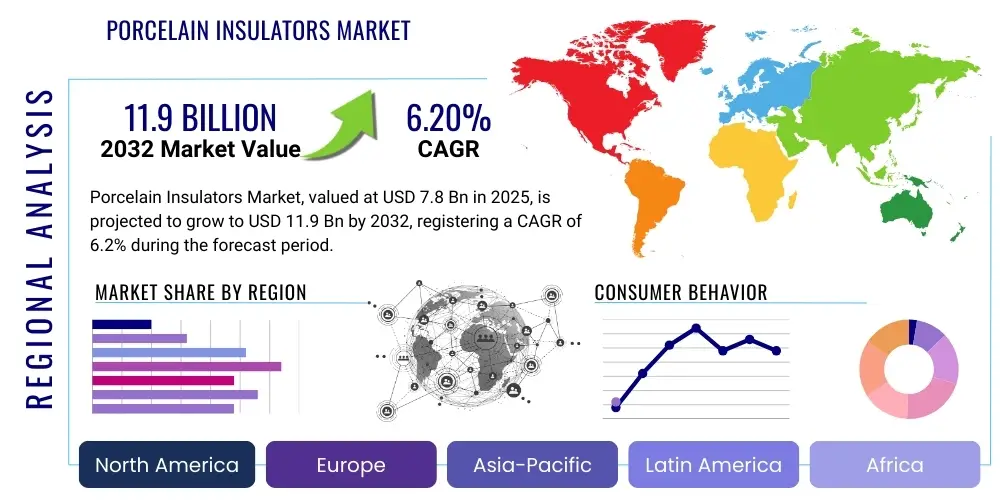

Porcelain Insulators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427390 | Date : Oct, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Porcelain Insulators Market Size

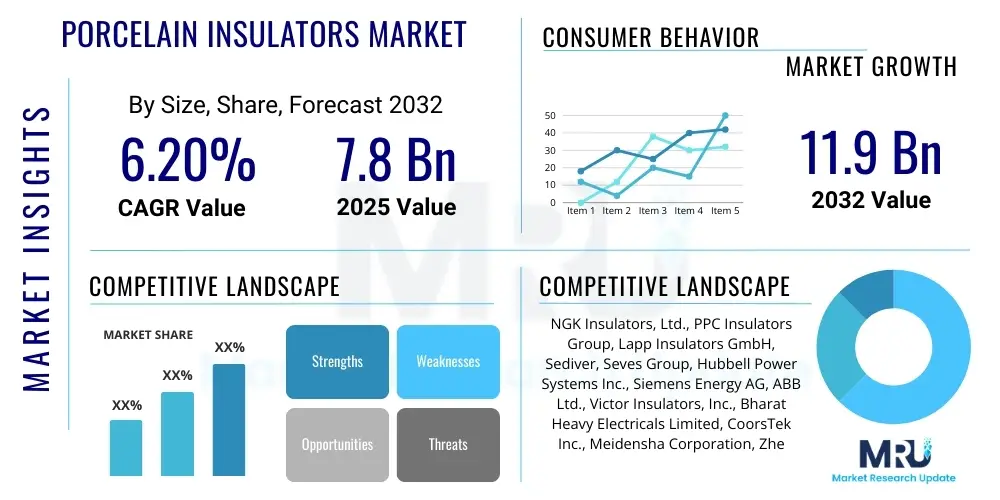

The Porcelain Insulators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at USD 7.8 billion in 2025 and is projected to reach USD 11.9 billion by the end of the forecast period in 2032.

Porcelain Insulators Market introduction

Porcelain insulators are critical components within electrical transmission and distribution systems, serving to mechanically support conductors while electrically isolating them from towers, poles, and other grounded structures. These robust devices prevent current leakage and flashovers, ensuring the safe and reliable operation of power grids. Manufactured primarily from high-grade ceramic materials such as alumina, silica, and feldspar, porcelain insulators are renowned for their excellent dielectric strength, thermal stability, mechanical robustness, and resistance to environmental degradation including UV radiation, moisture, and chemical pollution. Their inherent properties make them a preferred choice for various high-voltage applications across diverse climates.

The primary applications for porcelain insulators encompass high-voltage power transmission lines, where they support conductors over long spans and withstand immense mechanical stress, as well as in power distribution networks, substations, railway electrification systems, and various industrial electrical installations. Their widespread use stems from several key benefits, including their long operational lifespan, cost-effectiveness over the product lifecycle, high resistance to arc damage, and reliable performance under challenging environmental conditions. Porcelain insulators are particularly valued for their non-conductive nature and ability to withstand significant electrical stress without material breakdown.

The market for porcelain insulators is fundamentally driven by global trends in energy infrastructure development and modernization. Factors such as increasing electricity demand, particularly in rapidly industrializing and urbanizing regions, necessitate the expansion and upgrading of power grids. Significant investments in renewable energy sources, which often require new transmission infrastructure to integrate into existing grids, further propel market growth. Additionally, government initiatives focused on rural electrification, grid stability, and replacing aging infrastructure in developed economies contribute substantially to the sustained demand for these essential electrical components.

Porcelain Insulators Market Executive Summary

The Porcelain Insulators Market is experiencing robust growth, primarily fueled by the accelerating pace of global electrification, the expansion of renewable energy generation capacities, and substantial investments in modernizing aging power transmission and distribution infrastructure. Business trends indicate a shift towards higher voltage insulators to support efficient long-distance power transmission and the increasing adoption of smart grid technologies that demand more reliable and durable components. Manufacturers are focusing on enhancing product performance through advanced ceramic formulations and improved manufacturing processes, catering to the stringent requirements of utilities and industrial end-users. Strategic partnerships and mergers are also observed as companies seek to consolidate market share and leverage technological advancements.

Regional trends highlight Asia-Pacific as a dominant and rapidly expanding market, driven by massive infrastructure projects, burgeoning industrialization, and significant government spending on grid expansion and rural electrification programs, particularly in countries like China and India. North America and Europe demonstrate a consistent demand for porcelain insulators, primarily due to grid modernization efforts, the integration of distributed renewable energy sources, and the necessity to replace or upgrade an extensive network of aging transmission and distribution lines to enhance reliability and resilience. Emerging economies in Latin America, the Middle East, and Africa are also contributing to market growth through new power generation projects and efforts to expand electricity access.

Segmentation trends indicate a strong demand for suspension and post-type insulators, which are vital for high-voltage transmission and substation applications respectively. The high-voltage segment, encompassing both AC and DC applications, is expected to exhibit the fastest growth owing to the construction of ultra-high voltage (UHV) lines for bulk power transfer. Utilities remain the largest end-user segment, driven by continuous investment in power infrastructure. While composite insulators present a growing alternative, porcelain insulators maintain their strong market position due to their proven reliability, cost-effectiveness, and established manufacturing infrastructure. Environmental considerations and the drive for sustainable materials are also influencing product development and market dynamics, albeit to a lesser extent than for composite alternatives.

AI Impact Analysis on Porcelain Insulators Market

Common user questions regarding AIs impact on the porcelain insulators market frequently center on how artificial intelligence can enhance the reliability, efficiency, and longevity of electrical infrastructure. Users are keen to understand AIs potential in predictive maintenance to prevent costly outages, optimize manufacturing processes to reduce defects and waste, and improve the design phase for more durable and performant insulators. There is also significant interest in how AI could contribute to smart grid management, reducing stress on insulators, and providing real-time insights into grid health, ultimately leading to greater energy security and reduced operational expenditures for utilities.

Beyond operational improvements, users often inquire about the strategic implications of AI, such as its role in supply chain optimization, demand forecasting for raw materials, and identifying emerging market trends. While the direct application of AI within the physical insulator component itself is limited, its indirect influence across the entire value chain is substantial. Concerns sometimes arise regarding the initial investment costs for AI integration, the availability of skilled personnel, and data privacy issues. However, the overarching expectation is that AI will usher in a new era of proactive infrastructure management, significantly improving the performance and economic viability of porcelain insulator deployments by minimizing failures and extending service life.

- Predictive maintenance for infrastructure: AI algorithms analyze sensor data from power lines and substations to predict potential insulator failures before they occur, enabling proactive replacement and maintenance schedules. This reduces unexpected outages and extends the operational life of existing infrastructure, optimizing utility investments.

- Optimized manufacturing processes: AI can be integrated into the porcelain manufacturing process to monitor production parameters in real-time, identify anomalies, and fine-tune machinery. This leads to higher quality control, reduction in material waste, and improved consistency of insulator properties, enhancing overall product reliability.

- Enhanced grid stability and management: By analyzing vast amounts of grid data, AI can help in dynamic load balancing and fault detection, reducing electrical stress on insulators and preventing flashovers. This contributes to a more stable and resilient power grid, minimizing the risk of insulator-related failures.

- Improved design and material innovation: AI-driven simulation tools can rapidly test new insulator designs and material compositions under various environmental and electrical conditions. This accelerates research and development, leading to the creation of more robust, efficient, and application-specific porcelain insulators tailored for future grid demands.

- Supply chain and logistics optimization: AI can forecast demand for porcelain insulators and their raw materials with greater accuracy, optimizing inventory levels and ensuring timely delivery. It can also identify potential supply chain disruptions, allowing manufacturers to mitigate risks and maintain consistent production schedules.

DRO & Impact Forces Of Porcelain Insulators Market

The Porcelain Insulators Market is primarily driven by the escalating global demand for electricity, which necessitates continuous expansion and upgrading of power transmission and distribution networks worldwide. Significant government and private sector investments in smart grid initiatives and renewable energy projects, such as solar and wind farms, further fuel this demand, as new infrastructure is required to integrate these sources into existing grids. Urbanization and industrialization, particularly in developing economies, are creating an urgent need for robust electrical infrastructure, where porcelain insulators play a foundational role due to their proven reliability and cost-effectiveness. These macro-economic and energy transition trends are creating a sustained impetus for market growth.

Despite strong drivers, the market faces several restraints. The increasing adoption of alternative materials, particularly composite or polymer insulators, which offer advantages like lighter weight, superior hydrophobicity, and better resistance to vandalism in certain applications, poses a competitive challenge to porcelain insulators. Fluctuations in raw material prices, such as clay, feldspar, and quartz, can impact manufacturing costs and market pricing. Additionally, the aging electrical infrastructure in many developed regions, while creating replacement opportunities, also represents a slow and costly upgrade process that can limit the pace of new insulator installations. Supply chain vulnerabilities, exacerbated by geopolitical events or natural disasters, can also disrupt production and delivery schedules.

Opportunities for growth in the porcelain insulators market are abundant, particularly in emerging economies focused on rural electrification and expanding access to reliable power. The ongoing global trend of grid modernization offers significant potential for upgrading legacy systems with higher-performance porcelain insulators capable of handling increased voltage and environmental stress. Specialized applications, such as high-voltage direct current (HVDC) transmission lines, which require extremely durable and reliable insulation solutions, present a niche but growing market segment. Innovation in manufacturing processes, leading to enhanced product features like improved pollution performance and mechanical strength, can also open new avenues for market penetration.

The market is also shaped by several impact forces. Technological advancements, though slower than in other sectors, still influence product evolution, with efforts focused on enhancing the ceramic composition and glazing techniques for improved resistance to pollution, icing, and mechanical stress. Regulatory frameworks and evolving safety standards for electrical infrastructure globally significantly dictate product specifications and market entry requirements. Environmental considerations, including the sustainability of manufacturing processes and the recyclability of materials, are becoming increasingly important. Lastly, geopolitical factors, trade policies, and economic stability in key manufacturing and consuming regions can substantially impact raw material availability, production costs, and overall market dynamics.

Segmentation Analysis

The Porcelain Insulators Market is extensively segmented across various parameters including type, voltage, application, and end-use, allowing for a detailed understanding of market dynamics and tailored product strategies. This segmentation helps in identifying specific growth opportunities within different categories and understanding the nuanced demands of diverse end-users. The variations in insulator design and material composition are often driven by the specific electrical and mechanical requirements of each segment, ensuring optimal performance and safety across the vast spectrum of power infrastructure needs. Analyzing these segments provides a clear picture of where demand is strongest and how technological advancements are being applied.

For instance, the market can be segmented by the structural type of the insulator, each designed for distinct installation and functional purposes. Voltage levels dictate the material and geometric design, with higher voltages requiring more robust insulation properties. Applications categorize insulators based on where they are deployed within the electrical grid, such as transmission lines or substations. Finally, end-use segments differentiate between the primary consumers, like utilities or industrial entities, reflecting varying scales of demand and procurement processes. Each segment presents unique challenges and opportunities, influencing product development, pricing strategies, and regional market penetration efforts by manufacturers.

- By Type:

- Pin Type Insulators: Used for lower voltage distribution lines, mounted on cross-arms.

- Suspension Type Insulators: Employed in high-voltage transmission lines, forming long strings to support conductors.

- Post Type Insulators: Used in substations and switchyards for supporting bus bars and disconnecting switches, available in solid or hollow configurations.

- Shackle Type Insulators: Primarily for low voltage distribution, used in horizontal positions.

- Strain Type Insulators: Designed to bear mechanical tension at dead ends of lines or at sharp corners.

- By Voltage:

- Low Voltage Insulators (up to 1 kV): Primarily for household and small industrial distribution.

- Medium Voltage Insulators (1 kV to 72 kV): Common in local power distribution networks.

- High Voltage Insulators (72 kV to 245 kV): Used in major transmission lines.

- Ultra-High Voltage Insulators (above 245 kV): Essential for long-distance bulk power transmission and HVDC systems.

- By Application:

- Power Transmission: For high-voltage lines transmitting power over long distances.

- Power Distribution: For lower voltage networks distributing power to end-users.

- Substations: For insulating busbars, circuit breakers, and other equipment within substations.

- Railways: For overhead electrification systems in railway networks.

- Industrial Applications: Various specialized uses within heavy industries.

- By End-Use:

- Utilities: National and regional power generation, transmission, and distribution companies.

- Industrial: Heavy industries requiring dedicated power infrastructure.

- Commercial: Large commercial complexes and establishments.

- Residential: Local distribution to residential areas (often through utilities).

Porcelain Insulators Market Value Chain Analysis

The value chain for the Porcelain Insulators Market begins with the upstream activities involving the sourcing and processing of raw materials. Key raw materials include high-quality clays (kaolin), quartz, feldspar, and alumina, which are critical for achieving the desired mechanical strength, dielectric properties, and thermal characteristics of porcelain. Suppliers in this segment specialize in mining, purifying, and blending these minerals to meet strict industry standards. Energy supply for firing processes also represents a significant upstream cost component. Efficiency in raw material procurement and preparation directly impacts the final product quality and manufacturing costs, forming the foundational stage of the entire value chain.

Midstream activities primarily encompass the manufacturing process, which is highly specialized and requires significant capital investment in machinery and expertise. This stage involves several intricate steps: raw material grinding and mixing, shaping (e.g., wet process for large insulators, dry process for smaller ones), drying, glazing, and high-temperature firing in kilns to achieve vitrification and mechanical integrity. Quality control is paramount at every stage to ensure the insulators meet electrical and mechanical specifications, as well as international safety standards. Research and development efforts at this stage focus on improving material compositions, manufacturing precision, and overall product performance to enhance durability and efficiency under varying environmental conditions.

Downstream analysis highlights the distribution channels and the ultimate consumption by end-users. Porcelain insulators are typically distributed through a combination of direct sales to large utility companies, which often have long-term procurement contracts, and indirect channels involving specialized distributors, wholesalers, and electrical contractors. These intermediaries play a crucial role in reaching smaller utilities, industrial clients, and specific project-based demands. The effective management of logistics, warehousing, and inventory by these channels ensures timely delivery and installation of insulators, minimizing project delays and maintaining grid reliability. Post-sales services, including technical support and warranty provisions, are also critical aspects of the downstream value chain, ensuring customer satisfaction and fostering long-term relationships.

Porcelain Insulators Market Potential Customers

The primary potential customers for porcelain insulators are entities involved in the generation, transmission, and distribution of electrical power globally. This includes large national and regional utility companies (e.g., Transmission System Operators - TSOs, Distribution System Operators - DSOs) that own and operate vast networks of power lines, substations, and switchyards. These organizations consistently require insulators for new grid expansion projects, essential upgrades to existing infrastructure, and routine maintenance or replacement of aging components. Their procurement cycles are often long-term, characterized by stringent technical specifications, competitive bidding, and a strong emphasis on product reliability and safety standards to ensure uninterrupted power supply to millions of consumers and industries.

Beyond traditional power utilities, significant demand also originates from various industrial sectors and infrastructure projects. Railway authorities, particularly those developing or upgrading electrified rail networks, are key buyers, as porcelain insulators are integral to overhead catenary systems. Heavy industries, such as mining, metallurgy, and manufacturing, often operate extensive internal electrical networks and substations, necessitating a steady supply of insulators for their specific operational demands. Furthermore, governments and private developers undertaking large-scale infrastructure projects, including new townships, industrial parks, and rural electrification initiatives, contribute substantially to the customer base, seeking durable and cost-effective insulation solutions for their power infrastructure requirements.

Another emerging segment of potential customers includes companies involved in the development of renewable energy infrastructure. As solar farms and wind power plants proliferate, new transmission lines and substation equipment are required to connect these generation sources to the main grid. These projects often specify high-voltage porcelain insulators due to their proven performance in diverse environmental conditions and their ability to withstand the stresses associated with integrating intermittent power sources. Specialized electrical contractors and engineering, procurement, and construction (EPC) firms that undertake large-scale power infrastructure projects on behalf of utilities and private developers also represent significant indirect customers, influencing product specifications and purchasing decisions on a project-by-project basis.

Porcelain Insulators Market Key Technology Landscape

The technology landscape for the Porcelain Insulators Market is characterized by continuous advancements aimed at enhancing durability, performance, and resistance to environmental degradation, while also optimizing manufacturing efficiency. A primary focus is on advanced ceramic formulations, particularly the use of high-alumina porcelain. This specialized porcelain offers superior mechanical strength, making insulators more resistant to bending, tension, and impact, which is crucial for high-voltage and heavy-duty applications. Furthermore, improved dielectric properties of these advanced ceramics contribute to higher flashover voltages and reduced leakage currents, ensuring greater reliability and operational safety of the electrical grid even under adverse conditions like heavy pollution or icing.

Another significant area of technological development lies in surface treatment and glazing techniques. Manufacturers are employing innovative glazing compositions and application methods to create smoother, more uniform, and highly hydrophobic surfaces. This enhanced surface integrity not only improves the insulators resistance to pollution accumulation and moisture absorption, thereby minimizing flashovers and maintenance requirements, but also extends the operational lifespan by protecting the ceramic body from long-term environmental degradation. Research into self-cleaning or anti-fouling glaze technologies is also progressing, aiming to further reduce the need for manual cleaning in highly polluted industrial or coastal areas.

Automation and digital technologies are increasingly being integrated into the manufacturing process for porcelain insulators. Advanced robotic systems are utilized for precision shaping, handling, and assembly, leading to higher product consistency, reduced labor costs, and improved overall production efficiency. Digital twin technology and predictive analytics are being explored for design optimization and quality control, allowing engineers to simulate performance under various conditions and identify potential flaws before physical production. Furthermore, sophisticated testing methodologies, including advanced partial discharge detection and accelerated aging tests, ensure that insulators meet the most stringent international standards for electrical and mechanical performance, pushing the boundaries of reliability and longevity in critical power infrastructure.

Regional Highlights

- Asia-Pacific: This region dominates the global porcelain insulators market, driven by rapid industrialization, massive urbanization, and extensive infrastructure development projects, especially in China, India, and Southeast Asian countries. Significant investments in grid expansion, rural electrification, and the integration of large-scale renewable energy projects fuel consistent demand for various types of porcelain insulators.

- North America: The market here is characterized by significant investments in modernizing and replacing aging power transmission and distribution infrastructure. Emphasis on smart grid initiatives, grid resilience against extreme weather events, and the integration of renewable energy sources drives demand for high-performance and reliable porcelain insulators across the United States and Canada.

- Europe: This region exhibits stable demand, primarily due to ongoing grid modernization efforts, ambitious renewable energy targets, and the necessity to maintain and upgrade an extensive legacy power network. Countries like Germany, France, and the UK are investing in reinforcing their grids for improved efficiency and security, contributing to a steady market for insulators.

- South America: Emerging economies in this region, particularly Brazil, Argentina, and Chile, are witnessing growth due to electrification projects, infrastructure development, and increasing energy demand. Investments in new power generation capacity and cross-border transmission lines are key drivers for the porcelain insulators market.

- Middle East & Africa: This region is experiencing considerable growth, propelled by rapid urbanization, significant investments in new power generation plants, and ambitious projects to expand electricity access. Countries like Saudi Arabia, UAE, and South Africa are leading these developments, creating a strong market for power transmission and distribution components, including porcelain insulators.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Porcelain Insulators Market.- NGK Insulators, Ltd.

- PPC Insulators Group

- Lapp Insulators GmbH

- Sediver (MacLean Power Systems)

- Seves Group (GE Grid Solutions)

- Hubbell Power Systems Inc.

- Siemens Energy AG

- ABB Ltd.

- Victor Insulators, Inc.

- Bharat Heavy Electricals Limited (BHEL)

- CoorsTek Inc.

- Meidensha Corporation

- Zhengzhou Orient Power Co., Ltd.

- Shandong Ruitai High Voltage Insulator Co., Ltd.

- Jiangsu Jingyong Electric Co., Ltd.

Frequently Asked Questions

What are porcelain insulators primarily used for in electrical systems?

Porcelain insulators are primarily used to provide electrical insulation and mechanical support for conductors in high-voltage power transmission and distribution lines, substations, and other electrical equipment, preventing current leakage and ensuring safe operation.

How do porcelain insulators compare to composite insulators in terms of performance?

Porcelain insulators are known for their high mechanical strength, excellent dielectric properties, and long-term durability, especially in harsh environmental conditions. Composite insulators offer advantages in terms of lighter weight, hydrophobicity, and resistance to vandalism, but porcelain remains preferred for its proven reliability and cost-effectiveness in many traditional applications.

What factors are driving the growth of the porcelain insulators market?

Key drivers include increasing global electricity demand, significant investments in modernizing and expanding power transmission and distribution infrastructure, the integration of renewable energy sources into the grid, and rapid urbanization and industrialization in developing regions.

What are the main types of porcelain insulators available in the market?

The main types include pin type, suspension type, post type, shackle type, and strain type insulators, each designed for specific applications and voltage levels within electrical networks.

How does AI impact the manufacturing and maintenance of porcelain insulators?

AI impacts the market by enabling predictive maintenance for power grids, optimizing manufacturing processes for higher quality and efficiency, enhancing grid stability, and accelerating the design of more robust insulators through advanced simulations, ultimately improving reliability and extending lifespan.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager