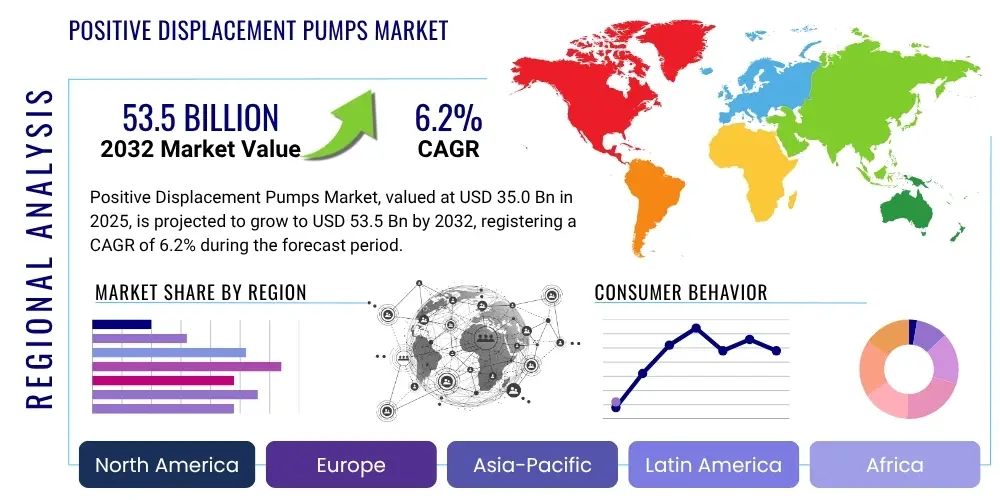

Positive Displacement Pumps Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429754 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Positive Displacement Pumps Market Size

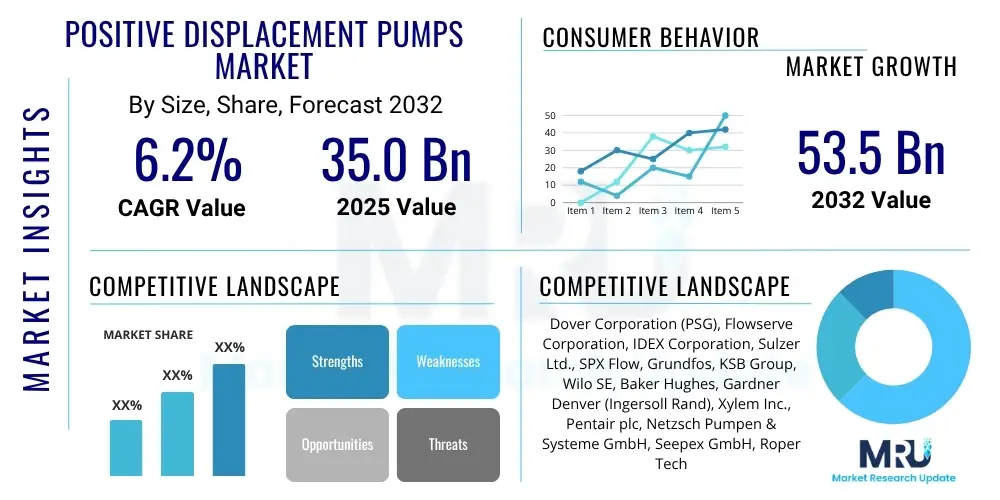

The Positive Displacement Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at USD 35.0 billion in 2025 and is projected to reach USD 53.5 billion by the end of the forecast period in 2032.

Positive Displacement Pumps Market introduction

The Positive Displacement Pumps Market is a critical segment within the industrial machinery sector, playing an indispensable role in a diverse array of applications where precise fluid handling, high pressure, or the transfer of viscous and shear-sensitive liquids is paramount. These pumps operate on a fundamental principle of trapping a fixed volume of fluid and mechanically forcing it into the discharge pipe, thereby ensuring a constant flow rate regardless of system pressure changes. This inherent design advantage differentiates them significantly from dynamic pumps, making them essential across numerous industries for specific and demanding tasks.

The product portfolio within this market is extensive, encompassing various types such such as rotary positive displacement pumps (including gear, lobe, screw, and vane pumps) and reciprocating positive displacement pumps (like piston, plunger, and diaphragm pumps). Each type offers distinct operational characteristics and is tailored for particular applications, from handling highly viscous crude oil in the petrochemical industry to dispensing precise dosages in pharmaceutical manufacturing. Major applications span critical sectors including oil and gas, chemical processing, water and wastewater treatment, food and beverage, pharmaceuticals, and pulp and paper, highlighting their versatility and widespread necessity.

The primary benefits driving the adoption of positive displacement pumps include their superior efficiency, especially when dealing with high viscosities or pressures, their exceptional ability to provide precise and repeatable flow rates, and their inherent self-priming capabilities. They are also adept at handling solids in suspension and highly sensitive fluids without degradation. The market growth is predominantly driven by global industrial expansion, significant investments in infrastructure development, increasing demand for energy-efficient pumping solutions, and the ever-growing need for precise fluid control in modern manufacturing processes. Stringent environmental regulations also push industries towards more reliable and leak-proof pumping systems, further bolstering market demand.

Positive Displacement Pumps Market Executive Summary

The Positive Displacement Pumps Market is poised for substantial growth, driven by an escalating demand for reliable and efficient fluid transfer solutions across various industrial landscapes. Key business trends indicate a strong move towards smart pumps integrated with IoT for enhanced monitoring and predictive maintenance, alongside a focus on developing pumps from advanced materials to withstand corrosive and abrasive environments. Manufacturers are increasingly investing in research and development to offer more energy-efficient models and customizable solutions that cater to niche application requirements, thereby maximizing operational uptime and reducing lifetime costs for end-users.

Regionally, the Asia Pacific (APAC) market is anticipated to exhibit the fastest growth, primarily fueled by rapid industrialization, burgeoning infrastructure projects, and significant investments in manufacturing and chemical sectors within countries like China and India. North America and Europe, while mature markets, are witnessing a surge in demand for advanced, automated, and digitally integrated positive displacement pumps, driven by strict regulatory standards and a push for operational excellence and sustainability. Latin America and the Middle East & Africa regions are also contributing to market expansion, largely due to ongoing oil and gas exploration activities, mining projects, and improvements in water and wastewater infrastructure.

From a segmentation perspective, rotary positive displacement pumps, particularly screw and gear pumps, are gaining traction due to their suitability for handling high-viscosity fluids and providing pulsation-free flow, critical in sectors like oil and gas and chemicals. Reciprocating pumps, such as diaphragm pumps, are seeing increased adoption in pharmaceutical and chemical industries for their precision and ability to handle abrasive or hazardous fluids. The market is also experiencing a trend towards modular designs and standardized components, facilitating easier maintenance and scalability. Overall, the market remains competitive, with key players focusing on technological innovation, strategic collaborations, and expanding their global distribution networks to capture a larger share of the evolving demand.

AI Impact Analysis on Positive Displacement Pumps Market

Users are increasingly seeking to understand how Artificial Intelligence (AI) can revolutionize the operation and maintenance of positive displacement pumps. Common questions revolve around AI's capability to enhance pump efficiency, facilitate predictive maintenance to minimize downtime, optimize operational parameters, and provide advanced diagnostics. There is also significant interest in how AI can contribute to energy savings, improve overall system reliability, and enable more autonomous pump operations, ultimately reducing operational expenditures and extending equipment lifespan. Users are keen on the practical applications and tangible benefits AI integration can offer in highly sensitive and critical fluid transfer processes, alongside concerns regarding data security, integration complexity, and the necessary skill sets for implementation.

- Predictive maintenance: AI algorithms analyze operational data (pressure, temperature, vibration) to forecast potential failures, enabling proactive servicing and reducing unscheduled downtime.

- Operational optimization: AI systems adjust pump speeds and flow rates in real-time based on process demands, optimizing energy consumption and improving process efficiency.

- Fault detection and diagnostics: AI can quickly identify anomalies and pinpoint the root cause of pump malfunctions, accelerating troubleshooting and repair processes.

- Remote monitoring and control: AI-powered platforms allow operators to monitor pump performance from anywhere, enabling remote adjustments and enhancing operational flexibility.

- Enhanced process control: AI integrates pump data with overall plant control systems, leading to more precise fluid handling, mixing, and dosing in complex industrial processes.

- Energy efficiency: AI algorithms identify patterns for optimal pump operation, minimizing energy waste and reducing carbon footprint through intelligent resource allocation.

- Supply chain optimization: AI can assist in predicting spare part requirements based on pump usage and wear patterns, improving inventory management and logistics for maintenance.

DRO & Impact Forces Of Positive Displacement Pumps Market

The Positive Displacement Pumps Market is significantly influenced by a confluence of driving forces, restraining factors, and emerging opportunities. A primary driver is the continuous expansion of industrial sectors globally, including chemicals, oil and gas, food and beverage, and pharmaceuticals, all of which rely heavily on precise and reliable fluid transfer systems. Furthermore, increasing investments in infrastructure development, such as water and wastewater treatment facilities and power generation plants, directly contribute to the demand for these pumps. The inherent ability of positive displacement pumps to handle viscous, abrasive, and shear-sensitive fluids with high accuracy and efficiency makes them indispensable in specialized applications, thereby solidifying their market position. The growing emphasis on energy efficiency and environmental compliance also pushes industries to adopt advanced pump technologies that reduce operational costs and minimize leaks or spills.

Despite these robust drivers, the market faces several restraints. The relatively high initial capital expenditure associated with positive displacement pumps compared to their centrifugal counterparts can be a barrier for some end-users, especially in price-sensitive developing markets. Additionally, the maintenance requirements for these pumps can be more intricate and specialized due to their precise internal clearances and specific material needs for seals and components, potentially leading to higher operational expenses over their lifecycle. Competition from other pump technologies, particularly centrifugal pumps which are more cost-effective for high-flow, low-pressure applications, also presents a significant challenge, limiting market penetration in certain segments.

However, the market is ripe with opportunities that are expected to propel its growth. The increasing adoption of smart pump technologies, integrating IoT sensors, and AI-driven predictive maintenance solutions offers a significant avenue for value creation and differentiation. Emerging economies, characterized by rapid industrialization and urbanization, present vast untapped markets for positive displacement pumps. Moreover, the growing demand for specialty chemicals, biofuels, and products from the biotechnology sector necessitates highly precise and sterile fluid handling, creating niche opportunities for advanced positive displacement pump designs. The expanding renewable energy sector, including concentrated solar power and geothermal plants, also presents new applications requiring specialized pumping solutions capable of handling high-temperature or corrosive fluids. These opportunities, coupled with ongoing technological advancements, are expected to mitigate the impact of existing restraints and foster sustained market expansion.

Segmentation Analysis

The Positive Displacement Pumps Market is comprehensively segmented based on various criteria to provide a granular understanding of its dynamics and potential growth areas. These segmentations typically include pump type, application, end-user industry, and geographical region, each offering unique insights into demand patterns and technological preferences. Analyzing these segments helps in identifying key market trends, competitive landscapes, and strategic opportunities for market players.

- By Type:

- Rotary Positive Displacement Pumps

- Gear Pumps (External Gear, Internal Gear)

- Lobe Pumps

- Screw Pumps

- Vane Pumps

- Peristaltic Pumps

- Reciprocating Positive Displacement Pumps

- Piston Pumps

- Plunger Pumps

- Diaphragm Pumps (Mechanical, Hydraulic, Air-Operated Double Diaphragm (AODD))

- Rotary Positive Displacement Pumps

- By Application:

- Dosing

- Metering

- Transfer

- Circulation

- Injection

- Mixing

- By End-User Industry:

- Oil & Gas (Upstream, Midstream, Downstream)

- Chemical & Petrochemical

- Water & Wastewater Treatment

- Food & Beverage

- Pharmaceuticals & Biotechnology

- Power Generation

- Pulp & Paper

- Mining

- Building & Construction

- Others (Marine, Textile, Automotive)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Positive Displacement Pumps Market

The value chain for the Positive Displacement Pumps Market begins with raw material suppliers and component manufacturers, forming the upstream segment. This stage involves the procurement of various metals such as stainless steel, cast iron, and exotic alloys, as well as polymers, elastomers, and ceramics, which are crucial for constructing durable and corrosion-resistant pump components like casings, impellers, shafts, and seals. Specialized manufacturers provide essential components such as motors, gearboxes, bearings, and control systems, which are integral to the pump's functionality and performance. The quality and availability of these upstream inputs directly influence the manufacturing costs and the final product's reliability and lifespan.

Moving downstream, the value chain encompasses pump manufacturing, assembly, testing, and ultimately, distribution and end-user engagement. Manufacturers assemble these components into complete pump units, often customizing them to meet specific industry requirements for pressure, flow rate, and fluid compatibility. After manufacturing, the pumps are channeled to end-users through various distribution models. Direct sales channels involve manufacturers selling directly to large industrial clients, often for complex projects requiring significant engineering support and after-sales service. Indirect channels, on the other hand, utilize a network of distributors, agents, and system integrators who provide local access, technical support, and sometimes even installation and maintenance services to a broader range of smaller and medium-sized enterprises. Original Equipment Manufacturers (OEMs) also play a vital role, incorporating these pumps into larger machinery or complete process systems.

The distribution network is a critical link, ensuring market reach and efficient delivery. Direct sales are often preferred for highly specialized or custom-engineered pumps, allowing for direct communication and tailored solutions between the manufacturer and the end-user. This approach fosters strong client relationships and provides immediate feedback for product development. Indirect sales through distributors and resellers are essential for broader market penetration, especially for standard pump models and in regions where a manufacturer lacks a direct presence. These intermediaries often manage inventory, provide localized support, and offer value-added services such as maintenance, repair, and overhaul (MRO). The effectiveness of these distribution channels significantly impacts market share, customer satisfaction, and the overall efficiency of bringing the product to market. Both direct and indirect models are indispensable for a comprehensive market strategy, catering to different customer needs and geographical expanses, thereby optimizing market access and responsiveness.

Positive Displacement Pumps Market Potential Customers

Potential customers for positive displacement pumps are primarily industries and enterprises that require precise, reliable, and efficient handling of a wide range of fluids, particularly those with high viscosity, shear sensitivity, or hazardous properties, or applications demanding high pressure and consistent flow rates. These end-users span across diverse sectors where fluid transfer is a critical part of their operational processes. The decision to invest in a positive displacement pump often hinges on the specific fluid characteristics, process requirements, and the need for operational integrity and safety, making these pumps indispensable in many industrial environments. The versatility and specialized capabilities of positive displacement pumps ensure a broad and stable customer base across various global industries.

Key sectors representing significant potential customer segments include the oil and gas industry, where positive displacement pumps are used for crude oil transfer, chemical injection, and drilling mud handling; the chemical and petrochemical industry, for precise dosing of reagents, transfer of corrosive chemicals, and handling of viscous polymers; and the water and wastewater treatment sector, for metering coagulants, disinfectants, and sludge transfer. The food and beverage industry also relies heavily on these pumps for handling viscous food products like chocolate, sauces, and dough, as well as for precise ingredient dosing, ensuring product quality and consistency. Furthermore, pharmaceutical and biotechnology companies are crucial customers, utilizing sterile and accurate positive displacement pumps for drug formulation, fermentation processes, and precise batch transfers of sensitive biological materials.

Beyond these core industries, other significant end-users include power generation plants for fuel oil transfer and chemical dosing, the pulp and paper industry for handling slurries and additives, and the mining sector for transferring highly abrasive slurries and dewatering applications. Manufacturers of paints, coatings, and adhesives also represent a strong customer base due to the pumps' ability to handle high-viscosity products. In essence, any industrial operation that demands accurate, controlled, and gentle handling of fluids, irrespective of their properties or operating conditions, is a potential customer for positive displacement pumps, highlighting the widespread applicability and critical nature of this technology in modern industrial processes. The continuous innovation in materials and smart features further expands their appeal to a broader spectrum of demanding applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 35.0 billion |

| Market Forecast in 2032 | USD 53.5 billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dover Corporation (PSG), Flowserve Corporation, IDEX Corporation, Sulzer Ltd., SPX Flow, Grundfos, KSB Group, Wilo SE, Baker Hughes, Gardner Denver (Ingersoll Rand), Xylem Inc., Pentair plc, Netzsch Pumpen & Systeme GmbH, Seepex GmbH, Roper Technologies Inc., Watson-Marlow Fluid Technology Solutions, Atlas Copco AB, LEWA GmbH, Graco Inc., Viking Pump (Unit of IDEX Corporation) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Positive Displacement Pumps Market Key Technology Landscape

The technological landscape of the Positive Displacement Pumps Market is evolving rapidly, driven by the need for enhanced efficiency, reliability, and integration into modern industrial ecosystems. A major trend is the incorporation of advanced sensing and monitoring technologies, including vibration sensors, pressure transducers, temperature sensors, and flow meters, which provide real-time operational data. This data forms the backbone for condition monitoring and predictive maintenance strategies, allowing operators to anticipate potential failures and schedule interventions proactively, thereby minimizing unscheduled downtime and optimizing maintenance costs. The use of variable speed drives (VSDs) is also becoming commonplace, enabling precise control over pump output and significant energy savings by adjusting pump speed to match process demands.

Further innovation is seen in the development of smart pumps, which leverage the Internet of Things (IoT) for connectivity and data transmission to cloud-based platforms. These platforms utilize sophisticated analytics, often incorporating Artificial Intelligence (AI) and machine learning algorithms, to process vast amounts of operational data. AI-driven analytics can identify subtle performance deviations, optimize pump parameters for maximum efficiency, and even offer prescriptive advice for operational adjustments or maintenance actions. This digital transformation allows for remote monitoring, diagnostics, and control, enhancing operational flexibility and responsiveness. The integration of augmented reality (AR) for field service technicians is also emerging, providing interactive guides for complex maintenance tasks and training.

Material science advancements are also pivotal, with manufacturers developing new alloys, ceramics, and advanced polymers that offer superior chemical resistance, abrasion resistance, and temperature tolerance, extending the lifespan and applicability of pumps in challenging environments. Modular pump designs are gaining traction, facilitating easier assembly, maintenance, and scalability, allowing for quick customization and simplified parts replacement. Furthermore, additive manufacturing (3D printing) is being explored for producing complex internal geometries and specialized components, potentially reducing lead times and enabling the creation of custom parts that optimize fluid dynamics. These technological advancements collectively contribute to making positive displacement pumps more intelligent, resilient, and integrated within Industry 4.0 frameworks, meeting the stringent demands of modern industrial processes.

Regional Highlights

- North America: A mature market characterized by stringent environmental regulations, a strong focus on advanced technology adoption, and significant investments in the oil & gas, chemical, and pharmaceutical sectors. The demand here is driven by the need for high-efficiency, reliable, and smart pumping solutions, particularly for critical applications and infrastructure upgrades.

- Europe: This region exhibits a steady demand for positive displacement pumps, largely influenced by robust manufacturing industries, high standards for energy efficiency, and a strong emphasis on sustainability. Germany, the UK, and France are key contributors, with growth fueled by water & wastewater treatment, food & beverage, and chemical industries seeking precision and compliance with strict EU directives.

- Asia Pacific (APAC): The fastest-growing market globally, propelled by rapid industrialization, urbanization, and substantial investments in manufacturing, infrastructure, and processing industries across China, India, and Southeast Asian nations. The region's growth is largely volume-driven, with increasing demand from the chemical, oil & gas, and water treatment sectors, alongside a growing adoption of advanced pump technologies.

- Latin America: This region presents considerable growth potential, primarily driven by resource extraction industries such as oil & gas, mining, and agriculture. Countries like Brazil and Mexico are experiencing increased industrial activity, leading to greater demand for robust positive displacement pumps capable of handling challenging media and remote operational conditions.

- Middle East & Africa (MEA): Dominated by the extensive oil & gas sector, particularly in the Gulf Cooperation Council (GCC) countries, driving demand for specialized positive displacement pumps for exploration, production, and refining processes. Significant investments in water desalination plants and infrastructure development projects across the region also contribute significantly to market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Positive Displacement Pumps Market.- Dover Corporation (PSG)

- Flowserve Corporation

- IDEX Corporation

- Sulzer Ltd.

- SPX Flow Inc.

- Grundfos Holding A/S

- KSB Group

- Wilo SE

- Baker Hughes Company

- Gardner Denver (an Ingersoll Rand brand)

- Xylem Inc.

- Pentair plc

- Netzsch Pumpen & Systeme GmbH

- Seepex GmbH

- Roper Technologies Inc.

- Watson-Marlow Fluid Technology Solutions (A Spirax Sarco Engineering Company)

- Atlas Copco AB

- LEWA GmbH

- Graco Inc.

- Viking Pump (A Unit of IDEX Corporation)

Frequently Asked Questions

What are positive displacement pumps and how do they work?

Positive displacement pumps operate by trapping a fixed amount of fluid and forcing it into the discharge pipe. Unlike centrifugal pumps, their flow rate is constant regardless of system pressure, making them ideal for precise metering, high-viscosity fluids, and high-pressure applications. They achieve this by using expanding and contracting cavities to move fluid.

Which industries primarily utilize positive displacement pumps?

Positive displacement pumps are widely used across diverse industries including oil and gas, chemical processing, water and wastewater treatment, food and beverage, pharmaceuticals, and pulp and paper. Their precision, ability to handle viscous liquids, and high-pressure capabilities make them indispensable in these sectors.

What are the main advantages of positive displacement pumps over centrifugal pumps?

Positive displacement pumps offer superior efficiency when handling high-viscosity fluids, provide highly accurate and consistent flow rates (metering capabilities), are self-priming, and can generate high discharge pressures independently of flow. Centrifugal pumps are generally preferred for high-flow, low-pressure applications with thin fluids.

What are the key types of positive displacement pumps available in the market?

The primary types include rotary positive displacement pumps, such as gear, lobe, screw, vane, and peristaltic pumps, which use rotating elements to move fluid. Reciprocating positive displacement pumps, like piston, plunger, and diaphragm pumps, use back-and-forth motion to displace fluid. Each type is suited for specific applications based on fluid characteristics and operational requirements.

How is AI impacting the Positive Displacement Pumps Market?

AI significantly impacts the market by enabling advanced predictive maintenance, optimizing pump operational parameters for enhanced energy efficiency, providing real-time fault detection and diagnostics, and facilitating remote monitoring and control. These AI applications lead to reduced downtime, lower operational costs, and improved overall system reliability and performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager