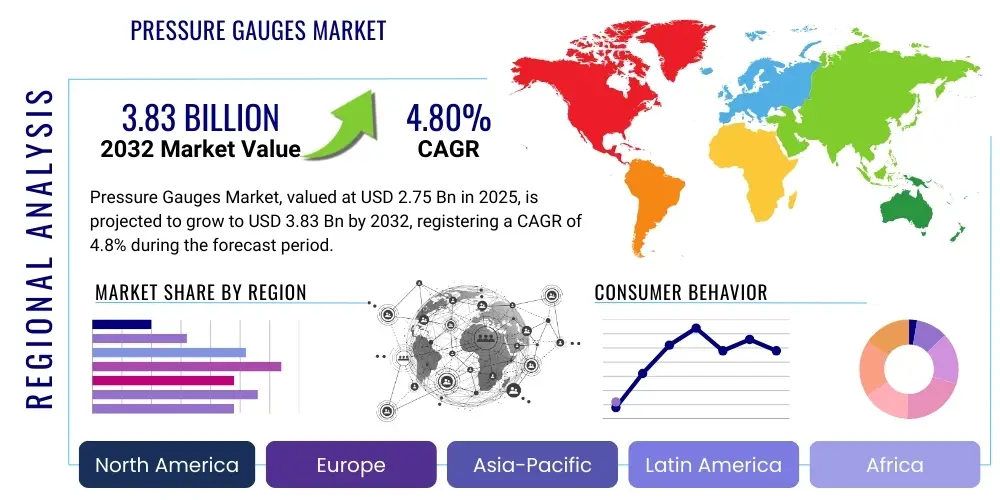

Pressure Gauges Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427593 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Pressure Gauges Market Size

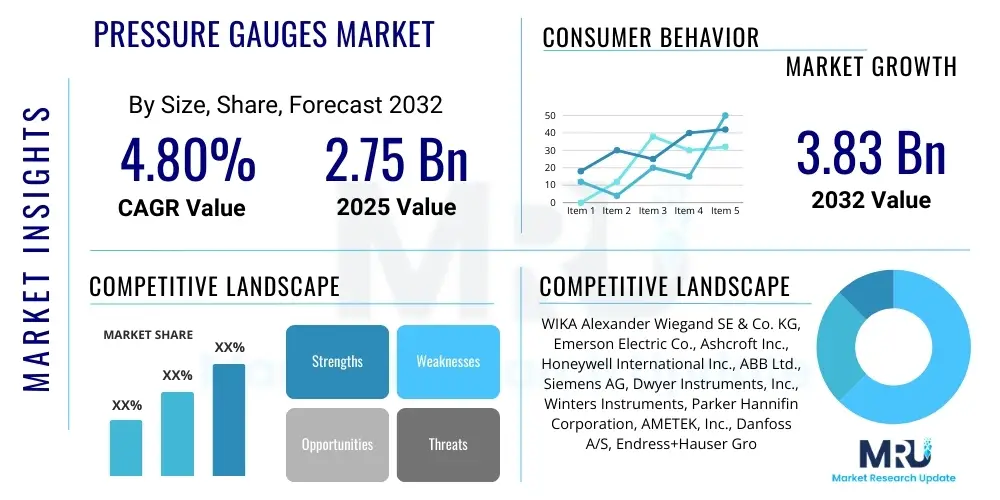

The Pressure Gauges Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 2.75 billion in 2025 and is projected to reach USD 3.83 billion by the end of the forecast period in 2032.

Pressure Gauges Market introduction

Pressure gauges are essential instruments used across diverse industries to measure, monitor, and display fluid pressure within systems. These devices provide critical data for operational efficiency, safety, and process control, ranging from simple mechanical Bourdon tube gauges to advanced digital and smart variants. Their applications are widespread, encompassing industrial manufacturing, oil and gas, chemical processing, automotive systems, medical equipment, and heating, ventilation, and air conditioning (HVAC) systems. The fundamental benefit of pressure gauges lies in their ability to prevent equipment damage, ensure regulatory compliance, and optimize system performance, making them indispensable components in almost any environment where fluid pressure is a critical parameter.

The markets sustained growth is primarily driven by ongoing industrialization, the increasing adoption of automation technologies, and stringent safety regulations that mandate precise pressure monitoring in high-risk environments. As industries evolve towards more complex and interconnected systems, the demand for highly accurate, reliable, and often smart pressure measurement solutions continues to expand. This widespread utility and the continuous need for process optimization and safety assurance underscore the foundational importance of pressure gauges in the global industrial landscape.

Pressure Gauges Market Executive Summary

The Pressure Gauges Market is experiencing dynamic shifts, characterized by several key business, regional, and segment trends. Business trends highlight a strong inclination towards the integration of digital capabilities, connectivity, and smart features, transforming traditional mechanical gauges into more sophisticated monitoring devices capable of real-time data transmission and analytics. Companies are increasingly focusing on providing solutions that enhance predictive maintenance and operational efficiency. From a regional perspective, Asia-Pacific is poised for robust growth due to rapid industrial expansion and infrastructure development, while North America and Europe demonstrate stable demand driven by technological upgrades, replacement needs, and adherence to stringent safety and environmental regulations.

Segmentation trends indicate a rising preference for digital and smart pressure gauges over conventional analog models, particularly in applications requiring higher accuracy and remote monitoring capabilities. The oil and gas, chemical, power generation, and automotive sectors remain dominant end-use industries, continually seeking more resilient and precise measurement solutions for demanding operational conditions. The convergence of IoT and AI further solidifies the markets trajectory towards intelligent pressure management systems, offering significant opportunities for innovation and market expansion across various industrial verticals.

AI Impact Analysis on Pressure Gauges Market

The integration of Artificial Intelligence (AI) is fundamentally transforming the Pressure Gauges Market, moving beyond simple measurement to predictive analytics and intelligent system control. Users frequently inquire about how AI can enhance the accuracy and reliability of pressure readings, automate maintenance, and integrate seamlessly with broader industrial IoT ecosystems. Key concerns revolve around the practical implementation costs, data security implications, and the need for specialized skills to manage AI-driven pressure monitoring systems. The overarching expectation is that AI will unlock new levels of operational efficiency, minimize downtime through advanced fault prediction, and contribute to safer working environments by proactive issue identification.

AIs influence is evident in several critical areas, particularly in enhancing the data analysis capabilities of smart pressure gauges. By leveraging machine learning algorithms, these devices can detect subtle anomalies in pressure trends that might indicate impending equipment failure, thereby enabling predictive maintenance strategies. This shift from reactive to proactive maintenance significantly reduces operational costs and enhances asset longevity. Furthermore, AI facilitates the optimization of industrial processes by providing real-time insights derived from complex pressure data, enabling automated adjustments to maintain optimal operational parameters and reduce energy consumption. The drive towards smart factories and Industry 4.0 paradigms further accelerates the adoption of AI-enabled pressure measurement solutions, making them indispensable for sophisticated process control and decision-making.

- Enhanced predictive maintenance by analyzing pressure data patterns to forecast equipment failures.

- Optimized process control through AI algorithms that automatically adjust system parameters based on real-time pressure feedback.

- Improved data interpretation and anomaly detection, leading to faster issue identification and resolution.

- Integration with industrial IoT platforms for comprehensive plant-wide monitoring and data aggregation.

- Development of self-calibrating and self-diagnosing pressure gauges, reducing manual intervention.

- Creation of intelligent alarm systems that prioritize critical pressure excursions and minimize false positives.

- Facilitation of remote monitoring and control, allowing operators to manage systems from anywhere.

DRO & Impact Forces Of Pressure Gauges Market

The Pressure Gauges Market is influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces shaping its trajectory. Key drivers include the relentless expansion of industrial sectors globally, the increasing emphasis on industrial automation, and the stringent safety and environmental regulations necessitating precise pressure control. Technological advancements, particularly in smart and digital gauges, offer enhanced accuracy, connectivity, and remote monitoring capabilities, further stimulating market growth. Conversely, significant restraints include the high initial investment costs associated with advanced digital and smart pressure gauges, which can be prohibitive for small and medium-sized enterprises (SMEs). Calibration challenges, the potential for sensor drift, and intense competition from alternative sensing technologies also pose notable hurdles.

Opportunities for growth are abundant in emerging markets, specialized niche applications requiring ultra-high precision, and the ongoing integration of IoT and AI into industrial infrastructure, creating demand for sophisticated, data-rich pressure measurement solutions. The shift towards sustainable manufacturing and energy efficiency also opens avenues for pressure gauges that can contribute to optimized resource utilization. Analyzing the impact forces through a framework like Porters Five Forces reveals that competitive rivalry among existing players is high due to a fragmented market with numerous global and regional participants. The bargaining power of buyers is moderate to high, as they often require customized solutions and can choose from various suppliers. The bargaining power of suppliers is relatively low for standard components but increases for specialized sensor technologies and intellectual property.

Furthermore, the threat of new entrants is moderate, as establishing the necessary manufacturing capabilities and gaining trust in critical industrial applications requires substantial capital and expertise, yet technological innovation can lower barriers. The threat of substitute products, such as non-contact pressure sensors or integrated flow meters with pressure sensing, remains a persistent challenge, urging manufacturers to continuously innovate and differentiate their offerings. These dynamic forces collectively dictate market pricing strategies, product development cycles, and the overall competitive landscape within the pressure gauges sector.

Segmentation Analysis

The Pressure Gauges Market is meticulously segmented across various dimensions to reflect the diversity in product offerings, technological advancements, and end-user applications. This detailed segmentation allows for a granular understanding of market dynamics, identifying specific growth pockets and evolving demand patterns. Analyzing the market through these segments helps stakeholders in tailoring product development, marketing strategies, and investment decisions to address specific needs within industrial, commercial, and research environments. The primary segmentation categories include product type, technology, end-use industry, and pressure range, each offering unique insights into market preferences and technological adoption rates.

For instance, the segmentation by product type distinguishes between analog, digital, and smart pressure gauges, highlighting the shift towards more advanced and connected solutions. Technology segmentation further explores the underlying mechanisms such as Bourdon tube, diaphragm, bellows, and semiconductor-based gauges, revealing preferences based on accuracy requirements and environmental conditions. End-use industry segmentation identifies the critical sectors driving demand, including oil and gas, manufacturing, chemical, power generation, automotive, medical, and HVAC, each with distinct requirements for durability, precision, and regulatory compliance. Finally, segmentation by pressure range categorizes gauges into low, medium, and high-pressure applications, reflecting the varied operational demands across industries.

- By Product Type:

- Analog Pressure Gauges

- Digital Pressure Gauges

- Smart/IoT-enabled Pressure Gauges

- By Technology:

- Bourdon Tube Pressure Gauges

- Diaphragm Pressure Gauges

- Bellows Pressure Gauges

- Semiconductor-Based Pressure Gauges (e.g., MEMS)

- By End-Use Industry:

- Oil & Gas

- Chemical & Petrochemical

- Manufacturing

- Power Generation

- Automotive

- HVAC

- Medical & Pharmaceutical

- Water & Wastewater Treatment

- Food & Beverage

- Aerospace & Defense

- By Pressure Range:

- Low Pressure Gauges (e.g., 0-15 psi)

- Medium Pressure Gauges (e.g., 15-1000 psi)

- High Pressure Gauges (e.g., >1000 psi)

- By Display Type:

- Dial

- LCD/LED

Pressure Gauges Market Value Chain Analysis

The value chain for the Pressure Gauges Market is a complex network encompassing raw material sourcing, manufacturing, distribution, and end-user application. Upstream activities involve the procurement of specialized materials such as high-grade stainless steel, brass, and various electronic components for sensors and digital displays. Suppliers of these materials play a crucial role in ensuring the quality and reliability of the final product. Midstream, the manufacturing process includes precision engineering, assembly of components, calibration, and quality assurance testing, where manufacturers transform raw materials and electronic parts into functional pressure gauges. This stage requires significant technical expertise and adherence to stringent industry standards.

Downstream activities focus on the distribution and sale of pressure gauges to various end-users and original equipment manufacturers (OEMs). The distribution channel typically involves a mix of direct sales, where manufacturers sell directly to large industrial clients or through their own sales teams, and indirect sales, which utilize a network of distributors, wholesalers, and specialized industrial supply companies. These intermediaries are vital for reaching a broad customer base, providing localized support, and managing inventory. The market also sees significant interaction with system integrators who incorporate pressure gauges into larger industrial control systems and solutions.

Both direct and indirect distribution strategies are critical. Direct sales are often preferred for highly technical or custom solutions, where direct communication with the end-user facilitates understanding specific requirements and providing tailored support. Indirect channels, on the other hand, are essential for widespread market penetration, especially for standard product lines and maintenance, repair, and operations (MRO) supplies. The efficiency of the distribution network, coupled with effective after-sales support and technical services, significantly influences customer satisfaction and market reach, ultimately driving the competitiveness and profitability across the pressure gauges value chain.

Pressure Gauges Market Potential Customers

The potential customer base for the Pressure Gauges Market is remarkably broad and diverse, reflecting the universal need for precise pressure measurement across nearly every industrial and commercial sector. End-users and buyers range from large multinational corporations operating complex manufacturing plants to small businesses requiring basic pneumatic system monitoring. This extensive reach underscores the foundational role pressure gauges play in ensuring operational safety, process efficiency, and regulatory compliance in a multitude of applications. Industries such as oil and gas, chemical processing, power generation, and water treatment are foundational customers, given their critical reliance on accurate pressure readings for safety and process control.

Beyond traditional heavy industries, there is significant demand from sectors undergoing rapid technological advancements and automation. The automotive industry utilizes pressure gauges for engine diagnostics, tire pressure monitoring, and hydraulic systems testing. The medical and pharmaceutical sectors depend on highly accurate and sterile pressure gauges for critical applications in drug manufacturing, medical gas delivery, and diagnostic equipment. HVAC systems, both commercial and residential, also represent a substantial customer segment, using gauges for refrigerant pressure monitoring and system optimization. Furthermore, research laboratories and academic institutions require specialized high-precision gauges for experimental setups and scientific investigations.

Original equipment manufacturers (OEMs) represent another significant customer segment, integrating pressure gauges directly into their machinery, systems, and products, such as compressors, pumps, filters, and hydraulic power units. These OEMs demand gauges that are robust, reliable, and easily integrated, often requiring customized specifications. The diverse needs of these various end-users drive continuous innovation in pressure gauge technology, from rugged industrial models designed for harsh environments to highly sensitive digital gauges for cleanroom applications, ensuring a consistently strong and varied demand landscape for market participants.

Pressure Gauges Market Key Technology Landscape

The Pressure Gauges Market is continuously evolving, driven by significant advancements in sensing technologies, materials science, and digital integration. A primary technological trend involves the increasing adoption of Micro-Electro-Mechanical Systems (MEMS) sensors, which offer superior accuracy, miniaturization, and cost-effectiveness compared to traditional mechanical sensors. MEMS-based pressure gauges are highly desirable for applications requiring high precision and compact form factors, facilitating their integration into smart devices and IoT ecosystems. Another critical area of innovation is in wireless connectivity, with technologies like Bluetooth, Wi-Fi, LoRa, and cellular (5G) enabling remote monitoring and data transmission, significantly enhancing operational flexibility and reducing manual intervention.

The integration of the Internet of Things (IoT) is profoundly reshaping the landscape, allowing pressure gauges to become part of larger interconnected industrial networks. IoT-enabled gauges can provide real-time data to central control systems, facilitating predictive maintenance, asset management, and comprehensive process optimization. Alongside IoT, advanced digital signal processing (DSP) and embedded software are enhancing the intelligence and functionality of digital gauges, enabling features such as self-calibration, diagnostic capabilities, and complex data analysis at the edge. New sensor materials and fabrication techniques are also improving the durability and performance of gauges in extreme conditions, such as high temperatures, corrosive environments, or high-vibration settings.

Furthermore, the application of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is emerging as a transformative technology. AI/ML can analyze vast amounts of pressure data to detect anomalies, predict equipment failures before they occur, and optimize process parameters autonomously. This capability shifts the paradigm from reactive to proactive maintenance and control, enhancing safety and efficiency across industrial operations. These technological advancements collectively contribute to the development of more intelligent, reliable, and efficient pressure measurement solutions, meeting the demanding requirements of modern industrial applications and driving the market forward.

Regional Highlights

- North America: A mature market characterized by high adoption of advanced digital and smart pressure gauges, driven by stringent safety regulations, technological innovation, and a strong presence of key industries like oil & gas, automotive, and aerospace. Emphasis on replacement and upgrade cycles.

- Europe: Similar to North America, with robust demand fueled by environmental regulations, automation in manufacturing, and a focus on Industry 4.0 initiatives. Germany, in particular, is a hub for high-precision instrumentation manufacturing and innovation.

- Asia-Pacific: The fastest-growing region due to rapid industrialization, infrastructure development, and burgeoning manufacturing sectors in countries like China, India, and Southeast Asia. Increasing investments in smart factories and process automation are key drivers.

- South America: Experiencing growth driven by investments in mining, oil & gas, and agriculture sectors. While adoption of advanced technologies is slower, there is a steady demand for reliable and cost-effective pressure measurement solutions.

- Middle East & Africa: Significant demand from the expanding oil & gas sector, chemical industries, and large-scale infrastructure projects. Focus on robust and reliable gauges for harsh environmental conditions and critical applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Pressure Gauges Market.- WIKA Alexander Wiegand SE & Co. KG

- Emerson Electric Co.

- Ashcroft Inc.

- Honeywell International Inc.

- ABB Ltd.

- Siemens AG

- Dwyer Instruments, Inc.

- Winters Instruments

- Parker Hannifin Corporation

- AMETEK, Inc.

- Danfoss A/S

- Endress+Hauser Group Services AG

- GE Measurement & Control (Baker Hughes Company)

- Bourdons-Haenni GmbH

- GSR Ventiltechnik GmbH & Co. KG

Frequently Asked Questions

What are the primary types of pressure gauges available in the market?

The market primarily offers three types of pressure gauges: analog (mechanical), digital, and smart (IoT-enabled) gauges. Analog gauges use mechanical movements, digital gauges provide numerical displays, and smart gauges offer advanced features like wireless connectivity and data analytics.

How do pressure gauges contribute to industrial safety?

Pressure gauges are crucial for industrial safety by providing real-time monitoring of system pressures, preventing over-pressurization which can lead to equipment failure, leaks, or explosions. They ensure operations remain within safe limits, protecting personnel and assets.

Which industries are the largest consumers of pressure gauges?

The largest consumers of pressure gauges include the oil and gas, chemical and petrochemical, manufacturing, power generation, automotive, and HVAC industries. These sectors critically rely on accurate pressure measurement for process control and safety.

What is the significance of smart pressure gauges in Industry 4.0?

Smart pressure gauges are vital in Industry 4.0 as they integrate with IoT ecosystems, enabling remote monitoring, predictive maintenance, and real-time data analysis. This enhances operational efficiency, reduces downtime, and facilitates automated process control in smart factories.

What factors should be considered when selecting a pressure gauge for a specific application?

Key factors include the required accuracy, pressure range, media compatibility, operating temperature, environmental conditions (vibration, corrosion), connection type, display preference (analog/digital), and specific industry certifications or regulatory compliance needs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Soil Pressure Gauges Market Statistics 2025 Analysis By Application (Civil Engineering, Construction, Others), By Type (200-mm Outer Diameter, 100 mm Outer Diameter), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Pore Pressure Gauges Market Statistics 2025 Analysis By Application (Civil Engineering, Construction, Others), By Type (Vented Gauge, Sealed Gauge), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Double Block and Bleed Valves Market Statistics 2025 Analysis By Application (Chemical Injection & Isolation, Pressure Transmission, Pressure Gauges & Switches, Ping/Instrument Interfaces), By Type (Ball Valves, Needle Valves), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Digital Pressure Gauges Market Statistics 2025 Analysis By Application (Power Industry, Chemical/Petrochemical Industry, Metallurgical Industry, Measurement, Military Machinery), By Type (?.5% of span, ?.25% of span, ?.1% of span, ?.05% of span, ?.02% of span), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager