Port Equipment Tire Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428863 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Port Equipment Tire Market Size

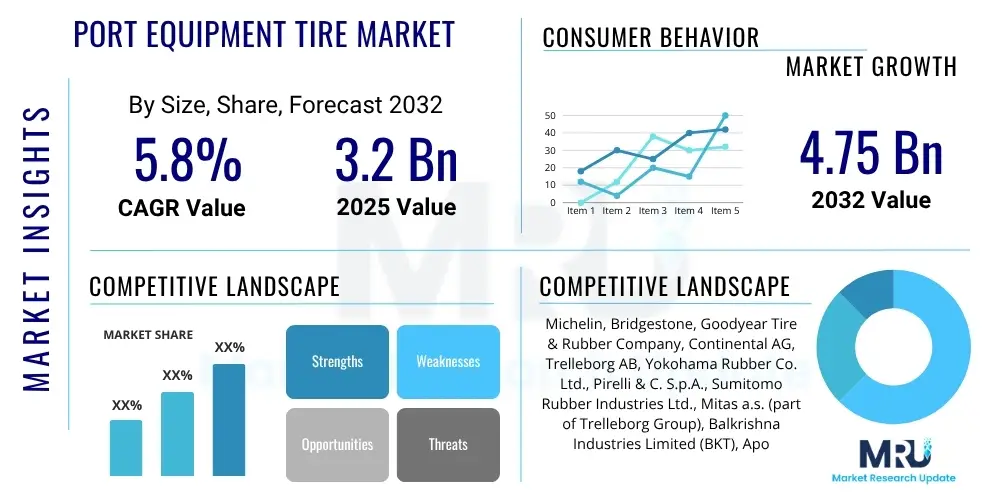

The Port Equipment Tire Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 3.2 Billion in 2025 and is projected to reach USD 4.75 Billion by the end of the forecast period in 2032.

Port Equipment Tire Market introduction

The Port Equipment Tire Market encompasses the manufacturing, distribution, and sale of specialized tires designed for a wide array of machinery operating within port and terminal environments. These tires are engineered to withstand extreme loads, abrasive surfaces, rigorous operating cycles, and challenging weather conditions inherent to port operations. The market is fundamentally driven by the relentless expansion of global trade and the ongoing modernization of port infrastructure, necessitating robust and reliable tire solutions for seamless cargo handling.

Products within this market range from solid tires, which offer unparalleled puncture resistance and stability for applications like forklifts and heavy-duty container handlers, to pneumatic tires, including radial and bias ply constructions, chosen for their cushioning, traction, and speed capabilities on equipment such as terminal tractors and straddle carriers. Each tire type is meticulously designed to optimize performance, enhance safety, and minimize downtime for specific equipment categories, contributing significantly to the operational efficiency and economic viability of global logistics hubs.

Major applications include container handling equipment such as reach stackers, empty container handlers, rubber tyred gantry cranes (RTGs), rail mounted gantry cranes (RMGs), as well as forklifts, terminal tractors, and straddle carriers. The primary benefits derived from high-quality port equipment tires include extended operational life, improved fuel efficiency, enhanced stability and safety for heavy loads, and reduced maintenance costs through superior durability and resistance to wear and tear. Driving factors for market growth include the increasing volume of maritime freight, the automation of port operations, technological advancements in tire materials and design, and the continuous investment in new port development and existing facility upgrades worldwide.

Port Equipment Tire Market Executive Summary

The Port Equipment Tire Market is currently experiencing robust growth, propelled by significant global business trends. The surging demand for efficient and rapid cargo throughput across international maritime trade routes is a primary catalyst. This is further exacerbated by the increasing sophistication of port logistics, which demands tires capable of higher speeds, heavier loads, and improved longevity. Business strategies are evolving towards greater emphasis on total cost of ownership rather than just initial purchase price, driving innovation in tire durability, fuel efficiency, and smart monitoring capabilities. Manufacturers are also focusing on sustainable production practices and materials to meet evolving environmental regulations and corporate responsibility mandates.

Regional trends indicate that Asia Pacific remains the dominant market, largely due to the presence of some of the world's busiest ports and continuous infrastructure development projects, particularly in China, India, and Southeast Asian nations. North America and Europe also demonstrate significant market shares, driven by technological adoption, port automation initiatives, and a strong replacement market. Emerging economies in Latin America, the Middle East, and Africa are showcasing impressive growth potential as investments in port modernization and expansion projects gather momentum, aiming to bolster their positions in global supply chains. These regions present substantial opportunities for both original equipment manufacturers (OEMs) and aftermarket suppliers.

Segment-wise, the market is broadly divided by tire type, equipment type, and application. The solid tire segment, valued for its puncture-proof design and stability, holds a substantial share, especially for heavy-duty lifting and container handling equipment that operates in high-risk environments. Pneumatic tires, particularly radial designs, are gaining traction due to their enhanced comfort, speed, and fuel efficiency, favored by terminal tractors and straddle carriers operating over longer distances within port confines. The aftermarket segment consistently accounts for a larger share, driven by the recurring need for tire replacements, while the OEM segment benefits from new equipment sales fueled by port expansion and automation. The trend towards larger, more automated port equipment is also influencing tire size and capacity requirements, pushing manufacturers to develop advanced solutions.

AI Impact Analysis on Port Equipment Tire Market

Users frequently inquire about how Artificial Intelligence will revolutionize the operational dynamics and material science within the Port Equipment Tire Market. Common questions revolve around AI's capacity to enhance tire lifespan through predictive maintenance, optimize logistical operations for autonomous port vehicles, and introduce groundbreaking efficiencies in tire design and manufacturing. There is a palpable expectation that AI will transition tires from passive components to active data contributors within smart port ecosystems. Key themes emerging from these inquiries include a desire for reduced operational costs, improved safety parameters, and the strategic integration of tire data into broader port management systems, alongside concerns regarding data privacy, cybersecurity, and the necessary infrastructure investment for AI adoption.

- AI enables predictive maintenance by analyzing real-time sensor data from tires, forecasting wear patterns, and optimizing replacement schedules to prevent unexpected failures and reduce downtime.

- Integration of AI with autonomous port equipment facilitates adaptive tire pressure management and route optimization, significantly extending tire longevity and improving fuel efficiency for driverless vehicles.

- AI-driven simulation and design tools accelerate the development of next-generation port equipment tires, allowing manufacturers to optimize material composition, tread patterns, and structural integrity for specific load and environmental conditions.

- Real-time monitoring systems powered by AI provide insights into tire health, temperature, and load distribution, enhancing operational safety and informing immediate adjustments to equipment usage.

- AI supports supply chain optimization for tire procurement and inventory management within ports, ensuring availability of correct tire types and sizes while minimizing storage costs.

- Machine learning algorithms analyze operational data to recommend optimal tire selection for different port equipment and tasks, maximizing performance and return on investment.

DRO & Impact Forces Of Port Equipment Tire Market

The Port Equipment Tire Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces that shape its trajectory. Key drivers include the consistent growth in global maritime trade, necessitating higher throughput and efficiency at ports worldwide. This global trade expansion directly translates into increased demand for port handling equipment and, consequently, for the specialized tires these machines require. Additionally, the ongoing modernization and automation of port terminals, driven by a desire for enhanced operational speed and reduced labor costs, fuel the demand for advanced, high-performance tires capable of supporting increasingly sophisticated and heavy-duty machinery. The need for improved fuel efficiency and extended tire life to minimize operational expenditures also acts as a strong driver, pushing manufacturers towards innovative product development.

Conversely, the market faces several notable restraints. The substantial initial investment required for high-quality, durable port equipment tires can be a barrier for smaller port operators, potentially leading them to opt for less robust, albeit cheaper, alternatives that may not offer the same long-term benefits. Intense price competition among tire manufacturers also constrains profit margins and the capacity for research and development. Furthermore, stringent environmental regulations regarding tire disposal and the use of certain materials in manufacturing pose challenges, requiring costly compliance measures and the development of sustainable alternatives. Economic downturns and geopolitical uncertainties can also dampen global trade volumes, subsequently reducing demand for new port equipment and replacement tires.

Opportunities within the market are abundant, primarily stemming from the increasing adoption of smart port technologies and the electrification of port equipment. The shift towards electric and hybrid terminal tractors, forklifts, and cranes creates a demand for tires optimized for new weight distribution, torque characteristics, and energy efficiency requirements. Emerging markets in Asia Pacific, Latin America, and Africa, with their rapid industrialization and burgeoning trade volumes, present significant untapped potential for market expansion and infrastructure development. Moreover, advancements in material science, such as the development of advanced rubber compounds and reinforcement technologies, offer avenues for creating tires with superior durability, lower rolling resistance, and enhanced puncture resistance, thereby addressing core customer needs. The opportunity for integrating tire sensors and AI-driven monitoring systems also represents a significant growth area.

Segmentation Analysis

The Port Equipment Tire Market is extensively segmented to reflect the diverse operational requirements and equipment types found within global port environments. This segmentation provides a granular view of market dynamics, allowing stakeholders to understand specific demand patterns, technological preferences, and growth opportunities across various categories. The primary segmentation criteria include tire type, equipment type, application, and sales channel, each influencing market share and competitive strategies differently. Analyzing these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for port operators to make informed procurement decisions based on their unique operational needs and equipment fleets. The market's complexity necessitates a detailed breakdown to capture the nuances of demand and supply.

- By Tire Type:

- Solid Tires: Characterized by exceptional puncture resistance and high load-carrying capacity, ideal for heavy-duty, stationary, or slow-moving equipment where stability and durability are paramount.

- Pneumatic Tires:

- Radial Tires: Offer superior comfort, traction, fuel efficiency, and longer lifespan, suitable for equipment requiring higher speeds and operating over longer distances, such as terminal tractors.

- Bias Tires: Known for their robust sidewalls and resistance to damage, often used in applications where sidewall impact is common, providing good stability.

- By Equipment Type:

- Container Handlers: Includes tires for Reach Stackers, Empty Container Handlers, Rubber Tyred Gantry (RTG) Cranes, and Rail Mounted Gantry (RMG) Cranes, demanding high load capacities and stability.

- Forklifts: Tires designed for various capacities of forklifts operating in port warehouses and yards, prioritizing durability and maneuverability.

- Terminal Tractors: Tires optimized for traction, speed, and fuel efficiency for vehicles that transport containers and trailers within the terminal.

- Straddle Carriers: Require specialized tires capable of handling extremely heavy loads and providing stability for lifting and transporting containers.

- Other Port Equipment: Includes tires for various utility vehicles, mobile cranes, and specialized lifting equipment within ports.

- By Application:

- Container Terminals: The largest segment, driven by the immense volume of containerized cargo globally.

- Bulk Cargo Terminals: Tires for equipment handling commodities like grains, coal, and minerals, often exposed to abrasive materials.

- General Cargo Terminals: For equipment managing diverse non-containerized cargo, requiring versatile tire solutions.

- Ro-Ro (Roll-on/Roll-off) Terminals: Tires for specialized vehicles handling wheeled cargo, emphasizing traction and stability.

- By Sales Channel:

- OEM (Original Equipment Manufacturer): Tires supplied directly to equipment manufacturers for new machinery installations.

- Aftermarket: Replacement tires sold through distributors, dealers, and service centers for existing port equipment fleets, representing a significant recurring revenue stream.

Value Chain Analysis For Port Equipment Tire Market

The value chain for the Port Equipment Tire Market is a complex network spanning raw material sourcing to end-user application, involving multiple stages and diverse stakeholders. Upstream activities begin with the procurement of critical raw materials, primarily natural rubber, synthetic rubber (such as SBR and BR), carbon black, steel cord, textile reinforcements (like nylon and polyester), and various chemicals and additives. Suppliers in this segment are global and often specialized, requiring tire manufacturers to establish robust supply chain management practices to ensure consistent quality and availability of these essential inputs. The volatile prices of raw commodities, particularly natural rubber, can significantly impact manufacturing costs and, subsequently, the pricing strategies throughout the value chain.

Midstream, the value chain focuses on the manufacturing process, which involves sophisticated engineering and advanced production technologies. Tire manufacturers design, develop, and produce a wide range of specialized tires, converting raw materials into finished products through processes like mixing, calendering, building, and curing. This stage requires substantial capital investment in machinery, research and development, and quality control. Manufacturers often differentiate themselves through proprietary rubber compounds, innovative tread designs, and advanced casing constructions that enhance durability, load capacity, and operational efficiency specific to port environments. Direct sales channels involve manufacturers supplying tires directly to major port equipment OEMs for initial installation on new machinery, building long-term partnerships that ensure product integration and technological alignment.

Downstream activities primarily involve distribution, sales, and aftermarket services. Tires reach end-users, which are primarily port operators and terminal companies, through a combination of direct and indirect channels. Direct distribution might involve manufacturers selling directly to large port authorities or global logistics companies with extensive equipment fleets. Indirect channels include a network of specialized dealers, distributors, and service providers who offer sales, installation, maintenance, and repair services for port equipment tires. These intermediaries play a crucial role in providing local support, inventory management, and technical expertise to end-users, particularly for the significant replacement market. The aftermarket segment is vital, as tires are consumable products requiring regular replacement due to wear and tear. Effective distribution channels and comprehensive aftermarket support are critical for customer satisfaction and long-term market presence.

Port Equipment Tire Market Potential Customers

The primary potential customers for the Port Equipment Tire Market are diverse entities operating within the global maritime logistics and cargo handling ecosystem. These end-users are characterized by their intensive use of heavy machinery within demanding operational environments, necessitating specialized, robust, and reliable tire solutions. The core customer base includes large international port authorities, which manage and operate extensive terminal infrastructure. These authorities oversee vast fleets of equipment, ranging from gantry cranes to terminal tractors, and require consistent supply of high-performance tires that can withstand continuous operation, extreme loads, and corrosive conditions inherent to maritime settings.

Beyond port authorities, significant customers include private terminal operators and stevedoring companies that lease or own cargo handling equipment within ports. These companies are driven by operational efficiency, safety, and cost-effectiveness, making them keen buyers of tires that offer extended lifespan, reduced maintenance, and improved fuel economy. Their purchasing decisions are often influenced by total cost of ownership rather than just the upfront price, favoring tires that deliver superior performance and durability in their specific applications, such as container handling, bulk cargo movement, or specialized Ro-Ro operations. The scale of their operations often dictates bulk procurement and long-term supply agreements with tire manufacturers or their distributors.

Furthermore, global logistics and shipping companies that operate their own dedicated port terminals or have significant assets within ports represent another critical customer segment. These entities prioritize equipment uptime and operational continuity to maintain tight shipping schedules and supply chain integrity. Equipment rental companies specializing in port machinery also constitute potential customers, as they need to equip their rental fleets with reliable and durable tires to meet the varied demands of their clientele. Lastly, original equipment manufacturers (OEMs) of port machinery are crucial customers, as they integrate these specialized tires into their new equipment before it is sold to port operators, forming a foundational demand stream for the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.2 Billion |

| Market Forecast in 2032 | USD 4.75 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Michelin, Bridgestone, Goodyear Tire & Rubber Company, Continental AG, Trelleborg AB, Yokohama Rubber Co. Ltd., Pirelli & C. S.p.A., Sumitomo Rubber Industries Ltd., Mitas a.s. (part of Trelleborg Group), Balkrishna Industries Limited (BKT), Apollo Tyres Ltd., ATG Tires (part of Yokohama Rubber Co. Ltd.), Maxam Tire International, Camso Inc. (part of Michelin Group), Shandong Linglong Tire Co. Ltd., Triangle Tyre Co. Ltd., Double Coin Holdings Ltd., Magna Tyres Group, Nokian Tyres PLC, CEAT Limited |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Port Equipment Tire Market Key Technology Landscape

The Port Equipment Tire Market is a hotbed of technological innovation, driven by the relentless demand for greater efficiency, durability, and sustainability within the challenging port environment. One of the most significant technological advancements revolves around material science, particularly in the development of advanced rubber compounds. Manufacturers are continuously investing in research to formulate compounds that offer superior resistance to cuts, punctures, and abrasion, while simultaneously providing lower rolling resistance to enhance fuel efficiency. This includes specialized synthetic rubbers, silica-based fillers, and polymers designed to withstand extreme temperatures and corrosive elements prevalent in port operations, significantly extending tire lifespan and reducing operational downtime for port operators.

Furthermore, innovations in tire construction and design are pivotal. This includes the widespread adoption of robust casing structures, often incorporating advanced steel cord and textile reinforcement technologies, to handle exceptionally heavy static and dynamic loads. Radial tire technology continues to evolve, offering improved load distribution, better heat dissipation, and enhanced stability for high-speed applications like terminal tractors. For solid tires, advancements focus on improved cushioning properties and enhanced bonding between the tread and the rim to prevent slippage and ensure consistent performance under maximum stress. The engineering of unique tread patterns is also crucial, providing optimal traction on wet, dusty, and uneven surfaces while minimizing wear and tear.

The integration of smart tire technologies is rapidly gaining traction within the port equipment sector. This involves embedding sensors, such as Tire Pressure Monitoring Systems (TPMS) and RFID tags, directly into the tire structure. These sensors collect real-time data on tire pressure, temperature, load, and wear levels, transmitting this information to fleet management systems. This data enables predictive maintenance, optimizes operational parameters, and enhances safety by alerting operators to potential issues before they escalate. Such technological integration is not only improving operational efficiency and reducing unexpected failures but also paving the way for further advancements in autonomous port equipment, where tire data plays a critical role in informed decision-making and operational optimization.

Regional Highlights

- Asia Pacific: This region stands as the undisputed leader in the Port Equipment Tire Market, driven by the presence of some of the world's largest and busiest container ports, including Shanghai, Singapore, Ningbo-Zhoushan, and Busan. Rapid industrialization, expanding manufacturing bases, and increasing intra-regional and inter-regional trade volumes across countries like China, India, Japan, South Korea, and Southeast Asian nations are fueling continuous investments in port infrastructure development and modernization. The surge in e-commerce and subsequent demand for efficient logistics also significantly contributes to the robust growth in port activities and, consequently, tire demand in this region.

- Europe: A mature market characterized by advanced port automation and a strong emphasis on sustainability and efficiency. Major ports such as Rotterdam, Hamburg, and Antwerp are key hubs for trade and technological adoption. The region benefits from a well-established replacement market and a strong focus on high-performance, environmentally compliant tires. Ongoing digitalization efforts in European ports and the transition towards electric port equipment are driving demand for technologically advanced and specialized tire solutions.

- North America: This region exhibits steady growth, largely propelled by significant investments in port expansion projects, particularly along the West and East Coasts, to accommodate larger vessel sizes and increasing trade volumes. The emphasis on intermodal transportation and the modernization of existing terminal facilities contribute to the demand for durable and efficient port equipment tires. The robust aftermarket segment and the adoption of advanced fleet management solutions are also key factors in this region's market dynamics.

- Middle East and Africa (MEA): Emerging as a high-growth region due to strategic geographic locations, substantial investments in port development, and economic diversification initiatives. Countries like UAE (Dubai, Abu Dhabi), Saudi Arabia, Qatar, and South Africa are undertaking ambitious projects to establish themselves as major global logistics and trade gateways. This proactive development of new ports and free trade zones is creating substantial opportunities for both OEM and aftermarket tire sales.

- Latin America: The market in Latin America is experiencing gradual growth, primarily driven by increasing commodity exports and infrastructure improvements in key economies such as Brazil, Mexico, and Chile. Investments in port modernization and efficiency enhancements are slowly picking up, aiming to streamline trade routes and improve regional competitiveness. The demand for reliable and cost-effective tire solutions is a significant consideration for port operators in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Port Equipment Tire Market.- Michelin

- Bridgestone

- Goodyear Tire & Rubber Company

- Continental AG

- Trelleborg AB

- Yokohama Rubber Co. Ltd.

- Pirelli & C. S.p.A.

- Sumitomo Rubber Industries Ltd.

- Mitas a.s. (part of Trelleborg Group)

- Balkrishna Industries Limited (BKT)

- Apollo Tyres Ltd.

- ATG Tires (part of Yokohama Rubber Co. Ltd.)

- Maxam Tire International

- Camso Inc. (part of Michelin Group)

- Shandong Linglong Tire Co. Ltd.

- Triangle Tyre Co. Ltd.

- Double Coin Holdings Ltd.

- Magna Tyres Group

- Nokian Tyres PLC

- CEAT Limited

Frequently Asked Questions

What types of tires are predominantly used in port equipment operations?

Port equipment primarily utilizes two main types of tires: solid tires and pneumatic tires. Solid tires, due to their puncture-proof design and high load-carrying capacity, are favored for heavy-duty, slow-moving equipment like forklifts and specific container handlers. Pneumatic tires, encompassing radial and bias constructions, offer better cushioning, traction, and speed, making them suitable for terminal tractors and straddle carriers operating over longer distances or requiring smoother rides.

What are the primary factors driving the growth of the Port Equipment Tire Market?

The Port Equipment Tire Market's growth is primarily driven by the continuous expansion of global maritime trade and freight volumes, leading to increased activity and throughput at ports worldwide. Other significant drivers include the ongoing modernization and automation of port infrastructure, demanding advanced an

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager