Portable Air Compressor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428264 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Portable Air Compressor Market Size

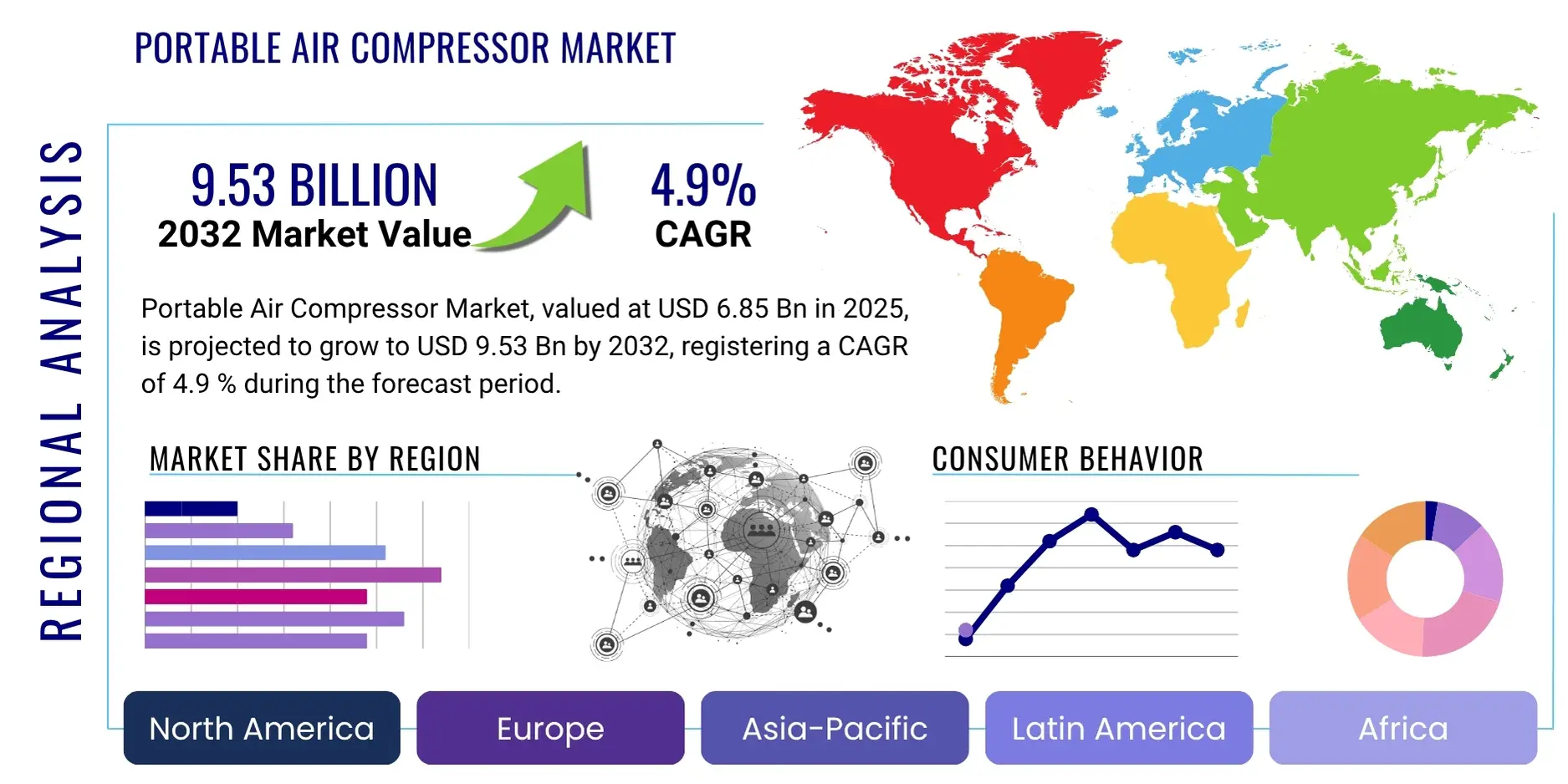

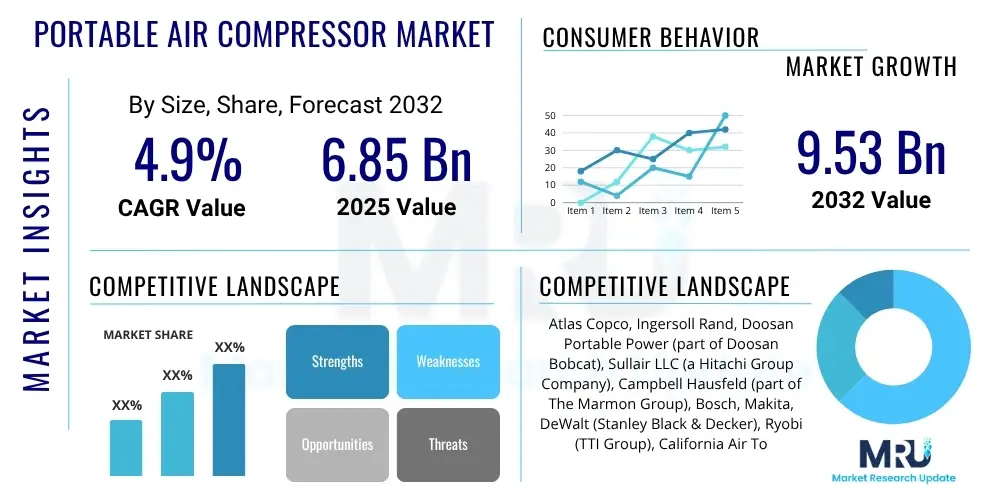

The Portable Air Compressor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.9% between 2025 and 2032. The market is estimated at USD 6.85 billion in 2025 and is projected to reach USD 9.53 billion by the end of the forecast period in 2032. This growth trajectory is underpinned by increasing industrialization, a surge in automotive aftermarket services, and a growing trend towards DIY and home improvement projects globally. The versatility and convenience offered by portable air compressors are key drivers for their expanding adoption across various sectors.

Market expansion is also significantly influenced by technological advancements, leading to more efficient, quieter, and durable products. Innovations in battery technology, motor design, and material science are enabling manufacturers to produce compressors that are lighter, more powerful, and offer extended operational times, catering to a wider array of consumer and professional needs. The ongoing infrastructure development projects in emerging economies further contribute to the sustained demand for portable air compressors, particularly in construction and related industries.

Portable Air Compressor Market introduction

The Portable Air Compressor Market encompasses a range of devices designed to compress and store air in a portable format, providing a versatile power source for various pneumatic tools and applications. These compressors typically consist of a motor, a pump, a receiver tank, and controls, all integrated into a compact and often lightweight unit that can be easily transported. Their primary function is to convert electrical or fuel-based power into kinetic energy in the form of compressed air, which is then utilized for a multitude of tasks ranging from inflating tires and powering spray guns to operating heavy-duty construction equipment.

Major applications for portable air compressors span across diverse industries, including automotive for tire inflation, impact wrenches, and paint spraying; construction for powering nail guns, jackhammers, and sandblasters; manufacturing for assembly line operations and small-scale machinery; and even healthcare for specific medical devices. Beyond professional uses, these compressors are increasingly popular among DIY enthusiasts and homeowners for tasks like woodworking, painting, and general maintenance, owing to their convenience and adaptability. Key benefits include enhanced mobility, reduced operational setup time, and the ability to operate in remote locations without fixed air supply infrastructure.

Driving factors for this market's robust growth include the rapid expansion of the construction sector globally, particularly in developing economies, leading to increased demand for portable pneumatic tools. Furthermore, the burgeoning automotive aftermarket and vehicle maintenance industry, coupled with rising disposable incomes supporting DIY culture, are significant contributors. Technological advancements focusing on energy efficiency, noise reduction, and the development of cordless, battery-powered units are also propelling market expansion by broadening the appeal and applicability of portable air compressors to a wider consumer base.

Portable Air Compressor Market Executive Summary

The Portable Air Compressor Market is currently experiencing dynamic growth, driven by a confluence of business trends that emphasize efficiency, mobility, and technological integration. Key business trends include the increasing adoption of cordless and battery-powered models, which offer unparalleled flexibility and ease of use, particularly in remote job sites or areas without direct power access. There is also a growing demand for oil-free compressors, especially in industries where air purity is critical, such as food processing, pharmaceuticals, and certain medical applications, reflecting a broader industry shift towards specialized, application-specific solutions. Manufacturers are continually investing in research and development to enhance product performance, durability, and user-friendliness, aligning with evolving consumer expectations for higher quality and reliability.

Regional trends reveal significant market expansion in Asia Pacific, propelled by rapid industrialization, extensive infrastructure development, and a burgeoning manufacturing sector in countries like China, India, and Southeast Asian nations. North America and Europe continue to be strong markets, characterized by high adoption rates in automotive repair, construction, and DIY segments, alongside a focus on advanced, energy-efficient models driven by stringent environmental regulations. Latin America and the Middle East & Africa are emerging as promising markets, buoyed by economic development, urbanization, and increasing investment in construction and energy sectors, leading to a rise in demand for versatile and robust portable air solutions.

Segmentation trends indicate strong growth in the electric-powered segment due to environmental concerns and the convenience of widespread electrical grids, although gas/diesel models remain crucial for heavy-duty, off-grid applications. By application, the automotive and construction sectors hold dominant shares, but the home & DIY segment is witnessing the fastest growth as portable compressors become more accessible and user-friendly. In terms of technology, rotary screw compressors are gaining traction in industrial settings for their continuous duty cycle capabilities, while reciprocating piston compressors remain popular for intermittent, general-purpose tasks due to their cost-effectiveness and broad utility.

AI Impact Analysis on Portable Air Compressor Market

The integration of Artificial Intelligence (AI) into the portable air compressor market is poised to revolutionize several facets, from operational efficiency and maintenance to supply chain management and product design. Users are primarily concerned with how AI can enhance the reliability and longevity of their equipment, seeking solutions for predictive maintenance that can anticipate failures before they occur, thus minimizing downtime and repair costs. There is also significant interest in AI's potential to optimize energy consumption, given that air compressors are often substantial energy users. Furthermore, users expect AI to improve the user experience through intelligent diagnostics, autonomous operation features, and seamless integration with broader smart infrastructure and IoT ecosystems, leading to more intelligent and adaptive tools.

Another key theme users frequently inquire about is the capability of AI to provide real-time performance monitoring and remote management. This would enable operators to track usage patterns, identify inefficiencies, and control compressors from a distance, which is particularly beneficial for large-scale construction sites or dispersed operations. The expectation is that AI will make portable air compressors "smarter," capable of learning from operational data to self-optimize, adjust to varying load demands, and even communicate with other smart tools on a job site. This intelligent evolution promises not only operational savings but also improved safety and enhanced overall productivity.

- Predictive Maintenance: AI algorithms analyze operational data (temperature, pressure, vibration) to forecast potential equipment failures, enabling proactive servicing and reducing unexpected downtime.

- Optimized Energy Consumption: AI-driven systems can dynamically adjust compressor output to match demand, minimizing energy waste and lowering operational costs.

- Autonomous Operation: AI can facilitate self-regulating compressors that adapt to varying environmental conditions and workload requirements without constant human intervention.

- Enhanced Diagnostics: Smart diagnostics powered by AI can quickly identify issues, suggest troubleshooting steps, and even order replacement parts automatically, streamlining repair processes.

- Supply Chain Optimization: AI improves inventory management for spare parts, forecasts demand more accurately, and optimizes logistics for raw materials and finished products, reducing lead times and costs.

- Remote Monitoring & Control: AI enables real-time monitoring of compressor performance and allows for remote adjustments and anomaly detection, enhancing operational efficiency and safety across distributed sites.

- Advanced Product Design: AI-driven simulations and generative design tools can optimize compressor components for weight reduction, noise dampening, and improved airflow, leading to more efficient and user-friendly products.

DRO & Impact Forces Of Portable Air Compressor Market

The Portable Air Compressor Market is significantly influenced by a set of interconnected Drivers, Restraints, and Opportunities (DRO), which collectively shape its growth trajectory and competitive landscape. The primary drivers fueling market expansion include the accelerating pace of industrialization and urbanization globally, particularly in emerging economies, which necessitates robust and mobile power solutions for construction and manufacturing activities. The steady growth of the automotive industry, encompassing both manufacturing and aftermarket services like tire shops and vehicle maintenance, consistently fuels demand for portable air tools. Furthermore, the increasing popularity of DIY and home improvement projects among consumers, seeking convenient and versatile tools, acts as a substantial market impetus. Technological advancements, leading to more compact, energy-efficient, and quieter compressor models, alongside the development of advanced battery technologies for cordless units, further enhance market appeal and broaden application scope.

Conversely, several restraints impede the market's full potential. The relatively high initial cost of advanced portable air compressor models, especially those with cutting-edge features or specialized capabilities, can be a barrier for small businesses and individual consumers. Noise pollution generated by some compressor types, particularly older or less refined models, remains a concern in residential and enclosed industrial settings, prompting demand for quieter alternatives. Additionally, intense competition from traditional, stationary air compressors for heavy-duty, continuous-operation industrial applications means portable units may not always be the preferred choice where mobility is less of a concern. Fluctuations in raw material prices, such as steel, copper, and specialized plastics, can also impact manufacturing costs and, subsequently, product pricing, affecting market stability.

Despite these challenges, numerous opportunities exist for market players to capitalize on. The expansion into untapped and emerging markets in regions such as Latin America, Africa, and parts of Asia offers significant growth potential as these economies develop their infrastructure and industrial capabilities. The ongoing focus on sustainability and energy efficiency presents an opportunity for manufacturers to innovate and develop greener, more power-efficient models, attracting environmentally conscious consumers and businesses. Moreover, the integration of smart technologies, such as IoT connectivity for remote monitoring and AI for predictive maintenance, opens new avenues for product differentiation and value-added services. Niche applications in sectors like medical, aerospace, and specialized agriculture also represent promising growth areas for tailored portable air compressor solutions, leveraging their specific requirements for precision, reliability, and mobility.

Segmentation Analysis

The Portable Air Compressor Market is highly diversified, segmented across various parameters including type, lubrication, technology, pressure, and application, to cater to a broad spectrum of user needs and industry requirements. This detailed segmentation allows manufacturers to target specific market niches with tailored products, optimizing functionality and cost-effectiveness. The market's structure reflects the wide range of tasks portable air compressors perform, from light-duty tasks like inflating car tires to heavy-duty industrial applications requiring continuous, high-pressure air supply. Understanding these segments is crucial for analyzing market dynamics, identifying growth opportunities, and formulating effective market strategies for both established players and new entrants.

Each segment is driven by unique demand characteristics. For instance, the demand for oil-free compressors is predominantly from industries where air purity is paramount, such as healthcare and food processing, while oil-lubricated models remain popular for general industrial and automotive uses due to their durability and lower cost. Similarly, electric portable compressors are favored for indoor and environmentally sensitive applications, whereas gas-powered units are indispensable for outdoor and remote job sites lacking electrical infrastructure. The ongoing evolution within these segments, particularly with advancements in battery technology for cordless solutions and smart features, continuously reshapes market preferences and drives innovation across the entire product portfolio.

- By Type:

- Reciprocating/Piston (Single-stage, Two-stage)

- Rotary (Screw, Vane, Scroll)

- By Lubrication:

- Oil-Lubricated

- Oil-Free

- By Technology:

- Electric (Corded, Cordless/Battery-powered)

- Gasoline/Diesel

- By Pressure:

- Low Pressure (Up to 100 PSI)

- Medium Pressure (101-200 PSI)

- High Pressure (Above 200 PSI)

- By Portability:

- Wheeled

- Hand-held

- By Application:

- Construction

- Automotive (Repair, Maintenance, Tire Shops)

- Manufacturing

- Energy & Mining

- Home & DIY

- Healthcare & Medical

- Agriculture

- Others (e.g., HVAC, Sandblasting)

Value Chain Analysis For Portable Air Compressor Market

The value chain for the Portable Air Compressor Market is a complex network of activities that spans from raw material sourcing to end-user consumption and after-sales support, illustrating the sequential processes that add value at each stage. It commences with upstream analysis, which involves the procurement of essential raw materials and components. This stage includes sourcing metals such as steel and aluminum for tanks and casings, copper for motor windings, specialized plastics for various parts, and electronic components for controls and smart features. Key suppliers in this segment focus on material quality, cost-effectiveness, and timely delivery, directly impacting the manufacturing capabilities and final product quality of air compressor OEMs. Manufacturers often work closely with these suppliers to ensure compliance with material specifications and to innovate in material science for lighter and more durable products.

Moving downstream, the value chain encompasses the manufacturing, assembly, distribution, and sales stages. Original Equipment Manufacturers (OEMs) design and assemble the compressors, integrating various components such as motors, pumps, tanks, and control systems. This stage involves significant investment in R&D, production technology, and quality control to produce reliable and efficient units. The distribution channel then plays a crucial role in delivering these products to the end-users. This involves both direct and indirect channels. Direct distribution might include OEMs selling directly to large industrial clients or through their own brand stores/e-commerce platforms, offering greater control over pricing and customer relationships. Indirect channels are more prevalent and involve a network of wholesalers, distributors, retailers (both brick-and-mortar hardware stores and online marketplaces), and specialized pneumatic equipment suppliers. These intermediaries provide market reach, logistics, and often, local customer support and technical expertise, making products accessible to a wider consumer base, from individual DIYers to large construction firms. After-sales services, including maintenance, repairs, and spare parts supply, form the final critical link, ensuring customer satisfaction and product longevity, thereby closing the value chain loop.

Portable Air Compressor Market Potential Customers

The Portable Air Compressor Market caters to a remarkably diverse range of end-users and buyers, spanning across various industrial, commercial, and consumer sectors, each with distinct needs and purchasing behaviors. At the industrial level, potential customers include large-scale construction companies involved in infrastructure projects, building development, and demolition, where portable compressors power heavy-duty pneumatic tools like jackhammers, rivet guns, and concrete vibrators. Manufacturing facilities, particularly those requiring intermittent or flexible air supply for assembly lines, small-scale machinery, or cleaning operations, also represent a significant customer base. Energy and mining sectors, operating in often remote and challenging environments, rely on robust portable compressors for drilling, ventilation, and equipment maintenance, prioritizing durability and high performance.

In the commercial sphere, the automotive aftermarket forms a cornerstone of demand, with auto repair shops, tire service centers, car detailing businesses, and mobile mechanics being primary buyers. These entities utilize compressors for tire inflation, operating impact wrenches, paint spraying, and cleaning. Agricultural businesses, ranging from small farms to large-scale operations, use portable air for equipment maintenance, crop dusting, and operating specific pneumatic tools. Furthermore, specialized service providers, such as those in HVAC installation, sandblasting, and emergency services, frequently depend on the mobility and reliability of these units. Even healthcare facilities, for specific medical equipment and laboratory applications requiring clean, portable air, constitute a niche but growing customer segment, often prioritizing oil-free models for air purity.

On the consumer front, the burgeoning segment of DIY enthusiasts and homeowners represents a rapidly expanding customer base. These individuals purchase portable air compressors for a wide array of personal projects, including inflating vehicle tires, sports equipment, and inflatable pools, as well as powering pneumatic nail guns for carpentry, paint sprayers for home renovation, and airbrushes for hobbies. The appeal for this segment lies in the convenience, ease of use, and versatility of modern portable compressors, which are becoming increasingly compact, lighter, and more affordable. This broad spectrum of potential customers underscores the widespread utility and indispensability of portable air compressors across nearly every facet of modern life and industry.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.85 Billion |

| Market Forecast in 2032 | USD 9.53 Billion |

| Growth Rate | 4.9% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Ingersoll Rand, Doosan Portable Power (part of Doosan Bobcat), Sullair LLC (a Hitachi Group Company), Campbell Hausfeld (part of The Marmon Group), Bosch, Makita, DeWalt (Stanley Black & Decker), Ryobi (TTI Group), California Air Tools, Quincy Compressor, Kaeser Compressors, Gardner Denver (part of Ingersoll Rand), Eaton Compressor, Schulz S.A., Festool (TTS Tooltechnic Systems AG & Co. KG), SENCO (Kyocera Senco Industrial Tools), Porter-Cable (Stanley Black & Decker), Kobalt (Lowe's), Craftsman (Stanley Black & Decker) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Portable Air Compressor Market Key Technology Landscape

The Portable Air Compressor Market is undergoing significant technological evolution, driven by the demand for enhanced efficiency, reduced noise, increased portability, and improved user experience. A pivotal area of innovation lies in motor and pump technologies. The adoption of brushless motors, particularly in electric and battery-powered units, is gaining traction due to their superior efficiency, longer lifespan, and quieter operation compared to traditional brushed motors. These advancements translate into longer runtimes for cordless models and lower energy consumption for corded units, addressing critical consumer pain points. Furthermore, advancements in pump design, including improved piston seals and rotary screw profiles, are contributing to higher air output per horsepower, reducing heat generation, and extending the maintenance intervals of the compressors.

Another crucial aspect of the technology landscape is the rapid development in power sources, especially for cordless portable compressors. The integration of advanced lithium-ion (Li-ion) battery technology is a game-changer, offering higher energy density, faster charging capabilities, and more consistent power delivery, which allows for longer uninterrupted operation in remote or power-constrained environments. Manufacturers are also exploring innovative fuel injection systems and smaller, more efficient internal combustion engines for gasoline and diesel-powered units, aiming to reduce fuel consumption and emissions while maintaining robust performance. The focus on modular battery systems, allowing batteries to be shared across various tools, further enhances convenience and cost-effectiveness for users with multiple cordless devices.

Beyond core mechanical and power components, the portable air compressor market is increasingly leveraging digital and smart technologies. IoT (Internet of Things) integration is enabling smart features such as remote monitoring, allowing users to track pressure levels, battery status, and operational hours via smartphone apps, facilitating proactive maintenance and operational management. AI and machine learning are beginning to be applied for predictive maintenance algorithms, anticipating potential failures and optimizing service schedules, thereby minimizing downtime. Furthermore, advancements in material science are leading to the use of lighter yet stronger composite materials, reducing the overall weight of the compressors without compromising durability, making them even more portable and user-friendly. Noise reduction technologies, through optimized housing designs, vibration dampening, and advanced mufflers, are also a key focus, catering to the growing demand for quieter operation in various settings.

Regional Highlights

- North America: This region stands as a mature market with robust demand from the automotive aftermarket, construction, and a strong DIY culture. High consumer spending and stringent environmental regulations drive the adoption of technologically advanced, energy-efficient, and quieter models. Significant investment in infrastructure projects also fuels demand for versatile portable air solutions.

- Europe: Characterized by stringent environmental norms and a strong focus on industrial automation and construction, Europe exhibits high demand for portable compressors. Germany, the UK, and France are key contributors, driven by manufacturing, professional trades, and a growing emphasis on electric and oil-free variants. Innovation in design and energy efficiency is paramount here.

- Asia Pacific (APAC): The fastest-growing region, APAC is propelled by rapid industrialization, massive infrastructure development, and a booming manufacturing sector, particularly in China, India, and Southeast Asian countries. Increasing urbanization, rising disposable incomes, and the expansion of automotive and construction industries are key growth drivers, creating significant opportunities for both established and emerging players.

- Latin America: This region is an emerging market with substantial growth potential, driven by expanding construction activities, urbanization, and increasing industrial investments. Countries like Brazil and Mexico are leading the demand, with a focus on cost-effective yet reliable portable air compressors that can withstand diverse operating conditions.

- Middle East and Africa (MEA): The MEA market is primarily driven by substantial investments in oil and gas, mining, and large-scale infrastructure projects. Demand for robust, high-performance portable compressors capable of operating in harsh environments is high. Economic diversification efforts and increased construction spending also contribute to market growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Portable Air Compressor Market.- Atlas Copco

- Ingersoll Rand

- Doosan Portable Power (part of Doosan Bobcat)

- Sullair LLC (a Hitachi Group Company)

- Campbell Hausfeld (part of The Marmon Group)

- Bosch

- Makita

- DeWalt (Stanley Black & Decker)

- Ryobi (TTI Group)

- California Air Tools

- Quincy Compressor

- Kaeser Compressors

- Gardner Denver (part of Ingersoll Rand)

- Eaton Compressor

- Schulz S.A.

- Festool (TTS Tooltechnic Systems AG & Co. KG)

- SENCO (Kyocera Senco Industrial Tools)

- Porter-Cable (Stanley Black & Decker)

- Kobalt (Lowe's)

- Craftsman (Stanley Black & Decker)

Frequently Asked Questions

Analyze common user questions about the Portable Air Compressor market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of portable air compressors?

Portable air compressors are versatile tools used across a wide array of applications due to their mobility and convenience. Their primary uses include automotive tasks such as inflating tires, operating impact wrenches for lug nuts, and powering paint spray guns for vehicle customization or repair. In construction, they are essential for driving pneumatic nail guns, operating jackhammers, sandblasters, and other heavy-duty equipment on job sites. DIY enthusiasts and homeowners leverage them for woodworking, painting projects, inflating sports equipment, and various home maintenance tasks. Additionally, they find applications in manufacturing for assembly operations, in agriculture for equipment maintenance, and even in some medical settings requiring clean, compressed air.

What are the key benefits of using a portable air compressor over a stationary one?

The primary benefit of a portable air compressor lies in its inherent mobility, allowing it to be easily transported to various job sites, remote locations, or different areas within a workshop where a fixed air supply is unavailable or inconvenient. This significantly enhances flexibility and operational efficiency. Unlike stationary compressors, portable units do not require permanent installation or extensive piping, reducing initial setup costs and complexity. They are also often more compact, making them suitable for smaller workspaces or garages where space is a premium. Furthermore, advancements in battery technology have led to cordless models, offering unparalleled freedom from power outlets, which is ideal for outdoor or off-grid applications. This combination of mobility, ease of setup, and adaptability makes them a preferred choice for a broad spectrum of intermittent or on-the-go pneumatic tasks.

What are the main types of portable air compressors available in the market?

The portable air compressor market offers several main types, primarily categorized by their compression mechanism. Reciprocating or piston compressors are the most common, utilizing a piston driven by a crankshaft to compress air. These are further divided into single-stage (compressing air once) and two-stage (compressing air twice for higher pressure) models, suitable for a wide range of general-purpose and heavy-duty applications. Rotary compressors, including screw, vane, and scroll types, are designed for continuous duty cycles and higher air volumes, making them ideal for industrial and more demanding professional uses. Rotary screw compressors, for example, use two interlocking helical rotors to compress air, offering smooth, quiet operation and high efficiency. Additionally, compressors can be differentiated by their power source (electric, gas, diesel) and lubrication method (oil-lubricated or oil-free, the latter being crucial for applications requiring clean air like painting or medical use).

How do I choose the right portable air compressor for my needs?

Choosing the right portable air compressor involves considering several key factors tailored to your specific application requirements. First, assess the CFM (Cubic Feet per Minute) and PSI (Pounds per Square Inch) ratings needed by your tools; ensure the compressor's output matches or exceeds these requirements to avoid underperformance. Next, consider the power source: electric models are quieter and emission-free for indoor use, while gas or diesel models offer greater power and mobility for outdoor, heavy-duty tasks. Tank size is also important; larger tanks provide more reserve air for continuous operation, while smaller tanks enhance portability. Lubrication type (oil-lubricated for durability or oil-free for clean air) should align with your application's purity needs. Finally, evaluate portability features like wheels and handle design, as well as noise levels, especially if operating in sensitive environments. Matching these specifications to your intended use will ensure optimal performance and satisfaction.

What technological advancements are impacting the portable air compressor market?

The portable air compressor market is continuously evolving with significant technological advancements aimed at improving efficiency, performance, and user convenience. Key innovations include the widespread adoption of advanced lithium-ion battery technology, enabling the development of powerful, long-lasting cordless compressors that offer unparalleled freedom and mobility. Brushless motor technology is also gaining prominence, providing superior efficiency, quieter operation, and extended lifespan compared to traditional brushed motors. Furthermore, the integration of IoT (Internet of Things) connectivity allows for remote monitoring of compressor performance, facilitating predictive maintenance and optimizing operational efficiency. Manufacturers are also focusing on enhanced material science to create lighter yet more durable compressors and incorporating advanced noise reduction techniques to improve user comfort, particularly in sensitive environments. These advancements collectively lead to more intelligent, robust, and user-friendly portable air compressor solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager