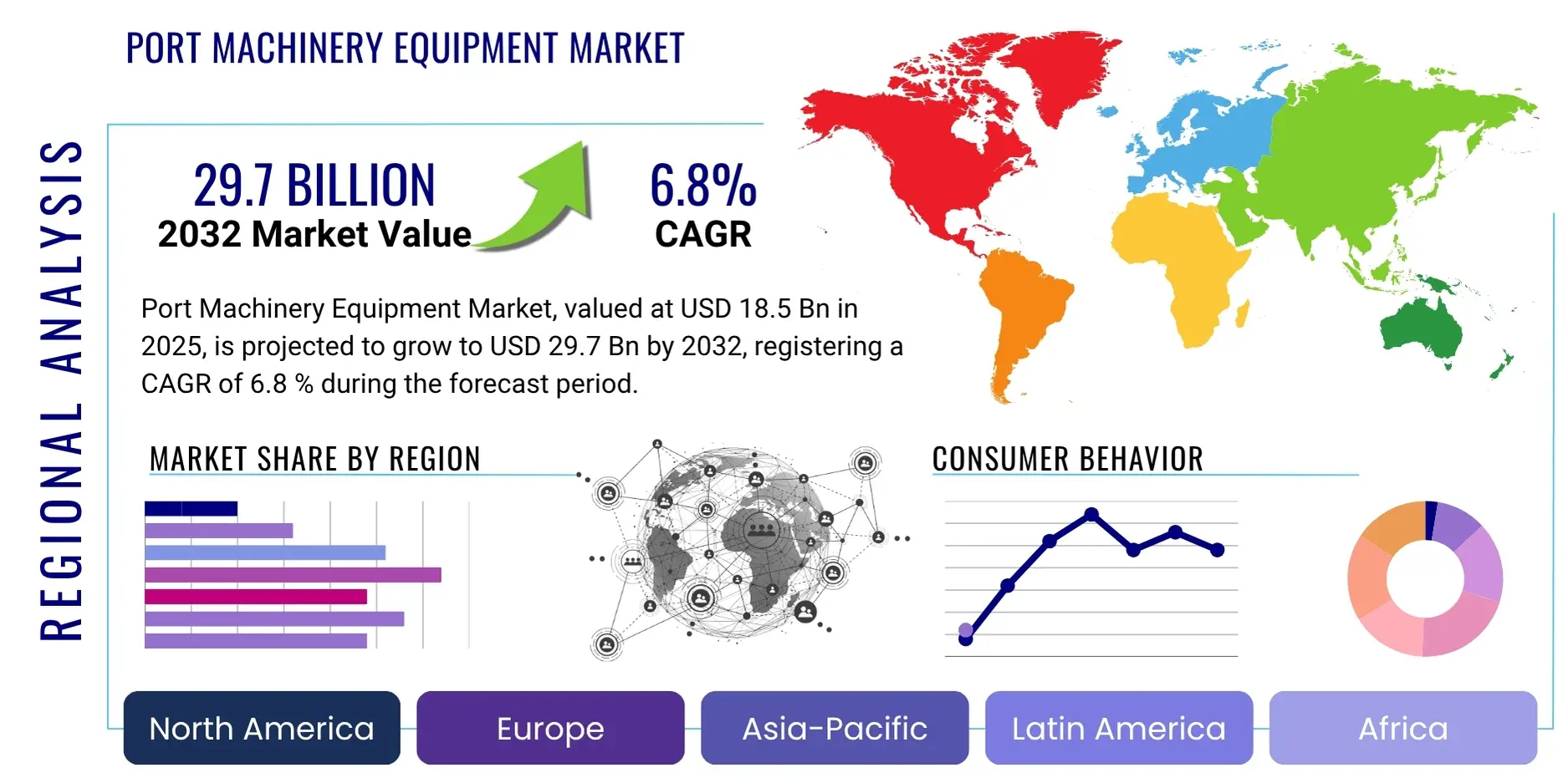

Port Machinery Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428179 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Port Machinery Equipment Market Size

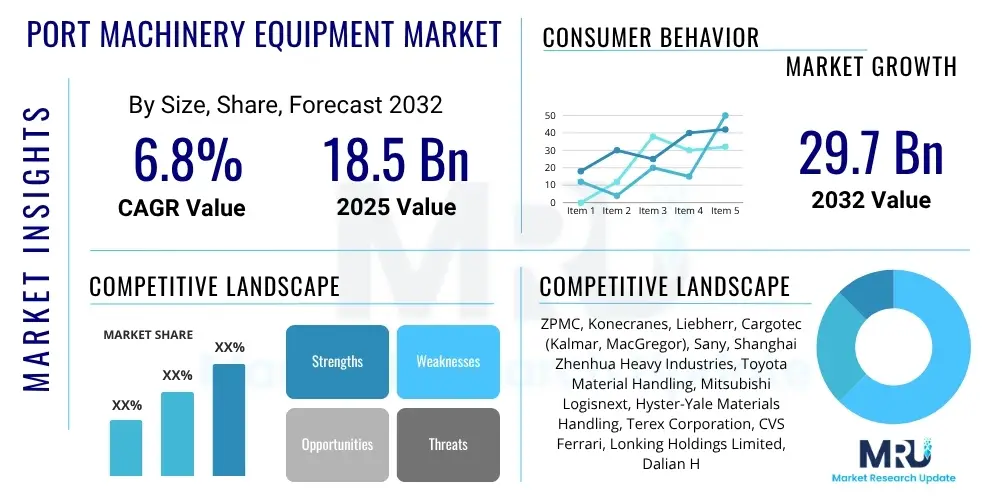

The Port Machinery Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 18.5 Billion in 2025 and is projected to reach USD 29.7 Billion by the end of the forecast period in 2032.

Port Machinery Equipment Market introduction

The Port Machinery Equipment Market encompasses a wide range of specialized heavy machinery and systems essential for efficient cargo handling, storage, and movement within port and terminal environments. These critical assets include various types of cranes, material handling equipment, and associated automation systems designed to manage the increasing volume and complexity of global trade. The market's primary objective is to enhance operational efficiency, reduce turnaround times for vessels, and ensure the safe and swift transfer of goods, ranging from vast containerized shipments to bulk commodities and general cargo.

Product descriptions within this market cover container handling equipment such as ship-to-shore (STS) cranes, rubber-tyred gantry (RTG) cranes, rail-mounted gantry (RMG) cranes, and mobile harbor cranes, alongside forklifts, reach stackers, straddle carriers, and terminal tractors. Major applications span across container terminals, bulk cargo ports, general cargo terminals, and specialized facilities for handling break-bulk and project cargo. The overarching benefits derived from this equipment include improved throughput, reduced labor costs through automation, enhanced safety protocols, and optimized land utilization within port areas, all of which are crucial for maintaining competitiveness in a dynamic global supply chain landscape.

Driving factors for this market's expansion are multifaceted, primarily fueled by the relentless growth in international trade volumes, the ongoing trend of containerization, and the increasing size of container vessels (ULCVs) that necessitate larger and more powerful handling equipment. Additionally, government investments in port infrastructure development, coupled with a global push for port modernization and automation, significantly contribute to market propulsion. The demand for eco-friendly and energy-efficient machinery also stimulates innovation and adoption of advanced solutions, further consolidating the market's growth trajectory.

Port Machinery Equipment Market Executive Summary

The Port Machinery Equipment Market is experiencing robust growth driven by significant shifts in global trade patterns and technological advancements. Business trends indicate a strong emphasis on automation and digitalization, as port operators seek to optimize efficiency, reduce operational costs, and enhance safety in increasingly complex logistics environments. There is a discernible move towards integrating advanced robotics, Internet of Things (IoT) solutions, and Artificial Intelligence (AI) into port operations, leading to a demand for smart, interconnected machinery capable of autonomous functions and predictive maintenance. Furthermore, sustainability initiatives are influencing procurement decisions, with a rising preference for electric and hybrid equipment to minimize environmental footprints and comply with stringent emission regulations.

Regional trends reveal varied growth dynamics, with Asia Pacific emerging as a dominant market, propelled by rapid economic growth, burgeoning manufacturing activities, and extensive port infrastructure development in countries like China, India, and Southeast Asian nations. North America and Europe also demonstrate significant market presence, characterized by substantial investments in upgrading existing ports with advanced automation and greener technologies to maintain their competitive edge. Emerging economies in Latin America, the Middle East, and Africa are increasingly investing in modern port machinery to capitalize on their strategic maritime locations and expanding trade capacities, albeit at different adoption rates influenced by economic stability and infrastructure readiness.

Segmentation trends highlight the increasing demand for advanced container handling equipment due to the pervasive containerization of global freight. Within this segment, automated guided vehicles (AGVs) and remotely operated cranes are gaining traction. By operation mode, the market is shifting from purely manual to semi-automated and fully automated solutions, driven by labor cost pressures and the pursuit of higher throughput. Furthermore, equipment designed for larger capacities is seeing increased adoption in response to the proliferation of mega-ships. The after-sales service and maintenance segment is also expanding, reflecting the need for specialized expertise to manage sophisticated machinery and maximize its operational lifespan, ensuring continuous and reliable port operations.

AI Impact Analysis on Port Machinery Equipment Market

User inquiries regarding AI's impact on the Port Machinery Equipment Market frequently revolve around automation, efficiency gains, safety improvements, and the future of manual labor. Common concerns include the initial investment costs, the complexity of integrating AI systems with legacy infrastructure, and the need for skilled personnel to operate and maintain these advanced technologies. There is also significant interest in how AI can enhance predictive maintenance, optimize resource allocation, and facilitate fully autonomous operations, leading to faster turnaround times and reduced operational expenses. Users often seek clarity on the tangible benefits and potential disruptive forces that AI introduces to traditional port management and equipment utilization paradigms.

- AI drives enhanced automation, enabling autonomous vehicles and cranes, reducing human intervention.

- Predictive maintenance powered by AI minimizes equipment downtime and extends operational lifespan.

- Optimized logistics and cargo flow through AI algorithms improve port efficiency and throughput.

- AI-enabled vision systems and sensors enhance safety by detecting anomalies and preventing collisions.

- Reduced operational costs are achieved via optimized energy consumption and resource allocation.

- Real-time data analytics and decision-making capabilities improve responsiveness to dynamic conditions.

- Remote operation and control centers become more prevalent, supported by AI for complex tasks.

- Training and simulation tools leveraging AI enhance operator proficiency and safety procedures.

DRO & Impact Forces Of Port Machinery Equipment Market

The Port Machinery Equipment Market is influenced by a dynamic interplay of drivers, restraints, and opportunities, alongside various impact forces that shape its trajectory. Key drivers include the exponential growth in global trade volumes, particularly containerized cargo, which necessitates higher capacity and more efficient handling solutions. The continuous trend towards larger vessel sizes (mega-ships) compels ports to upgrade their infrastructure and procure advanced, heavy-duty machinery. Furthermore, the global push for port automation and digitalization, aimed at reducing operational costs, improving safety, and increasing throughput, acts as a significant catalyst for market expansion. Government investments in port modernization initiatives and infrastructure development across various regions also substantially contribute to demand, seeking to enhance national logistics capabilities and economic competitiveness.

However, the market faces several notable restraints. The exceptionally high initial capital expenditure required for acquiring and implementing modern port machinery, especially automated systems, can be a deterrent for port authorities, particularly in developing regions with limited financial resources. Complex maintenance requirements and the need for highly skilled labor to operate and service sophisticated equipment also present challenges. Additionally, geopolitical uncertainties, trade disputes, and economic downturns can lead to fluctuations in global trade volumes, directly impacting investment decisions in new port machinery. Environmental regulations, while driving innovation towards greener technologies, can also impose additional costs and complexities on equipment manufacturers and port operators, necessitating significant R&D investments and operational adjustments.

Despite these challenges, numerous opportunities exist to propel market growth. The increasing adoption of green port initiatives, including the electrification of port equipment and the development of zero-emission machinery, presents a substantial growth avenue. The integration of advanced technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and blockchain for enhanced operational visibility, predictive maintenance, and optimized supply chain management offers innovative pathways. Furthermore, the retrofitting and upgrading of existing port machinery with modern components and automation features provide a cost-effective alternative to complete replacement, broadening the market scope. Emerging markets in Africa, Latin America, and parts of Asia, with their nascent but rapidly developing port infrastructures, represent significant untapped potential for future investments and equipment deployment, driven by industrialization and expanding regional trade networks.

Segmentation Analysis

The Port Machinery Equipment Market is meticulously segmented to provide a granular understanding of its diverse components and dynamics. This segmentation aids in identifying specific demand patterns, technological trends, and competitive landscapes across different applications and equipment types. The primary modes of segmentation typically include equipment type, application, capacity, and operation mode, each offering unique insights into market behavior and growth prospects. Understanding these distinct segments is crucial for manufacturers, investors, and port operators to strategically position themselves and capitalize on specific market opportunities, ensuring targeted development and deployment of solutions.

- By Equipment Type:

- Cranes (Ship-to-Shore Cranes, Rubber-Tyred Gantry Cranes, Rail-Mounted Gantry Cranes, Mobile Harbor Cranes)

- Forklifts

- Reach Stackers

- Straddle Carriers

- Terminal Tractors/Trailers

- Empty Container Handlers

- Material Handlers

- Automated Guided Vehicles (AGVs)

- Spreaders

- Conveyor Systems

- By Application:

- Container Handling

- Bulk Cargo Handling

- General Cargo Handling

- Break-Bulk Cargo Handling

- Ro-Ro (Roll-on/Roll-off) Operations

- By Capacity:

- Light Duty (e.g., smaller forklifts, terminal tractors)

- Medium Duty (e.g., standard reach stackers, RTG cranes)

- Heavy Duty (e.g., STS cranes for mega-ships, high-capacity material handlers)

- By Operation Mode:

- Manual/Conventional

- Semi-Automated

- Fully Automated

Value Chain Analysis For Port Machinery Equipment Market

The value chain for the Port Machinery Equipment Market commences with upstream activities involving the sourcing and processing of raw materials such as steel, specialized components, hydraulics, and electronic systems from a diverse network of suppliers. These suppliers provide critical inputs that form the foundation of heavy machinery manufacturing, including engines, power transmission systems, control software, and advanced sensor technologies. The quality and availability of these raw materials and components directly impact the overall production cost, lead times, and the performance characteristics of the final equipment. Strong supplier relationships are therefore paramount for ensuring consistent supply and adherence to rigorous quality standards.

Midstream in the value chain, the manufacturing and assembly phase involves the design, fabrication, and integration of these components into complete port machinery. This stage includes sophisticated engineering, precision manufacturing, and rigorous testing processes to ensure the equipment meets demanding operational requirements, safety standards, and environmental regulations. Manufacturers often invest heavily in research and development to innovate new designs, integrate automation capabilities, and enhance energy efficiency. Following manufacturing, the distribution channel plays a crucial role in delivering the finished products to end-users. This typically involves a combination of direct sales from manufacturers, where large-scale projects are handled in-house, and indirect channels through a network of authorized dealers, distributors, and agents who often provide localized sales, support, and after-sales services to a broader customer base, including smaller port operators.

Downstream activities primarily focus on the deployment, operation, and maintenance of the port machinery at various port and terminal facilities worldwide. This segment includes installation, commissioning, operator training, and ongoing maintenance, repairs, and spare parts supply. Effective after-sales service and support are critical for ensuring optimal equipment performance and minimizing downtime, directly impacting the operational efficiency and profitability of ports. The ultimate end-users, such as container terminals, bulk cargo ports, and general cargo facilities, rely on this comprehensive support to maximize the lifespan and utility of their machinery, thereby ensuring the seamless flow of global trade. The efficiency and effectiveness of these downstream services are vital for customer satisfaction and long-term market competitiveness.

Port Machinery Equipment Market Potential Customers

The primary potential customers and end-users of port machinery equipment are diverse entities operating within the global maritime trade and logistics sectors. These include various types of port authorities and terminal operators responsible for managing and operating port facilities, ranging from large international hubs to smaller regional ports. These entities invest in machinery to enhance their cargo handling capabilities, increase throughput, and improve overall operational efficiency, which is critical for accommodating growing trade volumes and larger vessel sizes. Their purchasing decisions are often driven by long-term strategic plans, infrastructure development goals, and the need to maintain competitive advantage in a highly competitive industry, requiring robust, reliable, and often automated equipment to meet the demands of modern shipping.

Another significant segment of potential customers includes shipping lines and logistics companies that own or lease their terminal facilities. These companies often seek specialized equipment that integrates seamlessly with their global supply chain operations, enabling faster vessel turnaround times and optimized cargo flow. Their investment decisions are influenced by their specific fleet requirements, cargo types, and the desire to control operational costs while ensuring rapid and efficient freight movement. Furthermore, independent stevedoring companies, which are contracted by port authorities or shipping lines to load and unload vessels, also represent key buyers, particularly for versatile and adaptable equipment suitable for a variety of cargo handling tasks, prioritizing equipment reliability and efficiency to meet contractual obligations and stringent deadlines.

Beyond the core port and shipping entities, other potential customers include industrial companies with their own private docks or dedicated terminals for handling specific commodities such as mining products, chemicals, or agricultural goods. These entities require specialized machinery tailored to their unique cargo types and operational scales, prioritizing safety, environmental compliance, and cost-effectiveness in their material handling processes. Additionally, government agencies involved in coastal development, maritime infrastructure projects, and defense operations may also procure port machinery for specific public utility or strategic purposes, contributing to a broad and multifaceted customer base that underpins the Port Machinery Equipment Market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 18.5 Billion |

| Market Forecast in 2032 | USD 29.7 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ZPMC, Konecranes, Liebherr, Cargotec (Kalmar, MacGregor), Sany, Shanghai Zhenhua Heavy Industries, Toyota Material Handling, Mitsubishi Logisnext, Hyster-Yale Materials Handling, Terex Corporation, CVS Ferrari, Lonking Holdings Limited, Dalian Heavy Industry Co., Ltd., Siemens AG, ABB Ltd., Gottwald Port Technology GmbH, Anhui Forklift Group Co., Ltd., JLG Industries, Inc. (Oshkosh Corporation), SENNEBOGEN Maschinenfabrik GmbH, Tadano Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Port Machinery Equipment Market Key Technology Landscape

The Port Machinery Equipment Market is undergoing a profound technological transformation, driven by the relentless pursuit of efficiency, sustainability, and safety in global maritime logistics. A pivotal technology enabling this evolution is the Internet of Things (IoT), which facilitates the seamless connectivity of port machinery. IoT sensors embedded in cranes, straddle carriers, and AGVs collect vast amounts of real-time operational data, including performance metrics, location tracking, and equipment health. This data is crucial for monitoring, diagnostics, and optimizing operational workflows, enabling proactive decision-making and enhancing overall situational awareness across the port ecosystem. The integration of IoT allows for centralized control and management of a vast array of equipment, transforming ports into smart, interconnected hubs that operate with unprecedented levels of coordination.

Artificial Intelligence (AI) and Machine Learning (ML) represent another cornerstone of the modern port machinery landscape. These technologies leverage the data gathered by IoT devices to power advanced analytics, predictive maintenance, and autonomous operations. AI algorithms can analyze historical and real-time data to forecast equipment failures, optimize energy consumption, and intelligently manage cargo flows, significantly reducing downtime and improving throughput. Autonomous Guided Vehicles (AGVs) and remotely operated cranes, guided by AI, are becoming increasingly common, automating repetitive and labor-intensive tasks and thereby enhancing safety, especially in hazardous areas. Machine learning also refines operational processes by continuously learning from performance data, leading to adaptive systems that improve over time without direct human programming, making port operations more resilient and responsive to dynamic conditions.

Further technological advancements include the widespread adoption of electrification and hybrid power solutions, responding to global pressures for reduced carbon emissions and sustainable operations. Electric and hybrid port equipment, such as electric RTG cranes, battery-powered terminal tractors, and hybrid reach stackers, significantly lower fuel consumption and noise pollution, contributing to greener ports. Robotics, integrated with AI, allows for precision handling of cargo and automation of various tasks, from container lashing to internal terminal transport. Additionally, advanced control systems, digital twins, and big data analytics provide a comprehensive digital representation of the port environment and equipment, enabling sophisticated simulations, operational planning, and continuous improvement initiatives. These technologies collectively reshape the capabilities and operational paradigms of port machinery, creating a more efficient, safer, and environmentally responsible maritime logistics industry.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to massive investments in port infrastructure, robust trade growth, and increasing container traffic in China, India, Japan, and Southeast Asian countries. The region is a hub for manufacturing and exporting, driving demand for advanced port machinery.

- Europe: A mature market characterized by high automation levels, strong emphasis on green technologies, and ongoing modernization of existing port facilities in key maritime nations such as Germany, Netherlands, and the UK. Focus on efficiency and sustainability.

- North America: Significant investments in port expansion and automation, particularly in the US and Canada, driven by increasing e-commerce volumes and the need to accommodate larger container vessels. Emphasis on reducing labor costs and improving supply chain resilience.

- Latin America: Emerging market with growing investments in port capacity expansion and modernization, fueled by rising commodity exports and intra-regional trade. Countries like Brazil, Mexico, and Chile are key contributors to market growth.

- Middle East and Africa (MEA): Rapidly developing region leveraging strategic geographical locations. Substantial port development projects in the UAE, Saudi Arabia, and various African nations are driving demand for new and advanced port machinery to support burgeoning trade routes.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Port Machinery Equipment Market.- ZPMC (Shanghai Zhenhua Heavy Industries Co., Ltd.)

- Konecranes Plc

- Liebherr Group

- Cargotec Corporation (Kalmar, MacGregor)

- Sany Group Co., Ltd.

- Toyota Material Handling Group

- Mitsubishi Logisnext Co., Ltd.

- Hyster-Yale Materials Handling, Inc.

- Terex Corporation (Terex Port Solutions)

- CVS Ferrari S.p.A.

- Lonking Holdings Limited

- Dalian Heavy Industry Co., Ltd.

- Siemens AG

- ABB Ltd.

- Gottwald Port Technology GmbH

- Anhui Forklift Group Co., Ltd. (HELI)

- JLG Industries, Inc. (Oshkosh Corporation)

- SENNEBOGEN Maschinenfabrik GmbH

- KION Group AG

- Manitou Group

Frequently Asked Questions

What is the projected growth rate for the Port Machinery Equipment Market?

The Port Machinery Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032, driven by global trade expansion and port modernization.

What are the primary drivers of growth in this market?

Key drivers include the continuous growth in global trade, increasing containerization, the trend towards larger vessel sizes, and significant investments in port automation and infrastructure development worldwide.

How is AI impacting port machinery equipment?

AI is significantly impacting the market by enabling advanced automation, optimizing logistics, facilitating predictive maintenance, enhancing safety features, and supporting autonomous operations for improved efficiency and reduced costs.

Which regions are leading the demand for port machinery equipment?

The Asia Pacific region is a dominant market due to extensive port development and trade growth, followed by Europe and North America, which focus on automation and green technologies.

What types of equipment are included in the Port Machinery Equipment Market?

The market encompasses a wide range of equipment including various types of cranes (STS, RTG, RMG, Mobile Harbor), forklifts, reach stackers, straddle carriers, terminal tractors, and automated guided vehicles (AGVs).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager