Precision Gearbox Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428575 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Precision Gearbox Market Size

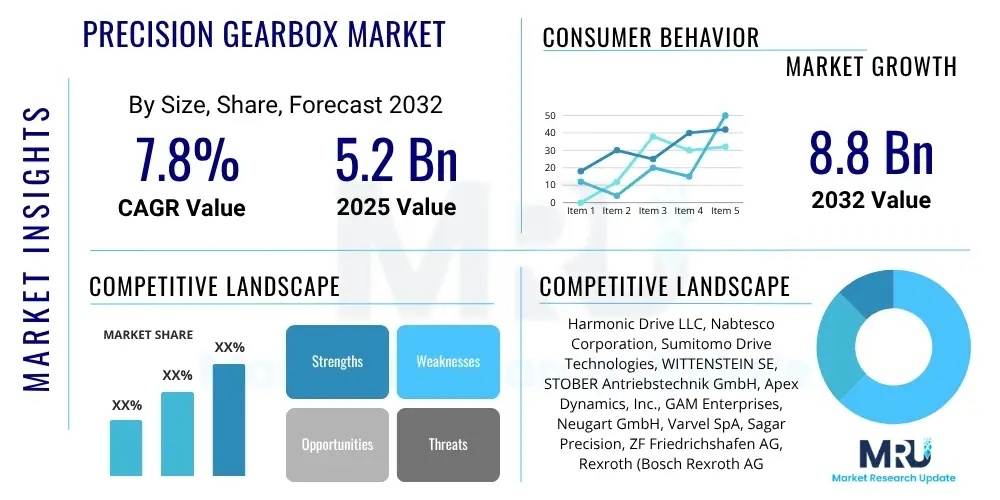

The Precision Gearbox Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 5.2 Billion in 2025 and is projected to reach USD 8.8 Billion by the end of the forecast period in 2032.

Precision Gearbox Market introduction

Precision gearboxes represent a critical class of mechanical power transmission components specifically engineered for applications demanding exceptional accuracy, minimal backlash, and high torque density. Unlike standard industrial gearboxes, these units are meticulously designed and manufactured to achieve superior repeatability and positional accuracy, which is paramount in advanced manufacturing and automated systems. Their sophisticated construction involves high-quality materials, precise machining tolerances, and often specialized gear geometries, all contributing to their ability to operate smoothly and reliably under stringent performance requirements, making them indispensable in the push towards greater industrial efficiency and automation.

The inherent benefits of integrating precision gearboxes into mechanical systems are multifaceted and profound, extending beyond mere power transmission. They significantly enhance overall operational efficiency by minimizing energy losses through optimized gear meshing and reduced friction. Furthermore, their superior accuracy translates directly into improved product quality and reduced waste in manufacturing processes, while their robust design ensures extended operational lifespans and reduced maintenance requirements. These advantages collectively contribute to lower total cost of ownership and higher return on investment for industries relying on consistent, high-performance motion control solutions across their production lines and specialized equipment.

The market for precision gearboxes is experiencing vigorous growth, predominantly fueled by the global acceleration of industrial automation and the pervasive adoption of Industry 4.0 initiatives. Key driving factors include the increasing deployment of industrial robots and collaborative robots (cobots) across various sectors, the continuous demand for high-performance CNC machine tools, and the expansion of smart factory concepts which necessitate highly precise and reliable motion components. Additionally, the rapid growth in specialized industries such as aerospace and defense, medical device manufacturing, and semiconductor production, each with stringent requirements for positional accuracy and system reliability, further amplifies the demand for technologically advanced precision gearboxes, fostering continuous innovation and market expansion.

Precision Gearbox Market Executive Summary

The Precision Gearbox Market is characterized by dynamic business trends centered on technological innovation, strategic collaborations, and a strong emphasis on product differentiation through enhanced performance parameters. Manufacturers are increasingly investing in research and development to integrate advanced materials like ceramic components and high-strength alloys, alongside incorporating smart features such as integrated sensors and predictive maintenance capabilities. A notable trend is market consolidation, where leading players acquire niche specialists to broaden their technological expertise and expand their product portfolios, aiming to offer more comprehensive solutions and strengthen their competitive foothold in a rapidly evolving industrial landscape, driven by demand for compact and efficient designs.

From a regional perspective, the Asia Pacific region stands out as the dominant and fastest-growing market for precision gearboxes, propelled by its extensive manufacturing infrastructure and significant government investments in industrial automation and smart factories, particularly in economies like China, Japan, and South Korea. North America and Europe demonstrate sustained growth, driven by the modernization of existing industrial bases, the high adoption rate of advanced robotics, and robust demand from critical sectors such as aerospace, medical equipment, and high-tech manufacturing. Emerging markets in Latin America and the Middle East and Africa are also gradually increasing their adoption of precision gearboxes as industrialization accelerates and manufacturing capabilities expand, supported by infrastructure development projects.

Segment-wise, the robotics and automation applications segment is expected to retain its leading position throughout the forecast period, reflecting the global imperative for automated production lines and autonomous systems. Planetary and harmonic gearboxes, known for their compact design, high torque density, and ultra-low backlash characteristics, are particularly favored within this segment for their suitability in sophisticated robotic joints and motion control systems. The ongoing evolution of these application areas, coupled with the increasing need for custom-engineered and highly efficient drive solutions, continues to shape market dynamics, pushing manufacturers to innovate and deliver gearboxes that can meet the rigorous demands of next-generation industrial and specialized machinery.

AI Impact Analysis on Precision Gearbox Market

Common user questions regarding the influence of Artificial Intelligence on the Precision Gearbox Market frequently revolve around topics such as the practical applications of AI in enhancing gearbox performance, the mechanisms through which AI contributes to predictive maintenance, and the overall implications for operational longevity and cost reduction. Users are keen to understand how traditional mechanical components can become 'smart' through AI integration, specifically inquiring about real-time monitoring capabilities, anomaly detection, and the potential for autonomous optimization. Underlying concerns often include the complexity of implementing AI solutions, data security challenges, and the potential skill gaps required to manage AI-driven systems within industrial environments. Nevertheless, there is a strong expectation that AI will be a transformative force, enabling unprecedented levels of efficiency, reliability, and precision in gearbox operation and design.

The integration of AI technologies is profoundly reshaping the functional capabilities of precision gearboxes, primarily by enabling advanced predictive maintenance strategies. By embedding an array of sensors within gearboxes—monitoring parameters like vibration, temperature, acoustic emissions, and lubrication quality—and feeding this data into sophisticated machine learning algorithms, AI can analyze complex patterns and accurately predict potential component failures long before they occur. This proactive approach allows for scheduled maintenance, minimizes unexpected downtime, and optimizes the replacement cycle of parts, drastically reducing operational costs and extending the useful life of the gearbox. Such intelligent monitoring transforms reactive maintenance into a data-driven, preventative process, significantly improving overall equipment effectiveness (OEE).

Beyond maintenance, AI is also driving innovation in the design, optimization, and real-time performance management of precision gearboxes. Generative design, powered by AI algorithms, allows engineers to explore thousands of design iterations to create gear structures that are not only lighter and stronger but also exhibit superior efficiency and thermal management characteristics, tailored precisely to specific application demands. During operation, AI-enabled control systems can dynamically adjust gearbox parameters in response to varying load conditions or environmental changes, ensuring optimal torque transmission and energy consumption. This adaptive intelligence not only maximizes performance but also paves the way for the development of fully autonomous drive systems capable of self-diagnosis and self-optimization, marking a significant leap forward in precision motion control technology.

- Enhanced Predictive Maintenance: AI-powered analytics of sensor data accurately predicts potential failures, enabling proactive maintenance and reducing unscheduled downtime.

- Real-time Performance Optimization: AI algorithms dynamically adjust operational parameters for maximum efficiency, minimizing energy consumption and wear under varying loads.

- Autonomous Anomaly Detection: Machine learning identifies subtle deviations from normal operating patterns, flagging issues before they escalate into critical failures.

- Optimized Design and Manufacturing: AI-driven generative design and simulation tools facilitate the creation of lighter, stronger, and more efficient gearbox components.

- Seamless Integration with Smart Factories: Enables advanced connectivity and data exchange with other industrial IoT devices, fostering comprehensive Industry 4.0 ecosystems.

- Improved Quality Control: AI vision systems and data analytics enhance inspection processes during manufacturing, ensuring superior product quality and minimizing defects.

- Adaptive Control Systems: AI allows gearboxes to adapt their performance characteristics in real-time to external conditions, enhancing responsiveness and precision.

DRO & Impact Forces Of Precision Gearbox Market

The Precision Gearbox Market is primarily propelled by several powerful drivers, most notably the relentless global push towards industrial automation and the widespread adoption of advanced robotics across manufacturing sectors. The fundamental requirements of Industry 4.0, which demand highly interconnected, intelligent, and efficient production environments, necessitate the integration of precision gearboxes for their unparalleled accuracy, repeatability, and reliability in complex motion control applications. Furthermore, the burgeoning demand for high-performance machinery in critical industries such as aerospace, medical device manufacturing, and semiconductor fabrication, where even minuscule errors can have significant consequences, further accentuates the need for sophisticated precision drive solutions. Continuous innovation in design methodologies and material science also contributes to this driving force, enabling manufacturers to produce gearboxes with enhanced torque density, reduced backlash, and extended operational lifespans, meeting increasingly stringent performance benchmarks.

Despite these robust growth drivers, the market faces notable restraints that could temper its expansion. A significant challenge is the inherently high initial cost associated with precision gearboxes, which stems from their intricate design, specialized manufacturing processes that require tight tolerances, and the use of premium, advanced materials. This elevated price point can act as a barrier to adoption for small and medium-sized enterprises (SMEs) with limited capital expenditure budgets. Additionally, the complexity of these high-precision components often demands specialized technical expertise for installation, commissioning, and ongoing maintenance, leading to potential skill gaps in the workforce. Macroeconomic uncertainties, trade tensions, and fluctuations in global industrial output can also lead to reduced capital investments in machinery, thereby dampening overall demand for high-value components like precision gearboxes.

Nevertheless, the market is rife with significant opportunities that innovative players can leverage for sustained growth. The accelerating industrialization and modernization efforts in developing economies, particularly across Asia Pacific and Latin America, coupled with governmental initiatives promoting local manufacturing and automation, present substantial new market penetration avenues. The increasing trend towards customization and modularity in gearbox design offers opportunities to cater to highly specialized niche applications and specific customer performance requirements, allowing for greater product differentiation. Furthermore, the integration of precision gearboxes with cutting-edge technologies like the Internet of Things (IoT), artificial intelligence (AI) for predictive maintenance, and digital twin capabilities, creates avenues for value-added services and new revenue streams. The continuous drive towards miniaturization and lightweight designs, essential for the next generation of collaborative robots and portable automated systems, also opens new frontiers for product development and market expansion, fostering technological leadership.

Segmentation Analysis

The Precision Gearbox Market undergoes a comprehensive segmentation based on several critical parameters, offering a granular view of its varied demand landscape and technological nuances. These categorizations typically include classifications by gearbox type, the specific application areas they serve, their torque handling capabilities, and their backlash characteristics. Each segment highlights distinct technological requirements and addresses the unique operational needs of various industrial sectors, providing invaluable insights into market dynamics, competitive positioning, and areas ripe for innovation. A thorough analysis of these segments is instrumental for stakeholders seeking to understand market structure and identify growth pockets within the highly specialized field of precision motion control.

Understanding the intricacies of these segmentations is paramount for manufacturers, suppliers, and investors to formulate effective business strategies, tailor product development, and optimize marketing efforts. For example, the demand for harmonic gearboxes, characterized by their exceptional precision and zero backlash, is primarily concentrated in advanced robotics and aerospace where ultra-fine positional accuracy is non-negotiable. Conversely, planetary gearboxes, known for their high torque density and compactness, find extensive use across a broader range of industrial automation applications. Similarly, considerations such as torque range and backlash level directly influence product selection, ensuring that the gearbox precisely matches the performance requirements of the end application, balancing cost, efficiency, and desired accuracy. This detailed segmentation not only clarifies market structure but also illuminates evolving customer preferences and technological shifts, guiding strategic investments and product roadmaps.

- By Type:

- Planetary Gearbox: Known for high torque density, efficiency, and compact design. Widely used in industrial automation and general robotics.

- Harmonic Gearbox: Offers zero backlash, high precision, and compact size. Essential for advanced robotics, medical equipment, and aerospace applications.

- Cycloidal Gearbox: Characterized by high torque capacity, shock resistance, and good torsional stiffness. Applied in heavy-duty automation and machine tools.

- Worm Gearbox: Provides high reduction ratios and inherent self-locking features. Utilized in applications requiring controlled speed and load holding.

- Bevel Gearbox: Primarily used for changing the direction of rotation, typically in right-angle drive configurations for various industrial machines.

- Hypoid Gearbox: An advanced form of bevel gearing offering smoother contact, higher torque transmission, and quieter operation in specific applications.

- By Application:

- Robotics & Automation: The largest segment, driven by industrial robots, collaborative robots, and autonomous guided vehicles (AGVs).

- Machine Tools: Critical for CNC machines, milling, turning, grinding, and laser cutting, where precision and repeatability are vital.

- Aerospace & Defense: Used in actuators, flight control systems, radar positioning, and satellite equipment, demanding extreme reliability.

- Medical Equipment: Employed in surgical robots, diagnostic imaging systems, laboratory automation, and patient positioning systems.

- Food & Beverage Processing: For packaging, conveying, mixing, and dispensing machinery, requiring hygienic and precise operations.

- Packaging Machinery: Ensures precise movement, indexing, and positioning in high-speed, automated packaging lines.

- Semiconductor Equipment: Essential for wafer handling, inspection, and assembly machines, where microscopic accuracy is crucial.

- Material Handling: Utilized in conveyors, palletizers, automated storage and retrieval systems (AS/RS), and forklifts.

- By Torque Range:

- Low Torque: Typically for small-scale automation, instrumentation, and compact robotic arms.

- Medium Torque: For general industrial automation, medium-sized robots, and standard machine tools.

- High Torque: Designed for heavy-duty industrial machinery, large-scale robotics, and specialized applications requiring substantial power transmission.

- By Backlash:

- Zero Backlash: The highest precision category, critical for applications like surgical robots, optical systems, and highly accurate positioning.

- Low Backlash: Preferred for most high-precision robotics, advanced machine tools, and demanding automation tasks.

- Standard Backlash: Used in applications where some rotational play is acceptable, balancing cost-effectiveness with operational performance.

- By End-User Industry:

- Automotive: Robotics in assembly lines, welding, paint shops, and component manufacturing.

- Electronics & Electrical: Precision assembly, testing, and handling of electronic components and circuit boards.

- Heavy Machinery: Construction, mining, agricultural equipment, and specialized industrial vehicles.

- Construction: Used in automated construction equipment, cranes, and material positioning systems.

- Printing: For precise paper handling, plate positioning, and ink application in high-speed printing presses.

Value Chain Analysis For Precision Gearbox Market

The value chain of the Precision Gearbox Market is an intricate network of specialized activities that begins with the meticulous sourcing of raw materials and culminates in the integration of the final product into sophisticated end-user applications. Upstream analysis reveals a critical dependence on high-quality raw material suppliers providing specialized steels, advanced alloys, engineering plastics, and potentially ceramic components, all of which must meet stringent metallurgical and dimensional specifications to ensure the durability, strength, and precise performance of the gearbox. Concurrently, manufacturers rely on a distinct set of component suppliers for precision bearings, sealing solutions, high-performance lubricants, and integrated sensors, which are fundamental to achieving the desired levels of accuracy, efficiency, and longevity in the final precision gearbox assembly. The quality and availability of these upstream inputs directly influence the manufacturing costs, reliability, and market competitiveness of precision gearboxes.

In the midstream segment of the value chain, the manufacturing process is characterized by highly specialized and complex techniques that demand exceptional engineering expertise and state-of-the-art machinery. This includes ultra-precision gear cutting, grinding, honing, and lapping processes, all designed to achieve the extremely tight tolerances and superior surface finishes essential for minimizing backlash and maximizing efficiency. Advanced heat treatment and surface hardening techniques are also critical to enhance the wear resistance and load-carrying capacity of gear components. The subsequent assembly phase often occurs in controlled environments, such as cleanrooms, to prevent contamination and ensure the precise alignment of components, which is paramount for the gearbox's final performance characteristics. Downstream activities primarily involve the integration of these precision gearboxes by Original Equipment Manufacturers (OEMs) into their high-value products, including industrial robots, CNC machines, and aerospace actuators, alongside system integrators who customize solutions for specific industrial automation projects.

The distribution channels for precision gearboxes are strategically designed to cater to a global clientele with varying technical and logistical requirements, encompassing both direct and indirect sales approaches. Direct sales are predominantly utilized for large-volume orders from major OEMs or for highly customized, complex solutions where extensive technical consultation, direct engineering support, and close collaboration between the manufacturer and the customer are essential. Conversely, indirect channels leverage a vast network of specialized distributors, value-added resellers, and regional sales agents. These partners provide crucial local market penetration, offer technical support, manage inventory, and provide rapid delivery for a broader range of customers, including smaller manufacturers, maintenance and repair operations (MRO), and regional system integrators. The selection of the appropriate distribution strategy is often influenced by the product's technical complexity, the geographic reach required, and the specific service level expectations of the customer base, ensuring efficient market access and robust post-sales support across diverse industrial sectors.

Precision Gearbox Market Potential Customers

The primary potential customers for precision gearboxes constitute a broad spectrum of industrial enterprises and advanced manufacturing firms that operate in sectors demanding exacting motion control and unparalleled reliability. At the forefront are Original Equipment Manufacturers (OEMs) who embed these sophisticated gearboxes into their high-tech machinery and systems. This includes leading manufacturers of industrial robotics, developers of advanced CNC machine tools, and specialized firms in the aerospace and defense sectors. These customers require gearboxes that not only offer superior accuracy and repeatability but also possess the durability and performance stability to withstand demanding operational conditions, ensuring their end products meet the most stringent industry standards and mission-critical application requirements.

Beyond traditional heavy industry, the customer base for precision gearboxes extends significantly into rapidly expanding and technologically advanced fields. Medical device manufacturers represent a crucial and growing segment, utilizing these precise components in applications such as surgical robots, sophisticated diagnostic imaging equipment, and automated laboratory systems where absolute precision, reliability, and often sterile operational capabilities are non-negotiable. Similarly, the semiconductor industry is a vital consumer, relying on precision gearboxes for ultra-accurate wafer handling, processing, and inspection equipment, where microscopic accuracy and contamination control are paramount. Furthermore, enterprises involved in renewable energy systems, including advanced solar tracking mechanisms and precision yaw and pitch drives for wind turbines, are increasingly adopting precision gearboxes for their robustness and efficiency in harsh environmental conditions.

An equally important segment of potential customers includes specialized system integrators and comprehensive automation solution providers. These entities procure precision gearboxes to engineer and assemble bespoke automation solutions tailored to the unique operational challenges of various industrial clients, effectively bridging the gap between component manufacturers and diverse end-user applications. Moreover, leading research and development institutions, academic establishments focused on advanced engineering, and government defense contractors frequently acquire precision gearboxes for cutting-edge prototyping, rigorous testing, and highly specialized defense and scientific instrumentation. This diverse and expanding customer ecosystem underscores the foundational and versatile role that precision gearboxes play in enabling high-performance, automated, and mission-critical operations across the global economy.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 5.2 Billion |

| Market Forecast in 2032 | USD 8.8 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Harmonic Drive LLC, Nabtesco Corporation, Sumitomo Drive Technologies, WITTENSTEIN SE, STOBER Antriebstechnik GmbH, Apex Dynamics, Inc., GAM Enterprises, Neugart GmbH, Varvel SpA, Sagar Precision, ZF Friedrichshafen AG, Rexroth (Bosch Rexroth AG), KHK Gears, Oerlikon Drive Systems, Eckart GmbH, S.T.M. Riduttori S.p.A., Bonfiglioli S.p.A., NIDEC CORPORATION, SEW-EURODRIVE GmbH & Co KG, Electromate Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Precision Gearbox Market Key Technology Landscape

The precision gearbox market is characterized by a rapidly evolving technology landscape, continuously driven by the imperative for enhanced performance, superior efficiency, and unwavering reliability across diverse industrial applications. A paramount technological advancement involves the relentless pursuit and integration of advanced materials, including high-strength and lightweight alloys such as hardened steels, titanium, and specialized aluminum compounds, alongside cutting-edge ceramics and high-performance engineering plastics. These materials are pivotal in reducing the overall weight of gearboxes, significantly increasing their torque density, substantially improving wear resistance, and enabling flawless operation in extremely challenging environments, such as those with high temperatures or corrosive agents. This focus on material science also extends to the development of innovative coatings and surface treatments, which further enhance durability, minimize friction, and contribute significantly to improved energy efficiency, thereby expanding the application scope into more demanding and specialized industrial settings.

Another profoundly impactful area of technological innovation resides within advanced manufacturing processes, which are being continually refined to achieve unprecedented levels of precision. Techniques such as ultra-precise gear hobbing, sophisticated grinding, meticulous honing, and advanced lapping are critical for producing components with extremely tight tolerances and exceptionally smooth surface finishes. These advancements directly translate into lower backlash, smoother and quieter operation, and significantly extended service life for the gearboxes, which are crucial performance metrics for precision applications. The increasing adoption of additive

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager