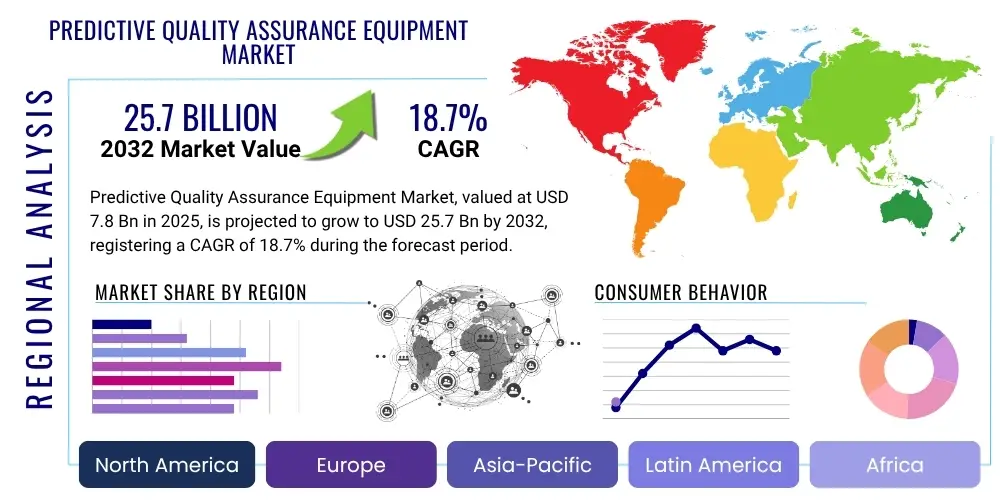

Predictive Quality Assurance Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430994 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Predictive Quality Assurance Equipment Market Size

The Predictive Quality Assurance Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.7% between 2025 and 2032. The market is estimated at USD 7.8 Billion in 2025 and is projected to reach USD 25.7 Billion by the end of the forecast period in 2032.

Predictive Quality Assurance Equipment Market introduction

The Predictive Quality Assurance Equipment Market encompasses sophisticated technologies and systems designed to anticipate and prevent product defects or operational failures before they occur. This proactive approach leverages data analytics, artificial intelligence, and real-time monitoring to ensure product integrity and process efficiency, a stark contrast to traditional reactive quality control methods. The core of these systems lies in their ability to analyze vast amounts of data from various sources such as sensors, production lines, and historical performance records to identify patterns and predict potential deviations from quality standards. This enables manufacturers to implement corrective actions preemptively, significantly reducing waste, rework, and costly recalls.

Products within this market range from advanced sensor arrays, machine vision systems, and non-destructive testing (NDT) equipment to integrated software platforms that incorporate machine learning algorithms for predictive modeling. These systems are crucial across diverse industrial sectors, including but not limited to automotive, aerospace, electronics, pharmaceuticals, and heavy machinery manufacturing. Their primary function is to continuously monitor critical parameters during production, ensuring that components and finished products meet stringent quality specifications. The integration of IoT devices allows for seamless data collection from numerous points, forming a comprehensive digital thread that enables robust predictive analytics. This holistic view provides unparalleled insights into manufacturing processes, empowering quality managers with actionable intelligence.

The benefits derived from adopting Predictive Quality Assurance Equipment are manifold, including substantial improvements in product quality, reductions in manufacturing costs, increased operational efficiency, and enhanced customer satisfaction. Key driving factors for market growth include the escalating demand for high-quality, defect-free products, the widespread adoption of Industry 4.0 initiatives, the increasing complexity of manufacturing processes, and the growing emphasis on sustainability through waste reduction. As industries strive for operational excellence and competitive advantage, the shift towards predictive rather than reactive quality management is becoming an imperative, propelling innovation and investment in this critical equipment sector.

Predictive Quality Assurance Equipment Market Executive Summary

The Predictive Quality Assurance Equipment Market is currently experiencing robust growth, driven by an accelerating global shift towards smart manufacturing and digital transformation across industries. Business trends indicate a pronounced move from traditional, reactive quality control methodologies to advanced, proactive systems that leverage real-time data and artificial intelligence to prevent defects. Manufacturers are increasingly prioritizing investment in solutions that enhance efficiency, minimize waste, and ensure higher product reliability, recognizing these as critical factors for maintaining competitiveness and achieving long-term sustainability. The market is also characterized by a growing integration of various technologies, including IoT, cloud computing, and advanced analytics, which enable more comprehensive and accurate predictive capabilities. Strategic partnerships and collaborations between technology providers and industrial players are becoming more common, fostering innovation and expanding the reach of these sophisticated solutions.

Regionally, Asia Pacific is emerging as a significant growth hub, propelled by rapid industrialization, increasing foreign direct investment in manufacturing, and governmental support for advanced manufacturing initiatives, particularly in countries like China, India, and South Korea. North America and Europe, while mature markets, continue to lead in technological innovation and early adoption of advanced predictive quality solutions, driven by stringent regulatory environments and a strong focus on high-value manufacturing sectors such as aerospace, automotive, and medical devices. Latin America, the Middle East, and Africa are also showing promising signs of growth, albeit from a smaller base, as industrial sectors in these regions modernize their operations and seek to improve product quality to compete on a global scale. This regional diversification indicates a globally pervasive recognition of the value that predictive quality assurance brings to manufacturing.

Segmentation trends reveal a substantial demand for software and analytics platforms that underpin predictive capabilities, often outpacing the growth of standalone hardware components. The proliferation of sensors and interconnected devices, a cornerstone of IoT, is fueling the data collection aspect, while sophisticated algorithms are transforming this raw data into actionable insights. End-user industries such as automotive, aerospace, and electronics manufacturing remain primary adopters, given their critical need for precision, safety, and reliability. However, significant opportunities are also emerging in process industries like pharmaceuticals, food and beverage, and chemicals, where consistent product quality and regulatory compliance are paramount. The market is witnessing a move towards integrated solutions that offer a complete ecosystem of hardware, software, and services, allowing for seamless implementation and maximized return on investment for end-users.

AI Impact Analysis on Predictive Quality Assurance Equipment Market

User inquiries regarding AI's influence on the Predictive Quality Assurance Equipment Market frequently center on how artificial intelligence enhances prediction accuracy, the practical challenges of integrating AI into existing manufacturing workflows, the ways AI-driven insights improve decision-making in quality control, and which specific industries stand to benefit most from these advancements. Concerns about data privacy, cybersecurity, the need for specialized skills, and the return on investment for AI-powered solutions are also prominent themes. There is a clear expectation that AI will transition quality assurance from merely detecting defects to actively preventing them, thereby revolutionizing operational efficiency and product reliability. Users are keen to understand the tangible benefits in terms of cost reduction, waste minimization, and acceleration of time-to-market.

The integration of AI fundamentally transforms predictive quality assurance by enabling a level of data analysis and pattern recognition that is unattainable with traditional methods. Machine learning algorithms can process vast datasets from sensors, production history, and environmental factors, identifying subtle correlations and anomalies that indicate potential quality issues long before they manifest. This allows manufacturers to move beyond statistical process control to truly proactive interventions, optimizing machine parameters, material inputs, and process flows in real time. AI also facilitates the development of self-optimizing systems that can learn from past outcomes, continuously refining their predictive models and improving overall accuracy, thereby leading to a significant reduction in defects and rework.

Furthermore, AI empowers quality engineers with deeper insights and automated decision support, translating complex data into clear, actionable recommendations. This capability is critical in today's intricate manufacturing environments where production lines are highly automated and interlinked. AI-driven predictive systems can prioritize maintenance tasks, identify root causes of variation, and even suggest optimal adjustments to manufacturing parameters, moving towards a truly autonomous quality management system. The widespread adoption of AI is not without its challenges, including the need for high-quality, labeled data for training models, the complexities of integrating AI with legacy systems, and the imperative to upskill the workforce to manage and interpret AI outputs effectively. Despite these hurdles, the transformative potential of AI in achieving zero-defect manufacturing is driving significant investment and innovation in the predictive quality assurance equipment sector.

- Enhanced prediction accuracy: AI algorithms analyze complex data patterns to identify potential defects with higher precision.

- Real-time anomaly detection: AI monitors production data continuously, flagging deviations instantly.

- Automated root cause analysis: AI can pinpoint the sources of quality issues faster than manual methods.

- Optimized process control: AI suggests adjustments to manufacturing parameters to prevent future defects.

- Reduced waste and rework: Proactive interventions minimize material loss and production delays.

- Improved product reliability: AI ensures consistent quality across production batches.

- Data-driven decision making: Provides actionable insights for quality managers and engineers.

- Personalized quality models: AI adapts to specific product lines and manufacturing variations.

- Faster time-to-market: Streamlined quality processes accelerate product development and launch.

DRO & Impact Forces Of Predictive Quality Assurance Equipment Market

The Predictive Quality Assurance Equipment Market is significantly shaped by a confluence of drivers, restraints, and opportunities, alongside various impacting forces. Key drivers include the relentless pursuit of operational excellence across manufacturing industries, where the demand for higher product quality and zero-defect output is paramount. The increasing complexity of modern manufacturing processes, coupled with stricter regulatory compliance requirements in sectors like aerospace, automotive, and pharmaceuticals, further compels manufacturers to adopt advanced predictive solutions. Furthermore, the pervasive trend of Industry 4.0, which emphasizes automation, connectivity, and real-time data exchange through the Internet of Things (IoT), acts as a powerful catalyst for the integration of predictive quality assurance systems. These systems promise substantial cost reductions through minimized waste, reduced rework, and optimized maintenance schedules, making them an attractive investment for businesses seeking to enhance their bottom line and competitive standing.

Despite the strong drivers, the market faces several notable restraints. The initial capital investment required for implementing advanced predictive quality assurance equipment and integrating it into existing infrastructure can be substantial, posing a barrier for small and medium-sized enterprises (SMEs). There is also a significant challenge related to the lack of a skilled workforce capable of operating, maintaining, and effectively interpreting the complex data generated by these sophisticated systems, leading to a skill gap. Concerns surrounding data security and privacy, especially when sensitive production data is transmitted and stored in cloud-based platforms, present another hurdle. The complexities involved in integrating diverse hardware and software components from multiple vendors into a cohesive system can also deter adoption, along with potential resistance to change within organizations accustomed to traditional quality control methods.

However, the market is rife with opportunities that promise future growth and innovation. The expansion into emerging economies, where manufacturing sectors are rapidly industrializing and modernizing, offers significant untapped potential for new deployments. Advancements in artificial intelligence, machine learning, and edge computing technologies are continually enhancing the capabilities and accessibility of predictive quality assurance solutions, leading to more accurate predictions and faster response times. The increasing adoption of digital twin technology allows for virtual simulation and testing, further refining predictive models. Moreover, the shift towards service-based models (Quality-as-a-Service) is reducing the upfront investment burden for end-users, making these technologies more accessible. Impact forces such as rapid technological evolution, the intensifying global competition in manufacturing, fluctuating economic conditions, and evolving environmental sustainability regulations all influence the strategic decisions and growth trajectory of market participants. These dynamics necessitate continuous innovation and adaptability from vendors to meet the evolving demands of the industrial landscape.

Segmentation Analysis

The Predictive Quality Assurance Equipment Market is segmented across various dimensions to provide a detailed understanding of its dynamics, key growth areas, and opportunities for stakeholders. These segmentations typically include analyses by component, deployment type, end-user industry, and application, each offering unique insights into market structures and demand patterns. The breakdown by components distinguishes between hardware, software, and services, reflecting the holistic nature of predictive quality solutions that require a blend of physical equipment, analytical platforms, and expert support. Deployment type differentiates between on-premise and cloud-based solutions, indicating preferences based on data security, scalability, and accessibility. End-user industries highlight the specific sectors that are primary adopters of these technologies, while application segments detail the specific quality control functions served by the equipment. This granular analysis is crucial for strategic planning and targeted market penetration.

- By Component

- Hardware: Includes sensors, cameras, machine vision systems, NDT equipment, robotic inspection systems, IoT devices.

- Software: Comprises data analytics platforms, machine learning algorithms, statistical process control (SPC) software, predictive maintenance software, quality management systems (QMS).

- Services: Encompasses implementation, consulting, training, maintenance, and support services.

- By Deployment Type

- On-Premise: Solutions hosted and managed within the organization's own infrastructure, preferred for high data security and control.

- Cloud-Based: Solutions delivered over the internet, offering scalability, flexibility, and reduced upfront IT infrastructure costs.

- By End-User Industry

- Automotive: For defect detection in assembly, component manufacturing, and powertrain.

- Aerospace and Defense: Critical for high-reliability components, structural integrity, and safety compliance.

- Electronics and Semiconductors: Ensures quality in microcomponents, PCBs, and integrated circuits.

- Heavy Machinery and Industrial Equipment: Predicts failures in large-scale machinery and reduces downtime.

- Pharmaceuticals and Biotechnology: Guarantees product purity, dosage accuracy, and regulatory adherence.

- Food and Beverage: Monitors quality, freshness, and safety of consumables, ensuring compliance.

- Energy and Utilities: For infrastructure integrity, predictive maintenance of critical assets.

- Others: Includes manufacturing in textiles, metals, plastics, etc.

- By Application

- Process Monitoring and Optimization: Real-time tracking of production parameters to prevent deviations.

- Defect Detection and Classification: Automated identification and categorization of product flaws.

- Predictive Maintenance: Anticipating equipment failures to schedule proactive maintenance.

- Supplier Quality Management: Assessing and ensuring the quality of incoming materials and components.

- Root Cause Analysis: Identifying underlying reasons for quality issues.

- Quality Data Analytics and Reporting: Generating insights and reports from collected quality data.

Value Chain Analysis For Predictive Quality Assurance Equipment Market

A comprehensive value chain analysis for the Predictive Quality Assurance Equipment Market illuminates the intricate network of activities involved in bringing these advanced solutions to end-users, from conceptualization to post-sales support. The upstream segment of the value chain is critical, encompassing the research and development efforts that give rise to innovative technologies, alongside the manufacturing of core components. This includes suppliers of advanced sensors (e.g., optical, acoustic, thermal), high-resolution cameras, robotics, and specialized non-destructive testing (NDT) equipment. Software developers providing AI and machine learning algorithms, data analytics platforms, and cloud infrastructure services also form a vital part of the upstream segment. The quality and reliability of these foundational components directly impact the performance and efficacy of the final predictive quality assurance systems, highlighting the importance of strong supplier relationships and continuous innovation at this stage.

The midstream activities involve the assembly and integration of these diverse components into cohesive predictive quality assurance systems. This stage often includes original equipment manufacturers (OEMs) who design and build the complete hardware solutions, as well as software integrators who customize and deploy the analytical platforms to meet specific industry or application requirements. System integrators play a crucial role in ensuring compatibility and seamless operation between various hardware and software elements, often tailoring solutions to fit a client's unique manufacturing environment and legacy systems. This phase also includes testing and validation to ensure that the integrated solution performs accurately and reliably under real-world conditions, conforming to industry standards and client expectations. Expertise in engineering, software development, and project management is paramount during these integration activities.

The downstream segment focuses on market access, distribution, and post-sales activities. Distribution channels are varied, encompassing direct sales teams that engage large enterprises, indirect channels such as value-added resellers (VARs) who provide specialized expertise and localized support, and distributors who manage broader geographical reach. The shift towards cloud-based and subscription models is also creating new distribution avenues, allowing for easier access and deployment. After-sales services, including installation, training, maintenance, technical support, and ongoing software updates, are critical for customer satisfaction and long-term client relationships. These services ensure the continued optimal performance of the equipment and help clients maximize their return on investment. The effectiveness of the distribution and service network directly influences market penetration and sustained growth, emphasizing the importance of a robust customer support infrastructure.

Predictive Quality Assurance Equipment Market Potential Customers

The Predictive Quality Assurance Equipment Market targets a broad spectrum of end-users and buyers across various industrial sectors, all united by a common need to enhance product quality, optimize production processes, and reduce operational costs. Primary potential customers include discrete manufacturing industries such as automotive, aerospace and defense, and electronics, where product reliability, safety, and precision are non-negotiable. These sectors consistently invest in cutting-edge technologies to maintain competitive advantage, meet stringent regulatory standards, and deliver high-performance products to their sophisticated consumer bases. For instance, automotive manufacturers utilize predictive quality equipment to identify potential defects in engine components, chassis, and electronic systems before they lead to costly recalls or safety hazards, ensuring vehicle integrity and brand reputation.

Beyond discrete manufacturing, process industries like pharmaceuticals, food and beverage, and chemicals represent a significant and growing customer base. In these sectors, consistent product formulation, purity, and adherence to health and safety regulations are paramount. Predictive quality assurance helps monitor critical parameters during production, ensuring batch consistency, preventing contamination, and verifying product specifications. Pharmaceutical companies, for example, leverage this equipment to maintain strict quality control throughout drug manufacturing, from raw material inspection to final product packaging, thereby safeguarding patient health and complying with global pharmacopeia standards. The complex and often continuous nature of these processes makes predictive insights invaluable for preventing costly deviations and ensuring uninterrupted operations.

Furthermore, heavy machinery and industrial equipment manufacturers, as well as the energy and utilities sector, are increasingly recognizing the value of predictive quality assurance. For heavy machinery, this involves ensuring the structural integrity and operational longevity of large components and assembled systems, reducing downtime and maintenance expenses. In energy and utilities, it translates to monitoring critical infrastructure like pipelines, turbines, and power distribution networks for potential failures, enhancing safety and reliability. Essentially, any industry where product quality directly impacts safety, cost, efficiency, and customer satisfaction is a prime candidate for adopting predictive quality assurance equipment. The drive for operational excellence and the imperative to minimize waste and defects are universal motivators for these diverse potential customers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 7.8 Billion |

| Market Forecast in 2032 | USD 25.7 Billion |

| Growth Rate | 18.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Rockwell Automation Inc., Honeywell International Inc., ABB Ltd., General Electric Company, FANUC Corporation, Cognex Corporation, Keyence Corporation, National Instruments Corporation, Teledyne FLIR LLC, OMRON Corporation, Hexagon AB, KUKA AG, Mitutoyo Corporation, Yokogawa Electric Corporation, Dassault Systèmes, PTC Inc., IBM Corporation, Microsoft Corporation, SAP SE |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Predictive Quality Assurance Equipment Market Key Technology Landscape

The Predictive Quality Assurance Equipment Market is underpinned by a dynamic and rapidly evolving technological landscape, where the convergence of several advanced technologies creates robust solutions for proactive quality management. Central to this landscape are the Internet of Things (IoT) and advanced sensor technologies, which enable the ubiquitous collection of real-time data from every stage of the manufacturing process. These sensors, ranging from optical and acoustic to thermal and vibration sensors, provide granular insights into machine performance, environmental conditions, and product characteristics. The sheer volume and velocity of data generated by IoT devices necessitate sophisticated processing capabilities, leading to the prominence of edge computing, which processes data closer to its source, reducing latency and bandwidth requirements while enhancing real-time responsiveness. This immediate data processing is crucial for detecting anomalies and predicting potential issues instantaneously, enabling timely interventions that prevent defects from propagating through the production line.

Artificial Intelligence (AI) and Machine Learning (ML) are the analytical brains of predictive quality assurance, transforming raw data into actionable intelligence. ML algorithms are trained on historical data to identify complex patterns, predict future outcomes, and classify potential defects with high accuracy. This includes supervised, unsupervised, and reinforcement learning techniques applied to anomaly detection, root cause analysis, and process optimization. Natural Language Processing (NLP) is also gaining traction for analyzing unstructured data from maintenance logs, customer feedback, and quality reports, offering another layer of predictive insight. Furthermore, computer vision and machine vision systems, powered by deep learning, enable automated visual inspection at unparalleled speeds and accuracies, detecting even minute surface defects or assembly errors that are invisible to the human eye. These AI-driven capabilities move quality control beyond simple thresholds to contextual and adaptive monitoring.

Beyond data collection and analysis, cloud computing provides the scalable infrastructure necessary for storing and processing vast amounts of data, facilitating collaborative platforms and offering advanced analytics as a service. Digital Twin technology is another transformative element, creating virtual replicas of physical products, processes, or entire production lines. These digital twins are fed real-time data, allowing for simulations, predictive modeling, and 'what-if' scenarios, which help anticipate quality issues and optimize process parameters in a virtual environment before making physical changes. Robotics and automation also play a significant role, not only in carrying out precise and repetitive tasks but also in facilitating automated inspection, material handling for testing, and seamless integration with predictive systems. The synergy of these technologies allows for comprehensive, intelligent, and highly efficient predictive quality assurance systems, driving innovation and efficiency across the manufacturing sector.

Regional Highlights

- North America: This region is a leading market for Predictive Quality Assurance Equipment, characterized by early adoption of advanced manufacturing technologies, significant R&D investments, and a strong presence of key market players. The automotive, aerospace, and electronics sectors in the United States and Canada are primary drivers, consistently investing in automation and AI-driven solutions to maintain global competitiveness and meet stringent quality standards. The region benefits from a robust technological infrastructure and a high awareness of the advantages of proactive quality management.

- Europe: Europe represents another mature and substantial market, driven by its robust manufacturing base, particularly in Germany, France, and the UK, and strict regulatory frameworks that emphasize product quality and safety. The region's strong focus on Industry 4.0 initiatives and smart factory concepts, coupled with a commitment to sustainable manufacturing, fuels the adoption of predictive quality assurance solutions. The automotive, machinery, and pharmaceutical industries are significant contributors to market growth here.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region in the Predictive Quality Assurance Equipment Market. This growth is attributed to rapid industrialization, increasing foreign direct investment in manufacturing across countries like China, India, Japan, and South Korea, and supportive government policies promoting technological modernization. The expanding electronics, automotive, and emerging pharmaceutical sectors are key growth engines, driving demand for efficient and high-quality production processes.

- Latin America: This region is an emerging market with growing potential, characterized by increasing industrialization and modernization efforts in countries such as Brazil, Mexico, and Argentina. As manufacturing facilities in Latin America seek to improve product quality and competitiveness on the global stage, the adoption of predictive quality assurance equipment is gradually rising, particularly in the automotive and food and beverage sectors.

- Middle East and Africa (MEA): The MEA market for predictive quality assurance is in its nascent stages but is experiencing steady growth, primarily driven by investments in industrial diversification, infrastructure development, and the adoption of advanced technologies in sectors like oil and gas, automotive assembly, and manufacturing. Increased awareness about industrial automation and quality control is propelling market expansion in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Predictive Quality Assurance Equipment Market.- Siemens AG

- Rockwell Automation Inc.

- Honeywell International Inc.

- ABB Ltd.

- General Electric Company

- FANUC Corporation

- Cognex Corporation

- Keyence Corporation

- National Instruments Corporation

- Teledyne FLIR LLC

- OMRON Corporation

- Hexagon AB

- KUKA AG

- Mitutoyo Corporation

- Yokogawa Electric Corporation

- Dassault Systèmes

- PTC Inc.

- IBM Corporation

- Microsoft Corporation

- SAP SE

Frequently Asked Questions

What is Predictive Quality Assurance Equipment?

Predictive Quality Assurance Equipment refers to advanced systems that utilize sensors, data analytics, and artificial intelligence to monitor manufacturing processes in real-time, anticipating and preventing product defects or operational failures before they occur. This proactive approach significantly reduces waste, rework, and associated costs, ensuring higher product quality and efficiency.

Which industries are the primary adopters of Predictive Quality Assurance Equipment?

The primary adopters include discrete manufacturing industries like automotive, aerospace and defense, and electronics, due to their stringent quality and safety requirements. Process industries such as pharmaceuticals, food and beverage, and chemicals are also significant users, where consistent product formulation and regulatory compliance are crucial.

How does AI enhance Predictive Quality Assurance?

AI, particularly machine learning, significantly enhances predictive quality assurance by enabling complex data pattern recognition from various sources. This allows for highly accurate defect prediction, real-time anomaly detection, automated root cause analysis, and optimization of manufacturing parameters, leading to superior quality control and reduced defects.

What are the main benefits of implementing Predictive Quality Assurance Equipment?

Key benefits include substantial improvements in product quality, significant reductions in manufacturing costs through minimized waste and rework, increased operational efficiency, enhanced compliance with industry regulations, and improved customer satisfaction. It transforms reactive quality control into a proactive, preventative strategy.

What are the key technological components of these systems?

The core technological components typically include advanced sensors, IoT devices for data collection, machine vision systems for inspection, AI and machine learning algorithms for data analysis and prediction, cloud computing for scalable data storage and processing, and digital twin technology for virtual process simulation and optimization.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager