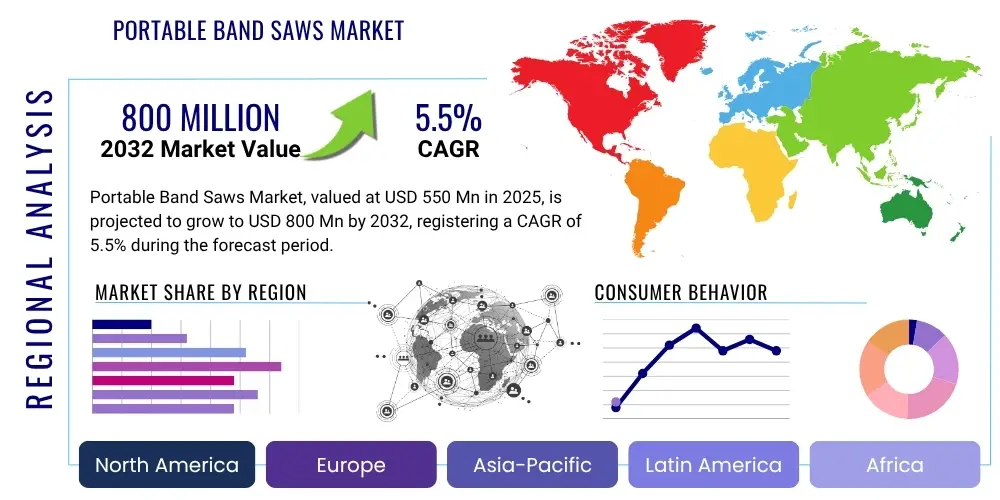

Portable Band Saws Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430115 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Portable Band Saws Market Size

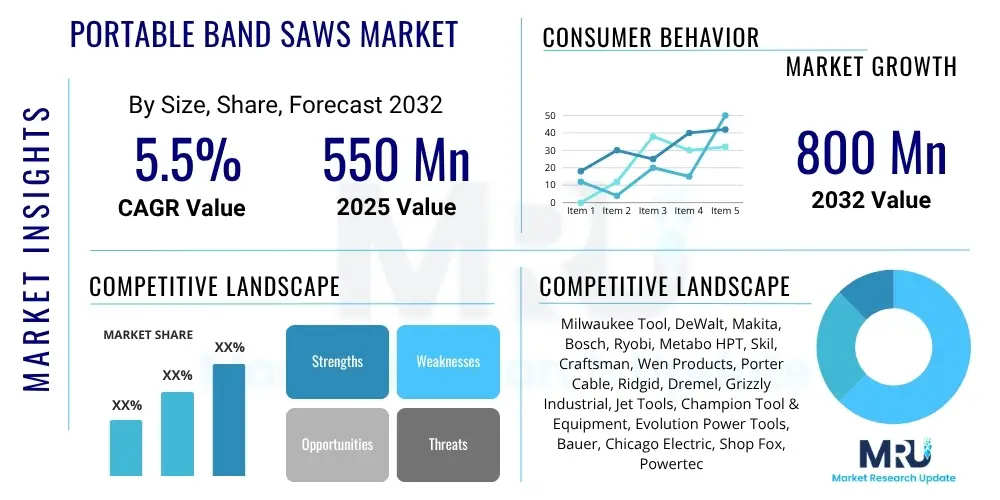

The Portable Band Saws Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2025 and 2032. The market is estimated at USD 550 Million in 2025 and is projected to reach USD 800 Million by the end of the forecast period in 2032.

Portable Band Saws Market introduction

The Portable Band Saws market encompasses an essential category of power tools designed for precision cutting of various materials across numerous professional and personal applications. These tools distinguish themselves by employing a continuous loop of a sharp, toothed metal blade that rotates around two or sometimes three wheels, providing a smooth and controlled cutting action. Unlike abrasive cutting methods, portable band saws generate minimal sparks and burrs, leading to cleaner finishes and significantly enhancing safety on job sites. Their core appeal lies in their portability, allowing users to transport the tool directly to the workpiece, thereby improving operational flexibility and reducing the need for material handling, which is crucial in dynamic work environments like construction sites or manufacturing facilities. The evolution of these tools has seen a consistent drive towards greater power efficiency, improved ergonomics, and enhanced material versatility.

Product descriptions for portable band saws highlight their robust construction and specialized capabilities for tasks such as cutting metal pipes, conduits, rebar, structural steel, and various plastic composites. Major applications span a wide array of industries, including plumbing for cutting copper and PVC pipes, electrical work for precise conduit and cable tray cutting, and general construction for sizing steel beams and framing materials. In manufacturing and fabrication workshops, they are indispensable for making accurate cuts in stock materials and for minor adjustments. The benefits extend beyond precision to include reduced noise levels compared to alternative tools, cleaner workspaces due to minimal debris, and often a faster cutting speed for specific materials. These advantages collectively position portable band saws as a preferred tool for professionals who demand efficiency, safety, and high-quality results in their daily operations, supporting critical infrastructure and industrial processes.

The primary driving factors propelling the growth of the portable band saws market are deeply intertwined with global economic development and industrial expansion. A booming global construction sector, particularly in emerging economies, fuels consistent demand for efficient material processing tools. Concurrently, the robust growth in manufacturing industries, including automotive, aerospace, and general fabrication, necessitates precise cutting solutions for component production and assembly. The increasing popularity of do-it-yourself (DIY) and home improvement projects among consumers further broadens the market base, as homeowners seek reliable tools for personal projects. Moreover, continuous technological advancements, such as the integration of more powerful brushless motors and longer-lasting lithium-ion battery technology for cordless models, significantly enhance product performance and user convenience, making these tools more appealing and accessible to a wider demographic. The emphasis on worker safety standards also subtly drives adoption, as band saws offer a safer alternative to certain high-spark cutting methods.

Portable Band Saws Market Executive Summary

The Portable Band Saws Market is currently experiencing a dynamic period of expansion, underpinned by several robust business trends that are reshaping the landscape of power tool consumption. A paramount trend is the accelerating shift towards cordless technology, driven by the demand for greater operational freedom and improved safety on job sites by eliminating trip hazards associated with power cords. Manufacturers are heavily investing in research and development to enhance battery life, charging speeds, and motor efficiency, particularly through brushless motor innovations, which collectively boost productivity and tool longevity. Furthermore, the market is witnessing an increased focus on ergonomic designs, anti-vibration systems, and integrated safety features, catering to professional users who require tools that minimize fatigue and enhance user control during prolonged operations. The proliferation of e-commerce platforms has also created new avenues for market penetration, allowing a wider range of brands and specialized products to reach both professional and DIY customers globally.

Regional trends reveal varied growth trajectories and market characteristics across different geographies. The Asia Pacific region is rapidly emerging as a primary growth engine, propelled by massive infrastructure development projects, rapid urbanization, and an expanding manufacturing footprint, particularly in countries like China, India, and Southeast Asia. This region's burgeoning industrial sector and increasing labor force are driving substantial demand for efficient and affordable power tools. North America, a mature market, maintains a stable and strong presence, characterized by high adoption rates of premium, technologically advanced portable band saws, driven by established construction industries and a strong professional trades segment that prioritizes brand reliability and performance. Europe demonstrates consistent growth, with an emphasis on high-quality engineering, strict safety compliance, and sustainable manufacturing practices influencing product innovation and consumer preferences across countries such as Germany, the UK, and France. Latin America and the Middle East and Africa represent evolving markets, with gradual growth spurred by localized construction booms and industrialization efforts.

Segmentation trends within the portable band saws market underscore critical shifts in product preference and application. The cordless segment is experiencing exponential growth and is projected to continue its dominance, as advances in battery technology make these tools increasingly comparable to their corded counterparts in terms of power and runtime. While corded models retain their niche in applications requiring continuous, heavy-duty operation where power access is not an issue, the flexibility of cordless tools is undeniable. In terms of applications, metalworking remains the largest segment, but there is significant expansion in demand from plumbing, electrical, and general construction sectors due to the versatility of these saws in cutting various pipes, conduits, and structural components. End-user segmentation shows a continued strong reliance from industrial and commercial professionals, while the residential and DIY segment is rapidly expanding, indicating a need for a broader range of product offerings that balance professional-grade features with user-friendliness and affordability.

AI Impact Analysis on Portable Band Saws Market

User inquiries about the potential impact of Artificial Intelligence on the Portable Band Saws Market frequently center on transformative capabilities that could elevate tool performance, user safety, and operational efficiency to unprecedented levels. Professionals and hobbyists alike express keen interest in AI's ability to facilitate predictive maintenance, allowing tools to self-diagnose potential mechanical issues or blade wear before critical failure occurs, thereby minimizing costly downtime and extending the operational lifespan of equipment. There is also considerable curiosity regarding AI-driven precision cutting, where intelligent algorithms could dynamically adjust cutting parameters such as blade speed, feed rate, and pressure based on real-time material analysis, ensuring optimal cut quality, reducing material waste, and significantly enhancing consistency, particularly in repetitive or intricate tasks. Furthermore, users are exploring how AI could integrate with tool operation to provide real-time guidance, optimize battery consumption in cordless models, and fundamentally improve worker safety through advanced anomaly detection or smart protective features that prevent accidents by recognizing hazardous situations.

The overarching themes derived from this analysis highlight a collective expectation for portable band saws to evolve from merely mechanical instruments into intelligent, responsive, and interconnected devices. Stakeholders anticipate AI to deliver more than just basic automation; they envision sophisticated assistance that renders cutting processes more intuitive, accelerates project completion times, and establishes new benchmarks for safety. Expectations also extend to AI's capability in comprehensive data collection and analytical processing, which could yield invaluable insights for future tool design improvements, optimize material compatibility, and streamline fleet management for large-scale industrial operations. The pervasive desire for a more autonomous, adaptive, and ultimately more productive cutting experience underscores the market's enthusiastic reception for AI integration, provided that these advancements translate into tangible value, address existing operational bottlenecks, and demonstrably improve the user's overall interaction with the tool, making high-precision tasks more accessible and less prone to human error.

- Enhanced Predictive Maintenance: AI algorithms analyze motor telemetry, cutting load, vibration patterns, and blade temperature to anticipate component fatigue or blade degradation, triggering proactive maintenance alerts and scheduling.

- Optimized Cutting Parameters: Embedded AI can instantaneously identify material properties via sensors, automatically adjusting blade speed, torque, and feed pressure to achieve perfect cuts, reduce blade strain, and maximize efficiency for diverse materials.

- Real-time Operator Guidance: Tools equipped with AI could provide immediate, haptic, or visual feedback to the user on cutting angle, pressure application, and technique, ensuring optimal results and reducing improper usage.

- Advanced Safety Features: AI-powered computer vision systems could detect foreign objects or human proximity to the cutting path, instantly halting blade movement to prevent accidents and enhance operator protection.

- Dynamic Battery Management: AI learns user cutting habits and material resistance to optimize power distribution, intelligently extending battery runtime and providing accurate remaining charge estimates for cordless models.

- Automated Quality Control: Post-cut analysis modules with AI could utilize integrated cameras and sensors to inspect the finished edge for burrs, inconsistencies, or deviations, ensuring uniform quality in production environments without manual inspection.

- Remote Diagnostics and Fleet Management: AI allows for centralized monitoring of tool performance, location, and operational data across large fleets, enabling efficient allocation, maintenance scheduling, and theft deterrence through geofencing and usage analytics.

- Adaptive Performance: AI can adapt tool performance based on environmental conditions like temperature or humidity, ensuring consistent operation and prolonging tool life in varied worksite scenarios.

DRO & Impact Forces Of Portable Band Saws Market

The Portable Band Saws Market is significantly propelled by several robust drivers, foremost among them being the sustained expansion of global construction and infrastructure development activities. This includes large-scale projects in residential, commercial, and industrial sectors, all of which require precise and efficient cutting of various materials, from rebar to conduits. Complementing this is the continuous growth in manufacturing industries, particularly in automotive, aerospace, and general fabrication, where portable band saws are indispensable for material processing, component trimming, and maintenance. The increasing emphasis on workplace safety standards also acts as a driver, as band saws offer a safer alternative to tools that produce excessive sparks or debris. Furthermore, the pervasive trend of technological innovation, especially in battery technology for cordless models and the development of more durable and application-specific blades, consistently enhances product appeal and widens their applicability, drawing in new users and encouraging upgrades among existing ones. This combined demand from professional trades and industrial applications forms the bedrock of market expansion.

Despite these strong drivers, the portable band saws market faces notable restraints that could temper its growth trajectory. The initial capital investment for high-quality, professional-grade portable band saws can be substantial, posing a barrier for small businesses or individual contractors with limited budgets. This is compounded by the ongoing operational costs, including regular replacement of blades and periodic maintenance, which adds to the total cost of ownership. Intense competition from alternative cutting tools, such as traditional abrasive chop saws, angle grinders, plasma cutters, and even stationary band saws, presents a challenge; these alternatives may offer perceived advantages in cost, versatility, or cutting capacity for specific tasks. Moreover, while portable band saws are generally safer, power tool operation inherently carries safety risks, and the need for skilled labor to operate these tools efficiently and safely can be a limiting factor in regions where specialized training is less accessible. Economic downturns or fluctuations in raw material prices can also influence production costs and consumer purchasing power.

However, the market is rife with significant opportunities for future growth and innovation. Emerging economies, particularly in Asia Pacific, Latin America, and parts of Africa, are undergoing rapid industrialization and urbanization, translating into substantial untapped potential for market penetration as construction and manufacturing activities escalate. The development of advanced materials, such as composites and specialized alloys, creates a demand for new, highly specific blade technologies and tool adaptations, opening avenues for product differentiation and market leadership. The integration of smart technologies, including IoT connectivity for tool diagnostics, asset tracking, and performance optimization, presents a compelling opportunity to offer value-added services and enhance fleet management capabilities for large industrial users. Additionally, the growing popularity of tool rental services provides an accessible entry point for users who require the tools for short-term projects without the commitment of a full purchase, expanding the overall user base. Regulatory pressures for safer and more environmentally friendly tools also stimulate innovation and product development, creating a virtuous cycle of improvement and market acceptance. These dynamic forces of drivers, restraints, and opportunities collectively shape the competitive landscape and future direction of the portable band saws market.

Segmentation Analysis

The Portable Band Saws Market undergoes comprehensive segmentation to dissect its intricate dynamics and identify granular insights into demand patterns, emerging preferences, and growth hotspots. This systematic categorization helps stakeholders, from manufacturers to retailers, to understand the market's structure and consumer behaviors with greater clarity. Products are primarily segmented by their power source, distinguishing between corded and cordless models, reflecting evolving user demands for mobility versus continuous power. Further segmentation includes application types, which delineate usage across metalworking, plumbing, electrical, construction, HVAC, and increasingly, DIY and home renovation tasks, highlighting the tools' versatility. End-user categories differentiate between industrial, commercial, and residential segments, each with distinct requirements for durability, power, and cost-effectiveness. Additionally, distribution channels, encompassing online and offline retail, illustrate how these products reach their diverse clientele, influenced by convenience, price, and product accessibility.

Beyond these broad categorizations, the market is also segmented by specific blade types, recognizing that the effectiveness of a portable band saw heavily relies on the appropriate blade for the material being cut. This includes bi-metal blades, favored for their versatility across various metals; carbon steel blades, typically used for softer materials and wood; and carbide-tipped blades, designed for superior longevity and performance in cutting harder alloys and stainless steel. This detailed segmentation is instrumental for strategic planning, enabling manufacturers to tailor their product development to meet precise market needs, optimize their R&D investments, and craft highly targeted marketing campaigns. Understanding these nuances also assists distributors and retailers in managing inventory, optimizing shelf space, and offering comprehensive solutions that address the specific challenges and requirements of different end-users. The interplay between these segments often dictates competitive strategies, driving innovation in both tool design and accessory development to capture maximum market share.

- By Type: This segment differentiates tools based on their power delivery method, directly impacting portability and continuous operation capabilities.

- Corded Portable Band Saws: Offer unlimited runtime, typically higher power output for heavy-duty tasks, and are preferred in workshops or sites with consistent power access.

- Cordless Portable Band Saws: Provide unparalleled mobility and flexibility, driven by advancements in lithium-ion battery technology and brushless motors, ideal for remote or confined job sites.

- By Application: Categorizes the primary use cases for which portable band saws are procured, reflecting their versatility across industries.

- Metalworking: Dominant segment, includes cutting pipes, conduits, structural steel, rebar, and various metal profiles in fabrication and repair.

- Plumbing: Essential for cutting copper, PVC, and other pipe materials for installation and repair.

- Electrical: Used for precision cutting of conduits, cable trays, and electrical tubing.

- Construction: Broad application across residential, commercial, and industrial construction for material sizing and modifications.

- HVAC: For cutting ductwork, pipes, and other components in heating, ventilation, and air conditioning systems.

- DIY and Home Renovation: Used by hobbyists and homeowners for various small-scale projects requiring metal or plastic cutting.

- Other Industrial Applications: Includes automotive repair, aerospace fabrication, mining, and general maintenance tasks.

- By End-User: Defines the primary purchasers and operational environments of the tools, influencing requirements for durability, power, and feature sets.

- Industrial: Large-scale manufacturing plants, heavy construction firms, and specialized fabrication shops requiring robust, high-performance tools for continuous use.

- Commercial: Small to medium-sized contractors, independent workshops, and maintenance service providers prioritizing versatility and portability.

- Residential: Individual homeowners, DIY enthusiasts, and hobbyists looking for user-friendly, affordable tools for occasional use.

- By Distribution Channel: Illustrates the routes through which portable band saws reach the end consumer, reflecting market access and purchasing preferences.

- Online Retail: E-commerce platforms offering convenience, competitive pricing, and a broad selection, catering to a global customer base.

- Offline Retail: Traditional hardware stores, specialized tool shops, and industrial distributors providing hands-on product experience, immediate availability, and expert advice.

- By Blade Type: Specifies the material and design of the cutting blade, optimized for different workpiece materials and cutting performance.

- Bi-Metal Blades: Highly versatile, durable, and commonly used for cutting various types of metal, offering a good balance of speed and longevity.

- Carbon Steel Blades: Economical, suitable for cutting softer metals, wood, and plastics; often used for general-purpose applications.

- Carbide Tipped Blades: Designed for superior performance and extended life when cutting hard alloys, stainless steel, and abrasive materials, providing exceptional durability and precision.

Value Chain Analysis For Portable Band Saws Market

The value chain for the Portable Band Saws Market commences with robust upstream analysis, focusing on the sourcing and processing of essential raw materials and the manufacturing of critical components. This phase is fundamental, involving suppliers of high-grade steel for precision blades and durable tool bodies, specialized plastics for ergonomic housings and protective components, and intricate electronic elements for motor control, speed variation, and safety features. A particularly crucial aspect of the upstream segment is the supply of advanced electric motors, including both brushed and increasingly prevalent brushless designs, along with state-of-the-art lithium-ion battery cells for cordless models. Key upstream players are tasked with ensuring the consistent provision of materials and components that meet stringent quality specifications, durability requirements, and performance benchmarks demanded by power tool manufacturers. Innovation at this foundational stage, especially in developing lighter, more powerful, and energy-efficient components, directly translates into superior end-product capabilities and significantly impacts manufacturers' competitive positioning in the market, driving continuous improvement in the portable band saw's overall functionality and lifespan.

The midstream activities in the value chain primarily involve the core manufacturing and assembly processes undertaken by leading market players. This stage encompasses sophisticated product design, precision engineering, component integration, and rigorous quality control protocols. Manufacturers invest heavily in research and development to introduce innovative models featuring enhanced ergonomics, advanced safety mechanisms such as blade guards and quick-stop brakes, and improved cutting precision through optimized gear systems and blade tracking. After the assembly and testing phases, the finished portable band saws proceed to distribution. This segment involves a dual approach, utilizing both direct and indirect distribution channels. Direct distribution strategies often target large industrial clients, governmental agencies, or major construction firms through direct sales forces or manufacturer-owned online stores. This allows brands to maintain tighter control over customer relationships, brand messaging, and pricing. Conversely, indirect channels are crucial for broader market penetration, encompassing a network of wholesalers, regional distributors, large-format hardware store chains, and an expanding array of e-commerce platforms. These indirect partners facilitate extensive market reach, catering to smaller commercial outfits, independent contractors, and individual DIY enthusiasts, ensuring accessibility across diverse geographical and demographic segments.

The downstream analysis of the value chain focuses on how portable band saws reach their ultimate end-users and the critical after-sales support mechanisms. This includes comprehensive marketing and sales efforts designed to highlight product benefits, competitive pricing strategies, and robust customer service operations. Effective distribution networks are paramount at this stage, ensuring that products are not only readily available but also supported by efficient logistics and inventory management. The end-users, who are the ultimate buyers and operators of these tools, include a wide spectrum: professional tradespeople such as electricians, plumbers, and welders; various segments of the construction industry; manufacturing and fabrication facilities; and a rapidly growing segment of DIY enthusiasts and hobbyists. The efficiency and reliability of both online and offline retail channels significantly influence customer satisfaction. Online platforms offer unparalleled convenience, extensive product information, and competitive pricing, empowering informed purchasing decisions. In contrast, physical retail stores provide the invaluable opportunity for hands-on product inspection, immediate purchase and takeaway, and access to expert advice from sales associates. Post-purchase activities such as warranty services, repair facilities, and the availability of spare parts and specialized blades further strengthen brand loyalty and contribute to the long-term success of portable band saw products in the market.

Portable Band Saws Market Potential Customers

The Portable Band Saws Market attracts a broad and diverse spectrum of potential customers, each with specific requirements and applications that drive their purchasing decisions. At the forefront are professional tradespeople across various critical sectors. This includes electricians, who rely on these tools for clean and efficient cuts of electrical conduit, wireways, and cable trays; plumbers, utilizing them for precise cutting of copper, PVC, and steel pipes for installation and repair work; and HVAC technicians, who need accurate cuts for ductwork and ventilation components. Welders and metal fabricators also represent a significant customer base, valuing portable band saws for making precise cuts in structural steel, tubing, and various metal profiles, often minimizing secondary finishing operations. These industrial and commercial users typically prioritize tools that offer superior durability, high power output, consistent performance under heavy loads, and advanced features such as ergonomic designs and robust battery life for cordless models, reflecting their daily professional demands.

Beyond individual trades, the broader construction industry forms a substantial segment of potential customers, encompassing general contractors, specialized subcontractors, and facility maintenance teams. These entities deploy portable band saws extensively for on-site material preparation, modifications to existing structures, and routine repairs across commercial, residential, and industrial construction projects. Manufacturing facilities, particularly those involved in automotive, aerospace, and general machinery fabrication, are also key buyers. In these environments, portable band saws are integrated into production lines for cutting raw stock, trimming components, and performing repair or modification tasks, where material integrity and precision are paramount. Furthermore, maintenance and repair operations (MRO) in diverse institutional settings, such as schools, hospitals, commercial complexes, and government buildings, depend on these versatile tools for myriad repair and installation tasks that necessitate swift, accurate, and relatively quiet material severance without the extensive setup of stationary equipment.

The burgeoning do-it-yourself (DIY) and home renovation market constitutes another rapidly expanding segment of potential customers. Homeowners, enthusiastic hobbyists, and operators of small personal workshops are increasingly investing in portable band saws for a wide array of projects, ranging from custom metal art and small-scale fabrication to general home repairs and improvements that involve cutting various materials. This segment often seeks more compact, lighter-weight, and user-friendly models, with a strong emphasis on affordability and ease of operation rather than continuous heavy-duty performance. Additionally, vocational training schools and educational institutions acquire these tools for practical instruction, equipping future tradespeople with essential hands-on skills. The growing tool rental market also taps into a segment of users who require portable band saws for short-term projects but prefer not to commit to a full purchase, demonstrating the tool's wide appeal across varied user needs and financial capacities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 550 Million |

| Market Forecast in 2032 | USD 800 Million |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Milwaukee Tool, DeWalt, Makita, Bosch, Ryobi, Metabo HPT, Skil, Craftsman, Wen Products, Porter Cable, Ridgid, Dremel, Grizzly Industrial, Jet Tools, Champion Tool & Equipment, Evolution Power Tools, Bauer, Chicago Electric, Shop Fox, Powertec |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Portable Band Saws Market Key Technology Landscape

The Portable Band Saws Market is relentlessly driven by a dynamic key technology landscape, marked by continuous innovation aimed at elevating tool performance, enhancing user comfort, and maximizing operational efficiency across diverse applications. A foundational advancement is the widespread adoption and refinement of brushless motor technology. These motors offer substantial advantages over conventional brushed designs, including significantly higher efficiency, translating into greater power output per charge, extended tool life due to reduced wear and tear on components, and minimal maintenance requirements. This technological shift directly contributes to the development of more powerful and inherently reliable tools capable of enduring demanding industrial applications. Concurrently, advancements in lithium-ion battery technology are pivotal, serving as the primary catalyst for the exponential growth of cordless portable band saws. Modern battery packs deliver dramatically extended runtimes, enable rapid charging cycles, and boast improved power-to-weight ratios, granting users unparalleled mobility and productivity on job sites unhindered by the constraints of power cords or outlets. The synergy between brushless motors and advanced lithium-ion batteries has redefined user expectations for portable power tools.

Beyond core power systems, ergonomic design principles constitute another critical facet of the technology landscape, with manufacturers deeply focused on crafting tools that prioritize user comfort and minimize fatigue during prolonged operation. This involves meticulous attention to optimized tool balance, the integration of advanced anti-vibration systems to mitigate harmful oscillations, and the application of textured, non-slip grips for enhanced control and safety. Variable speed control has become a ubiquitous standard feature, empowering users to precisely adjust blade speed to match the specific material being cut and the required finish, thereby improving cutting quality, extending blade life, and preventing material damage. Integrated LED work lights further augment user experience by illuminating the cutting area in dimly lit environments, significantly improving both safety and cutting accuracy. Moreover, the continuous development of specialized blades, including durable bi-metal, cost-effective carbon steel, and ultra-hard carbide-tipped options, each meticulously engineered for optimal performance on specific materials, underscores the ongoing innovation in cutting technology that directly impacts tool versatility and efficiency.

Emerging technologies are increasingly shaping the future of portable band saws, particularly through the integration of smart features and advanced Internet of Things (IoT) connectivity in premium models. These sophisticated advancements enable capabilities such as comprehensive tool diagnostics, real-time usage tracking for performance analytics, and even remote management features, which are especially beneficial for large-scale industrial operations and efficient fleet management. Some cutting-edge tools are beginning to incorporate embedded sensors that provide real-time feedback on cutting pressure, angle, and depth, thereby enhancing accuracy, preventing blade damage, and optimizing cutting parameters on the fly. Furthermore, innovations in material science play a crucial role, facilitating the development of lighter yet more robust composite materials for tool housings, which reduces the overall weight of the tool without compromising its structural integrity or resistance to harsh working conditions. These multifaceted technological shifts are continually refining the portable band saw, transforming it into a more versatile, intelligent, and exceptionally user-friendly instrument, capable of meeting the evolving demands of a broad spectrum of professional and personal applications while simultaneously boosting safety and productivity.

Regional Highlights

- North America: This region consistently represents a mature and significantly dominant market for portable band saws, characterized by a high rate of adoption of advanced power tools across well-established construction, robust manufacturing, and extensive industrial maintenance sectors. The formidable presence of leading global market players, coupled with a strong cultural emphasis on worker safety, efficiency, and productivity, drives substantial demand for high-performance, durable, and increasingly cordless tool solutions. The United States and Canada are the primary economic powerhouses within this region, contributing substantially through ongoing infrastructure investments, a highly skilled professional trades workforce, and a consumer base that prioritizes quality and brand reliability. Innovation in battery technology and smart tool integration sees rapid uptake here.

- Europe: The European market for portable band saws demonstrates consistent and steady growth, fundamentally propelled by stringent quality standards, an inherent focus on industrial precision, and increasing governmental and private sector investments in renovation, refurbishment, and modern infrastructure projects. Countries such as Germany, the United Kingdom, and France lead the charge in adopting technologically advanced and meticulously ergonomically designed portable band saws. There is a discernible and strong preference among European professionals for tools that not only meet but exceed rigorous safety and environmental regulations, actively pushing manufacturers towards developing more energy-efficient, sustainable, and long-lasting product designs that align with regional values and operational requirements.

- Asia Pacific (APAC): The APAC region is unequivocally projected to be the fastest-growing market for portable band saws globally, underpinned by unprecedented rapid industrialization, burgeoning construction activities, and substantial government investments in critical infrastructure development. This explosive growth is particularly evident in economic giants like China and India, alongside dynamic Southeast Asian nations. The relentless expansion of manufacturing bases, coupled with a vast and rapidly growing labor force, significantly contributes to an escalating demand for efficient and readily available power tools. Regional economic development, coupled with swift urbanization trends, acts as a powerful catalyst, fueling the widespread adoption of portable band saws across various industrial applications and a burgeoning DIY segment.

- Latin America: This region presents itself as an emerging market with considerable untapped potential for portable band saws, notably marked by increasing construction projects and a burgeoning industrial expansion, with Brazil and Mexico acting as key economic drivers. The demand profile in Latin America leans towards cost-effective yet reliably performing portable band saws, driven by a developing industrial landscape and a growing awareness among professionals of the benefits of efficient and modern construction practices. Factors such as economic stability, foreign direct investment into industrial sectors, and improvements in trade infrastructure play a crucial role in shaping the market dynamics and fostering growth opportunities within this diverse region.

- Middle East and Africa (MEA): The MEA market for portable band saws is experiencing a gradual but steady growth trajectory, predominantly influenced by ongoing large-scale infrastructure projects, especially in the oil and gas sector and the urban development initiatives within the Gulf Cooperation Council (GCC) countries. The demand in this region often centers on robust, high-durability tools capable of operating effectively and reliably in challenging, often harsh, environmental conditions such as extreme heat and dust. As industrial diversification and economic development progress in various African nations, the market for portable band saws is anticipated to witness further expansion, albeit from a relatively smaller base, driven by increasing professionalization of trades and a greater emphasis on efficient project execution.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Portable Band Saws Market.- Milwaukee Tool

- DeWalt

- Makita

- Bosch

- Ryobi

- Metabo HPT

- Skil

- Craftsman

- Wen Products

- Porter Cable

- Ridgid

- Dremel

- Grizzly Industrial

- Jet Tools

- Champion Tool & Equipment

- Evolution Power Tools

- Bauer

- Chicago Electric

- Shop Fox

- Powertec

Frequently Asked Questions

What is a portable band saw primarily used for?

A portable band saw is mainly used for cutting various materials such as metal (pipes, conduits, rebar, structural steel), plastics, and wood, especially in applications requiring precise, burr-free cuts on job sites or in workshops. It offers clean, controlled cuts with minimal sparks.

What are the main advantages of a cordless portable band saw over a corded one?

Cordless portable band saws offer superior mobility and flexibility, allowing users to operate without being restricted by power outlets or tangled cords. They are ideal for remote job sites, enhance safety by eliminating tripping hazards, and are increasingly powerful due to advanced battery technology.

How do I choose the right blade for my portable band saw?

Choosing the right blade depends significantly on the material you are cutting. Bi-metal blades are versatile for various metals, carbon steel blades are suitable for softer materials and wood, while carbide-tipped blades excel in cutting harder alloys and stainless steel, offering extended durability.

Are portable band saws considered safer than angle grinders for cutting metal?

Generally, portable band saws are considered significantly safer for cutting metal than angle grinders. They produce fewer sparks, generate less heat, and create less debris, reducing the risk of fire, burns, and other injuries, while providing more controlled and precise cuts for specific applications.

What are the key factors driving the growth of the portable band saws market?

Key growth drivers include the expanding global construction and manufacturing sectors, increasing adoption of advanced cordless tool technology for enhanced portability and efficiency, a rising trend in DIY and home improvement projects, and continuous innovation in tool performance, safety, and ergonomics.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager