PVA films' role in addressing contemporary environmental and functional challenges across diverse end-use industries.

Polyvinyl Alcohol Films Market Executive Summary

The Polyvinyl Alcohol Films Market is currently experiencing a period of significant growth and dynamic evolution, shaped by prominent business trends that prioritize sustainability, efficiency, and innovative product development. Industry players are increasingly investing in research and development to create advanced PVA film formulations that boast superior barrier properties against oxygen and moisture, alongside precisely controllable dissolution rates and enhanced mechanical strength. This focus on product differentiation and functional enhancement is a direct response to rising consumer expectations for high-performance, eco-friendly materials. Furthermore, there is a clear trend towards strategic collaborations and partnerships across the value chain, aimed at optimizing raw material sourcing, streamlining production processes, and expanding market reach into emerging application areas. These concerted efforts are not only driving technological advancements but also fostering greater market penetration and competitiveness for PVA film manufacturers globally.

Regionally, the market exhibits varied but generally upward trends. The Asia Pacific region stands out as a dominant force, characterized by rapid industrial expansion, burgeoning consumer markets, and substantial investments in both manufacturing capacities and sustainable technologies, particularly in countries like China, India, and Japan. These economies are witnessing an increasing adoption of PVA films in both consumer goods and agricultural sectors. North America and Europe, while more mature markets, are demonstrating robust growth propelled by stringent environmental regulations, a high level of consumer awareness regarding ecological impacts, and a strong preference for innovative, biodegradable packaging solutions. The demand in these regions is also bolstered by the sophisticated healthcare and specialty chemical industries. Latin America and the Middle East & Africa are emerging as promising markets, driven by developing infrastructure, rising disposable incomes, and a gradual shift towards modern industrial practices that incorporate sustainable materials.

From a segmentation perspective, the market's growth is heavily influenced by specific end-use applications. The packaging segment, particularly for unit-dose detergents and agrochemicals, continues to hold a substantial market share, acting as a primary catalyst for demand due to convenience and environmental benefits. The agricultural sector is poised for significant expansion, driven by innovations in controlled-release fertilizers and pesticides that utilize PVA films to enhance crop yield and reduce chemical runoff. The medical and pharmaceutical industries are also growing rapidly, adopting PVA films for sterile packaging and advanced drug delivery systems, leveraging their non-toxicity and solubility properties. Moreover, the textile and electronics sectors are contributing to diversified demand for PVA films in niche applications, collectively illustrating a broad and resilient growth trajectory for the Polyvinyl Alcohol Films Market across its various segments.

AI Impact Analysis on Polyvinyl Alcohol Films Market

The integration of Artificial Intelligence (AI) into the Polyvinyl Alcohol Films Market is rapidly becoming a pivotal factor, addressing both operational efficiencies and strategic advancements. Common inquiries from users and industry stakeholders frequently center on how AI can revolutionize traditional manufacturing paradigms, enhance product innovation cycles, and optimize complex supply chain networks. There is significant interest in AI's capacity to move beyond conventional data analysis, offering predictive capabilities for market demand fluctuations, material performance under various conditions, and even anticipating potential bottlenecks in production. Stakeholders are particularly keen to understand how AI-driven insights can lead to more sustainable manufacturing practices, such as reducing waste, optimizing energy consumption, and improving the overall environmental footprint of PVA film production, aligning with global sustainability goals.

Moreover, the dialogue often extends to AI's role in accelerating the discovery and development of novel PVA film formulations. Researchers are exploring how machine learning algorithms can analyze vast datasets of polymer properties, synthesis pathways, and application performance to predict ideal material compositions for specific functional requirements, such such as enhanced solubility, barrier properties, or mechanical strength. This predictive modeling capability holds the promise of significantly shortening R&D timelines and reducing the costs associated with traditional trial-and-error experimentation. Furthermore, AI's application in quality control is a critical area of focus, with automated inspection systems capable of real-time defect detection and process adjustment, ensuring consistent product quality and minimizing manufacturing variations that can impact end-use performance.

- AI-driven predictive analytics significantly optimize raw material procurement and demand forecasting, leading to reduced inventory costs and minimized material waste throughout the supply chain.

- Machine learning algorithms enhance quality control processes during film manufacturing, enabling real-time identification of defects and precise adjustments to production parameters, ensuring consistent product quality.

- AI accelerates research and development for novel PVA film formulations by analyzing complex material data, predicting optimal compositions, and simulating performance, thereby shortening innovation cycles.

- Smart manufacturing systems integrated with AI optimize energy consumption and operational efficiency on production lines by dynamically adjusting machinery settings and identifying areas for process improvement.

- AI-powered supply chain optimization tools provide real-time visibility, track logistics, and forecast potential disruptions, improving delivery timelines and overall supply chain resilience for PVA films.

DRO & Impact Forces Of Polyvinyl Alcohol Films Market

The Polyvinyl Alcohol Films Market operates under the strong influence of several dynamic Drivers, Restraints, and Opportunities (DRO), which collectively shape its growth trajectory and competitive landscape. A primary driver is the accelerating global shift towards environmental sustainability and biodegradable materials. As industries and consumers become increasingly aware of the ecological impact of conventional plastics, the demand for eco-friendly alternatives like PVA films, known for their water solubility and biodegradability, is surging across packaging, agriculture, and medical applications. This momentum is further amplified by the escalating popularity of convenience-driven, single-dose consumer products, such as laundry and dishwashing pods, where PVA films offer precise dosing and seamless integration into washing cycles, eliminating plastic waste and enhancing user experience. Moreover, continuous technological advancements in PVA film manufacturing, leading to improved barrier properties, customizable dissolution rates, and enhanced mechanical strength, are broadening their applicability and appeal, fueling market expansion.

Despite significant drivers, the market also faces notable restraints. One key challenge is the relatively higher production cost of PVA films when compared to conventional petroleum-based plastics. This cost differential can sometimes hinder adoption, particularly in price-sensitive emerging markets or bulk applications where cost-effectiveness is paramount. Furthermore, the volatility of raw material prices, primarily polyvinyl acetate and its precursors, can introduce significant uncertainty into the supply chain and impact manufacturers' profitability, making long-term strategic planning more complex. The market also contends with the availability of alternative biodegradable and compostable polymers, which, while sharing sustainability goals, may offer different performance characteristics or cost structures, leading to competitive pressure and requiring continuous innovation from PVA film producers to maintain market share and differentiation.

Opportunities for growth within the Polyvinyl Alcohol Films Market are abundant and diversified. The increasing investment in research and development promises to unlock new formulations and functionalities, such as PVA films with improved resistance to specific chemicals or enhanced performance in extreme temperatures, thereby opening doors to novel niche applications. The expansion into emerging economies, characterized by rapidly developing consumer bases and industrial sectors, presents significant untapped potential for market penetration and volume growth. Furthermore, the push for circular economy principles and advanced recycling technologies could further integrate PVA films into broader sustainable material ecosystems, enhancing their long-term viability and appeal. The continuous pursuit of innovation in areas such as edible films, smart packaging, and advanced agricultural solutions positions PVA films as a versatile material with substantial future growth prospects, leveraging their unique environmental and functional attributes to address evolving global demands.

Segmentation Analysis

The Polyvinyl Alcohol Films Market is meticulously segmented to offer a detailed and nuanced understanding of its intricate structure and diverse functional areas. This comprehensive segmentation allows industry stakeholders to identify specific market niches, evaluate competitive landscapes, and formulate highly targeted strategies, moving beyond a monolithic view of the market. The classification typically encompasses key dimensions such as the film's application, the end-use industry it serves, the specific type or composition of the film, and its physical attributes like thickness. Each segment and its corresponding sub-segments are influenced by distinct market drivers, consumer behaviors, technological requirements, and regulatory environments, collectively painting a granular picture of market dynamics and potential growth vectors. By dissecting the market into these components, a more precise assessment of demand patterns, supply chain dependencies, and innovation opportunities becomes achievable, facilitating informed decision-making for manufacturers, investors, and policymakers alike.

The strategic importance of this segmentation lies in its ability to highlight areas of high growth and emerging trends. For instance, the packaging application segment is undergoing rapid innovation, particularly in unit-dose formats for consumer goods, driven by convenience and sustainability mandates. Similarly, within the end-use industry categories, the healthcare and pharmaceutical sectors are demonstrating significant potential for specialized PVA films that meet stringent safety and efficacy standards for drug delivery and medical disposables. Understanding these detailed segments allows companies to tailor their product offerings, marketing efforts, and distribution networks to specific customer needs, thereby maximizing market penetration and profitability. It also aids in forecasting future demand shifts as industries evolve and new applications for PVA films emerge, underpinning long-term strategic planning and resource allocation. This systematic approach to market segmentation provides the critical analytical framework needed to navigate the complexities and capitalize on the opportunities within the Polyvinyl Alcohol Films ecosystem.

- Application:

- Packaging: Encompassing individual dose packaging for laundry detergents, dishwasher tablets, agrochemicals (e.g., pesticides, fertilizers), and increasingly, food packaging solutions requiring barrier properties and biodegradability.

- Agriculture: Includes applications such as seed tapes and seed pods to optimize planting, controlled release films for pesticides and fertilizers, and protective films for crop cultivation.

- Medical: Utilized in disposable laundry bags for infectious materials in hospitals, water-soluble wrappers for medical instruments, and as components in advanced drug delivery systems and patches.

- Textile: Employed as sizing agents for yarns to improve weaving efficiency, temporary support backings for embroidery, and in specialty non-woven applications.

- Electronics: Used as optical films for display screens, protective layers for sensitive components, and in printed circuit board manufacturing due to its barrier properties.

- Others: Broad category including applications in water treatment chemicals packaging, concrete additives packaging in construction, and specialized industrial releases.

- End-Use Industry:

- Consumer Goods: Primarily for household cleaning products (detergents, dishwashing) and personal care items in unit-dose formats.

- Agriculture: Directly serving farming communities and agrochemical companies for crop protection and enhancement.

- Healthcare & Pharmaceuticals: Catering to hospitals, clinics, and pharmaceutical manufacturers for medical packaging and drug delivery.

- Textile: Supporting textile mills and apparel manufacturers with processing aids and temporary materials.

- Electronics: Serving electronics manufacturers for display and component protection.

- Construction: For packaging of various construction chemicals and admixtures.

- Water Treatment: Utilized in packaging of water treatment chemicals and flocculants.

- Film Type:

- Water-Soluble Films: The most common type, designed to dissolve completely in water at specific temperatures, critical for unit-dose applications.

- Non-Water-Soluble Films (High Barrier Films): Specialized PVA films modified to provide superior gas barrier properties without dissolving in water, used in specific food packaging or industrial applications.

- Heat Sealable Films: Formulations that allow for easy sealing through heat, essential for automated packaging processes.

- Thickness:

- Less than 30 Microns: Typically used for lighter packaging, rapid dissolution, and delicate applications.

- 30-70 Microns: A common range for laundry pods and general-purpose water-soluble packaging, balancing strength and dissolution.

- Above 70 Microns: Employed for more robust applications requiring higher strength, slower dissolution, or specific industrial uses.

Value Chain Analysis For Polyvinyl Alcohol Films Market

The value chain of the Polyvinyl Alcohol Films Market is an intricate network spanning from the foundational chemical synthesis to the final end-user application, highlighting critical stages of transformation and distribution. The upstream segment primarily involves the production and supply of key raw materials. This process typically begins with petrochemical derivatives, notably crude oil and natural gas, which are processed into ethylene. Ethylene is then reacted with acetic acid to produce vinyl acetate monomer (VAM), the fundamental building block. VAM is subsequently polymerized to polyvinyl acetate (PVAc) resin, which undergoes hydrolysis to yield polyvinyl alcohol (PVA) resin. Major chemical companies, often integrated petrochemical giants, play a crucial role in this initial phase, ensuring the availability and quality of these foundational polymers. The efficiency and cost-effectiveness at this upstream stage significantly influence the overall market dynamics, as raw material costs represent a substantial portion of the final product's expense, impacting profitability margins throughout the chain.

Moving downstream, the PVA resin then enters the midstream segment, which is dominated by film manufacturers. Here, PVA resin is processed using various advanced techniques such as extrusion, casting, or blowing to produce films of diverse specifications. This stage involves significant technological expertise to control parameters like film thickness, molecular weight, degree of hydrolysis, and incorporation of plasticizers or additives, all of which dictate the final film's properties—including its water solubility, mechanical strength, gas barrier characteristics, and heat sealability. Film manufacturers continuously invest in R&D to innovate new film formulations and optimize production processes, aiming for enhanced performance, improved sustainability profiles, and cost-efficient manufacturing. This segment is characterized by specialized equipment and stringent quality control measures to ensure that the produced films meet the precise requirements of their intended end-use applications, which can range from ultra-thin, fast-dissolving films to more robust, high-barrier variants.

The final stages of the value chain involve the distribution channels and the ultimate consumption by end-users. Distribution can occur through both direct and indirect channels. Direct distribution involves PVA film manufacturers selling directly to large industrial customers, such as major consumer goods companies, agrochemical producers, or pharmaceutical firms, often through long-term contracts and tailored supply agreements. Indirect distribution leverages a network of specialized distributors, wholesalers, and sometimes retailers to reach a broader and more fragmented customer base, including smaller manufacturers, regional agricultural suppliers, or specialized medical product assemblers. These distributors often provide value-added services like inventory management, technical support, and customized cutting or slitting of films. The effectiveness of these distribution networks is critical for market penetration and timely delivery of products. The end-users, ranging from household consumers using laundry pods to farmers employing seed tapes, represent the final link, where the functional and environmental benefits of PVA films are realized, completing the comprehensive value chain cycle.

Polyvinyl Alcohol Films Market Potential Customers

The Polyvinyl Alcohol Films Market targets a broad and diverse spectrum of potential customers across various industrial and consumer sectors, each drawn to the unique attributes of PVA films, particularly their water solubility, biodegradability, and excellent barrier properties. One of the most significant customer segments lies within the Fast-Moving Consumer Goods (FMCG) industry, specifically manufacturers of household cleaning products. These companies are avid buyers of PVA films for creating innovative unit-dose packaging for laundry detergents, dishwasher tablets, and other concentrated cleaning agents. The convenience, pre-measured dosage, and environmental benefit of reducing plastic waste offered by PVA films make them an indispensable component for these products, catering directly to evolving consumer preferences for sustainable and efficient household solutions. The demand from this segment is consistently high, driving significant volume within the PVA film market and encouraging ongoing product innovation tailored to high-speed packaging lines.

Another crucial customer base resides within the agricultural sector, where agrochemical manufacturers and progressive farming operations increasingly rely on PVA films. For these customers, PVA films are instrumental in developing advanced agricultural solutions such as seed tapes, which ensure precise seed placement and germination, and controlled-release systems for pesticides and fertilizers. By encapsulating these chemicals in PVA films, agricultural users can achieve targeted application, reduce chemical runoff into the environment, and enhance the efficiency of resource utilization, leading to improved crop yields and reduced ecological impact. This customer segment values the film's biodegradability and its ability to dissolve safely, ensuring that no harmful plastic residues are left in the soil. The healthcare and pharmaceutical industries also represent a growing segment of potential customers, including hospitals, clinics, and drug manufacturers. These entities utilize PVA films for critical applications such as disposable, water-soluble laundry bags for infectious linens, thereby minimizing contamination risks, and as innovative components in advanced drug delivery systems and medical device packaging, leveraging their non-toxicity and controlled dissolution properties to enhance patient safety and product efficacy.

Beyond these major sectors, the Polyvinyl Alcohol Films Market serves a variety of other specialized end-users. The textile industry, for example, uses PVA films as temporary support materials for embroidery backings and as sizing agents for yarns, which dissolve post-processing, leaving no residue and improving textile quality. In the electronics sector, manufacturers are exploring PVA films for their optical properties and as protective layers for sensitive components or in the production of specialized printed circuit boards. Furthermore, the construction industry utilizes PVA films for packaging of specific chemical additives for concrete, allowing for easy mixing without manual handling of powders. Water treatment companies also represent a niche customer group, employing PVA films for packaging water-soluble chemicals used in purification processes. This wide array of potential customers underscores the versatility and broad market appeal of PVA films, driven by their unique combination of functional performance and environmental advantages, catering to diverse needs across a multitude of applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 450 Million |

| Market Forecast in 2032 | USD 700 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kuraray Co., Ltd., Sekisui Chemical Co., Ltd., Mitsubishi Chemical Corporation, Nippon Gohsei (part of Mitsubishi Chemical), The Dow Chemical Company, Eastman Chemical Company, BASF SE, Changchun Group, Selenis, CCP Technologies, Adeka Corporation, Wuxi Xiezheng Chemical, Aicello Corporation, Unitika Ltd., PT. Indonesia Polyethylene, Hunan Xiangwei Co., Ltd., Taiwan VCM Corp., Sipchem, Saudi Basic Industries Corporation (SABIC), LyondellBasell Industries N.V. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polyvinyl Alcohol Films Market Key Technology Landscape

The Polyvinyl Alcohol Films Market is propelled by a continuously evolving and highly specialized technology landscape, which is fundamental to enhancing product performance, sustainability, and manufacturing efficiency. At the core of this landscape are advancements in film manufacturing processes, primarily extrusion and casting techniques. While these methods have been long-standing, ongoing innovations focus on refining them to produce ultra-thin films with exceptional uniformity, superior mechanical properties, and precise control over film thickness. This includes optimizing die designs, improving temperature control during processing, and developing high-speed production lines that can maintain consistent quality while increasing output. The integration of advanced automation and sensor technologies into these processes allows for real-time monitoring and adjustment, minimizing waste and maximizing resource utilization, which are crucial for cost competitiveness and environmental stewardship in modern film production.

Furthermore, significant technological progress is being made in the realm of material science and polymer chemistry specifically tailored for PVA. This involves developing new grades of PVA resins with modified molecular weights, degrees of hydrolysis, and copolymer compositions to achieve desired functional attributes. For instance, researchers are engineering PVA variants that offer enhanced solubility in cold water, improved gas barrier performance against oxygen and moisture, or superior resistance to specific chemicals. The incorporation of advanced plasticizers and additives plays a vital role in fine-tuning the film's flexibility, tear strength, and heat-sealability, allowing for customization to meet diverse application requirements from fast-dissolving detergent pods to robust agricultural films. The development of blended polymer systems, where PVA is combined with other biodegradable or compostable polymers, is also a key area of focus, aiming to leverage the best properties of multiple materials to create composite films with synergistic benefits for specialized applications.

Beyond core manufacturing and material innovation, the technology landscape also encompasses sophisticated surface modification and coating techniques. These technologies are employed to impart additional functionalities to PVA films that are not inherently present in the base polymer. Examples include anti-fog coatings for packaging applications, printable surfaces for enhanced branding and information dissemination, or specialized barrier coatings to further augment protection against specific gases or liquids while maintaining biodegradability. Moreover, advancements in analytical and characterization techniques are crucial, enabling manufacturers to precisely measure and control film properties, ensuring compliance with stringent quality standards and regulatory requirements across various industries. The continuous interplay between these manufacturing, material, and surface technologies drives the innovation cycle within the PVA film market, expanding its utility and strengthening its position as a sustainable and high-performance material for a wide array of global demands.

Regional Highlights

- Asia Pacific (APAC): This region stands as the largest and fastest-growing market for Polyvinyl Alcohol films, primarily fueled by rapid industrialization, burgeoning population growth, and increasing disposable incomes in countries like China, India, Japan, and South Korea. The expansion of the consumer goods sector, particularly for household cleaning products in unit-dose formats, coupled with significant growth in agriculture and healthcare, drives substantial demand. Government initiatives promoting sustainable packaging and local manufacturing capabilities further solidify APAC's leading position, making it a pivotal region for investment and market expansion.

- North America: A mature yet dynamically growing market, North America exhibits high adoption rates of PVA films, largely driven by a strong consumer preference for convenience products and a robust regulatory environment that increasingly favors biodegradable materials. The United States and Canada are key contributors, with significant demand stemming from the laundry and dishwashing pod market, as well as specialized applications in medical and agricultural sectors. Continuous innovation by regional players and strategic collaborations are essential for maintaining competitive edge and expanding the application base in this technologically advanced market.

- Europe: Characterized by stringent environmental regulations and a high level of consumer awareness regarding sustainability, Europe is a crucial market for PVA films. Countries such as Germany, the UK, France, and Italy are at the forefront of adopting eco-friendly packaging solutions and investing heavily in research and development for advanced biodegradable materials. The strong presence of major chemical and consumer goods companies, combined with a focus on circular economy principles, drives steady growth and innovation in diverse applications, from industrial to consumer-specific uses.

- Latin America: This region is emerging as a promising market for PVA films, with significant growth potential driven by developing economies, increasing industrialization, and rising consumer awareness of sustainable alternatives. Countries like Brazil, Mexico, and Argentina are witnessing expanding consumer goods and agricultural sectors, creating new avenues for PVA film adoption. While still developing compared to other regions, increasing foreign investments and a gradual shift towards modern packaging and agricultural practices are expected to accelerate market growth in the coming years.

- Middle East and Africa (MEA): The MEA region represents an nascent market for Polyvinyl Alcohol films, with growth primarily influenced by expanding infrastructure projects, increasing industrial output, and a rising awareness of environmental concerns in certain urban centers. Investments in agriculture and water treatment sectors, alongside a growing consumer base, are contributing to the gradual uptake of PVA films. While smaller in market share compared to other regions, strategic partnerships and focused market penetration efforts are essential to unlock the long-term potential of this developing region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polyvinyl Alcohol Films Market.- Kuraray Co., Ltd.

- Sekisui Chemical Co., Ltd.

- Mitsubishi Chemical Corporation

- Nippon Gohsei (part of Mitsubishi Chemical)

- The Dow Chemical Company

- Eastman Chemical Company

- BASF SE

- Changchun Group

- Selenis

- CCP Technologies

- Adeka Corporation

- Wuxi Xiezheng Chemical

- Aicello Corporation

- Unitika Ltd.

- PT. Indonesia Polyethylene

- Hunan Xiangwei Co., Ltd.

- Taiwan VCM Corp.

- Sipchem

- Saudi Basic Industries Corporation (SABIC)

- LyondellBasell Industries N.V.

Frequently Asked Questions

Analyze common user questions about the Polyvinyl Alcohol Films market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are Polyvinyl Alcohol Films and their primary characteristics?

Polyvinyl Alcohol (PVA) films are water-soluble synthetic polymer films made from PVA resin. Their primary characteristics include excellent gas barrier properties (especially oxygen), complete solubility in water (at specific temperatures), inherent biodegradability, and a non-toxic profile, making them highly versatile for various applications requiring controlled dissolution or environmental compatibility.

In which industries are PVA films most widely applied?

PVA films are most widely applied in the consumer goods industry for unit-dose packaging of detergents and dishwashing products, the agriculture sector for seed tapes and controlled-release agrochemicals, the healthcare field for disposable laundry bags and drug delivery, and in the textile industry for temporary sizing and embroidery backings. Their use is expanding into electronics and specialty chemical packaging.

How do PVA films contribute to environmental sustainability?

PVA films contribute to environmental sustainability by being biodegradable and water-soluble. Once dissolved, they break down into naturally occurring compounds like carbon dioxide and water through microbial activity, reducing the accumulation of plastic waste and offering a greener alternative to conventional non-degradable plastics, particularly in packaging and single-use applications.

What are the key factors driving the growth of the PVA Films Market?

Key growth drivers for the PVA Films Market include the escalating global demand for sustainable and eco-friendly packaging solutions, the increasing consumer preference for convenient unit-dose products, continuous advancements in film manufacturing technologies improving performance, and the expanding applications in precision agriculture and medical sectors that leverage PVA's unique properties.

What challenges does the PVA Films Market face?

The Polyvinyl Alcohol Films Market faces challenges such as higher production costs compared to established conventional plastics, significant volatility in the prices of raw materials, intense competition from other emerging biodegradable polymers, and the need to navigate complex and evolving regulatory landscapes in different regions concerning material standards and disposal methods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager