Portland Cement Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427765 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Portland Cement Market Size

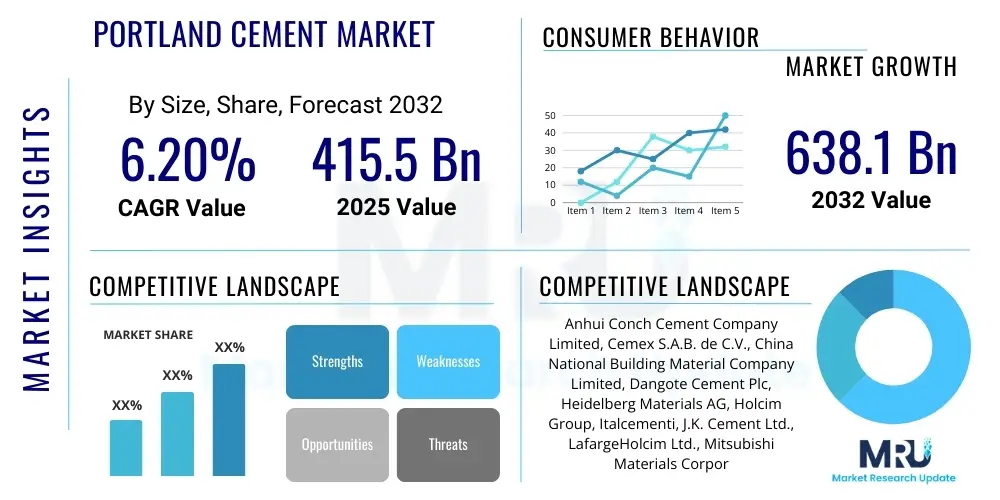

The Portland Cement Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at USD 415.5 billion in 2025 and is projected to reach USD 638.1 billion by the end of the forecast period in 2032.

Portland Cement Market introduction

The Portland Cement market encompasses the production, distribution, and consumption of hydraulic cement, a fundamental building material globally. Portland cement, derived primarily from limestone, clay, and other raw materials, undergoes a complex manufacturing process involving grinding, heating in kilns to form clinker, and then grinding again with gypsum to produce a fine powder. This versatile material forms the basis of concrete, mortar, and grout, making it indispensable to the construction industry. Its properties, such as strength, durability, and adaptability, make it a preferred choice for a wide array of applications, from foundational structures to architectural finishes. The markets robust growth is fundamentally driven by global urbanization trends, burgeoning population growth, and extensive infrastructure development initiatives, particularly in emerging economies where demand for housing, commercial spaces, and public utilities continues to surge.

Major applications for Portland Cement span residential, commercial, industrial, and infrastructure construction sectors. In residential construction, it is critical for building homes, apartments, and low-rise structures. Commercial applications include office buildings, retail centers, and hospitality establishments, while industrial uses range from factories to warehouses. Infrastructure projects, such as roads, bridges, dams, airports, and public utilities, consume significant volumes of Portland cement dueating to its structural integrity requirements. The inherent benefits of Portland cement, including its exceptional compressive strength, long-term durability, fire resistance, and cost-effectiveness compared to alternative materials, underpin its sustained demand. Furthermore, advancements in cement technology, such as the development of specialized cements for specific environmental conditions or performance requirements, continue to expand its utility and market reach.

Portland Cement Market Executive Summary

The Portland Cement market is currently experiencing dynamic shifts driven by a confluence of global business, regional, and segment-specific trends. Business trends are heavily influenced by a growing emphasis on sustainability, leading to increased investment in green cement technologies, carbon capture, utilization, and storage (CCUS) solutions, and energy-efficient production methods to mitigate the industrys significant environmental footprint. Digitalization is also a key business trend, with manufacturers adopting Industry 4.0 technologies like automation, IoT, and data analytics to optimize operations, enhance supply chain efficiency, and improve product quality. Mergers and acquisitions remain a strategic tool for market consolidation and expansion into new geographic territories, while volatile raw material prices and energy costs continue to pose challenges, pushing companies to innovate in resource management and procurement strategies.

Regionally, the Asia Pacific continues to dominate the market in terms of both production and consumption, propelled by rapid urbanization, substantial government investments in infrastructure, and a burgeoning construction sector in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, exhibit stable demand driven by renovation activities, sustainable building practices, and a focus on advanced construction techniques, including prefabrication and modular construction. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth trajectories, supported by population expansion and ongoing development projects. Segment-wise, Ordinary Portland Cement (OPC) remains the most widely used, but there is an increasing demand for blended cements, which offer enhanced performance characteristics and reduced environmental impact. Furthermore, demand from infrastructure projects is particularly robust, reflecting significant public and private sector investments worldwide aimed at modernizing and expanding essential utilities and transportation networks.

AI Impact Analysis on Portland Cement Market

The integration of Artificial Intelligence (AI) across the Portland Cement market is profoundly reshaping operational efficiencies, sustainability initiatives, and overall market dynamics. Stakeholders are keenly exploring AIs potential to optimize complex manufacturing processes, from raw material sourcing and clinker production to energy consumption management, which directly addresses the industrys high energy intensity. Predictive analytics, powered by AI, is becoming instrumental in forecasting equipment maintenance needs, thereby minimizing costly downtime and extending asset lifespans within cement plants. Furthermore, AI-driven solutions are crucial for enhancing quality control, allowing for real-time adjustments in cement composition and ensuring product consistency, which is vital for structural integrity in construction applications and meeting stringent performance specifications. Users are increasingly seeking insights into how AI can specifically address the industrys environmental footprint, particularly concerning CO2 emissions reduction, by optimizing fuel consumption, improving clinker factor, and enabling the development of novel, greener cement formulations with lower embodied carbon. The overarching expectation is that AI will not only drive significant cost efficiencies and operational improvements but also foster innovation in product development and compliance with increasingly stringent environmental regulations, making cement production more sustainable and competitive globally. This focus on efficiency and sustainability reflects a broad user concern about the environmental impact of cement production and the potential for technological solutions to mitigate it.

- AI-powered predictive maintenance for kilns and grinding mills reduces unplanned downtime and maintenance costs.

- Optimization of raw material blending and proportioning using AI algorithms enhances product quality and consistency.

- Energy consumption reduction through AI-driven process control, leading to lower operational costs and greenhouse gas emissions.

- Supply chain optimization using AI for demand forecasting, inventory management, and logistics, improving efficiency.

- Development of new, low-carbon cement formulations through AI-assisted materials science research and simulation.

- Enhanced quality control systems utilizing machine vision and AI for real-time defect detection and composition analysis.

- Improvement in operational safety through AI-based monitoring and early detection of potential hazards in plants.

DRO & Impact Forces Of Portland Cement Market

The Portland Cement market is influenced by a complex interplay of Drivers, Restraints, Opportunities, and broader Impact Forces that shape its trajectory. Key drivers include aggressive urbanization trends globally, especially in emerging economies, leading to a relentless demand for housing, commercial infrastructure, and public facilities. Significant government spending on large-scale infrastructure projects, such as smart cities, transportation networks, and energy facilities, further propels consumption. The increasing focus on affordable housing initiatives worldwide also contributes substantially to market expansion. Conversely, the industry faces substantial restraints, primarily stemming from stringent environmental regulations aimed at reducing carbon emissions and managing waste, which necessitate costly investments in cleaner technologies. Volatility in the prices of raw materials, such as limestone and fuel (coal, petcoke), coupled with high energy consumption inherent in cement production, significantly impacts manufacturing costs and profitability. Additionally, the emergence of alternative building materials and construction methods, though nascent, poses a long-term threat to traditional cement demand.

Despite these challenges, numerous opportunities exist for market players. The growing emphasis on sustainable construction practices and green building standards is driving demand for blended cements and low-carbon cement alternatives, offering avenues for product differentiation and market growth. Investments in digitalization and automation within manufacturing processes present opportunities for enhanced efficiency, cost reduction, and improved product quality. Furthermore, the immense market potential in developing countries, characterized by expanding populations and rapidly evolving economies, represents a significant growth opportunity for manufacturers seeking to expand their geographical footprint. The impact forces at play, such as intense competitive rivalry among established players and new entrants, exert pressure on pricing and innovation. The bargaining power of buyers, particularly large construction firms, and the bargaining power of suppliers of raw materials and energy, significantly influence profit margins. The threat of substitutes, while currently moderate, is evolving with advancements in sustainable building materials, compelling the industry to innovate continually. Overall, the market remains dynamic, characterized by a persistent drive for growth tempered by environmental imperatives and economic fluctuations.

Segmentation Analysis

The Portland Cement market is extensively segmented based on various criteria to provide a granular understanding of its diverse landscape and consumer needs. This segmentation allows for targeted market strategies and product development, addressing specific application requirements, material compositions, and end-user demands across different geographical regions. Key segmentation categories typically include cement type, application, and end-use, each revealing distinct market dynamics and growth opportunities for manufacturers and stakeholders. Understanding these segments is crucial for accurate market forecasting, competitive analysis, and strategic positioning within the global construction industry. This detailed breakdown highlights the versatility of Portland cement and its various formulations designed to meet specialized performance criteria for a multitude of construction projects, from standard residential buildings to complex infrastructure.

- By Type:

- Ordinary Portland Cement (OPC): Standard cement widely used for general construction.

- Portland Slag Cement (PSC): Blended cement using ground granulated blast furnace slag, offering enhanced durability and workability.

- Portland Pozzolana Cement (PPC): Blended cement incorporating pozzolanic materials (e.g., fly ash, calcined clay), providing improved resistance to chemical attacks and better workability.

- White Portland Cement: Produced from raw materials with very low iron content, primarily for architectural and decorative purposes.

- Sulphate-Resisting Portland Cement (SRPC): Designed to resist sulphate attacks in harsh chemical environments.

- Low Heat Portland Cement (LHPC): Used for mass concreting projects to reduce heat generation and prevent cracking.

- Rapid Hardening Portland Cement (RHPC): Achieves higher strength faster, suitable for repair work and precast applications.

- By Application:

- Residential Construction: Foundations, walls, floors, and roofs for homes and apartments.

- Commercial Construction: Office buildings, retail spaces, hotels, and educational institutions.

- Industrial Construction: Factories, warehouses, power plants, and chemical facilities.

- Infrastructure Projects: Roads, bridges, dams, airports, ports, tunnels, and public utilities.

- By End-Use:

- Ready-Mix Concrete (RMC): Pre-mixed concrete delivered to construction sites, a dominant consumer of cement.

- Precast Products: Concrete blocks, pipes, panels, and railway sleepers manufactured off-site.

- Mortars & Plasters: Binding agents for masonry, rendering, and decorative finishes.

- Others: Grouts, specialized repair materials, and decorative concrete applications.

Portland Cement Market Value Chain Analysis

The Portland Cement markets value chain is an intricate network of activities that transforms raw materials into finished cement products and delivers them to the end-user, encompassing several critical stages from upstream sourcing to downstream consumption. The upstream segment primarily involves the extraction and processing of essential raw materials, most notably limestone, clay, shale, and gypsum, from quarries and mines. This stage also includes the procurement of energy sources such as coal, petcoke, or natural gas, which are crucial for the high-temperature clinkerization process in kilns. Key stakeholders in this phase include mining companies, energy suppliers, and specialized logistics providers that manage the transportation of these bulk materials to cement manufacturing plants. Efficiency and cost-effectiveness at this initial stage are paramount, as raw material and energy costs represent a significant portion of the total production cost, making strategic sourcing and long-term supply agreements vital for manufacturers.

The core of the value chain is the manufacturing process itself, where raw materials are crushed, ground, blended, and then heated in rotary kilns to produce clinker, which is subsequently ground with gypsum and other additives to yield various types of Portland cement. This energy-intensive process requires substantial capital investment in machinery, technology, and skilled labor. Downstream activities focus on the distribution and sale of the finished cement. This involves a complex network of transportation, including road, rail, and sea freight, to move cement from production plants to regional warehouses, distribution centers, and directly to major construction sites. The primary distribution channels include direct sales to large construction companies, government agencies, and ready-mix concrete producers, as well as indirect sales through a vast network of dealers, distributors, and retailers who cater to smaller construction projects and individual buyers. The efficiency of this distribution network is crucial for timely delivery and maintaining product availability across diverse geographic markets.

Further along the value chain, the product reaches the end-users, primarily construction companies, infrastructure developers, precast concrete manufacturers, and individual contractors. These entities utilize Portland cement to produce concrete, mortar, and various other building materials for residential, commercial, industrial, and infrastructure projects. The value chain is also influenced by supporting services such as research and development for new cement types and sustainable production methods, quality control and testing, and after-sales technical support for customers. Collaboration and integration across these stages, including vertical integration by some major players, are key strategies to optimize efficiency, reduce costs, ensure quality, and enhance market responsiveness. The increasing focus on sustainability and digitalization is driving innovations throughout this value chain, from greener raw material sourcing to optimized logistics and smarter construction applications.

Portland Cement Market Potential Customers

The Portland Cement market serves a vast and diverse customer base, primarily comprising entities within the global construction ecosystem. The primary end-users and buyers of Portland cement are construction companies, ranging from multinational conglomerates executing mega-infrastructure projects to small, local contractors building residential homes. These companies depend on a consistent supply of high-quality cement for their core operations, utilizing it to produce concrete, mortar, and other essential building components. Their purchasing decisions are often driven by factors such as product quality, supplier reliability, price competitiveness, and adherence to specific project specifications. The scale of their projects dictates the volume of cement purchased, with large-scale developers often engaging in direct procurement from manufacturers, while smaller entities rely on an extensive network of distributors and retailers.

Another significant segment of potential customers includes ready-mix concrete (RMC) producers. These specialized companies purchase bulk quantities of Portland cement, along with aggregates and water, to produce and deliver fresh concrete directly to construction sites. RMC producers value consistency in cement quality, reliable supply chains, and often seek long-term contractual relationships with cement manufacturers. Their operational efficiency and the quality of their final product are directly tied to the performance of the cement they procure. Similarly, precast concrete manufacturers constitute a crucial customer group. These firms utilize Portland cement to produce various pre-fabricated concrete elements such as blocks, pipes, panels, railway sleepers, and structural components off-site, which are then transported and assembled at construction locations. For precast manufacturers, cement properties like early strength development and consistency are paramount to their production processes and the durability of their finished products.

Beyond these core construction-related entities, government agencies and public sector undertakings are also major buyers, particularly for large-scale public infrastructure projects like roads, bridges, dams, and public utility facilities. These buyers often issue tenders and procure cement through competitive bidding processes, emphasizing quality certifications, adherence to national standards, and often, local content requirements. Individual builders, masons, and homeowners also represent a substantial customer segment, typically purchasing smaller quantities through retail hardware stores or local dealers for renovation projects, extensions, or small-scale construction tasks. The diverse needs of these customer groups necessitate a robust distribution network and a range of product offerings from cement manufacturers, tailored to different applications and volume requirements, emphasizing the importance of a customer-centric approach in the market.

Portland Cement Market Key Technology Landscape

The Portland Cement markets technology landscape is undergoing a significant transformation, driven by an imperative to enhance operational efficiency, reduce environmental impact, and develop advanced material properties. Key technological advancements are predominantly centered around optimizing the energy-intensive clinker production process and mitigating associated carbon dioxide emissions. Modern cement plants are increasingly adopting advanced grinding technologies, such as vertical roller mills (VRMs), which offer significantly higher energy efficiency compared to traditional ball mills, leading to reduced electricity consumption. Furthermore, waste heat recovery systems are becoming standard, capturing exhaust heat from kilns and coolers to generate electricity, thereby improving the overall energy balance of the plant and contributing to lower operational costs. Innovations in kiln technologies, including the use of alternative fuels (e.g., biomass, municipal solid waste) and optimized burner designs, are also crucial for reducing reliance on fossil fuels and lowering the carbon footprint of cement production.

Beyond process optimization, a substantial focus lies on technologies that enable the production of greener and more sustainable cement. This includes the development and adoption of carbon capture, utilization, and storage (CCUS) technologies, which are critical for capturing CO2 emissions directly from the flue gases of cement kilns. While still in nascent stages for widespread commercial application in cement, CCUS represents a long-term solution to decarbonize the industry. Research into novel cementitious materials, such as calcium sulfoaluminate (CSA) cements, geopolymers, and the increased use of supplementary cementitious materials (SCMs) like fly ash, blast furnace slag, and calcined clays, is also a prominent technological trend. These materials allow for a reduction in the clinker content of cement, directly lowering the embodied carbon and enhancing specific performance characteristics, such as durability and resistance to chemical attacks, offering a path towards low-carbon concrete solutions.

Digitalization and automation are also fundamentally reshaping the technological landscape of the Portland Cement market. The implementation of Industry 4.0 concepts, including the Internet of Things (IoT), artificial intelligence (AI), machine learning, and advanced sensor technologies, is enabling real-time monitoring and control of the entire production process. Predictive maintenance systems, powered by AI, forecast equipment failures, minimizing downtime and optimizing maintenance schedules. Data analytics platforms process vast amounts of operational data to identify bottlenecks, optimize energy usage, and ensure consistent product quality. Robotics and advanced automation systems are being deployed for tasks such like raw material handling, kiln feeding, and packaging, improving safety and operational efficiency. Furthermore, digital twins of cement plants are emerging as powerful tools for simulation, optimization, and training, allowing manufacturers to model and improve plant performance in a virtual environment before implementing changes in the physical world. These technologies collectively contribute to a more efficient, sustainable, and responsive cement manufacturing industry.

Regional Highlights

- Asia Pacific: This region stands as the undisputed largest market for Portland Cement, driven by robust economic growth, rapid urbanization, and extensive infrastructure development, particularly in countries like China, India, and Southeast Asian nations. Significant government investments in smart cities, transportation networks, and housing projects continue to fuel demand.

- North America: Characterized by a mature construction market, demand in North America is stable, primarily driven by renovation, maintenance, and repair activities for existing infrastructure, coupled with moderate new construction. The region is witnessing a growing emphasis on sustainable building practices and advanced concrete solutions.

- Europe: Similar to North America, Europe is a mature market focusing on sustainable construction, energy efficiency, and the use of eco-friendly cement alternatives. Demand is influenced by EU regulations on emissions and the push towards circular economy principles, with countries like Germany, France, and Italy being key contributors.

- Latin America: This region exhibits promising growth potential, supported by increasing investments in infrastructure, housing, and commercial construction projects, especially in Brazil, Mexico, and Colombia. Economic stability and population growth are key underlying drivers.

- Middle East & Africa (MEA): The MEA region is experiencing significant market expansion propelled by ambitious infrastructure development plans, particularly in the GCC countries (Saudi Arabia, UAE) for mega-projects and diversified economies. Urbanization and housing initiatives also contribute substantially to cement consumption across Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Portland Cement Market.- Anhui Conch Cement Company Limited

- Cemex S.A.B. de C.V.

- China National Building Material Company Limited (CNBM)

- Dangote Cement Plc

- Heidelberg Materials AG (formerly HeidelbergCement AG)

- Holcim Group

- Italcementi (Heidelberg Materials AG subsidiary)

- J.K. Cement Ltd.

- LafargeHolcim Ltd.

- Mitsubishi Materials Corporation

- Siam Cement Group (SCG)

- Taiheiyo Cement Corporation

- UltraTech Cement Limited

- Votorantim Cimentos S.A.

- CRH plc

- Buzzi Unicem S.p.A.

- Aditya Birla Group (Grasim Industries Limited)

- Shandong Shanshui Cement Group Ltd.

Frequently Asked Questions

What are the primary drivers of Portland Cement market growth?

The primary drivers include rapid global urbanization, significant government and private investments in infrastructure development (e.g., roads, bridges, smart cities), and robust growth in residential and commercial construction sectors, particularly in emerging economies with expanding populations.

How do environmental regulations impact the Portland Cement industry?

Environmental regulations, especially those targeting CO2 emissions and waste management, significantly impact the industry by mandating investments in greener technologies like carbon capture, promoting the use of alternative fuels, and encouraging the development of low-carbon and blended cements, driving up operational costs while fostering sustainability.

What role does technology play in modern cement manufacturing?

Technology plays a critical role in enhancing efficiency, quality, and sustainability. This includes advanced grinding mills for energy efficiency, waste heat recovery systems, automation, IoT for real-time monitoring, AI for predictive maintenance and process optimization, and R&D for low-carbon cement formulations and carbon capture technologies.

Which geographical region dominates the Portland Cement market?

The Asia Pacific region currently dominates the Portland Cement market in terms of both production and consumption. This is largely attributed to rapid industrialization, extensive infrastructure projects, and high population growth rates in key countries such as China, India, and various Southeast Asian nations.

What are the key types of Portland Cement and their applications?

Key types include Ordinary Portland Cement (OPC) for general construction, Portland Pozzolana Cement (PPC) for improved durability and chemical resistance, White Portland Cement for aesthetic purposes, and Sulphate-Resisting Portland Cement (SRPC) for aggressive environments. Their applications range from residential and commercial buildings to critical infrastructure projects and specialized repairs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager